Documente Academic

Documente Profesional

Documente Cultură

DC

Încărcat de

Daniell ToidyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DC

Încărcat de

Daniell ToidyDrepturi de autor:

Formate disponibile

1. The torque is inversely proportional to the speed for shunt motor.

This is because, as the

speed of the motor decreased, the counter emf generated form the armature decrease,

causing increase current flow through the armature coil thus producing higher torque.

As E decrease, Ia will increase. The increase in Ia wil result in torque increase.

2. When the shunt motor is loaded, the speed of the motor decrease. The reduce in speed will

also reduce the back emf generated by the armature. This reduction in back emf results in

the increase of the net voltage, since the supply voltage is constant. As a result, the current

also increase due to the increased net voltage. The increase in current will also increase the

torque generated by the motor. The increase in amount of torque increase the speed, thus

replacing the speed lost during the loading.

3. Speed of the DC shunt motor can be regulated by 2 method

- Field Rheostat control

i. Field rheostat control.

This method adjust the speed of the by variable resistance inserted in series

with the field winding. An increase in resistance will reduce the field current,

causing a reduction in flux and increasing the speed of the motor. This method

of speed control is independent of the load loaded on the motor. The power

dissipated by the resistance is very small since the field current in a small value.

ii. Field voltage control

This method uses a variable voltage supply for the field current which is

separated from the main supply to which the armature is connected.

- Armature control

i. Armature resistance control

This method uses a variable resistance in series with the armature. The flux is

kept constant and the voltage drop in the resistance in series with the armature

reduces the armature voltage. This is recommended in small machine because

the power dissipated by the resistance is high.

4. Field failure can be caused by insulation problem such as water or metal chips that short the

electrical circuit to ground of which overload the motor. Overloading a motor can lead to

high current and voltage which may burn the armature and field winding. In order to

troubleshoot field failure, the field have to be isolated and the commutator, brushes and

brush holder must be cleaned periodically with recommended cleaning solvent.

5. A dc compound motor contains series, shunt and armature winding. The shunt winding is

connected parallel to the armature winding while the series field winding is connected in

series with the armature winding.

6. Iron losses are subdivided in hysteresis and eddy current losses. Hysteresis losses occur

when armature winding revolve in alternating magnetic field. As field magnets in dc field

always magnetized in one direction, so no hysteresis losses. The iron core of the armature

revolves in a magnetic field cause eddy current losses. Hence, as the field of the dc machine

is excites, the eddy current losses is present.

7. Cumulative compounded DC motor is the one which series field is connected in a way that it

assists the field of the shunt winding. However, differential compounded motor is the one

which the series winding is connected so that the field produced from the series winding

oppose the shunt winding. To determine a type of compound motor, we can determine the

direction of the field produced by the shunt field winding and checking the direction of the

series field winding. If both of them are in the same direction, the motor is cumulatively

compounded. On the other hand, if the field is different direction, then the motor is

differentially compounded. Eddy current are electric current induced within the iron core

due to the changing of magnetic field. Since the machine is at standstill, therefore hysteresis

lost is absent in the motor and the iron lost will be the eddy current lost.

8. This is because the speed of the motor stays relatively constant (changes 5 to 15%) from no

load to full load due to the phenomena in number 2.

9. During the starting of the motor, the counter emf from the armature is zero due to the

armature not spinning. This will result in a high starting current 20 to 30 time greater than

the full load current. Therefore, to reduce this starting current, a rheostat is placed in series

with the armature. When starting the motor, the resistance is placed at its maximum value

and slowly reduce to 0 as the motor turn into full speed.

REF

http://4electrical-guys.blogspot.com/2012/06/difference-between-cumulative-compound.html

http://hyperphysics.phy-astr.gsu.edu/hbase/solids/hyst.html

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Sem 20180426 Ats Iem FL1Document2 paginiSem 20180426 Ats Iem FL1Choco Mila BeidinÎncă nu există evaluări

- 29 TA4 FlexibleEarthDocument1 pagină29 TA4 FlexibleEarthvinoth sekarÎncă nu există evaluări

- ThermocoupleDocument11 paginiThermocouplejithabhasuÎncă nu există evaluări

- Common Base ConfigurationDocument7 paginiCommon Base ConfigurationVickeyÎncă nu există evaluări

- Fundamentals of Electroanalytical ChemistryDocument19 paginiFundamentals of Electroanalytical ChemistryAmida OaxacaÎncă nu există evaluări

- PreviewpdfDocument90 paginiPreviewpdfnekosnow rosecatÎncă nu există evaluări

- Navistar Electricidad BasicaDocument128 paginiNavistar Electricidad BasicaHenry MorenoÎncă nu există evaluări

- Passive and Active Battery Balancing Comparison Based On MATLAB SimulationDocument7 paginiPassive and Active Battery Balancing Comparison Based On MATLAB SimulationNhật NguyễnÎncă nu există evaluări

- Bcr3Am: Mitsubishi Semiconductor TriacDocument5 paginiBcr3Am: Mitsubishi Semiconductor TriacbuayamyÎncă nu există evaluări

- Advanced Manufacturing Technology (PC-ME701)Document23 paginiAdvanced Manufacturing Technology (PC-ME701)Deepak KumarÎncă nu există evaluări

- CD4016Document8 paginiCD4016api-3708997100% (1)

- A Low-Cost Impedance Meter Using a PC Sound CardDocument4 paginiA Low-Cost Impedance Meter Using a PC Sound Carddavorko_tÎncă nu există evaluări

- Aircraft GFI Relay OperationDocument3 paginiAircraft GFI Relay Operationraghav787Încă nu există evaluări

- Semiconductors Notes PDFDocument20 paginiSemiconductors Notes PDFVishalÎncă nu există evaluări

- Technology and Livelihood Education: Electrical Installation and MaintenanceDocument11 paginiTechnology and Livelihood Education: Electrical Installation and MaintenanceAV Montes100% (1)

- Eh600 A Series 2Document92 paginiEh600 A Series 2Nguyễn Đình Bảo KhangÎncă nu există evaluări

- Iooll: Multi-Level Conversion: A N D Voltage-Source Inverters High Voltage ChoppersDocument7 paginiIooll: Multi-Level Conversion: A N D Voltage-Source Inverters High Voltage ChoppersВладимир ПоповÎncă nu există evaluări

- LSUBL6432ADocument4 paginiLSUBL6432ATotoxaHCÎncă nu există evaluări

- EMT - Assingment (Electromagnatic Floater)Document10 paginiEMT - Assingment (Electromagnatic Floater)Iqbal Haziq AzmiÎncă nu există evaluări

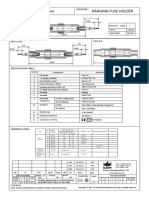

- Hanging fuse holder product detailsDocument1 paginăHanging fuse holder product detailsbemlÎncă nu există evaluări

- Technical Seminar PPT TemplateDocument16 paginiTechnical Seminar PPT TemplateDamineni PoojithaÎncă nu există evaluări

- Joffrey Ramos Galanta: Marine Electrician/General ElectricianDocument4 paginiJoffrey Ramos Galanta: Marine Electrician/General ElectricianJoffrey GalantaÎncă nu există evaluări

- Tine: Trdsforner Naaibun: Hourard Kva, LvaDocument12 paginiTine: Trdsforner Naaibun: Hourard Kva, LvaRekha NairÎncă nu există evaluări

- Equipment Wire Data SheetDocument3 paginiEquipment Wire Data Sheetamro emadÎncă nu există evaluări

- GJSET - Paper 00078 PDFDocument7 paginiGJSET - Paper 00078 PDFdennypolariszÎncă nu există evaluări

- Electronics For IT Ch2 20212 P3Document39 paginiElectronics For IT Ch2 20212 P3Thành Bùi VănÎncă nu există evaluări

- Mode of Arc Extinction Mode of Arc Extinction: High Resistance Arc Interruption High Resistance Arc InterruptionDocument9 paginiMode of Arc Extinction Mode of Arc Extinction: High Resistance Arc Interruption High Resistance Arc Interruptionwan anisÎncă nu există evaluări

- Sensors and Actuators SyllabusDocument14 paginiSensors and Actuators SyllabusKeerthan R VarmaÎncă nu există evaluări

- HT-LT Stay InsulatorDocument6 paginiHT-LT Stay InsulatorsaratÎncă nu există evaluări

- Lab4 Thermal Relay-EngDocument4 paginiLab4 Thermal Relay-EngRazvanTomaÎncă nu există evaluări