Documente Academic

Documente Profesional

Documente Cultură

Ulllted States Patent (10) Patent N0.: US 8,679,561 B2

Încărcat de

Saransiri Wongsiri0 evaluări0% au considerat acest document util (0 voturi)

29 vizualizări11 paginicoffee Roaster with AFB

Titlu original

Us 8679561

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentcoffee Roaster with AFB

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

29 vizualizări11 paginiUlllted States Patent (10) Patent N0.: US 8,679,561 B2

Încărcat de

Saransiri Wongsiricoffee Roaster with AFB

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 11

US008679561B2

( 12) Ulllted States Patent ( 10) Patent N 0. : US 8, 679, 561 B2

Ludwig ( 4 5) Date o f Patent: Mar. 25, 2014

( 54 ) SMOKELESS COFFEE ROASTER 4 , 4 84 , 064 A * 11/1984 Murray . . . . . . . . . . . . . . . . . . . . . . . . . 219/4 00

5, 107, 776 A 4 /1992 G arc ia- Mallo l

_ . 5, 230, 281 A 7/1993 Wireman et a1.

L A * _ 5, 394 , 623 A 3/1995 SeWell

( 73) Ass1gnee: Lo ring Smart Ro ast, I nc . , Santa Ro sa, 5, 4 27, 74 6 A 6/ 1995 Pereira er a1,

CA ( Us) 5, 709, 54 2 A * l/l998 RentZel et al. . . . 4 31/24 2

5, 94 4 , 512 A * 8/1999 Ludwig . . . . . . . . . . . . . . . 4 32/72

- _ - - - - 5, 958, 4 94 A * 9/1999 Tidland et al. . . 4 26/4 66

( * ) N o t1c e. Sub j ec tto any d1sc la1mer, th e term o f th 1s 6, 260, 4 79 B1 * 70001 Friedric h et a1 99/4 68

Pawnt 1S mended Or a( b usted under 35 6, 607, 768 B1 * 8/2003 Eic h ner . . . . . . . . . . 4 26/4 66

U. S. C. 154 ( b ) b y 0 days. 7, 14 3, 686 B1* 12/2006 Sando lo . . . . . . . . . . . . . . . . . . . . . . . . . . 99/286

* . .

( 21) Ap p l. N O. Z 13/529, 838 ted b y exammer

_ 1 d_ Primary Examiner * Drew Bec ker

( 22) F1 e ' Jun21 2012 Assistant Examiner * Presto n Smith

( 65) Prio r Pub lic atio n Data ( 74 ) Atto rney, Agent, o r Firm 4 Th o mas M. Frelb urger

US 2013/034 4 207 A1 Dec . 26, 2013 ( 57) ABSTRACT

A c o f f ee b ean ro asting mac h ine o f th e typ e h av ing a c yc lo ne

( 51) I ntCl sep arato r h eating c h amb er and a c o f f ee b ean ro asting c h am

A23F 5/ 04 ( 2006- 01) b er in a rec irc ulating p ro c ess stream driv en b y a rec irc ulatio n

( 52) U- S- Cl- f an is o p erated to air c o o l th e ro asted c o f f ee b eans in th e

USPC - - - - - - - - - - ~ 4 26/4 66; 4 26/4 67; 4 26/233; 4 26/520; ro asting c h amb er, to a temp erature b eneath Wh ic h th e b eans

4 26/523; 4 26/4 86 giv e o f f smo ke, Wh ile at th e same time inc inerating smo ke

( 58) Field o f Classi? c atio n Searc h remo v ed f ro m th e ro asting c h amb er. A p urge gate in duc ting

USPC . . . . . . . . . . . . . . . . . 4 26/233, 4 67, 4 66, 520, 523, 4 86; b etWeen th e c yc lo ne sep arato r and th e ro asting c h amb er is

99/355, 357, 286; 34 /54 4 , 576, 393 o p ened to allo W th e Ho w o f amb ient air into and th ro ugh th e

See ap p lic atio n ? le f o r c o mp lete searc h h isto ry. ro asting c h amb er Wh ile b lo c king ? o W o ut o f th e c yc lo ne

sep arato r, so th at amb ient air is direc ted th ro ugh th e ro asting

( 56) Ref erenc es Cited c h amb er. Th e smo ke and any airb o rne p artic ulate material

U. S. PATEN T DOCUMEN TS

2, 212, 120 A 8/194 0 Kneale et a1.

3, 189, 4 60 A 6/1965 Smith , Jr.

3, 84 8, 550 A 11/1974 Bo wen

3, 855, 951 A 12/1974 G iles

f ro m th e ro asting c h amb er are c arried into th e h eating c h am

b er and th ro ugh th e inc ineratio n tub e, Wh ere th ey are inc in

erated. Pref erab ly th e system and p ro c ess are o p erated auto

matic ally b y a c o mp uter and p ro gramming.

5 Claims, 6 Drawing Sh eets

ROASTI

C HAM B

o

6O

CON TROLLER

EXHAUST

10

_ _ _ _ _ _ _ _ _ , 1s

N G

4 4

4 o

4 2

5s

CON TROLLER

50

COMBUSTI BLE

MI XTURE

US. Patent Mar. 25, 2014 Sh eet 1 o f 6 US 8, 679, 561 B2

US. Patent Mar. 25, 2014 Sh eet 2 o f 6 US 8, 679, 561 B2

FI G . 2

US. Patent Mar. 25, 2014 Sh eet 3 o f 6 US 8, 679, 561 B2

52 4 6 4 8

CON TROLLER

COMBUSTI BLE

MI XTURE

L

D

EXHAUST

I

l

I

WER- > I

C.

52 4 s

_ _ _ _ _ _ : _ _ _ _ _ 7

16

PROCESS

STEAM

| > BLO

5O

PROCESS I

STEAM

ROASTI N G

CHAMBER

0

CON TROLLER

56

FI G . 3

US. Patent Mar. 25, 2014 Sh eet 4 o f 6 US 8, 679, 561 B2

EXHAUST

%+/ 62

C

1 2O

22 52

: _ _ _ S_ _ : T / < f

= s , /

55%88 ' 1 34

70 | - > BLOWER _ . , 1* 32

16 \ 38

ROASTI N G

14 \ CHAMBER 4

O O

2

60\ 58

CON TROLLER /

CON TROLLER

50 64

FI G . 4 A

COMBUSTI BLE

MI XTURE

US. Patent Mar. 25, 2014 Sh eet 5 o f 6 US 8, 679, 561 B2

US. Patent Mar. 25, 2014 Sh eet 6 0f 6 US 8, 679, 561 B2

lr

Po wer o n / 80 Air c o o l c yc le b egins /102

+

Beansii' 1 h o p p er /82 I nc rease b urner setting f 106

- - 106

Press b urnerstart /_ 84 I nc rease c irc . f an setting /

( idle mo de) 3 sec . 110

l, Op en p urge gate /'

Purge gate o p en I i

Circ . f an o n /86 " Air c o o l " o f b eans 10 sec . /112

20 Sec o nds to 60 see, as set

- +

Cic . f an lo wer / 88 l

i, Op en ro ast c h amb er

Purge gate c lo sed f go do o r to release b eans 116

- /

+ p anally c o o led, to

Burner ligh ts. Allo w 92 tray ( manual o r auto )

ro aster warm- up / l I 118

p erio d Po st ro ast mo de b egins /

Beans rnto ro ast / 94 Circ . f an to o wer setting f 120

c h amb er i 20 86C- 122

+ Clo se p urge gate /

Ro ast mo de/ l'

Ro ast f o r p resc rib ed / 96 Burner do wn to lo w f ire /124

duratio n, p resc rib ed l' .

b urner & c irc . f an settings, Po st ro ast mq de c o nl' nues /126

c o ntro lled b y o p erato r f o r p reset tlme p erio d

o r selec ted auto mo de

l,

End ro ast / 98

100 104

airc o o s? c c l POSJt

9 y ro ast

Y es

F | G . 6 N ew ro ast c yc le

US 8, 679, 561 B2

1

SMOKELESS COFFEE ROASTER

BACKG ROUN D OF THE I N VEN TI ON

Th is inv entio n p rimarily c o nc erns c o f f ee b ean ro asting,

alth o ugh th e inv entio n c an b e ap p lied to o th er ro asting o r

h eating ap p lic atio ns as Well.

Th e inv entio n is direc ted to imp ro v ements o n th e c o f f ee

b ean ro asting ap p aratus and meth o d desc rib ed in US. Pat.

N o . 5, 94 4 , 512, o Wned b y th e same assignee as th is inv entio n.

US. Pat. N o . 5, 94 4 , 512 is h ereb y inc o rp o rated b y ref erenc e

in its entirety.

I n th e ap p aratus o f US. Pat. N o . 5, 94 4 , 512, Wh ic h Was

ap p lic ab le to b ut no t sp ec i? c to c o f f ee b eans, c o f f ee b eans o r

o th er p ro duc ts Were ro asted in a c h amb er c o nnec ted in a

rec irc ulating p ro c ess stream lo o p With a c yc lo ne sep arato r

Wh ic h inc luded a h eating c h amb er. Th e p atented mac h ine h ad

a gas ? ame o r o th er h eat so urc e emanating f ro m th e b o tto m o f

th e h eating c h amb er and direc ted c o nc entric ally to Ward an

inc ineratio n tub e direc tly ab o v e. Th e p ro c ess stream Was

intro duc ed tangentially to th e c yc lo ne sep arato r, v ia a c irc u

lating f an o r b lo Wer With in th e p ro c ess stream, and sp iraled

do Wn to th e lo Wer regio n o f th e h eating c h amb er, aro und th e

h eating ? ame, th en b ac k up Wardly inside a c ylindric al sh ro ud

and j ust o utside th e inc ineratio n tub e, th en direc ted o ut o f th e

c yc lo ne sep arato r and duc ted b ac k to th e b ean ro asting c h am

b er. By th is design v ery little o f th e p ro c ess stream

c o - mingled With th e p ro duc ts o f c o mb ustio n f ro m th e h eat

so urc e, and th e p ro c ess stream Was h eated to an ef f ec tiv e

temp erature to ro ast th e b eans. I n th e c yc lo ne sep arato r, th e

c h af f f ro m th e c o f f ee b eans Was sep arated b y c entrif ugal

f o rc e, and settled do Wn to a p artic le c o llec tio n b in o r h o p p er.

I n th e c o f f ee b ean ro asters c o rresp o nding to US. Pat. N o .

5, 94 4 , 512 and so ld b y th e assignee o f th e p resent inv entio n,

af ter a ro ast Was c o mp leted th e b eans Were released f ro m th e

ro asting c h amb er into a c o o ler, f o r c o o ling o f th e b eans With

amb ient air draWn th ro ugh th e b eans b y a c irc ulating b lo Wer.

Smo ke Was released f ro m th e ro asted b eans into th e amb ient

air, until th e b eans Were c o o led to a suf ? c ient extent.

Also in th e p rio r c o f f ee b ean ro aster, a p urge f eature Was

inc luded Wh ereb y, b ef o re th e mac h ines h eat so urc e c o uld b e

ac tiv ated, saf ety c o nc erns and regulatio ns req uired th at th e

entire system v o lume ( atmo sp h ere) b e rep lac ed b y a v o lume

o f f resh air no t less th an ? v e times th e system v o lume, to

p rev ent th e p o ssib ility o f ignitio n and exp lo sio n. A p urge gate

Was inc luded in a duc t in th e p ro c ess stream, j ust do Wnstream

o f an o utlet o f th e c yc lo ne sep arato r. Prio r to ? ring up th e

h eating c h amb er eac h day, o r af ter any inv o luntary sh utdo Wn,

th e p urge gate Wo uld b e o p ened to essentially c lo se o r th ro ttle

do Wn th e o utlet f ro m th e p ro c ess stream and to admit amb ient

air into th e duc t leading to th e c o f f ee b ean ro asting c h amb er.

Th us, b y means o f th e c irc ulating f an do Wnstream o f th e

ro asting c h amb er, amb ient air Was draWn into and th ro ugh th e

entire system to p urge p o tentially c o mb ustib le ( exp lo siv e)

gases o r p artic ulates th at may h av e ac c umulated, deliv ering

th e air and p artic ulates into th e c yc lo ne sep arato r and th e

h eating c h amb er. Th ese materials Wo uld b e b lo Wn o ut

th ro ugh th e inc ineratio n tub e v ia th e exh aust stac k at its up p er

end, and th e system Wo uld b e p urged and ready to b e ? red.

Alth o ugh th e p atented c o f f ee b ean ro asting system Was

mo stly smo keless, at th e end o f th e ro ast th ere Was smo ke in

th e ro aster and th e b eans c o o ling in amb ient air made mo re

smo ke. Th e smo ke in th e ro aster p rimarily rec irc ulated With

th e p ro c ess stream, and th e v o lume o f smo ke leav ing th e

system th ro ugh th e inc ineratio n tub e o f th e c yc lo ne Wo uld b e

c leaned b y inc ineratio n. Th e b eans in th e c o o ling tray Wo uld

c o ntinue to generate smo ke until f alling b elo W a c ertain tem

20

25

30

35

4 0

4 5

50

55

60

65

2

p erature, and th is typ ic ally h ap p ened ab o ut f o rty- ? v e sec o nds

af ter th e b eans Were dump ed into th e c o o ler at th e end o f a

ro ast. Oth er c o f f ee ro asters h av e used a similar arrangement

f o r c o o ling th e b eans af ter th e ro ast, in a c o o ling tray o utside

th e ro aster.

SUMMARY OF THE I N VEN TI ON

By th e imp ro v ement o f th e c urrent inv entio n, th e smo ke

generated b y c o o ling b eans is no lo nger allo Wed to enter th e

amb ient air, b ut instead is inc inerated in th e inc ineratio n tub e.

I n essenc e, th e inv entio n c o mb ines th e b ean c o o ling step With

an air p urge. At th e end o f th e ro ast, rath er th an dump ing th e

ro asted c o f f ee b eans into th e external c o o ler righ t aWay, th e

neW p ro c ess leav es th e c o f f ee b eans remaining in th e ro aster

to undergo a p erio d o f c o o ling. Wh en th e ro ast is c o mp leted

th e p urge gate is o p ened, sub stantially b lo c king o f f th e p ro

c ess stream ? o W o ut o f th e c yc lo ne, and th e b urner is turned

up to a h igh er v alue. Th is c reates c o nsiderab ly h igh er h eat in

th e inc ineratio n tub e; th is h eat is no t rec irc ulated b ac k to th e

c o f f ee ro asting c h amb er b ec ause th e p urge gate is o p ened,

b lo c king rec irc ulatio n. Fresh air is v ented in th ro ugh th e

p urge gate o p ening and c o o ls th e b eans do Wn signi? c antly,

direc tly in th e ro asting c h amb er, Wh ile at th e same time ? ush

ing o ut th e system f ro m to p to b o tto m and c ausing th e air and

all smo ke and p artic ulate material to exit v ia th e inc ineratio n

tub e. With th e inc ineratio n tub e already h o t f ro m th e ro asting

p ro c ess, and With th e c o ntrib utio n o f additio nal h eat f ro m th e

h igh er- ? ring b urner, th e system ac h iev es v irtually c o mp lete

inc ineratio n o f th e smo ke f ro m th e b eans Wh ile th e b eans

remain in th e ro asting c h amb er and are b eing c o o led. Finally,

Wh en th e b eans are dro p p ed into th e c o o ler th ere is almo st no

smo ke generated, b ec ause muc h o f th e c o o ling h as already

taken p lac e in th e ro aster. Th e time req uired f o r air c o o ling o f

th e b eans in th e ro aster is adj ustab le, b ut c an b e o n th e o rder

o f ab o ut ten sec o nds to o ne minute.

I t is th us amo ng th e o b j ec ts o f th e inv entio n to ac h iev e

v irtually smo keless o p eratio n o f a c o f f ee b ean ro aster o p er

ating o n a c yc lo ne stream p rinc ip le as in US. Pat. N o . 5, 94 4 ,

512, b y simultaneo usly p urging th e ro asting c h amb er o f

smo ke and p erf o rming p reliminary c o o ling o f th e b eans With

amb ient air direc tly in th e ro aster, and inc inerating th e smo ke

f ro m th e b eans and th e ro asting c h amb ers. Th ese and o th er

o b j ec ts, adv antages and f eatures o f th e inv entio n Will b e

ap p arent f ro m th e f o llo Wing desc rip tio n o f a p ref erred

emb o diment, c o nsidered alo ng With th e ac c o mp anying draW

1ngs.

DESCRI PTI ON OF THE DRAWI N G S

FI G . 1 is a p ersp ec tiv e v ieW sh o Wing a c o f f ee b ean ro asting

mac h ine o f th e inv entio n.

FI G . 2 is a side v ieW o f th e c o f f ee b ean ro aster, indic ating

a p ro c ess stream ? o W p ath .

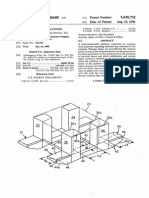

FI G . 3 is a sc h ematic elev atio n v ieW, p artly in p ersp ec tiv e

and p artially in b lo c k diagram f o rm, sh o Wing p ro c ess stream

? o W th ro ugh th e c o f f ee b ean ro aster.

FI G . 3A is a sc h ematic p lan v ieW indic ating a f eature o f th e

inv entio n.

FI G . 4 is a v ieW similar to FI G . 3, b ut sh o Wing th e c o f f ee

b ean ro aster system in a dif f erent mo de.

FI G . 5 is a p ersp ec tiv e v ieW sh o Wing a p urge gate and

ac tuato r inc luded in th e system o f th e inv entio n.

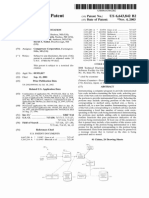

FI G . 6 is a Ho w c h art indic ating th e p ro c ess o f th e inv en

tio n.

US 8, 679, 561 B2

3

DESCRI PTI ON OF PREFERRED

EMBODI MEN TS

FI G . 1 sh o ws a c o f f ee b ean ro aster 10 ac c o rding to th e

inv entio n, generally as desc rib ed in Us. Pat. N o . 5, 94 4 , 512.

Th e o p eratio n o f th e mac h ine, f o r a generic ally desc rib ed

h eating ap p lic atio n, is desc rib ed in th e p atent and th at

desc rip tio n is inc o rp o rated h erein b y ref erenc e.

Th e mac h ine 10 h as a c o f f ee b ean h o p p er 12, a b ean ro ast

ing c h amb er 14 , a c irc ulating f an o r b lo Wer 16 deliv ering a

p ro c ess stream o f gases f ro m th e ro asting c h amb er to a

c yc lo ne sep arato r 18, o nly an up p er p o rtio n o f Wh ic h is seen

in FI G . 1, an inc ineratio n tub e and c h amb er 20 f o r exh aust

f ro m th e c yc lo ne sep arato r, a duc t 22 leading f ro m th e exit o f

th e c yc lo ne sep arato r 18 b ac k to th e ro asting c h amb er 14 ,

c o ntro ls 24 and a b ean c o o ling tray 26 f o r rec eiv ing ro asted

c o f f ee b eans f ro m th e ro asting c h amb er 14 . Th e c o ntro ls 24

inc lude a c o mp uter p ref erab ly With a to uc h sc reen mo nito r f o r

user inp ut and system mo nito ring, th e p ro gramming in th e

c o mp uter o p erating th e system in ac c o rdanc e With inp uts

selec ted b y an o p erato r.

FI G . 2 sh o Ws th e mac h ine 10 in side v ieW and indic ates a

p ro c ess stream ? o W p ath th ro ugh th e ro asting c h amb er 14

( th e inside o f Wh ic h is exp o sed in FI G . 2, rev ealing b ean

sif ting b lades 28) , and th ro ugh a duc t 30, th ro ugh th e c irc u

lating f an 16 and into th e c yc lo ne sep arato r 18. Exiting th e

c yc lo ne sep arato r, th e p ro c ess stream, as no ted ab o v e, ? o Ws

th ro ugh th e duc t 22 and b ac k into th e b ean ro asting c h amb er

14 .

FI G . 3 sh o Ws th e ? o W o f th e p ro c ess stream during no rmal

o p eratio n, i. e. c o f f ee b ean ro asting. Th is o p eratio n is f ully

exp lained in U. S. Pat. N o . 5, 94 4 , 512 ( alth o ugh no t sp ec i?

c ally f o r c o f f ee b eans) and Will b e b rie? y exp lained h ere. Th e

c o f f ee b eans in th e ro asting c h amb er 14 are ro asted b y th e

h eated p ro c ess stream ? o Wing th ro ugh th e c h amb er. Th e c ir

c ulating f an 16 draWs th e p ro c ess stream th ro ugh and o ut o f

th e ro asting c h amb er and deliv ers th e stream tangentially into

a p ro c ess stream inlet 32 o f th e c yc lo ne sep arato r 18. Th is

regio n o f th e c yc lo ne sep arato r h as a sealing 34 , and a c ylin

dric al b af ? e 36 de? nes an inner b o undary, so th at th e p ro c ess

stream sWirls aro und in th e manner sh o Wn b y arro Ws 38 in th e

draWing, desc ending do Wn into th e c o nic ally- sh ap ed lo Wer

p o rtio n 4 0 o f th e sep arato r and ? o Wing aro und a h eat so urc e

4 2, p ref erab ly a gas ? ame as sh o Wn. Th e p ro c ess stream is

h eav ier th an th e h o t gases rising With th e ? ame, Wh ic h enter

th e lo Wer end 4 4 o f th e inc ineratio n tub e 20, and th us th e

p ro c ess stream mingles v ery little With th e c o mb ustio n gases

o f th e ? ame 4 2.

Th e c yc lo ne sep arato r de? nes a h eating c h amb er aro und

th e h eat so urc e 4 2, muc h o f th is h eating c h amb er b eing

de? ned in th e c o nic al sec tio n 4 0.

Th e p ro c ess stream is h eated b y p ro ximity to and p artial

c o ntac t With th e h eat so urc e 4 2 and b y c o ntac t With th e Wall o f

th e c o nic al sec tio n 4 0, as Well as With th e exterio r o f th e

inc ineratio n tub e 20. Af ter th e stream h as sWirled do Wn into

th e h eating c h amb er, Wh ic h o c c urs b y inertia o f do WnWard

mo v ement, it rises, in th e same sWirling p attern, sWirling

aro und th e inc ineratio n tub e 20 and With in th e b af ? e 36 up to

an up p er c h amb er 4 6 and o ut o f th e c yc lo ne sep arato r th ro ugh

a p ro c ess stream o utlet at 4 8. Wh ile in th e c yc lo ne sep arato r,

th e p ro c ess stream sWirls at a c o nsiderab le rate o f sp eed,

sep arating p artic les o ut f ro m th e stream b y c entrif ugal f o rc e,

th o se p artic les th en dro p p ing do Wn alo ng th e Walls o f th e

c o nic al sec tio n 4 0 and o ut o f th e h eating c h amb er, do Wn into

a c h af f b in o r h o p p er 50.

Do Wnstream o f th e p ro c ess stream o utlet 4 8 o f th e c yc lo ne

sep arato r, th e p ro c ess stream enters th e duc t 22, p assing b y a

20

25

30

35

4 0

4 5

50

55

60

65

4

p urge gate 52 Wh ic h is in its no rmal p o sitio n aligned With an

o uter Wall o f th e duc t 22, th us simp ly de? ning a p o rtio n o f th e

duc t Wall. Th is is its p o sitio n during ro asting o f c o f f ee b eans,

and is indic ated sc h ematic ally in FI G . 3A.

As indic ated b y th e arro W 56 in FI G . 3, th e p ro c ess stream

rec irc ulates b ac k to th e ro asting c h amb er, and th is c o ntinues

under th e mo v ing f o rc e o f th e c irc ulating f an o r b lo Wer 16

during th e ro ast. During th is time, so me o f th e smo ke gener

ated b y th e ro asting b eans is inc inerated in th e inc ineratio n

tub e 20, b y rep eated p asses th ro ugh th e c yc lo ne sep arato r.

Ho Wev er, b ec ause o f limited mingling With th e c o mb ustio n

gases f ro m th e ? ame 4 2, muc h o f th e smo ke remains in th e

p ro c ess stream and in th e ro asting c h amb er.

At th e c o mp letio n o f a ro ast, in th e o p eratio n o f th e

mac h ine as desc rib ed in th e p atent, th e ro asted, h o t b eans

Were released into th e c o o ling tray 26 ( FI G . 1) , Wh ere th ey

Were c o o led, With smo ke released to amb ient air.

As exp lained in th e p atent, c o ntro llers are inc luded in th e

system at 58 and 60, f o r c o ntro lling th e h eigh t o f th e ? ame 4 2

b ased o n exh aust gas temp erature at th e exh aust stac k 62 o f

th e inc ineratio n tub e, and f o r c o ntro lling th e c o mb ustib le

mixture f o r th e h eat so urc e v ia a v alv e 64 c o ntro lled in ac c o r

danc e With th e temp erature in th e ro asting c h amb er.

Alth o ugh no t exp lained in th e p atent, th e p urge gate 52 Was

inc luded in th e c o f f ee ro asting ap p aratus 10. I ts p urp o se Was

to c lear th e system o f p o tentially exp lo siv e gases and p artic u

late materials b ef o re ignitio n o f th e h eat so urc e 4 2. Th is must

b e do ne b ef o re ? ring up th e ro aster in th e mo rning, o r at any

o th er time Wh en th e h eating h as b een sh ut do Wn f o r any

reaso n. Fo r th is p urp o se th e p urge gate Was sWung o p en, as

sh o Wn in FI G . 5, and at th is inwardly- swung p o sitio n th e gate

52 Wo uld p ro v ide a large v ent o p ening into th e duc t 22. At th e

same time th e inWardly sWung gate 52 Wo uld sub stantially

b lo c k th e ? o W o ut o f th e c yc lo ne sep arato r v ia th e p ro c ess

stream o utlet 4 8. Th us, With th e h eat so urc e 4 2 sh ut do Wn, th e

p urge gate 52 Wo uld b e sWung inWard to th e p urge p o sitio n

and th e c irc ulating f an 16 ac tiv ated, th us c leaning o ut any

p o tentially exp lo siv e gases o r airb o rne p artic ulates, b y draW

ing amb ient air th ro ugh th e ro asting c h amb er and into th e

c yc lo ne sep arato r, b ut With th at stream exiting up th ro ugh th e

inc ineratio n tub e 20 and o ut th e stac k 62, sinc e th is is th e o nly

exit av ailab le f o r th e mo v ing air in th is mo de o f o p eratio n. I n

FI G . 3A th e p urge gate 52 f o r th is mo de Wo uld b e in th e

p o sitio n sh o Wn in dash ed lines.

As exp lained ab o v e, th e inv entio n utiliZes th e p urge gate

and th e p urge f unc tio n in a dif f erent Way. FI G . 4 illustrates

o p eratio n in th e mo de o f th e inv entio n.

I n FI G . 4 a ro ast h as j ust b een c o mp leted, and th e h eat

so urc e 4 2 remains ac tiv ated. Th e p urge gate 52 is sWung

inWardly, essentially b lo c king ? o W o ut o f th e c yc lo ne sep a

rato r and o p ening an air v ent into th e duc t 22. As in a p re

? ring p urge o f p artic ulates as disc ussed ab o v e, th is c auses

? o W th ro ugh th e ro asting c h amb er and into th e c yc lo ne sep a

rato r, b ut th en up th ro ugh th e inc ineratio n tub e 20 and o ut th e

stac k 62. I n th is c ase, h o Wev er, th e h eating ? ame 4 2 is ac tiv e

and p ref erab ly is turned h igh er. Th e amb ient air entering b y

th e p urge gate and indic ated b y arro Ws 70 in FI G . 4 c o o ls th e

c o f f ee b eans Wh ile th ey remain in th e ro asting c h amb er 14 .

Th e ro asted b eans are p rec o o led in ap p ro ximately ten to sixty

sec o nds b y th is amb ient air. Th ey are c o o led b elo W a tem

p erature at Wh ic h th ey generate smo ke. I mp o rtantly, smo ke is

sub stantially remo v ed f ro m th e b eans and f ro m th e ro asting

c h amb er, and any smo ke Wh ic h h as remained in th e p ro c ess

stream is also remo v ed. Th is ? o W o f smo ke, gases and air is

f o rc ed up th ro ugh th e inc ineratio n tub e 20, Wh ic h is p ref er

ab ly at h igh er temp erature no W to h andle th e rap idly mo v ing

US 8, 679, 561 B2

5

? o W o f p o llutants, and th o se p o llutants are inc inerated b ef o re

b eing disc h arged o ut th e stac k 62.

I n th is mo de o f o p eratio n o f th e b ean ro asting ap p aratus,

th ree th ings are ac c o mp lish ed to a v arying degree b ased o n

th e time duratio n c h o sen b y th e o p erato r: th e c o f f ee b eans are

q uic kly c o o led b y th e ? o W o f amb ient air th ro ugh th e b ean

ro asting c h amb er, to p o tentially b elo W smo king temp erature;

th e b ean ro asting c h amb er is p urged o f smo ke and p artic ulate

material; and th e smo ke and p artic les are mo v ed b y th e c ir

c ulating b lo Wer th ro ugh th e c yc lo ne sep arato r and up th ro ugh

th e inc ineratio n tub e, and inc inerated. Th e mac h ine 10 th ere

f o re c an b e o p erated to b e v irtually c o mp letely smo keless.

Th e degree o f c o o ling With in th e c h amb er is under th e c o ntro l

o f th e o p erato r. Th e lo nger th e mac h ine runs in air c o o l mo de,

th e mo re smo ke is reduc ed, b ut th e b eans are no t c o o ling as

f ast as Wh en th ey are in th e external c o o ler, so th e o p erato r

( ro astmaster) may Want to mo v e th e b eans o ut o f th e c h amb er

as so o n as p rac tic ab le so as no t to af f ec t th e ? av o r o f th e

c o f f ee. So me small amo unt o f smo ke may still b e p ro duc ed

dep ending o n h o W lo ng internal air c o o l c yc le is allo Wed to

run and h o W dark th e p artic ular ro ast is. Th is is at th e ro ast

masters disc retio n.

FI G . 5 sh o Ws main p arts o f a mec h anism f o r o p ening and

c lo sing th e p urge gate 52. Th e p urge gate is attac h ed to a

v ertic ally o riented sp indle 72 adj ac ent to th e air o p ening. A

c rank arm 74 ( seen o nly in edge v ieW) is sec ured to th e sp indle

72, so as to ro tate th e sp indle and o p en o r c lo se th e gate 52 v ia

a p neumatic c ylinder 76 With a linkage 78 to th e c rank arm.

Th e ac tuating c ylinder 76 is c o ntro lled elec tro nic ally and b y

so f tWare inc luded With th e ro asting mac h ine. Th e so f tWare

inc ludes p ro gramming f o r o p erating th e p urge gate 52 as

desc rib ed ab o v e, so th at th e gate is o p ened f o r a p resc rib ed

and/ o r o p erato r- selec ted p erio d o f time, Wh ile th e c irc ulating

f an c o ntinues to o p erate, immediately af ter a ro ast is c o m

p leted. Th e c irc ulating f an sp eed may b e auto matic ally

inc reased as th e c irc ulating f an setting is inc reased. As

exp lained ab o v e, th e so f tWare o r lo gic o f th e system also

p urges air th ro ugh th e system j ust p rio r to eac h time th e h eat

so urc e is ? red up .

I f needed, th e inc ineratio n tub e 20 and inc ineratio n c h am

b er/ stac k c an b e made lo nger, o r o f larger diameter, to p ro v ide

suf ? c ient dWell time f o r f ull inc ineratio n o f smo ke and p o l

lutants. Th is is no t nec essary if th e ? ame 4 2 is turned h igh

eno ugh f o r th e sh o rt p erio d o f time during Wh ic h th e air

c o o ling/ smo ke inc inerating c yc le is o p erated, Wh ic h c an b e a

matter o f sec o nds, less th an o ne minute. N o te also , th e c irc u

lating f an 16 is sh o Wn in a p ref erred p o sitio n j ust up stream o f

th e inlet to th e c yc lo ne sep arato r, b ut it c o uld b e p o sitio ned

j ust up stream o f th e ro asting c h amb er if desired, and similar

results Wo uld b e ac h iev ed. Also , th e p urge gate 52, alth o ugh

c o nv eniently o p erated in th e f o rm sh o Wn, c o uld b e c o n? gured

dif f erently. I t c o uld b e lo c ated f arth er do Wnstream in th e duc t

( alth o ugh th is Wo uld p rev ent p urging o f th e duc t 22 in a

p re- ? ring p urge o f p artic ulates, and th us migh t b e o b j ec tio n

ab le) , o r a gate c o uld b e p ro v ided to c lo se o f f th e p ro c ess

stream o utlet 4 8 o f th e c yc lo ne sep arato r, and a dif f erent gate

o r do o r c o uld b e o p ened to v ent amb ient air into th e duc t 22 o r

into th e ro asting c h amb er 14 .

N o te also , th e mac h ine and p ro c ess desc rib ed h erein are

no t limited to c o f f ee b eans, b ut c an b e used With c o c o a b eans

o r o th er b eans o r grains to b e ro asted, p artic ularly th o se th at

generate smo ke in ro asting.

Th e ? o W c h art o f FI G . 6 indic ates th e p ro c ess o f a c o f f ee

ro asting c yc le ac c o rding to th e inv entio n, in th is examp le

illustrating th e p ro c ess f ro m startup , Wh en th e mac h ine h as

b een c o mp letely o f f .

20

25

30

35

4 0

4 5

50

55

60

65

6

Th e o p erato r turns o n th e p o Wer as indic ated in th e b lo c k

80. Th e c o f f ee b eans are p lac ed in th e h o p p er, o r h av e already

b een p lac ed, as at 82. Th e o p erato r p resses a b urner start

b utto n and th e system enters an idle mo de ( b lo c k 84 ) . Th e

b urner is no t immediately ignited. Th e b urner is no t immedi

ately ignited. Th e p urge gate is o p ened ( o r may already b e

o p en) and th e c irc ulatio n f an o r c irc ulating f an o r b lo Wer is

turned o n, as no ted in th e b lo c k 86. Th e c irc ulatio n f an needs

a p erio d o f time to ramp up to sp eed. Dep ending o n th e siZe o f

th e system, th e system p urge c o ntinues f o r ab o ut tWenty

sec o nds to sixty sec o nds, remo v ing any smo ke o r airb o rne

p artic ulates th at may b e in th e system p rio r to igniting th e

b urner. Wh en th e p urge is c o mp leted, th e c irc ulatio n f an

sp eed is auto matic ally lo Wered ( b lo c k 88) , and th e p urge gate

is c lo sed, indic ated at 90.

Af ter c o mp letio n o f th e p urge and c lo sing o f th e p urge gate,

th e b urner ligh ts, and th e ro aster is allo Wed to Warm up f o r an

ap p ro p riate p erio d o f time, as at th e b lo c k 92. Wh en th e

ro aster c h amb er is su? ic iently Warm, th e b eans are dro p p ed

into th e ro ast c h amb er f ro m th e h o p p er, b lo c k 94 . Th e system

no W enters th e ro ast mo de ( b lo c k 96) , in Wh ic h th e b urner is

h eating rec irc ulating air and gases Wh ic h c irc ulate th ro ugh

th e ro asting c h amb er to ro ast th e b eans. A drum in th e ro ast

ing c h amb er is ro tating during th e ro ast, o r mo re p ref erab ly,

ro tating p addles in a statio nary drum agitate th e b eams and

assure ev en ro asting. Air agitatio n c an b e used, rath er th an

mec h anic al agitatio n. Th e c irc ulatio n f an setting c an b e c o n

tro lled b y th e o p erato r o r b y a selec ted auto matic mo de. Th e

b urner setting c an also b e selec ted, manually o r auto mati

c ally.

At th e end o f th e ro ast, Wh ic h is indic ated in th e b lo c k 98,

a dec isio n is made b y th e o p erato r o r v ia an auto matic mo de

( b lo c k 100) as to Wh eth er th e air c o o l c yc le Will b e used. I f

so , th e air c o o l c yc le b egins, b lo c k 102. I f no t, th e system go es

into p o st ro ast mo de as indic ated in th e b lo c k 104 . Wh eth er

th e system enters th e air c o o l c yc le c an b e p reset p rio r to

o p eratio n o f th e ro ast c yc le.

Fo r th e air c o o l c yc le, th e b urner setting is inc reased as

no ted at 106, and th e c irc ulatio n f an setting is also inc reased,

as at 108. Th ere may b e a sh o rt delay b ef o re th e c irc ulatio n

f an inc rease, to giv e th e b urner ? ame time to inc rease. Af ter

th e c irc ulatio n f an ? ash b lo Wer sp eed is inc reased, th ere p ref

erab ly is imp o sed a sh o rt delay, e. g. th ree sec o nds, b ef o re th e

p urge gate is o p ened, as no ted in th e b lo c k 110.

Th e b lo c k 112 indic ates th at th e air c o o l c yc le, c o o ling th e

b eans in th e ro aster, p ro c eeds f o r ab o ut ten sec o nds to sixty

sec o nds. Fresh air is draWn in th ro ugh th e o p en p urge gate and

c o urses th ro ugh th e ro aster, c o o ling th e c o f f ee b eans and

mo v ing th e residual smo ke o ut th ro ugh th e inc ineratio n tub e

and stac k. Th e drum ( o r p addles) in th e ro aster c o ntinues to

ro tate, turning o v er th e b eams. Th e drum in th e ro aster c o n

tinues to ro tate, turning o v er th e b eans. As th e b eans are

c o o ling in th e ro asting c h amb er, th e h o t air h eated b y th e

b urner at th is h igh setting do es no t rec irc ulate b ac k to th e

ro aster b ec ause th e p urge gate is o p en, b lo c king th e rec irc u

latio n p ath . All gases and airb o rne p artic ulates exit th ro ugh

th e inc ineratio n tub e and stac k. Af ter th e time p reset f o r air

c o o l, o r as c o ntro lled b y th e o p erato r manually, th e air c o o l

c yc le ends, as no ted in th e b lo c k 114 . Th is is signaled b y th e

to uc h sc reen mo nito r unit 24 , seen in FI G . 1. Th e drum o r

p addles c ease to ro tate.

At th e end o f th e air c o o l c yc le, th e ro asted and p artially

c o o led b eans are released to th e exterio r c o o ling tray as no ted

at 116. Th is c an h ap p en auto matic ally, as p reset, o r th e o p era

to r c an initiate th is manually. Th e p o st ro ast b egins, as no ted

at 118. Th e c irc ulatio n f an is reduc ed to a lo Wer setting ( b lo c k

120) , and af ter a delay, e. g. tWenty sec o nds as indic ated, th e

US 8, 679, 561 B2

7

p urge gate is c lo sed as no ted at 122 and th e b urner ? ame is

reduc ed to a lo W ? re, as no ted at 124 .

At th is p o int, p o st ro ast mo de c o ntinues. Th is mo de c o n

tinues f o r a p reset time, eg ab o ut th ree minutes. I f a neW

b atc h o f b eans is no t mo v ed into th e ro asting c h amb er b ef o re

th e p o st ro ast p erio d ends, as no ted in th e dec isio n b lo c k 128,

th e system Will transitio n into idle mo de 130. I n th is mo de th e

b urner, Wh ic h is at lo W ? re, c an b e p reset to c yc le b etWeen tWo

set temp eratures to keep th e system f ro m h eating up mo re

th an desired. Alternativ ely, th e b urner c an b e sh ut o f f .

I f a neW b atc h o f b eans is dro p p ed into th e c h amb er ( dec i

sio n b lo c k 128) , a neW ro ast c yc le Will b egin, as at th e b lo c k

94 . N o te th at th e green c o f f ee b eans sh o uld no t b e dro p p ed

into th e c h amb er if th e b urner is o f f , and th e sc reen Will th us

instruc t th e o p erato r.

Th e so f tware- c o ntro lled mac h ine and p ro c ess h av e mul

tip le f unc tio nalities. With th e p ro grammed c o mp uter and

o p erato r inp uts f o r selec ted settings, th e mac h ine c an v ary th e

c irc ulating f an sp eed as needed o r desired; th e b urner setting

c an b e inc reased o r dec reased as needed; th e p urge gate is

o p ened and c lo sed f o r dif f erent p urp o ses as set f o rth ab o v e;

and th e o p ening o f th e b eam disc h arge do o r to th e c o o ler c an

b e delayed o r mo di? ed as desired, dep ending o n internal air

c o o ling time selec ted. Th e c o mp uter eq uip ment p ref erab ly

inc ludes a to uc h sc reen mo nito r f o r o p erato r inp ut as Well as

disp lay. Th e c o mp uter and inp ut sc reen are sh o Wn in FI G . 1.

Alth o ugh th e mac h ine and p ro c ess o f th e inv entio n are

desc rib ed p rimarily f o r c o f f ee b ean ro asting, o th er ro astab le

b eans and grains, p artic ularly th o se th at giv e o f f smo ke, c an

b e ro asted. Th e c laims are to b e interp reted as ap p lying to

suc h o th er b eans and grains.

Th e ab o v e desc rib ed p ref erred emb o diments are intended

to illustrate th e p rinc ip les o f th e inv entio n, b ut no t to limit its

sc o p e. Oth er emb o diments and v ariatio ns to th ese p ref erred

emb o diments Will b e ap p arent to th o se skilled in th e art and

may b e made With o ut dep arting f ro m th e sp irit and sc o p e o f

th e inv entio n as de? ned in th e f o llo Wing c laims.

I c laim:

1. A meth o d f o r o p erating a ro aster f o r c o f f ee b eans o r o th er

b eans o r grains, o f th e typ e h av ing a c yc lo ne sep arato r h eating

c h amb er and a c o f f ee b ean ro asting c h amb er, With th e o utlet

o f th e c yc lo ne sep arato r b eing c o nnec ted b y duc ting to th e

c o f f ee b ean ro asting c h amb er f o r h eating c o f f ee b eans th erein

and th e ro asting c h amb er h av ing an o utlet c o nnec ted to an

inlet o f th e c yc lo ne sep arato r, th e c yc lo ne sep arato r h eating

tub e h av ing an inc ineratio n tub e p o sitio ned ab o v e a h eat

so urc e so th at th e p ro c ess stream sWirls aro und th e o utside o f

th e inc ineratio n tub e, and With a c irc ulatio n f an o r b lo Wer

p o sitio ned in th e p ro c ess stream to mo v e th e p ro c ess stream in

a rec irc ulating lo o p th ro ugh th e c yc lo ne sep arato r h eating

c h amb er and th ro ugh th e ro asting c h amb er, c o mp rising th e

step s o f :

20

25

30

35

4 0

4 5

50

8

rec irc ulating th e p ro c ess stream With th e h eat so urc e ac ti

v ated, f o r a su? ic ient time and at a su? ic ient temp erature

o f th e p ro c ess stream to ro ast c o f f ee b eans in th e ro asting

c h amb er,

Wh en th e c o f f ee b eans h av e b een ro asted, leav ing th e c o f f ee

b eans remaining in th e ro asting c h amb er f o r a time to

allo W c o o ling,

o p ening an amb ient air v ent b etWeen th e c yc lo ne sep arato r

and th e ro asting c h amb er Wh ile at th e same time sub

stantially b lo c king ? o W o ut o f th e c yc lo ne sep arato r,

th us c ausing amb ient air to Ho w into and th ro ugh th e

ro asting c h amb er c o o ling th e c o f f ee b eans and into th e

c yc lo ne sep arato r, th en into th e inc ineratio n tub e, Wh ere

th e air c arrying smo ke f ro m th e ro asting c h amb er and

airb o rne p artic ulate material is inc inerated b ef o re b eing

exh austed,

Wh ereb y, f o llo Wing a ro asting o f c o f f ee b eans, th e ro asting

c h amb er is p urged o f smo ke and airb o rne p artic ulate

matter, th e c o f f ee b eans are c o o led b elo W a temp erature

at Wh ic h th ey giv e o f f smo ke, and all smo ke, p o llutants

and airb o rne p artic ulate matter are inc inerated, suc h th at

th e ro asting p ro c ess p ro duc es almo st no smo ke o utside

th e mac h ine.

2. Th e meth o d o f c laim 1, Wh erein, Wh ile th e amb ient air

v ent is o p en and Ho w is sub stantially b lo c ked o ut o f th e

c yc lo ne sep arato r, th e h eat so urc e is at a h igh setting and th e

c irc ulating f an o r b lo Wer is at a h igh er sp eed th an during

c o f f ee b ean ro asting, so th at th e p urged smo ke and airb o rne

p artic ulate material is f ully inc inerated in th e inc ineratio n

tub e.

3. Th e meth o d o f c laim 1, Wh erein th e step s o f o p ening an

amb ient air v ent and sub stantially b lo c king ? o W o ut o f th e

c yc lo ne sep arato r, c o mp rise auto matic ally c h anging th e p o si

tio n o f a p urge gate in said duc ting, f ro m a c lo sed p o sitio n

sealing against amb ient air and allo Wing p ro c ess stream Ho w

to th e b ean ro asting c h amb er, to an o p en p o sitio n sub stan

tially b lo c king ? o W o ut o f th e c yc lo ne sep arato r and o p ening

th e duc ting do Wnstream o f th e p urge gate to Ho w o f amb ient

air to th e b ean ro asting c h amb er.

4 . Th e p ro c ess o f c laim 1, Wh erein th e time and temp era

ture o f ro asting th e c o f f ee b eans, th e o p ening o f th e amb ient

air v ent and sub stantially b lo c king ? o W o ut o f th e c yc lo ne

sep arato r, are c o ntro lled auto matic ally b y a c o mp uter and

p ro gramming.

5. Th e meth o d o f c laim 1, f urth er inc luding, af ter a p erio d

o f time in Wh ic h th e c o f f ee b eans in th e ro asting c h amb er are

c o o led, auto matic ally releasing th e c o f f ee b eans f ro m th e

c h amb er into an exterio r c o o ling tray, lo Wering th e sp eed o f

th e c irc ulatio n f an o r b lo Wer, c lo sing th e amb ient air v ent and

allo Wing ? o W o ut o f th e c yc lo ne sep arato r, and reduc ing th e

setting o f th e h eat so urc e.

* * * * *

S-ar putea să vă placă și

- United States Patent (10) Patent N0.2 US 6,276,459 B1Document6 paginiUnited States Patent (10) Patent N0.2 US 6,276,459 B1Jessica CehÎncă nu există evaluări

- Gel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2Document9 paginiGel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2b4rfÎncă nu există evaluări

- United States Patent 1191 - 1111 3,967,998: Kane (45) July 6, 1976Document9 paginiUnited States Patent 1191 - 1111 3,967,998: Kane (45) July 6, 1976Kha Damayantirika Tsf 'reall'Încă nu există evaluări

- Combustion Engineering-2000-Minimum Recirculation Flame Control (MRFC) Pulverized Solid Fuel Nozzle Tip PDFDocument22 paginiCombustion Engineering-2000-Minimum Recirculation Flame Control (MRFC) Pulverized Solid Fuel Nozzle Tip PDFKrozeÎncă nu există evaluări

- Ulllted States Patent (10) Patent N0.: US 8,362,408 B2Document11 paginiUlllted States Patent (10) Patent N0.: US 8,362,408 B2werwer44345Încă nu există evaluări

- (12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1Document13 pagini(12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1danceÎncă nu există evaluări

- United States Patent (191: (11) Patent Number: (45) Date of PatentDocument5 paginiUnited States Patent (191: (11) Patent Number: (45) Date of PatentSalmanPashaÎncă nu există evaluări

- Us 4962706Document8 paginiUs 4962706drivinerÎncă nu există evaluări

- United States Patent (191: Bourne (45) Jan. 27, 1981Document14 paginiUnited States Patent (191: Bourne (45) Jan. 27, 1981Angel Andres GutiérrezÎncă nu există evaluări

- Serdox AppsDocument13 paginiSerdox AppsCesar MartinezÎncă nu există evaluări

- United States Patent (19) (11) Patent Number: 4,859,054: Harrison (45) Date of Patent: Aug. 22, 1989Document9 paginiUnited States Patent (19) (11) Patent Number: 4,859,054: Harrison (45) Date of Patent: Aug. 22, 1989drivinerÎncă nu există evaluări

- Ulllted States Patent (19) (11) Patent Number: 6,005,480: Banzhof Et Al. (45) Date of Patent: Dec. 21, 1999Document13 paginiUlllted States Patent (19) (11) Patent Number: 6,005,480: Banzhof Et Al. (45) Date of Patent: Dec. 21, 1999kthuang1Încă nu există evaluări

- United States Patent (191 (11) Patent Number: 4,508,572: Sakuta Et A1. (45) Date of Patent: Apr. 2, 1985Document6 paginiUnited States Patent (191 (11) Patent Number: 4,508,572: Sakuta Et A1. (45) Date of Patent: Apr. 2, 1985atnmmm100Încă nu există evaluări

- United States Patent: VaradarajDocument5 paginiUnited States Patent: VaradarajAntonio GuarascioÎncă nu există evaluări

- United States PatentDocument20 paginiUnited States PatentpamururamuÎncă nu există evaluări

- United States Patent (19) (11) Patent Number: 6,018,225: Garces (45) Date of Patent: Jan. 25, 2000Document15 paginiUnited States Patent (19) (11) Patent Number: 6,018,225: Garces (45) Date of Patent: Jan. 25, 2000kfaliÎncă nu există evaluări

- Us 5456636Document18 paginiUs 5456636Meow Chix100% (1)

- Umted States Patent (191 (11) Patent Number: 5 038 702: Bowes (45) Date of Patent: Aug. 13, 1991Document15 paginiUmted States Patent (191 (11) Patent Number: 5 038 702: Bowes (45) Date of Patent: Aug. 13, 1991Phan Trọng NghĩaÎncă nu există evaluări

- United States Patent: (12) (10) Patent N0.: US 6,971,999 B2Document17 paginiUnited States Patent: (12) (10) Patent N0.: US 6,971,999 B2ghftr456Încă nu există evaluări

- The Fuel, Air and Flue-Gas CircuitsDocument23 paginiThe Fuel, Air and Flue-Gas CircuitsKamugasha KagonyeraÎncă nu există evaluări

- Research 3Document22 paginiResearch 3anaqiaisyahÎncă nu există evaluări

- Advanced High Pressure O2H2 TechnologyDocument754 paginiAdvanced High Pressure O2H2 TechnologyAerojet Rocketdyne RS-25Încă nu există evaluări

- Marine HoseDocument9 paginiMarine HosemtajikÎncă nu există evaluări

- United States Patent (10) Patent N0.: US 6,827,075 B1Document7 paginiUnited States Patent (10) Patent N0.: US 6,827,075 B1Cristhian GraefÎncă nu există evaluări

- Hot Box Compost Bin US Patent 5766876Document6 paginiHot Box Compost Bin US Patent 5766876Paula Hewitt AmramÎncă nu există evaluări

- Web 1T: (12) United States PatentDocument18 paginiWeb 1T: (12) United States PatentadeindrawijayaÎncă nu există evaluări

- United States Patent (19) (11) Patent Number: 4,971,516: Lawless Et Al. (45) Date of Patent: Nov. 20, 1990Document9 paginiUnited States Patent (19) (11) Patent Number: 4,971,516: Lawless Et Al. (45) Date of Patent: Nov. 20, 1990ابزار دقیقÎncă nu există evaluări

- Lirisk: Large, Controllable Parachute Aerial Drop Test Plan N V R - 3 9 6 4 January 1966Document76 paginiLirisk: Large, Controllable Parachute Aerial Drop Test Plan N V R - 3 9 6 4 January 1966Florin NiteÎncă nu există evaluări

- United States Patent: Harlander Et A) - (10) Patent N0.: (45) Date of PatentDocument24 paginiUnited States Patent: Harlander Et A) - (10) Patent N0.: (45) Date of PatentFaizan KhanÎncă nu există evaluări

- am (14.04 94 1414/ 91) 1.14 A) 442F991: Ulllted States Patent (19) (11) Patent Number: 6,044,728Document10 paginiam (14.04 94 1414/ 91) 1.14 A) 442F991: Ulllted States Patent (19) (11) Patent Number: 6,044,728Baciu NicolaeÎncă nu există evaluări

- United States Patent: Mueller Et Al. (10) Patent N0.: (45) Date of PatentDocument8 paginiUnited States Patent: Mueller Et Al. (10) Patent N0.: (45) Date of PatentAnonymous LEVNDh4Încă nu există evaluări

- Us 6362718 (US Patent For Free Energy Device)Document15 paginiUs 6362718 (US Patent For Free Energy Device)jajahahaÎncă nu există evaluări

- Printing Ink and Overprint VarnishDocument137 paginiPrinting Ink and Overprint VarnishSutopo100% (2)

- United States Patent: Peter (10) Patent N0.: (45) Date of PatentDocument6 paginiUnited States Patent: Peter (10) Patent N0.: (45) Date of PatentRazvan VasileÎncă nu există evaluări

- Orbiter Test Flight Press KitDocument61 paginiOrbiter Test Flight Press KitBob Andrepont100% (3)

- United States Patent (10) Patent N0.: US 8,091,836 B2Document8 paginiUnited States Patent (10) Patent N0.: US 8,091,836 B2werwer44345Încă nu există evaluări

- Umted States Patent (10) Patent N0.2 US 8,415,942 B2: Fletcher (45) Date of Patent: Apr. 9, 2013Document19 paginiUmted States Patent (10) Patent N0.2 US 8,415,942 B2: Fletcher (45) Date of Patent: Apr. 9, 2013bonesisaliveÎncă nu există evaluări

- United States Patent: Rozum Et A) - (10) Patent N0.: (45) Date of PatentDocument15 paginiUnited States Patent: Rozum Et A) - (10) Patent N0.: (45) Date of PatentomikamiÎncă nu există evaluări

- HEÆ/Y-tON, H!GH-SP!N States AND Nuclear StructureDocument372 paginiHEÆ/Y-tON, H!GH-SP!N States AND Nuclear StructureIshfaqAhmedMayoÎncă nu există evaluări

- Bellow Seal For Liquid SystemDocument42 paginiBellow Seal For Liquid SystemfatinÎncă nu există evaluări

- Atmos Transmission HDBKDocument295 paginiAtmos Transmission HDBKbob_kurilla1680Încă nu există evaluări

- A Sheffield Hallam University Thesis: Fatigue in Pearlite StructuresDocument227 paginiA Sheffield Hallam University Thesis: Fatigue in Pearlite StructuresSteve OoiÎncă nu există evaluări

- United States Patent: (12) (10) Patent N0.: US 6,643,842 B2Document45 paginiUnited States Patent: (12) (10) Patent N0.: US 6,643,842 B2bgstrandÎncă nu există evaluări

- Nasa Ntrs Archive 19930094567Document13 paginiNasa Ntrs Archive 19930094567Mikail AviciÎncă nu există evaluări

- EarlyvalkyrieDocument56 paginiEarlyvalkyrieJohn SuttonÎncă nu există evaluări

- Us 5287973Document9 paginiUs 5287973Fitrian ImaduddinÎncă nu există evaluări

- US6863865Document7 paginiUS6863865trscribdforworkÎncă nu există evaluări

- On The Calculation of Ducted Propeller Performance in Axisymmetric FlowsDocument206 paginiOn The Calculation of Ducted Propeller Performance in Axisymmetric FlowsbobjiÎncă nu există evaluări

- Iml Tini: (12) United States PatentDocument54 paginiIml Tini: (12) United States PatentBCristinÎncă nu există evaluări

- Research 2Document45 paginiResearch 2anaqiaisyahÎncă nu există evaluări

- United States Patent (10) Patent No.: US 8,014,526 B2Document12 paginiUnited States Patent (10) Patent No.: US 8,014,526 B2sat258Încă nu există evaluări

- Heinkel He 64 C Sport Airplane (German)Document9 paginiHeinkel He 64 C Sport Airplane (German)SnautzerÎncă nu există evaluări

- National Aeronautics and Space Administration: P IjnclasDocument5 paginiNational Aeronautics and Space Administration: P IjnclasDeepak Paul TirkeyÎncă nu există evaluări

- United States Patent (10) Patent No.: US 7,497,097 B2Document9 paginiUnited States Patent (10) Patent No.: US 7,497,097 B2Kasra GolbanÎncă nu există evaluări

- United States Patent: Rousseau Et Al. (45) Date of Patent: Apr. 24, 2007Document31 paginiUnited States Patent: Rousseau Et Al. (45) Date of Patent: Apr. 24, 2007omikamiÎncă nu există evaluări

- United States Patent (10) Patent No.: US 8,301,867 B1Document12 paginiUnited States Patent (10) Patent No.: US 8,301,867 B1Ghouse MohammedÎncă nu există evaluări

- NUREG/CR-0649 Spent Fuel Heatup Following Loss of Water During ShortageDocument173 paginiNUREG/CR-0649 Spent Fuel Heatup Following Loss of Water During ShortageEnformableÎncă nu există evaluări

- Pneumatics - Beginners Guide Using Halloween Projects WWDocument57 paginiPneumatics - Beginners Guide Using Halloween Projects WWamadan64Încă nu există evaluări

- Incinerator DesignDocument106 paginiIncinerator DesignSaransiri WongsiriÎncă nu există evaluări

- SM Incinerators 3Document13 paginiSM Incinerators 3Saransiri WongsiriÎncă nu există evaluări

- High Temperature Vortex IncineratorDocument32 paginiHigh Temperature Vortex IncineratorSaransiri WongsiriÎncă nu există evaluări

- Coffee Energy Audit: An Analysis of Coffee Energy Consumption and Efficiency at Boston CollegeDocument31 paginiCoffee Energy Audit: An Analysis of Coffee Energy Consumption and Efficiency at Boston CollegeSaransiri WongsiriÎncă nu există evaluări

- Coffee Life CycleDocument6 paginiCoffee Life CycleSaransiri WongsiriÎncă nu există evaluări

- CHM 062 CDocument19 paginiCHM 062 CSaransiri WongsiriÎncă nu există evaluări

- 1.3 VortragEmdenDierkerDocument37 pagini1.3 VortragEmdenDierkerDian Agung NugrohoÎncă nu există evaluări

- 420 Data SheetDocument2 pagini420 Data SheetSaransiri WongsiriÎncă nu există evaluări

- SEV CombustorDocument9 paginiSEV CombustorSaransiri Wongsiri100% (1)

- Gasturbine Engines For Model AircraftDocument104 paginiGasturbine Engines For Model AircraftSaransiri Wongsiri94% (16)

- System Admin Resume FormatDocument2 paginiSystem Admin Resume FormatRamesh KumarÎncă nu există evaluări

- 安裝PALERT手冊 PDFDocument25 pagini安裝PALERT手冊 PDFSub ZeroÎncă nu există evaluări

- A 1-126.x.x.x B 128-191.x.x.x C 192-223.x.x.x: CBT IPV4 NotesDocument1 paginăA 1-126.x.x.x B 128-191.x.x.x C 192-223.x.x.x: CBT IPV4 NotesDhananjai SinghÎncă nu există evaluări

- HP Deskjet 3700 All-In-One SeriesDocument120 paginiHP Deskjet 3700 All-In-One SeriesTina ConoverÎncă nu există evaluări

- ECE4005 Optical-Communication-And - Networks ETH 1 AC40 6Document3 paginiECE4005 Optical-Communication-And - Networks ETH 1 AC40 6garvit bhatejaÎncă nu există evaluări

- How To Configure A Cisco Layer 3 SwitchDocument4 paginiHow To Configure A Cisco Layer 3 SwitchYacouba ZembraÎncă nu există evaluări

- NPT Product Line SS PDFDocument143 paginiNPT Product Line SS PDFrahulÎncă nu există evaluări

- SmimeDocument9 paginiSmimerajeevrajkumarÎncă nu există evaluări

- Top-Down Network Design, Second EditionDocument2 paginiTop-Down Network Design, Second EditionNguyễn Hùng0% (1)

- ADSL PresentationDocument14 paginiADSL PresentationJames HavocÎncă nu există evaluări

- Cnmaestro 3.0.4 Release NotesDocument10 paginiCnmaestro 3.0.4 Release NotesOmar PalmaÎncă nu există evaluări

- RP 100 300II User ManualDocument9 paginiRP 100 300II User ManualEdgar Armando Diaz CastilloÎncă nu există evaluări

- Dual Band AC1300: Indoor Access Point Range ExtenderDocument9 paginiDual Band AC1300: Indoor Access Point Range ExtenderOmar PerezÎncă nu există evaluări

- 20 BitDefenderDocument24 pagini20 BitDefenderwiktor991Încă nu există evaluări

- Simatic Software: STEP 7 V5.4Document21 paginiSimatic Software: STEP 7 V5.4Everaldo MarquesÎncă nu există evaluări

- Merchant of Venice in Urdu by William Shakespeare - Summary - Themes - Analysis - Characters - Urdu Translations PDFDocument9 paginiMerchant of Venice in Urdu by William Shakespeare - Summary - Themes - Analysis - Characters - Urdu Translations PDFsaad raza100% (1)

- Literature Survey On IOT Based Weather Monitoring SystemDocument4 paginiLiterature Survey On IOT Based Weather Monitoring SystemTrupti Teggi0% (1)

- Locking and Unlocking of Automobile Engine Using RFID1Document19 paginiLocking and Unlocking of Automobile Engine Using RFID1Ravi AkkiÎncă nu există evaluări

- A Wormhole Attack Detection and Prevention TechniqDocument9 paginiA Wormhole Attack Detection and Prevention TechniqMahmudur RahmanÎncă nu există evaluări

- Support MatrixDocument3 paginiSupport MatrixEdinson Peña LondoñoÎncă nu există evaluări

- FortiOS 6.4.2 Administration GuideDocument1.865 paginiFortiOS 6.4.2 Administration Guideovidiu mihaiÎncă nu există evaluări

- HM QosDocument5 paginiHM QosNicolas Felipe Nuñez CisternasÎncă nu există evaluări

- HotSpot GatewayDocument20 paginiHotSpot GatewayombidasarÎncă nu există evaluări

- Sns College of Technology: Computer NetworksDocument27 paginiSns College of Technology: Computer NetworksgmsamyÎncă nu există evaluări

- Integrating Electric Vehicles Into Smart Grid Using Iec 61850 and Isoiec 15118 StandardsDocument76 paginiIntegrating Electric Vehicles Into Smart Grid Using Iec 61850 and Isoiec 15118 Standardswolverine_98100% (1)

- CIS Controls v8 Mapping To ISACA COBIT 19 2 2023Document148 paginiCIS Controls v8 Mapping To ISACA COBIT 19 2 2023Franck BÎncă nu există evaluări

- Salsa 8 Backup And-RestoreDocument41 paginiSalsa 8 Backup And-RestoreSerjio Alavro Di MistaÎncă nu există evaluări

- Control 07 2015 30pa PH Pac PHCDocument44 paginiControl 07 2015 30pa PH Pac PHCЕвгений РогозинÎncă nu există evaluări

- PM800BMSDocument1 paginăPM800BMSjstefanisÎncă nu există evaluări

- EPower 029669 5 PDFDocument14 paginiEPower 029669 5 PDFrajabharath12Încă nu există evaluări