Documente Academic

Documente Profesional

Documente Cultură

Ig 011 B 0030 0801 Ya

Încărcat de

mileTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ig 011 B 0030 0801 Ya

Încărcat de

mileDrepturi de autor:

Formate disponibile

NARUITELJ / CLIENT:

REPUBLIC OF KOSOVO

MINISTRY OF TRANSPORT AND COMMUNICATIONS

PROJEKT / PROJECT:

MORIN TO MERDARE

KOSOVO MOTORWAY PROJECT

DIONICA / SECTION:

Section 1 - km 0+750 3+000

VRSTA / TYPE:

GEOTEHNIKI PROJEKT

GEOTECHNICAL DESIGN

RAZINA / LEVEL:

MAIN DESIGN

SADRAJ / TITLE:

GEOTEHNIKI PROJEKT TERRAMESH ZIDA

OD KM 2+580 DO KM 2+720

GEOTECHNICAL DESIGN

TERRAMESH WALL FROM KM 2+580 TO KM 2+720

GLAVNI PROJEKTANT / MAIN DESIGNER:

MIRJANA MAALA-BUHIN, dipl.ing.gra.

PROJEKTANT / DESIGNER:

IVANKA BRUNETTA, dipl.ing.gra.

PROJEKTANTI SURADNICI / ASSOCIATES DESIGNERS:

MARKO BIAN, dipl.ing.gra.

JELENA FILI, dipl.ing.gra.

DATUM / DATE:

listopad / October 2010

OZNAKA DOKUMENTA / FILE CODE:

IG 011 B 0030 0801 YA REVISION YA

KONZULTANT / CONSULTANT:

INSTITUT IGH

10 000 ZAGREB, J. RAKUE 1

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 2 of 24

The following persons have participated in the realization of the Geotechnical Design for the

detailed design of Terramesh wall on the Kosovo Route 7, Morine - Merdare Motorway, Section

1 (from km 2+580 to km 2+720):

Designer: Ivanka Brunetta, B.Sc. (Civ.Eng.)

Associates: Marko Bian, B.Sc. (Civ.Eng.)

Jelena Fili, B.Sc. (Civ.Eng.)

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 3 of 24

Prepared by:

INSTITUT IGH d.d.

GEOTECHNICAL DEPARTMENT

Project:

MORIN TO MERDARE MOTORWAY

Assignment:

MAIN GEOTECHNICAL DESIGN FOR

TERRAMESH WALL ON

MORIN TO MERDARE MOTORWAY

SECTION 1

FROM KM 2+580 TO KM 2+720

Type: GEOTECHNICAL DESIGN

TECHNICAL REPORT

Place and date: Zagreb, October 2010

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 4 of 24

CONTENTS

1. TECHNICAL DESCRIPTION.............................................................................. 5

1.1. INTRODUCTION ................................................................................... 5

1.2. DESIGN SOLUTION ................................................................................ 5

1.3. DESCRIPTION OF DESIGNED WORKS............................................................ 5

2. EMBANKMENT STABILITY ANALYSIS .................................................................. 7

3. TECHNICAL REQUIREMENTS FOR WORK EXECUTION AND QUALITY ASSURANCE AND

CONTROL PROGRAM..................................................................................12

3.1. GENERAL..........................................................................................12

3.1.1. Introduction................................................................................12

3.1.2. Staking our and topographic works.....................................................12

3.1.3. Clearing the terrain.......................................................................12

3.2. EXCAVATIONS ....................................................................................12

3.3. DISPOSAL OF MATERIAL.........................................................................13

3.4. PREPARATION OF FOUNDATION SOIL .........................................................13

3.5. GABIONS WITH TIE RODS .......................................................................13

3.5.1. Introductory notes ........................................................................13

3.5.2. System ......................................................................................13

3.5.3. Wire for production of mesh ............................................................13

3.5.4. PVC lining...................................................................................14

3.5.5. Mesh.........................................................................................14

3.5.6. Production and quality control..........................................................14

3.5.7. Delivery, storage and handling..........................................................15

3.5.8. Installation .................................................................................15

3.5.9. Installation procedure....................................................................15

3.5.10. Testing of the material used in the gabion with tie rods system....................16

3.5.11. References....................................................................................16

3.6. GABION STONE FILL .............................................................................16

3.7. GEOTEXTILE ......................................................................................17

3.8. FILL ON THE MESH AND FILL BEHIND THE MESH ............................................17

3.8.1. Material and installation .................................................................17

3.8.2. Quality control.............................................................................17

3.9. SLOPE PROTECTION BY STONE REVETMENT OF EMBANKMENT ...........................17

3.10. SOLUTION AND CONSTRUCTION SITE rEMEDIATION .....................................17

3.11. CONCLUSION ..................................................................................18

4. STAKEOUT.................................................................................................19

5. BILL OF QUANTITIES .....................................................................................22

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 5 of 24

1. TECHNICAL DESCRIPTION

1.1. INTRODUCTION

Part of the route from chainage km 2+580 to km 2+720 of the motorway through Kosovo,

from Morine to Merdare, Section 1, requires construction of an embankment with slope

inclination steeper than 1:1,5.

In order to resolve the problem of embankment on the subject location, it was decided that

the embankment should be constructed applying gabions with tie rods (Maccaferri Terramesh

system), enabling construction of slope steeper than 1:1,5.

1.2. DESIGN SOLUTION

A slope with inclination 1:1,5, approximately 1,5 m height, is designed from the motorway

edge. The toe consists of a berm followed by two gabion blocks with ties, slope of facing

10:1, with a berm 1,5 m wide in between.

The gabion blocks are constructed of elements height 1,0 m. The highest gabion construction

on the subject embankment section is 10 m.

Protection of the embankment slope with gabions and tie rods (Maccaferri Terramesh

system) proposes the use of the following elements (height x width x length):

1,0 m x 2,0 m x 6,0 m,

1,0 m x 2,0 m x 8,0 m,

The elements are made of mesh with the following characteristics:

Mesh type 8x10, hexagonal, double laid,

Tensile strength 46 kN (without creep),

Wire 2,7 mm, galvanized, PVC coated,

The wire can be treated with galfan zinc prior to PVC coating (galfan - 95% zinc, 5 %

aluminum),

Tensile strength of wire used for mesh is between 350 and 550 N/mm

2

, with minimum

10% yield during cracking.

Beginning of the embankment is secured with gabions which help in the formation of slope

10:1, with mesh tied to them as tie rods.

All used material must be in accordance with the defined technical requirements for work

execution, all in accordance with the GTC. The defined quality control and quality assurance

program must be followed for individual works.

1.3. DESCRIPTION OF DESIGNED WORKS

Preliminary works mark the beginning of the works on embankment. Approach roads must be

ensured as well as working plateaus for mounting of gabions with tie rods.

Machinery and other equipment must be ensured for execution of work on the subject

embankment and gabions with tie rods.

Cleaning of the terrain surface is done to remove the shrubs and trees, roots and loose

surface layer. Cleaning of terrain is done on the complete surface where the embankment is

to be constructed.

Prior to placing the gabions with tie rods, the excavation, i.e. the basic embankment must be

completed on the part which ensures free ongoing of work activities

Excavation is to be done in material category A, as wide excavation and one part (Sections 13

and 14) in material category C, where the soil replacement must be done shown on Figure 3

and appendix 1507 and 1508. Construction of gabion system with tie rods can start upon

completion of the required part of excavation, i.e. embankment.

The material from excavation can be placed on the gabion mesh and the embankments of the

gabion structure, i.e. material with adequate grading.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 6 of 24

Preparation of the foundation plateau for construction of the lower gabion rows with tie

rods is done upon completion of excavation works. Since the excavation is done in rock

material - Category A and one part (Sections 13 and 14) in material category C, where the soil

replacement must be done shown on Figure 3 and appendix 1507 and 1508 - prior to

construction of gabions with tie rods, leveling of the surface must be done in all as in

construction of road subgrade.

Placing of gabions with tie rods can be done after preparation of foundation plateau which

must be leveled horizontaly in the transverse direction. The first gabion mesh with tie rods is

placed on the prepared foundation plateau.

Gabion baskets are filled with crushed stone material. Stone material placed on the gabion

facing must have particle size 20-25 cm and must be placed manually. The gabion fill must

have a minimum particle size of 15 cm, to ensure that the material will not fall out through

the mesh.

During the procedure of gabion arrangement, the difference between the fill height in

adjacent elements must not be greater than 1/3 of the gabion height (33 cm). Gabion baskets

and the horizontal mesh of adjacent elements are interconnected by< galvanized rings

(distance between rings is 20 cm). Gabions are tied to other gabions in the previous and the

following/next rows.

Execution of embankment on the tie rods and behind the gabions with tie rods is done

simultaneously, but after installation of gabions. Embankment slope above the gabions is

done with an inclination of 1:1,5, with a stone lining on the surface. Thickness of layers

during embankment construction must not exceed 50 cm, and after spreading and

compaction, in accordance with the technical requirements.

Maximum difference in height between the rock fragments placed on the anchored mesh and

the embankment behind the anchor mesh, in relation to the gabion must not exceed 1m.

Geotextile is placed behind the gabion baskets. Geotextile is placed according to the

characteristic profile.

Finishing works include removal of all excess material, terrain leveling and site clearance

and rehabilitation.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 7 of 24

2. EMBANKMENT STABILITY ANALYSIS

Stability analyses were done with the SLOPE/W (Geo-Slope International Ltd. Calgary,

Alberta, Canada) program of the GEOSLOPE software, according to the Spencer Method

(1967). Analyses were done for permanent load, along with the seismic stability control.

For the purposes of analysis, characteristics of gabions with tie rods were taken according to

the specifications of the Terramesh system, obtained from the WERKOS d.o.o. Company.

This is why the system to be used for work execution must correspond to Maccaferri

Terramesh system specifications.

Therefore, the mesh strength, for which the tensile strength is defined as P

c

=46 kN/m for a

designed life period of 60 years, has the following safety factors:

For a design period of 60 years f

m

=1,20

For mechanical damages during construction works f

d

=1,25

For aggressive influence of environment f

e

=1,10,

Therefore, maximum design load taken over by the reinforcement is:

P

des

= P

c

/ (f

m

x f

d

x f

e

) = 27,9 kN/m

Analysis of stability ware done for the greatest height of gabion with tie rods (10 m) located

on limestone and for the highest (9 m) located on the clay with rock debris, delluvium,

quaternery, which are to be constructed on the subject section.

Analyses are given in Figures 1 and 3. A geotechnical model and results of analysis for

permanent load are given.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 8 of 24

Analysis of stability for the highest gabions with tie rods (H=10 m) located on the

limestone

1

.

6

1

.6

1

.

7

2

.

6

1.561

333,834 m

R

o

a

d

a

x

i

s

P=27,9 kN/m

q=33 kN/m'

10:1

10:1

Soil Model: Mohr-Coulomb

Unit Weight: 19

Cohesion: 4

Phi: 45

Soil Model: Mohr-Coulomb

Unit Weight: 20

Cohesion: 0

Phi: 45

Soil Model: Mohr-Coulomb

Unit Weight: 19

Cohesion: 15

Phi: 25

Description: RMR=39, cs=64 MPa, mi=7

Soil Model: Shear/Normal Fn.

Unit Weight: 25

Shear/Normal Fn. #: 2

Ru: 0.23

Description: RMR=48, cs=91 MPa, mi=7

Soil Model: Shear/Normal Fn.

Unit Weight: 27

Shear/Normal Fn. #: 3

Ru: 0.23

KM 2+690

Fromroad axis (m)

-70 -65 -60 -55 -50 -45 -40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 35

H

e

i

g

h

t

(

m

)

295

300

305

310

315

320

325

330

335

340

345

350

Figure 1: Geotechnical model and results of stability analyses

Safety factor for the static load Fs=1,561, which is satisfactory.

Table 1 shows results of the slide stability analyses at the bottom of individual gabion block

with tie rods.

Safety factor - F

S

Bottom of GABION 1 -

Bottom of GABION 2 2,943

Bottom of GABION 3 2,741

Bottom of GABION 4 2,429

Bottom of GABION 5 -

Bottom of GABION 6 2,279

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 9 of 24

Bottom of GABION 7 2,076

Bottom of GABION 8 1,858

Bottom of GABION 9 1,704

Bottom of GABION 10 1,561

Table 1: Results of the Stability Analyses

For analyses under dynamic conditions, the maximum horizontal acceleration for a 200 year

recurrence interval was taken as:

g a

H

= 20 , 0

max

g a

V

= 10 , 0

max

1

.

1

9

4

1

.

5

4

4

1

.

8

4

4

1.094

333,834 m

R

o

a

d

a

x

i

s

P=27,9 kN/m

10:1

10:1

Soil Model: Mohr-Coulomb

Unit Weight: 19

Cohesion: 4

Phi: 45

Soil Model: Mohr-Coulomb

Unit Weight: 20

Cohesion: 0

Phi: 45

Soil Model: Mohr-Coulomb

Unit Weight: 19

Cohesion: 15

Phi: 25

Description: RMR=39, cs=64 MPa, mi=7

Soil Model: Shear/Normal Fn.

Unit Weight: 25

Shear/Normal Fn. #: 2

Ru: 0.23

Description: RMR=48, cs=91 MPa, mi=7

Soil Model: Shear/Normal Fn.

Unit Weight: 27

Shear/Normal Fn. #: 3

Ru: 0.23

KM 2+690

Fromroad axis (m)

-70 -65 -60 -55 -50 -45 -40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 35

H

e

i

g

h

t

(

m

)

295

300

305

310

315

320

325

330

335

340

345

350

Figure 2: Analyses of stability under dynamic conditions

Figure 2 shows the analysis for seismic load, without traffic load.

The analysis gave the safety factor of F

s

=1,094.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 10 of 24

Analysis of stability for the highest gabions with tie rods (9 m) located on the clay with

rock debris, delluvium, quaternery

1.73

1

.8

3

2

.

1

3

2

.

1

3

1.630

333,958 m

R

o

a

d

a

x

i

s

P=27,9 kN/m

q=33 kN/m'

10:1

10:1

Soil Model: Mohr-Coulomb

Unit Weight: 19

Cohesion: 4

Phi: 45

Soil Model: Mohr-Coulomb

Unit Weight: 20

Cohesion: 0

Phi: 45

Soil Model: Mohr-Coulomb

Unit Weight: 19

Cohesion: 15

Phi: 25

Description: RMR=39, cs=64 MPa, mi=7

Soil Model: Shear/Normal Fn.

Unit Weight: 25

Shear/Normal Fn. #: 2

Ru: 0.23

Description: RMR=48, cs=91 MPa, mi=7

Soil Model: Shear/Normal Fn.

Unit Weight: 27

Shear/Normal Fn. #: 3

Ru: 0.23

KM 2+710

From road axis (m)

-70 -65 -60 -55 -50 -45 -40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30

H

e

i

g

h

t

(

m

)

295

300

305

310

315

320

325

330

335

340

345

Figure 3: Geotechnical model and result of stability analyses

Safety factor for static condition is Fs=1,630, which is satisfactory. It is necessary for stability

of the wall to replace low bearing soil, under the wall, as shown on Figure 3 and on appendix

1507 and 1508.

Table 2 shows results of the slide stability analyses at the bottom of individual gabion block

with tie rods

Safety factor - F

S

Bottom of GABION 1 -

Bottom of GABION 2 2,661

Bottom of GABION 3 2,258

Bottom of GABION 4 2,233

Bottom of GABION 5 -

Bottom of GABION 6 2,106

Bottom of GABION 7 1,869

Bottom of GABION 8 1,780

Bottom of GABION 9 1,637

Table 2: Results of stability analyses

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 11 of 24

For analyses under dynamic conditions, the maximum horizontal acceleration for a 200 year

recurrence interval was taken as:

g a

H

= 20 , 0

max

g a

V

= 10 , 0

max

1

.

3

5

9

1

.

3

5

9

1

.

5

5

9

1

.

8

5

9

1

.

9

5

9

1.259

333,958 m

R

o

a

d

a

x

i

s

P=27,9 kN/m

10:1

10:1

Soil Model: Mohr-Coulomb

Unit Weight: 19

Cohesion: 4

Phi: 45

Soil Model: Mohr-Coulomb

Unit Weight: 20

Cohesion: 0

Phi: 45

Soil Model: Mohr-Coulomb

Unit Weight: 19

Cohesion: 15

Phi: 25

Description: RMR=39, cs=64 MPa, mi=7

Soil Model: Shear/Normal Fn.

Unit Weight: 25

Shear/Normal Fn. #: 2

Ru: 0.23

Description: RMR=48, cs=91 MPa, mi=7

Soil Model: Shear/Normal Fn.

Unit Weight: 27

Shear/Normal Fn. #: 3

Ru: 0.23

KM 2+710

Fromroad axis (m)

-70 -65 -60 -55 -50 -45 -40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30

H

e

i

g

h

t

(

m

)

295

300

305

310

315

320

325

330

335

340

345

Figure 4: Analysis of stability under dynamic conditions

Figure 4 shows the analysis for seismic load, without traffic load.

The analysis gave the safety factor of F

s

=1,259.

The safety factor F

s

>1 is taken as satisfactory for all stability analyses under dynamic

conditions. Therefore is can be concluded that the confirmed geometry of embankment and

gabions with tie rods has a satisfactory factor of safety under dynamic conditions.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 12 of 24

3. TECHNICAL REQUIREMENTS FOR WORK EXECUTION AND QUALITY

ASSURANCE AND CONTROL PROGRAM

3.1. GENERAL

3.1.1. Introduction

In order to execute the embankment works successfully, respective Laws and regulations

must be respected, as well as Technical requirements, given in the text.

The Quality Assurance and Quality Control Program, as well as the Technical requirements are

given per individual works.

The Technical Requirements are in accordance with:

Applicable Design and work execution principles applied in civil engineering,

General Technical Conditions for road works (IGH, Zagreb, 2001.)

Technical conditions can be supplemented and changed during work execution, but only

within the framework defined by the design and in agreement with the Designer and Client.

These supplements and changes are an additional obligation for the Contractor. If they

require a change in conditions defined by the Contract, then an Annex to the Contract is

required.

3.1.2. Staking our and topographic works

Staking out must be done prior to start of works. Staking out of the embankment elements

shall be done in accordance to this design.

Design profiles and excavation line shall be staked out, followed by staking out of the

structure itself. Staking out of the profile and structure of the gabions with tie rods must be

secured from destruction, it must be clearly marked during the complete duration of works.

Works are to be executed according to the GTC.

Compliance of the staking out works with the Staking out Survey Report and the Design is

checked by the Supervising Engineer, the required exactness of the staking out works is 1cm.

During work execution, the compliance of works and design is checked. The required level of

exactness is given for every group of works.

During the excavation stage the dimension of foundation plateaus are checked and recorded.

During construction, the achieved elevation levels per profile are checked for every row of

gabions, as well as the compliance of the constructed facing of slope with the designed.

3.1.3. Clearing the terrain

Terrain clearance, including cutting of low, sporadic shrubs and removal of the loose, surface

rock material and fragments.

3.2. EXCAVATIONS

Excavation of the subject embankment shall be done in soil category A, as wide excavation

and one part (Sections 13 and 14) in material category C, where the soil replacement must be

done shown on Figure 3 and appendix 1507 and 1508.

Excavation is doe according to the levels and measurements given in this design. The works

are executed, checked and calculated in accordance to the GTC.

Topographic staking out is done according to the measurements and levels given in this design

profiles. Staking out exactness of 1 cm is requested. Upon completion of individual stages of

excavation, geodetic control of executed works is done, with the same measuring exactness.

The following must be checked during excavation works:

Excavation to be done according to profiles and elevation levels given in this design,

Slope inclination must be in accordance with the design,

That the evenness of excavation bottom is 5 cm,

The excavation dimensions are checked geodetically and for some section are entered into

the site diary.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 13 of 24

3.3. DISPOSAL OF MATERIAL

Material which is transported to the construction site to be used in construction and material

from excavation (suitable for use) is stockpiled on the site itself for subsequent use, i.e. until

subsequent transport (material not suitable for use).

Stockpiling must be done in a secure and safe manner, without consequences (landslides,

demolition).

3.4. PREPARATION OF FOUNDATION SOIL

Foundation soil surfaces need to be prepared for mounting of the system of gabions with tie

rods. Excavations are done in rock material, category A, therefore prior to installation of the

gabion system with tie rods, contact surfaces between the mesh and the foundation soil must

be leveled, in all similar to the preparation of road subgrade. Works are executed, checked

and calculated in accordance with the GTC Item 2-10.3 for subrgrades in rock material and in

cuts.

Controls must be done in accordance with the GTC for subgrades.

Foundation plateau levels are checked through surveying, with an exactness of 1 cm.

3.5. GABIONS WITH TIE RODS

3.5.1. Introductory notes

The manufacturer's specifications of the adopted system must be confirmed by respective

certificates of conformity and Reports of respective tests which confirm the required

properties, as well as validation tests. The product must be in accordance with the already

mentioned Technical Conditions and the Maccaferri Terramesh system specifications.

Gabions with tie rods consist of elements made of woven double twisted hexagonal mesh type

8x10, made of galvanized and plastic coated wire diam. 2,7 mm with PVC lining

Elements width 2,0 m, height 1,0 m and length 6,0 and 8,0 m are adopted for the subject

embankment.

3.5.2. System

Partial safety factors for the system must be in accordance with the design partial safety

factors for the 60 year service life of structure:

f

m

= 1,2 safety factor of production and exploitation of data,

f

d

= 1,25 safety factor for mechanical damage, for the use of rock material for fill,

f

e

= 1,1 safety factor for environmental influence.

3.5.3. Wire for production of mesh

Wire for production of mesh must have a tensile strength between 350 and 550 N/mm

2

with a

minimum yield strength during fracture of 10%, it must be galvanized (or galfan zinc

treated),all in accordance with respective relevant standards (BS, DIN or ASTM).

Different types of wire are as follows:

Main: Minimum weight of galvanization 275 g/m

2

, minimum diameter of steel core 2,70 mm

(0,06), minimum diameter with lining 3,7 mm.

Ends and borders: Minimum weight of galvanization 275 g/m

2

, minimum diameter of steel

core 3,40 mm (0,08), minimum diameter with lining 4,4 mm.

Connections and joints: Minimum weight of galvanization 240 g/m

2

, minimum diameter of

steel core 2,20 mm (0,06), minimum diameter with lining 3,2 mm.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 14 of 24

3.5.4. PVC lining

PVC material for lining of wire must have the following characteristics:

Specific weight 13,0-13,5 kN/m

3

, hardness 50-60 , tensile strength exceeding 210

kN/m

2

,

Elongation 200-280%, weight loss less than 5% after 24 hours at temperature of 105

o

C,

satisfactory abrasion resistance.

Furthermore, the material must satisfy the quality and durability requirements:

Resistance to salt,

Resistance to UV rays,

Resistance to high and low temperature exposure.

The requirements are that the required initial characteristics do not significantly change after

the implemented tests:

That no cracks, air bubbles or unacceptable color changes appear,

That the change in specific weight does not reach 6%,

That the change in hardness does not reach 10%,

That changes in tensile strength and elongation do not reach 25%,

That the change in resistance to abrasion doe not reach 10%,

That the temperature at which material becomes brittle does not fall under 20

o

C.

All the mentioned properties must be proven according to some relevant standard (BS, DIN

and ASTM).

3.5.5. Mesh

Every mesh board must be strengthened at the edges and connected with galvanized, PVC

lined wire. Front board (gabion facing) must be strengthened on the inside, minimum with a

wire used for ends and borders, in order to reach the required firmness during mounting.

The front and upper board of the gabion basket are overlapped during production. The back

and lateral sides of the gabion basket are made of special mesh peaces, fixed to the board

during production. Additional, special mesh board which serves as a diaphragm wall is fixed to

the front and lateral sides at the construction site, at every 1m length.

The dimensions oft he board must be in accordance with the design, with a tolerance in

length of 1%.

The tensile strength f mesh must be at least 46 kN/m, without creep.

All required properties must be in accordance with one of the relevant standards (BS, DIN or

ASTM).

3.5.6. Production and quality control

Gabion mesh with tie rods must be delivered directly from the manufacturer or from the

authorized supplier, with all required certificates and the certificate of conformity with the

manufacturer's specifications.

The mesh is made of double twisted hexagonal wire, with edges strengthened with larger

diameter wire. The mesh is cut to required length, while the thicker wire, used for

strengthening, is folded toward the board after cutting and woven into the wire fabric.

Lateral boards are fixed to the main board, the diaphragm wall is not connected to the main

board during production but is delivered separate with the main board and connected at the

construction site.

Factory quality control includes visual control and control of dimensions of the wire, control

of the galvanization percentage, thickness of plastific coating and control of the dimensions

of woven mesh.

Production must be controlled in accordance to ISO 9002.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 15 of 24

3.5.7. Delivery, storage and handling

Upon delivery to the construction site, the elements must be stored at a place distanced from

the construction site traffic to prevent accidental damage. The elements must remain in their

packages until their installation or mounting.

A label bearing the certificate number, name of manufacturer, number of batch and number

of product must be on every pile.

The piles must be handled with care to avoid damage oft he wire lining. Individual elements

can be manually handled.

During installation the elements are to be connected with anti corrosion protected steel rings

at every 20 cm. The rings must be at least 3 mm diameter, tensile strength 170 kg/m

2

.

3.5.8. Installation

The following must be considered Prior to and during installation works:

Preparation of foundation soil and construction of embankment in accordance with the

technical requirements of the design.

Properties of material used for fill must satisfy the design requirements.

The product must be protected from damage caused by traffic at the construction site

and equipment used for installation purposes.

Connection of elements must be done with anti corrosion protected steel, daim. 3

mm, are every 20 cm.

The elements shall be placed longitudinally, parallel to the direction of main stress.

Positions for installation are defined by surveying and staking out according to the

measurements and dimension lines given in the cross sections. Staking out must be exact to

1 cm. Geodetic control of installation is continuously done during work execution, and

surveying of the executed work after installation of each gabion row, all according to equal

exactness level.

3.5.9. Installation procedure

Gabion elements are opened, the front side is shaped into a gabion basket, connected by

rings, the mesh is extended into the required direction, in accordance with the design.

Gabion baskets and the horizontal mesh of the adjacent elements are interconnected in

rows by galvanized rings (distance between rings is 20 cm). The gabions are also

connected with the gabions in the previous row.

The diaphragm wall of the gabion is installed (separate mesh board dividing the element

in two parts each 1 m length).

The facing of the gabion is filled first with crushed stone material, followed by

mechanical filling of the remaining part of the gabion, followed by a fill over the

reinforcing mesh.

At approximately 1/3 and 2/3 of the gabion height, tie rods are mounted, longitudinally 2

tie rods on each gabion half (the diaphragm wall is in the middle of the element - 2 m

long, thus every element has 8 tie rods.

Geotextile is placed behind the gabions, 300 g/m

2

, according to the normal cross section.

Geotextile is placed on the lower mesh, approximately 1,0 m width, vertically along the

back of the gabion, and horizontally under the upper mesh , again 1 m wide. Geotextile is

overlaping. Width of the overlap is 20 cm.

The fill is placed on the mash, minimum 150 mm thick. The mesh must be adequately

covered by the fill material prior to compaction or drive over. The vehicles must not pass

directly over the mesh.

Maximum thickness of the layers to be compacted depends on the type of fill material, as

well as on the machinery available at the construction site, but it must not exceed 500

mm.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 16 of 24

During the arrangement of gabions, the difference in the height of fill between adjoining

gabion elements must not exceed 1/3 of the gabion height (33 cm).

Reinforced bottom surface and the embankment behind are executed simultaneously but

parallel to the execution of gabions.

Gabion facing is designed as vertical. Inclination toward the front is not acceptable but an

inclination of 5% toward the back can be tolerated.

3.5.10. Testing of the material used in the gabion with tie rods system

Quality control includes:

Initial testing of the reinforcing steel

Initial testing of the reinforcing steel must satisfy all criteria declared by the manufacturer

and the number of tests is defined by the greater of the following values: one test for every

delivered group, or a minimum of 3 test cycles.

Control test and validation tests of the reinforcing steel

Tests on reinforcing steel must satisfy all criteria declared by the manufacturer and the

number of tests is defined by the greater of the following values: one test for every delivered

group: one test for every delivered group, or a minimum of 6 test cycles

3.5.11. References

Along with the proof that he has fulfilled all technical requirements, the manufacturer shall

also give references of similar structures where their product was used or installed.

3.6. GABION STONE FILL

Stone used for the gabion facing must have a grain size of 20-25 cm, and is manually

arranged. The gabion fill must have a minimum grain size of 15 cm, in order to ensure that it

does not fall out through the mesh. Maximum tolerated particle size is 25 cm.

The following tolerances are allowed for the stone fill:

Grain size over 25 cm diam. Under the condition that the overall quantity does not

exceed 5% of the cell volume,

Grain size smaller than the minimum allowed, but not smaller than 8 cm diam., up to

10% of the cell volume.

The quality of technical-building stone must be in accordance with the following standards:

1. Determination of frost resistance EN 12 371

2. Determination of resistance to crystallization (15 cycles) EN 12 370

3. Determination of compressive strength (dry condition and water saturated state)

EN 1926

4. Determination of water absorption at atmospheric pressure EN 13 755

5. Spatial masses EN 1936

6. Density EN 1936

7. Porosity EN 1936

The following values are required: minimum density 2600 kg/m

3

, water absorption max. 2,5%,

compressive strength min. 80 MPa, consistency: Percent by mass loss, max. 10%.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 17 of 24

3.7. GEOTEXTILE

Geotextile is placed between the embankment and the gabion, in accordance with the

characteristic cross section.

Characteristics of geotextiles:

PROPERTY UNIT VALUE

Mechanical

Tensile Strengt kN/m

18,5

Tensile Elongation % >55

Resistance to static puncture N

Dynamic pyramid puncture resistance mm

3000

<17

Hydraulic

Apparent Opening Size mm

0,1-0,2

Permittivity sec-1 >1

The placement of geotextile is visually inspected.

3.8. FILL ON THE MESH AND FILL BEHIND THE MESH

3.8.1. Material and installation

In order to be installed into the fill on the mesh and behind the mesh, the material must

satisfy all the GTC requirements for construction of stone material fill (Item 2-09 and 2-09.3).

Installation is performed in accordance with the GTC (Item 2-09.3), under the condition that

the layers are not more than 50 cm thick.

3.8.2. Quality control

Control tests are the responsibility of the Contractor, validation tests are approved by the

Supervising engineer (GTC, Item 2-09). Control and validation tests include:

Control of the dimensions and slope of fill,

Determining the modulus of compressibility (Ms) by circular plate, or the degree of

compaction S

z

in relation to the standard Proctor's Procedure,

Determining the grain size distribution of the material used for fill.

Quality control is done in accordance with the GTC (Item 2-09). Criteria that need to be

fulfilled are the GTC criteria (Item 2-09.3).

3.9. SLOPE PROTECTION BY STONE REVETMENT OF EMBANKMENT

Above the gabions to the shoulder height, the embankment with inclination 1:1.5 of a slope is

constucted. For the surface protection of a slope, stone revetment is applied. Selected larger

stones from the stone material, provided for incorporation into the embankment, is applied

for this slope protection (must meet requirements for stone filling gabions). The thickness of

this slope protection is 30-50 cm.

3.10. SOLUTION AND CONSTRUCTION SITE REMEDIATION

After completion of construction works according to design, and remediation of possible

faults, the terrain surrounding the construction site needs to be rehabilitated and the

executed works incorporated into the surroundings as best as possible.

All equipment, excess construction material and excess material from excavation need to be

removed from the construction site and adequately managed. The surface terrain needs to be

as designed, and the surrounding terrain needs to be brought to its original state.

The approach roads to the construction site need to be remedied in accordance with the

visual requirements of the environment, and the roads that shall be permanently used must

be rehabilitated and improved according to the criteria applicable during the maintenance

stage of structure.

Control is implemented during work execution and upon completion of all works.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 18 of 24

3.11. CONCLUSION

The works have been designed on the basis of forecasted data determined during

geotechnical investigations. If discrepancies from the forecasted situation are determined

during work execution, the design solutions need to be adjusted to the actual situation. All

changes in the design can be done only upon the approval by the Designer.

Due to the nee to adjust to the construction technologies, the contractors can propose

changes and adjustments of designed works, but all such changes must be approved by the

designer and supervising engineer prior to implementation.

Continuous supervision must be ensured during work execution.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 19 of 24

4. STAKEOUT

No Point X Y Z

1 S1L_01 7464973,77 4669521,55 327,70

2 S1L_02 7464976,43 4669517,58 327,70

3 S1L_03 7464976,60 4669517,33 331,70

4 S1L_04 7464986,40 4669502,75 -

5 S1R_01 7464983,20 4669525,44 327,70

6 S1R_02 7464984,73 4669523,16 327,70

7 S1R_03 7464984,90 4669522,91 331,70

8 S1R_04 7464995,13 4669507,70 -

9 S2L_01 7464982,37 4669526,67 326,70

10 S2L_02 7464985,10 4669522,62 326,70

11 S2L_03 7464985,32 4669522,29 331,70

12 S2R_01 7464991,79 4669530,58 326,70

13 S2R_02 7464993,39 4669528,20 326,70

14 S2R_03 7464993,62 4669527,87 331,70

15 S2R_04 7465003,79 4669512,75 -

16 S3L_01 7464990,94 4669531,85 325,70

17 S3L_02 7464992,98 4669528,83 325,70

18 S3L_03 7464994,04 4669527,25 331,70

19 S3R_01 7465000,35 4669535,77 325,70

20 S3R_02 7465001,28 4669534,40 325,70

21 S3R_03 7465002,34 4669532,83 331,70

22 S3R_04 7465012,39 4669517,88 -

23 S4L_01 7464999,48 4669537,08 324,70

24 S4L_02 7465001,50 4669534,07 324,70

25 S4L_03 7465002,61 4669532,41 331,70

26 S4R_01 7465008,19 4669542,04 324,70

27 S4R_02 7465009,80 4669539,65 324,70

28 S4R_03 7465010,91 4669537,99 331,70

29 S4R_04 7465020,92 4669523,11 -

30 S5L_02 7465010,08 4669539,24 324,70

31 S5L_03 7465011,19 4669537,58 331,70

32 S5R_01 7465016,76 4669547,22 324,70

33 S5R_02 7465018,37 4669544,82 324,70

34 S5R_03 7465019,49 4669543,16 331,70

35 S5R_04 7465029,39 4669528,43 -

36 S6L_02 7465018,65 4669544,40 324,70

37 S6L_03 7465019,77 4669542,74 331,70

38 S6R_01 7465025,11 4669552,73 324,70

39 S6R_02 7465026,95 4669549,98 324,70

40 S6R_03 7465028,07 4669548,32 331,70

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 20 of 24

41 S6R_04 7465037,81 4669533,84 -

42 S7R_01 7465034,08 4669557,30 324,70

43 S7R_02 7465035,25 4669555,56 324,70

44 S7R_03 7465036,37 4669553,90 331,70

45 S7R_04 7465046,15 4669539,34 -

46 S8L_01 7465033,26 4669558,52 323,70

47 S8L_02 7465035,20 4669555,64 323,70

48 S8R_01 7465042,00 4669563,45 323,70

49 S8R_02 7465043,49 4669561,22 323,70

50 S8R_03 7465044,67 4669559,48 331,70

51 S8R_04 7465054,44 4669544,94 -

52 S9L_02 7465043,21 4669561,64 323,70

53 S9L_03 7465044,39 4669559,90 331,70

54 S9R_01 7465050,18 4669569,20 323,70

55 S9R_02 7465051,51 4669567,22 323,70

56 S9R_03 7465052,69 4669565,48 331,70

57 S9R_04 7465062,67 4669550,63 -

58 S10L_01 7465048,60 4669571,56 321,70

59 S10L_02 7465051,12 4669567,80 321,70

60 S10L_03 7465052,41 4669565,89 331,70

61 S10R_01 7465057,60 4669576,08 321,70

62 S10R_02 7465059,42 4669573,38 321,70

63 S10R_03 7465060,70 4669571,47 331,70

64 S10R_04 7465070,83 4669556,41 -

65 S11L_02 7465059,14 4669573,79 321,70

66 S11L_03 7465060,43 4669571,89 331,70

67 S11R_01 7465066,45 4669580,84 321,70

68 S11R_02 7465067,44 4669579,37 321,70

69 S11R_03 7465068,72 4669577,47 331,70

70 S11R_04 7465078,95 4669562,25 -

71 S12R_01 7465069,73 4669593,89 321,70

72 S12R_02 7465075,74 4669584,95 321,70

73 S12R_03 7465077,02 4669583,04 331,70

74 S12R_04 7465087,01 4669568,19 -

75 S13L_01 7465072,54 4669589,71 322,70

76 S13L_02 7465075,38 4669585,49 322,70

77 S13L_03 7465076,60 4669583,67 331,70

78 S13R_01 7465076,77 4669601,34 322,70

79 S13R_02 7465083,68 4669591,07 322,70

80 S13R_03 7465084,90 4669589,25 331,70

81 S13R_04 7465095,03 4669574,19 -

82 S14L_01 7465082,25 4669593,20 324,70

83 S14L_02 7465083,37 4669591,53 324,70

84 S14L_03 7465084,48 4669589,87 331,70

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 21 of 24

85 S14R_01 7465085,86 4669605,75 324,70

86 S14R_02 7465091,67 4669597,11 324,70

87 S14R_03 7465092,78 4669595,45 331,70

88 S14R_04 7465103,01 4669580,24 -

NOTE: The table give point staking. Point Sxx_01 is related to the start of excavation for each

section, Point Sxx_02 for the lower edge of the first row of gabions, Point Sxx_03 for the

upper edge of the last line of gabions and Point Sxx_04 is on the intersection of Terramesh

wall cross section with the centre line of the highway.

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 22 of 24

5. BILL OF QUANTITIES

Item Description Unit measure Quantity Unit price Total

1. Stakeout.

Prior to beginning of works, but after excavation of the gabion

structure, design profiles and excavation line must be staked out.

Stakeout of the structure profile must be adequately protected

and must be clearly marked during the complete period of works.

Works are executed, checked and calculated in accordance with

the GTC (Item 1-02).

Calculated per pc of staked out profile.

pcs 88 ............. .............

2. Excavation in material category A and one part (Sections 13 and

14) in material category C, where the soil replacement must be

done, for construction of gabion with tie rods. Executed as wide

excavation in the embankment toe. Transversely and

longitudinally a horizontal surface must be formed, for installation

of gabions

Works are executed, checked and calculated in accordance with

the GTC (Item 2-02.1).

Calculated per m

3

of excavation in natural state.

m

3

5740,00 ............. .............

3. Preparation of the excavation surface for installation of gabion

mesh. This is relevant for the contact surfaces between the mesh

and the foundation soil. Excavation is done in rock material,

category A, therefore prior to installation of gabions with tie rods,

leveling of the surface must be performed as for road subgrade.

Works are executed, checked and calculated in accordance with

the GTC (Item 2-10.3) for subrgade in rock material and cuts.

Calculation per m

2

of surfaces prepared for installation of gabion

mesh.

m

2

1622,00 ............. .............

4. Supply, delivery and installation of gabion with tie rods elements.

All elements and the system as a whole must be in accordance

with technical solutions given in the design.

Calculated per pc of element installed in the structure, with

defined dimensions (length x width x height).

6 m x 2 m x 1 m .

pc 240,00 ............. .............

8 m x 2 m x 1 m .

pc 285,00 ............. .............

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 23 of 24

5. Supply, delivery and placing of geotextile. Geotextile is placed

according to characteristic profile , between the gabion and

embankment.

Calculated per m

2

of placed geotextile.

m

2

3780,00 ............. .............

6. Supply, delivery and installation of crushed stone material used to

fill the gabion baskets.

Stone used for the gabion facing must have grain size 20-25 cm

and is manually arranged.

The gabion fill must have a minimum grain size of 15 cm, to

prevent the material from falling through the mesh. Maximum

allowed grain size is 25 cm.

Fill material is mechanically placed in the gabion.

The following discrepancies are tolerated for stone fill material:

- grain size larger than 25 cm, under the condition that the

overall quantity is less than 5% of the cell volume,

- grain size less than minimum but not less than 8 cm, up to 10%

of cell volume.

Diaphragm walls must be placed before filling the gabion baskets,

i.e. during placing of tie rods.

Calculated per m

3

of executed gabions.

m

3

1050,00 ............. .............

7. Supply, delivery and installation of stone material to be placed on

the system mesh.

Material must be in accordance with the GTC (Item 2-09.3) for

construction of stone material fill.

Installation is done in two layers minimum, at every distance

between the tie rod mesh, which bring the thickness of layer down

to 0,5 m, and the maximum grain size to 25 cm (half of the layer

).

Works are executed, checked and calculated in accordance with

the GTC (Item 2-09.3) for stone material fill.

Calculated per m

3

of executed fill on the mesh.

m

3

6390,00 ............. .............

8. Supply, delivery and installation of crushed stone for preparation

of stone lining of the embankment above the gabion, as protection

against erosion. The stone must satisfy all design requirements for

gabion fill material. It is mechanically arranged in a layer of 30-50

cm.

Calculated per m

2

of placed stone lining.

m

2

393,00 ............. .............

File Code: IG 011 B 0030 0801 - YA INSTITUT IGH d.d.

Type: GEOTECHNICAL DESIGN

GEOTECHNICAL

DEPARTMENT

Zagreb, Janka Rakue 1

KOSOVO MOTORWAY PROJECT, SECTION 1

GEOTECHNICAL DESIGN REPORT

Terramesh_km 2+580-2+720_eng.doc Page 24 of 24

9. Measuring the modulus of deformation within the fill by a multi-

channel analysis of surface waves and the measurement of spatial

displacement at three points of the profile 2+690 road axis (0+110

gabion wall axis)

Works are executed in all according to the technical requirements

defined in the geotechnical design. Item includes supply, delivery

and installation of all materials and equipment, measurements and

preparation of reports, with the confirmation of design solution

according to the measurement results

Determining the modulus of deformation by multi-channel analysis

(measurement and data analysis) pc

Supply and installation of bench marks pc

Measurements and data analysis pc

Designer: Ivanka Brunetta, BSc.CE

Associate: Marko Bian, BSc.CE

Jelena Fili, BSc.CE

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Surviving Chemistry: A Guided Study Book For High School ChemistryDocument83 paginiSurviving Chemistry: A Guided Study Book For High School ChemistryE3 Scholastic Publishing100% (2)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Application of Rogowski CoilsDocument6 paginiApplication of Rogowski CoilscatalinccÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Tower Safety HandbookDocument38 paginiTower Safety HandbookbonthrewÎncă nu există evaluări

- TensileDraw LT FULLDocument2 paginiTensileDraw LT FULLmileÎncă nu există evaluări

- Yarde Metals Shapes CatalogDocument493 paginiYarde Metals Shapes Catalogdncz69Încă nu există evaluări

- IxFORTEN PresentationDocument63 paginiIxFORTEN Presentationmile0% (1)

- Coagulation FlocculationDocument71 paginiCoagulation FlocculationDeepa Singh100% (1)

- Projekat KonstrukcijeDocument93 paginiProjekat Konstrukcijemile100% (1)

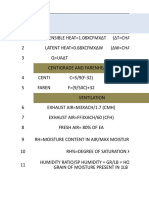

- All Formulas HvacDocument11 paginiAll Formulas HvacrockÎncă nu există evaluări

- 9040 Washing and SterilizationDocument1 pagină9040 Washing and SterilizationCalidad LassÎncă nu există evaluări

- 05 FiniteElementMethodDocument83 pagini05 FiniteElementMethodmileÎncă nu există evaluări

- Hala Roznjace TR LimDocument14 paginiHala Roznjace TR LimmileÎncă nu există evaluări

- A Practical Design To Tensegrity Design - BookDocument212 paginiA Practical Design To Tensegrity Design - BookBryce WinterbottomÎncă nu există evaluări

- Resetka 31 32Document1 paginăResetka 31 32mileÎncă nu există evaluări

- Cutting 10540 ImprovementDesign Rev0Document15 paginiCutting 10540 ImprovementDesign Rev0mileÎncă nu există evaluări

- MakMax Case Study Mumbai AiportDocument2 paginiMakMax Case Study Mumbai AiportmileÎncă nu există evaluări

- Armaturni Detali Petar Poparsov 36a 333Document1 paginăArmaturni Detali Petar Poparsov 36a 333mileÎncă nu există evaluări

- 8 Katalog UzadDocument18 pagini8 Katalog UzadmileÎncă nu există evaluări

- Calculations of The ConnectionDocument6 paginiCalculations of The ConnectionmileÎncă nu există evaluări

- Calculations of The ConnectionDocument6 paginiCalculations of The ConnectionmileÎncă nu există evaluări

- Final Design ArhitectureDocument127 paginiFinal Design ArhitecturemileÎncă nu există evaluări

- Binder 1Document2 paginiBinder 1mileÎncă nu există evaluări

- Armaturni Detali Petar Poparsov 36a 222Document1 paginăArmaturni Detali Petar Poparsov 36a 222mileÎncă nu există evaluări

- 01 121 Ab G S FoundationsDocument1 pagină01 121 Ab G S FoundationsmileÎncă nu există evaluări

- 02 121 Ab G S Facades PDFDocument1 pagină02 121 Ab G S Facades PDFmileÎncă nu există evaluări

- 03 121 Ab G S Details PDFDocument1 pagină03 121 Ab G S Details PDFmileÎncă nu există evaluări

- Numerical Cutting Pattern GenerationDocument19 paginiNumerical Cutting Pattern GenerationmileÎncă nu există evaluări

- MM2 Numerical Theory MEMBRANE STRUCTURESDocument81 paginiMM2 Numerical Theory MEMBRANE STRUCTURESmileÎncă nu există evaluări

- 3 Beams of Steel Grid 240: 1 M14 (5.6) L 180mm N 16Document1 pagină3 Beams of Steel Grid 240: 1 M14 (5.6) L 180mm N 16mileÎncă nu există evaluări

- Cutting 10540 ImprovementDesign Rev1Document86 paginiCutting 10540 ImprovementDesign Rev1mileÎncă nu există evaluări

- Tasks PDFDocument6 paginiTasks PDFmileÎncă nu există evaluări

- MM6 Chapter 06 Analysis Rev 05 2010Document13 paginiMM6 Chapter 06 Analysis Rev 05 2010mileÎncă nu există evaluări

- Cutting Pattern FabricDocument15 paginiCutting Pattern FabricShaikh Muhammad AteeqÎncă nu există evaluări

- Schedule 03-2011 PDFDocument3 paginiSchedule 03-2011 PDFmileÎncă nu există evaluări

- PFEIFER at IMS Dessau MoodleDocument64 paginiPFEIFER at IMS Dessau MoodlemileÎncă nu există evaluări

- Exercise 4.3Document3 paginiExercise 4.3Anonymous w7ujq3cH2FÎncă nu există evaluări

- N 15862Document12 paginiN 15862Saleem BaigÎncă nu există evaluări

- Week 2-Basic Cost ManagementDocument21 paginiWeek 2-Basic Cost ManagementRichard Oliver CortezÎncă nu există evaluări

- Dow Coring Asia ManualDocument69 paginiDow Coring Asia ManualGULJAR SINGHÎncă nu există evaluări

- Changshu Walsin Specialty Steel Co., LTD: Company ProfileDocument1 paginăChangshu Walsin Specialty Steel Co., LTD: Company ProfileHarish KrishnamoorthyÎncă nu există evaluări

- TDS Shell Gadus S2 V220 2Document2 paginiTDS Shell Gadus S2 V220 2regisÎncă nu există evaluări

- Boiler DraughtDocument4 paginiBoiler Draughtshivrant shivrant0% (1)

- Summary NG Pagtatasa NG Pangangailangan (Needs Assessment Survey)Document3 paginiSummary NG Pagtatasa NG Pangangailangan (Needs Assessment Survey)Karlo AvendañoÎncă nu există evaluări

- High Voltage Transformer: InstructablesDocument6 paginiHigh Voltage Transformer: InstructablespinoÎncă nu există evaluări

- (L01) Invue Arb Arbor Post Top Td516018en SssDocument4 pagini(L01) Invue Arb Arbor Post Top Td516018en SssStephanie GutierrezÎncă nu există evaluări

- Sheet Rolling Machine - SynopsisDocument8 paginiSheet Rolling Machine - SynopsisTanviÎncă nu există evaluări

- Document 1Document6 paginiDocument 1LaurenceFabialaÎncă nu există evaluări

- Sedar Perkasa SDN BHD - Company Profile 2023Document48 paginiSedar Perkasa SDN BHD - Company Profile 2023choong chloeÎncă nu există evaluări

- Shaper, Slotter and PlanerDocument9 paginiShaper, Slotter and PlanerRenjith RajendraprasadÎncă nu există evaluări

- Revista ANSYSDocument52 paginiRevista ANSYSEgar MtzÎncă nu există evaluări

- 1000 Bolted JointsDocument3 pagini1000 Bolted JointsMahmoud FawzyÎncă nu există evaluări

- BT134WDocument7 paginiBT134WMiloud ChouguiÎncă nu există evaluări

- Miniature Lamp GuideDocument3 paginiMiniature Lamp GuideKAZIMALI25Încă nu există evaluări

- Integrated Waste Management PDFDocument7 paginiIntegrated Waste Management PDFTechsrijan DriveÎncă nu există evaluări

- Usg Gypsum Board Arc Spec en 09260 092116Document27 paginiUsg Gypsum Board Arc Spec en 09260 092116mariutza_luciaÎncă nu există evaluări

- 4.0 Drill Pipe W XT39 ConnectionsDocument1 pagină4.0 Drill Pipe W XT39 ConnectionsDugas DeivyÎncă nu există evaluări

- Thermal Lab PPT - Heat Balance SheetDocument10 paginiThermal Lab PPT - Heat Balance SheetAyush SinghalÎncă nu există evaluări

- CAE-ECM System For Electrochemical Technology of Parts and ToolsDocument7 paginiCAE-ECM System For Electrochemical Technology of Parts and Toolsdavid2404Încă nu există evaluări