Documente Academic

Documente Profesional

Documente Cultură

7-SCC C60 Mix Design MDC 2

Încărcat de

Kelly Juarez0 evaluări0% au considerat acest document util (0 voturi)

323 vizualizări1 paginăThis document provides a mix design for self-consolidating concrete (SCC) to be used for post-tensioning beams. The mix includes Portland cement, sand, crushed granite aggregate, and a superplasticizer. Test results show the mix meets requirements for compressive strength and flow properties of SCC, with a slump flow between 660-750mm and T500 time below 2 seconds. The mix design was tested and found to conform to specifications for producing high-quality SCC.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document provides a mix design for self-consolidating concrete (SCC) to be used for post-tensioning beams. The mix includes Portland cement, sand, crushed granite aggregate, and a superplasticizer. Test results show the mix meets requirements for compressive strength and flow properties of SCC, with a slump flow between 660-750mm and T500 time below 2 seconds. The mix design was tested and found to conform to specifications for producing high-quality SCC.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

323 vizualizări1 pagină7-SCC C60 Mix Design MDC 2

Încărcat de

Kelly JuarezThis document provides a mix design for self-consolidating concrete (SCC) to be used for post-tensioning beams. The mix includes Portland cement, sand, crushed granite aggregate, and a superplasticizer. Test results show the mix meets requirements for compressive strength and flow properties of SCC, with a slump flow between 660-750mm and T500 time below 2 seconds. The mix design was tested and found to conform to specifications for producing high-quality SCC.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

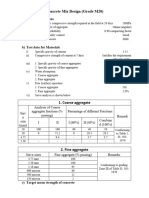

Test report nr.

MIX - MDC SCC 2

MIX DESIGN (BS EN 206-1: 2000) Stationary Plants

SCC C60 mix design MDC 2

Client: Gamuda Bhd

Application: Post tensioning Beams - SCC

COMPOSITION

Cement 1 Cem I 52.5 N YTL (335 kg/m) Cement 2: --

Chemical Admixtures : Mineral Admixtures:

Superplasticiser: CM 727 (2.00%) Type I: -- (+ 0.10%) Superplasticiser: CM 727 (2.00%) Type I: --

Admixture 2: -- Type II: PFA Type C (165 kg/m) (k = 1.0)

Admixture 3: Other: --

Adjuvant: --

Fraction: 0/5 M sand (55%) 5/10 mm (45%) -- -- --

Origin: Mining sand Crushed granite -- -- --

REQUIREMENTS

Classification: EN 206-1 C 50/60 SCC SF2-VS1 Cl 0.1 XC4 XS3, XD3, XF1 max 10 mm

Aggregates

(+ 0.10%)

Classification: EN 206-1 C 50/60 SCC SF2-VS1 Cl 0.1 XC4 XS3, XD3, XF1 max 10 mm

Placing meth.: Pump Walz: --

Water (free)/ Cementitious 0.50 (EN 206-1) Flow table: --

Entrapped Air: 3.0 Slump: --

Grading envelope: None Slump Flow: 660 750 - t500 2 sec

Technologist: Tec. Emanuele Nieli

Sieve Opening [mm]

Combined Grading Updated to 12.10.2012

0.063 0.075 0.150 0.300 0.600 1.18 2.36 5 10.0 14 20 37.5

0.0 2 3 6 17 34 49 62 99 100 100 100

Cement 1

Cement 2

Superplasticiser

Admixture 2

Sieve Opening [mm]

Unit Weight Mass Volume

Component

-- --

[kg/m]

--

10.00

3.15

--

1.08

106.3

--

9.3

[kg/dm] [dm]

Yeld for 1000.0 dm Input

335

-- 60

80

100

P

a

s

s

i

n

g

[

%

]

Admixture 2

Admixture 3

Filler

Pigments

Silica Fume

Fly Ash

Powders

Adjuvant

Aggregates Vibrated Density: [kg/m] 2305

--

--

--

--

--

--

74.0

--

--

--

--

2.23

--

-- --

--

165

--

--

--

--

-- -- --

0

20

40

60

80

P

a

s

s

i

n

g

[

%

]

Opening [mm]

0.125 0.300 0.600 1.18 2.36 5 10 14 37.5 45 22.4

Aggregates Vibrated Density: [kg/m]

Water (free) / Cementitious: [-]

Theoretical air content: [%]

Aggregates/ Powders: [-]

Aggregates / Cementitious: [-]

Volume of Aggregates: [dm]

Water Powders ( < 0.125 mm): [kg/m]

to be dosed Fines (powders+ fine sand+silt.): [kg/m]

2305

--

--

--

--

--

--

28

528

0.34

615

2.5

3.1

3.2

--

338.5

276.9

--

163

2.64

--

--

894

731

2.64

-- --

0/5 M sand

5/10 mm

-- --

to be dosed Fines (powders+ fine sand+silt.): [kg/m]

from admix. Recommended Mixing Time: [sec]

theor. Evaluation of the Content of Powders + Fines:

Notes:

Grancia, 08.07.2013 General Manager: Dott. M. Di Tommaso

IMM Section: Testing of Concrete Materials (Internal procedure: CF-09)

--

--

1.00

--

--

Dosage of Superplasticizer to be confirmed after Plant trials.

528

Conforming

> 90 7

163

170 170

IMM Section: Testing of Concrete Materials (Internal procedure: CF-09)

Results refer to tested samples only. Originally signed and stamped copies are legally binding only. Reproduction without permission is prohibited.

SCC C60 mix design MDC 2

S-ar putea să vă placă și

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionDe la Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotÎncă nu există evaluări

- Concrete Materials: Properties, Specifications, and TestingDe la EverandConcrete Materials: Properties, Specifications, and TestingEvaluare: 4.5 din 5 stele4.5/5 (5)

- Is Concrete Mix DesignDocument21 paginiIs Concrete Mix DesignahmedanyÎncă nu există evaluări

- Mix DesignDocument29 paginiMix Designshahhassa9Încă nu există evaluări

- Concrete Mixed Design MethodDocument11 paginiConcrete Mixed Design Methodabdicasis rashidÎncă nu există evaluări

- 2.5 Concrete Mix Design and RedesignDocument20 pagini2.5 Concrete Mix Design and RedesignmgsvettyÎncă nu există evaluări

- MIX DESIGN of SCCDocument2 paginiMIX DESIGN of SCCPrachi TaoriÎncă nu există evaluări

- Perlite Concrete Mix DesignDocument1 paginăPerlite Concrete Mix DesignHaniAminÎncă nu există evaluări

- Concrete Mixed Design For C30Document2 paginiConcrete Mixed Design For C30raju_420034520Încă nu există evaluări

- Mix Design FormsDocument13 paginiMix Design FormsSashi KumarÎncă nu există evaluări

- Concrete CalculationDocument10 paginiConcrete CalculationkwameÎncă nu există evaluări

- Optimal Mix Design For Pervious ConcreteDocument9 paginiOptimal Mix Design For Pervious ConcretejanakarajÎncă nu există evaluări

- Concrete Mix DesignDocument6 paginiConcrete Mix DesignDane BautistaÎncă nu există evaluări

- M-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeDocument3 paginiM-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeSai CharanÎncă nu există evaluări

- M25 Mix Design & Trial SheetDocument3 paginiM25 Mix Design & Trial Sheetabir senguptaÎncă nu există evaluări

- AdmixturesDocument8 paginiAdmixturesHaroon AkbarÎncă nu există evaluări

- Project:: Use of Metakaoline and Alccofine As A Admixture in ConcreteDocument52 paginiProject:: Use of Metakaoline and Alccofine As A Admixture in ConcreteAnonymous wlbOBqQWDÎncă nu există evaluări

- Chuong Trinh Tinh CP BTDocument10 paginiChuong Trinh Tinh CP BTusername2006Încă nu există evaluări

- Concrete Mix Design Optimized ApproachDocument8 paginiConcrete Mix Design Optimized ApproachHerman MwakoiÎncă nu există evaluări

- Concrete Setting TimeDocument2 paginiConcrete Setting TimeLloyd R. PonceÎncă nu există evaluări

- 17.sec.1700 (Structural Concrete)Document16 pagini17.sec.1700 (Structural Concrete)aalignup arc & const. pvt ltdÎncă nu există evaluări

- Mix Design Concrete Indian and ACI CodeDocument88 paginiMix Design Concrete Indian and ACI CodejinshadÎncă nu există evaluări

- Test Report of MetakaolinDocument14 paginiTest Report of MetakaolinAbdul Falahitawan UfalÎncă nu există evaluări

- Combined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationDocument9 paginiCombined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationAndrew MwambaÎncă nu există evaluări

- Concrete Mix DesignDocument5 paginiConcrete Mix DesignMichaelScofieldÎncă nu există evaluări

- Mr. K.R.Thanki (BE Civil) Lecturer Civil Engineering Department Government Poly Technic, Junagadh, Gujarat-IndiaDocument42 paginiMr. K.R.Thanki (BE Civil) Lecturer Civil Engineering Department Government Poly Technic, Junagadh, Gujarat-IndiasereneÎncă nu există evaluări

- Cementitious Materials For ConcreteDocument6 paginiCementitious Materials For ConcreteRm1262Încă nu există evaluări

- Concrete Mix Proportioning Using Micro SilicaDocument6 paginiConcrete Mix Proportioning Using Micro SilicaGandhi HammoudÎncă nu există evaluări

- Concrete Mix DesignDocument23 paginiConcrete Mix DesignSyahmi FadziÎncă nu există evaluări

- Design Mix ConcreteDocument7 paginiDesign Mix ConcreteAnand.5Încă nu există evaluări

- Concrete Mix DesignDocument20 paginiConcrete Mix DesignRony BaloyiÎncă nu există evaluări

- How Much Cement, Sand and Water Is Required For 12mm Thick Plastering - HapphoDocument7 paginiHow Much Cement, Sand and Water Is Required For 12mm Thick Plastering - HapphoJatinder BhatiaÎncă nu există evaluări

- Foamed ConcreteDocument14 paginiFoamed ConcretemilanÎncă nu există evaluări

- BASF Introduces Smart Dynamic ConcreteDocument4 paginiBASF Introduces Smart Dynamic ConcreteNurul Hidayati100% (1)

- C-35 Mix Design by Estimate of MassDocument26 paginiC-35 Mix Design by Estimate of MassTewodros TadesseÎncă nu există evaluări

- 3.3 Road Note No. 4-1Document40 pagini3.3 Road Note No. 4-1Asad Choudhary100% (1)

- Lab Concrete Mix Design C25aDocument17 paginiLab Concrete Mix Design C25aSoundar PachiappanÎncă nu există evaluări

- High Strength Concrete Mix DesignDocument2 paginiHigh Strength Concrete Mix DesignKimo KenoÎncă nu există evaluări

- M 15 Mix Designs As Per IS-10262-2009Document25 paginiM 15 Mix Designs As Per IS-10262-2009Prasad MsrkÎncă nu există evaluări

- Project 8th SemDocument21 paginiProject 8th Semamish rajÎncă nu există evaluări

- Concrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateDocument2 paginiConcrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateAnonymous PeFQLw19Încă nu există evaluări

- Understanding Ancient Geopolymers Used in Egyptian Pyramids To Modernize Contemporary Concrete MasonryDocument8 paginiUnderstanding Ancient Geopolymers Used in Egyptian Pyramids To Modernize Contemporary Concrete MasonrySusan Wers100% (1)

- Mix Design As Per BSDocument10 paginiMix Design As Per BSChetan SohalÎncă nu există evaluări

- Concret CementDocument29 paginiConcret CementKamal Hameed Al-taiy100% (1)

- Concrete Mix DesignDocument7 paginiConcrete Mix Designtangudusrikanth513gmÎncă nu există evaluări

- Normal Concrete Mix DesignDocument4 paginiNormal Concrete Mix Designmurnal0% (1)

- Mix Design M40Document3 paginiMix Design M40D21Încă nu există evaluări

- Quantity of CementDocument19 paginiQuantity of CementAl Patrick Dela CalzadaÎncă nu există evaluări

- Concrete Mix DesignDocument6 paginiConcrete Mix DesignMichaelScofieldÎncă nu există evaluări

- Concrete Mix Design C30 - MDocument7 paginiConcrete Mix Design C30 - MMitendra Kumar ChauhanÎncă nu există evaluări

- M-30 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For Proportioning Grade Designation M30Document4 paginiM-30 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For Proportioning Grade Designation M30Kumkum MukherjeeÎncă nu există evaluări

- Fly Ash ConcreteDocument14 paginiFly Ash Concretenaveenthirumal67% (3)

- Mix Design For M35 Grade of ConcreteDocument2 paginiMix Design For M35 Grade of ConcreteLambu Sampath100% (2)

- Portland Cement Plastering IFC PDFDocument12 paginiPortland Cement Plastering IFC PDFTEC PlantÎncă nu există evaluări

- Concrete Mix Design Final 7654Document11 paginiConcrete Mix Design Final 7654talatzahoorÎncă nu există evaluări

- International Refereed Journal of Engineering and Science (IRJES)Document7 paginiInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comÎncă nu există evaluări

- Contract Section (KM 1+564 To 10+000)Document2 paginiContract Section (KM 1+564 To 10+000)Nisar AhmadÎncă nu există evaluări

- RCC M-25, Ultratech, OPC43Document5 paginiRCC M-25, Ultratech, OPC43Sanjoy RoyÎncă nu există evaluări

- Strength of ConcreteDocument3 paginiStrength of ConcretelombangrurusÎncă nu există evaluări

- Concrete Mix Design: RequirmentsDocument56 paginiConcrete Mix Design: RequirmentssushilkumarÎncă nu există evaluări

- The Internet of ThingsDocument33 paginiThe Internet of ThingsKaedara KazuhaÎncă nu există evaluări

- Class XI-Writing-Job ApplicationDocument13 paginiClass XI-Writing-Job Applicationisnprincipal2020Încă nu există evaluări

- Physics Cheat SheetDocument8 paginiPhysics Cheat SheetJeremiah MoussaÎncă nu există evaluări

- Etymological Wordplay in Ovid's Pyramus and ThisbeDocument5 paginiEtymological Wordplay in Ovid's Pyramus and Thisbeignoramus83Încă nu există evaluări

- Colombo Port City Causing Unimaginable Environmental HarmDocument6 paginiColombo Port City Causing Unimaginable Environmental HarmThavam RatnaÎncă nu există evaluări

- 6 1 Maxima and MinimaDocument10 pagini6 1 Maxima and MinimaSebastian GarciaÎncă nu există evaluări

- Emerging and Less Common Viral Encephalitides - Chapter 91Document34 paginiEmerging and Less Common Viral Encephalitides - Chapter 91Victro ChongÎncă nu există evaluări

- Habibillah Energi Adidaya Statement of QualificationsDocument56 paginiHabibillah Energi Adidaya Statement of QualificationsjakalegawaÎncă nu există evaluări

- Motorola Phone Tools Test InfoDocument98 paginiMotorola Phone Tools Test InfoDouglaswestphalÎncă nu există evaluări

- The Goldfish and Its Culture. Mulertt PDFDocument190 paginiThe Goldfish and Its Culture. Mulertt PDFjr2010peruÎncă nu există evaluări

- Pro Con ChartDocument3 paginiPro Con Chartapi-461614875Încă nu există evaluări

- EtchDocument2 paginiEtchlex bactolÎncă nu există evaluări

- Contingency Measures and ProceduresDocument25 paginiContingency Measures and ProceduresKaren Villapando LatÎncă nu există evaluări

- Linguistic LandscapeDocument11 paginiLinguistic LandscapeZara NurÎncă nu există evaluări

- The Status of The Translation ProfessionDocument172 paginiThe Status of The Translation ProfessionVeaceslav MusteataÎncă nu există evaluări

- DRUG STUDY (Erythromycin)Document3 paginiDRUG STUDY (Erythromycin)Avianna CalliopeÎncă nu există evaluări

- Apspdcl PDFDocument21 paginiApspdcl PDFK.sanjeev KumarÎncă nu există evaluări

- Certification Programs: Service As An ExpertiseDocument5 paginiCertification Programs: Service As An ExpertiseMaria RobÎncă nu există evaluări

- IBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Document27 paginiIBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Milek Anil KumarÎncă nu există evaluări

- Btech Me 5 Sem Heat and Mass Transfer Eme504 2020Document2 paginiBtech Me 5 Sem Heat and Mass Transfer Eme504 2020SuryaÎncă nu există evaluări

- Restoring PH Balance in The BodyDocument6 paginiRestoring PH Balance in The Bodycinefil70Încă nu există evaluări

- Calculations: M 0 M 1 c1 c1 0 c2 c2 1 2Document6 paginiCalculations: M 0 M 1 c1 c1 0 c2 c2 1 2shadab521100% (1)

- HRIRDocument23 paginiHRIRPhuong HoÎncă nu există evaluări

- Reading Comprehension Lesson Plan FinalDocument9 paginiReading Comprehension Lesson Plan Finalapi-254917183Încă nu există evaluări

- FS1 Worksheet Topic 6Document2 paginiFS1 Worksheet Topic 6ALMALYN ANDIHÎncă nu există evaluări

- Eps 400 New Notes Dec 15-1Document47 paginiEps 400 New Notes Dec 15-1BRIAN MWANGIÎncă nu există evaluări

- Intercostal Drainage and Its ManagementDocument36 paginiIntercostal Drainage and Its ManagementAnusha Verghese67% (3)

- Compuware DCRUM Intro 2012 Version 12.00Document142 paginiCompuware DCRUM Intro 2012 Version 12.00JanÎncă nu există evaluări

- Lesson 3: Letters of RequestDocument4 paginiLesson 3: Letters of RequestMinh HiếuÎncă nu există evaluări

- Delay Codes1 3Document10 paginiDelay Codes1 3AhmedÎncă nu există evaluări