Documente Academic

Documente Profesional

Documente Cultură

220v DC System

Încărcat de

Babu AravindTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

220v DC System

Încărcat de

Babu AravindDrepturi de autor:

Formate disponibile

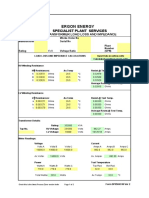

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

NTPC REF NO: SIM/ 1/ TS/ 1 /112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

LIST OF CONTENTS

1. PLANT DETAILS

2. TESTING OBJECTIVES

3. TESTING PROPOSALS

4. SERVICES REQUIRED

5. SAFETY PRECAUTIONS

6. EMERGENCY PROCEDURES

7. STATE OF THE PLANT

8. COMMISSIONING PROCEDURE

9. COMPLETION OF CRITERIA

10. APPENDICES

SHEET 1 OF 15

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

SHEET 2 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1 / 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

1.0 PLANT DETAILS

This system consists of:

i.

Battery Bank

ii.

Battery Charger - Main and Standby

iii.

DC Distribution board.

The battery is installed in the battery room in the HT switchgear room. This

provides a 220 V DC supply to the relay and control circuits in the Generator.

Generator transformer and Unit transformer protection and control panels, 11KV

and 3.3 KV HT switchgear and 4.5 V LT switchgears Unit and station service

boards and aux. Control panels.

Battery Cells - Data Sheet

Guaranteed AH Capacity at 10 Hrs.discharge

Rate 1 Volt / Cell at 27 C

990 AH

Designation

KPH 990 P

1.4 -- 1.42 V/Cell

Voltage

1.53 -- 1.67 V/Cell

Trickle charging current

1 to 2 MA /AH

Boost charging current

198 A

Recommended range of floating/trickle

Charging voltage

Recommended range of boost charging

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

SHEET 3 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1/112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

Open circuit voltage of cell when completely

Discharged at 27 C at 5 hrs discharge rage

Dimension (mm)

1.0 V

-

522 L x 192 W x 405 H

Per cell required for first filling at 27 C

18 Lit / cell, 1.19 +- 0.01

Specific gravity of cell when fully charged

1.19+- 0.01

Continuously

50 C

Net dry cell weight

45 Kg

With electrolyte

68 Kg

Cell container material

Polypropylene

No of cells / Bank

169

Amount of specific gravity or electrolyte

Max. electrolyte temp. that cell can withstand

Charger - I & II

Input Voltage

415 V+- 10%

Output Voltage

220 V DC

Float Voltage

236 V DC

Boost Voltage

287.3 V DC

Rectifier current limit

400 A

Battery current limit

198 A

Auto charge over current

40 A

Steady state output voltage Regulation (For +- 10% I/P

Voltage variation

0 - 100 % load variation

at a time).

+-1%

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

SHEET 4 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1 / 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

2.0 TESTING OBJECTIVES:

2.1 To ensure that all the relevant checklists have been completed for the battery,

battery charger and distribution boards.

2.2 To complete the connections between the battery / battery charger and the

distribution boards.

2.3 To make the distribution board live at 220 V DC in a safe and orderly manner.

2.4 To carry tests and checks to ensure that all the components on the borads are

operating satisfactorily including cables to all the remote points in the 400 KV

substation and control room.

STATION : NTPC SIMHADRI BHEL REF NO: PS-DC-186-500-112

SHEET 5 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1 /112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

3.0

3.1

TESTING PROPOSALS:

AC distribution board for 3 phase AC input supply to chargers will be made

live.

3.2

Each module will be checked individually.

3.3

Each outgoing supply will be tested up to the fuses at the remote end.

3.4

Battery E/F will be simulated for both the poles and E/F relay sensitivity will be

checked.

STATION : NTPC SIMHADRI BHEL REF NO: PS-DC-186-500-112

NTPC REF NO: SIM/ 1/ TS/ 1 /112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

4.0

SERVICES REQUIRED:

4.1

415 V, 3 Phases, 50 Hz supply.

4.2

Adequate running water.

4.3

Suitable voltmeter, ammeter, thermometer and hydrometer.

4.4

Variable resistance or water load for discharging the battery.

4.5

Electrolyte for cells as per IS-266

4.6

Pure battery grade distilled water.

4.7

Funnel, jugs, cleaning brush, wire brush etc.

4.8

Variable resistance box of 15 to 150 K Ohms

4.9

1 No. 500 VDC megger.

4.10

1 No. oscilloscope, preferably dual beam or dual trace.

4.11

1 No. AVO meter or multimeter 0 - 1000 V DC

4.12

1 No. phase rotation indicator.

SHEET 6 OF 15

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

SHEET 7 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1 / 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

5.0

SAFETY PRECAUTIONS:

The following equipment will be available at all times:

5.1

Eye wash bottle

5.2

Safety goggles.

5.3

Rubber gloves

5.4

Insulated spanners and tools

5.5

5% to 10% ammonia or soda solution.

5.6

Exhaust fan near ceiling.

5.7

Acid proof aprons.

PLANT:

5.8

Acid proof ashphault flooring battery room.

5.9

Fire extinguishers installed.

5.10

" NO SMOKING AND 'NAKED FLAME' notices should be displayed.

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

SHEET 8 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1 / 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

6.0

EMERGENCY PROCEDURE:

6.1

First aid charts for acid injuires and electrical shock will be displayed.

6.2

In case of any accident involving acid burns neutralizing solution must be

applied.

6.3

All the persons working on battery shall wear, acid proof aprons.

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

NTPC REF NO: SIM/ 1/ TS/ 1 / 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

7.0

STATE OF THE PLANT:

7.1

Check list for the following plant item completed.

i.

Battery charger

ii.

DC distribution board.

7.2

All outgoing cabling work completed up to remote end panels.

7.3

All outgoing feeders from DC distribution board switched off.

7.4

Safety clearance certificates signed and returned by all parties.

SHEET 9 OF 15

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

SHEET 10 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1 / 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

8.0

COMMISSIONING PROCEDURE:

1.

TESTING OF BATTERY CHARGERS:

8.1

The insulation value shall be checked with 500 V DC Megger. During this test, all

low voltage circuits & Relays etc, shall be kept shorted.

8.2

The panel shall be switched on at no load. For this, first make input switch Q1 ON

& check the voltages at all phases indicated by lamps VD1, VD2 & VD# &

voltmeter by selector switch VS1. Now the voltage is connected to the primary of

the Main transformer which steps the voltage down as required for the specific DC

output Voltage & isolates AC Input line from Battery circuits. The transformer's

secondary is connected to the Full wave rectifier assembly.

The bridge is standard three phase full wave half controlled silicon bridge. The

voltage control is accomplished by the application of a positive pulse to the gate

terminals of the SCR at the desired time. Before the pulse is applied , the SCR is

open and no current flows in the circuit. As soon as SCR is fired, it operates as a

standard silicon rectifier until the forward current is reduced to almost zero.

8.3

Check the no load output voltage at the output terminals.

8.4

Ensure the output voltage is steady without any trouble for 15 minutes.

8.5

Check for annunciation interlocks etc.

STATION : NTPC SIMHADRI BHEL REF NO: PS-DC-186-500-112

SHEET 11 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1 / 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

8.6

If load is available, the equipment shall be loaded progreesively upto rated value

Check for voltage regulation, free from oscillation, ripple etc.

8.7

Check for dropping characteristics at higher loads.

8.8

Run the equipment for 2 hours and observe of stability and check for local heating.

When unit is loaded the ripple voltage level (peak to peak) may be observed on a

CRO. This will be within limits. Incase, it is more than specified , then it means

firing is disturbed.

II

FIRST CHARGING OF BATTERY:

8.9

DC Voltage needed for battery charging will be 2 times the no of cells in battery

bank. The initial charging will take approximately 16 to 24 hours since the batteries

are already charged and sent as maintenance free ones.

8.10

It is of utmost importance that the terminal of the battery is connected to +ve load

of charging source. So polarity should be ascertained.

8.11

Check thoroughly to ensure cells are connected in series and all fastenings and

connections are tight. The test polarity of the charging leads and correct the +ve

terminal to that of charger.

8.12

Commence charging not later than 24 hours after connecting all battery cells.

8.13

Give the first portion of charge at a rate of 100 Amps for 10 Hours

8.14

Discharge it using Water resistance or halogen lamps at a rate of

8.15

Give the second charging at the rate of approximately 20 Amps till the signs of

completion of charge observed.

for hours.

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500- 112 SHEET 12 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1/ 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

8.16

Select any one cell (except the end cell or regulating cell) as pilot cell out of every

rack as given in the layout of the battery bank.

8.17

Voltage and specific gravity reading from pilot cells will indicate the state of

charging of the whole battery system.

8.18

All cell terminals & connections are to be applied with pertroleum jelly. No

adjustment should be made which will disturb charging.

8.19

When all the cells have been greasinyg freely and when voltage and specific gravity

of pilot cell has been constant over 3 successive hour readings, the cells can be

deemed to be fully charged and the charging may be terminated. Then wipe down

outside of all cells and clean the floor.

8.20

Put the battery system on trickle charging when charging completes.

CAUTION : DONT TOUCH BATTERY TERMINALS WHEN CLEANING OUTSIDE AND

BATTERY AREA. USE PROPER GLOVES AND OTHER SAFETY MATERIALS.

8.21

The trickle charge should be adjusted to give optimum battery voltage of 1.53 - 1.67

volts per cell.

III

ENERGISING OF DISTRIBUTION BOARD:

8.22

Take final I.R. value of the board

8.23

Ensure that all outgoing circuits are locked in OFF position.

8.24

Ensure that all safety procedures have been observed.

8.25

Check that polarities of D.C switch board battery charger and battery are matching.

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

SHEET 13 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1/ 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

8.26

Close the incomer switch of board to charge it.

8.27

Measure D.C Voltage at the Input.

8.28

Observe D.C board for any abnormality.

8.29

If board condition is satisfactory, check that all remote end fuses of outgoing

circuits are removed.

8.30

Switch ON outgoing feeders one by one. Record the following for each circuit.

i.)

Polarity at both ends of circuit

ii.)

Voltage at both ends of circuit.

IV

EARTHFAULT RELAY ON LOAD TEST:

8.31

To carry out on load test for the Battery E/F relay, connect variable resistance box

of the range of 15 to 150 K Ohms between +ve pole of the board and earth

8.32

Keep selectivity setting plug of E/F relay at 3 ms setting.

8.33

Cut out resistance slowly to simulate an E/F and observe the current in milli

ammeter when the relay operates.

8.34

Record resistance and current in mA

8.35

Carry out this test on each available setting on relay.

8.36

While doing test observe and record the direction of deflection in the ammeter.

Check whether it confirms the pole on which the fault is simulated.

8.37

Repeat 8.32 to 8.37 on -ve pole of the board

8.38

The test is satisfactory if the operation of the relay confirms with the setting

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

SHEET 14 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1 / 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

9.COMPLETION CRITERIA:

220 V DC System for main plant is ready and All measurements and remote

indication points are recorded and kept along with this Schedule.

STATION : NTPC SIMHADRI

BHEL REF NO: PS-DC-186-500-112

SHEET 15 OF 15

NTPC REF NO: SIM/ 1/ TS/ 1/ 112

PLANT AREA: ELECTRICAL SYSTEM

TESTING SCHEDULE : 220 V DC SYSTEM FOR MAIN PLANT

10.APPENDICES

DRAWINGS: LAY OUT OF BATTERY ARRANGEMENT

SCHEMATIC DIAGRAM OF BATTERY CHARGERS

SCHEMATIC DIAGRAM OF DC DISTRIBUTION BOARD.

220 V DC SYSTEM FOR MAIN PLANT

S-ar putea să vă placă și

- Subject Code: Ee 1005 Subject Name: Power Quality: What Are The Causes Due To Short Circuit in TheDocument22 paginiSubject Code: Ee 1005 Subject Name: Power Quality: What Are The Causes Due To Short Circuit in TheChetan KotwalÎncă nu există evaluări

- What Is The Difference Between Power and Distribution TransformerDocument8 paginiWhat Is The Difference Between Power and Distribution Transformermaniking1Încă nu există evaluări

- HV Cable Commissioning ReportDocument10 paginiHV Cable Commissioning Reportvo100% (1)

- Check List of Lightning Protection ErectionDocument1 paginăCheck List of Lightning Protection ErectionUtku Can KılıçÎncă nu există evaluări

- Power Transformer Testing ProceduresDocument4 paginiPower Transformer Testing Proceduresyadav_sctÎncă nu există evaluări

- Site Testing Pre Commissioning PDFDocument2 paginiSite Testing Pre Commissioning PDFadi nugrohoÎncă nu există evaluări

- Notes On Tripping RelaysDocument7 paginiNotes On Tripping RelaysSenthil KumarÎncă nu există evaluări

- Transformer injection connection scheduleDocument5 paginiTransformer injection connection scheduleNiall BegleyÎncă nu există evaluări

- Project Title: Operating Area: Main Contractor: T&C Contractor: Contract No.: SubstationDocument1 paginăProject Title: Operating Area: Main Contractor: T&C Contractor: Contract No.: SubstationRam KumarÎncă nu există evaluări

- MN000301R171Document24 paginiMN000301R171juancgr77Încă nu există evaluări

- Mvaj101 - Trip RelayDocument2 paginiMvaj101 - Trip RelayratheeshkumardÎncă nu există evaluări

- SWGR Maint & TestingDocument47 paginiSWGR Maint & Testingashumanu427Încă nu există evaluări

- Psps Unit 1 QBDocument9 paginiPsps Unit 1 QBNaveen RajÎncă nu există evaluări

- Commissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDocument11 paginiCommissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDinesh PitchaivelÎncă nu există evaluări

- Site Inspection and Test Record: 13.8/4.16KV UAT-14 TRAFO RTCC PANELDocument6 paginiSite Inspection and Test Record: 13.8/4.16KV UAT-14 TRAFO RTCC PANELAshraf MohammedÎncă nu există evaluări

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pagini86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanÎncă nu există evaluări

- QCP 22 HVAC Cab LayingDocument2 paginiQCP 22 HVAC Cab LayingNEERAJ DAHIYAÎncă nu există evaluări

- Testing of Power and Distribution TransformerDocument82 paginiTesting of Power and Distribution Transformeramulya sÎncă nu există evaluări

- PSG Two Marks Q and A PDFDocument21 paginiPSG Two Marks Q and A PDFKRCT EEE HODÎncă nu există evaluări

- Transformer Testing and Maintenance EssentialsDocument44 paginiTransformer Testing and Maintenance Essentialsniyaz100% (3)

- Engine Generator Set Inspection Checklist: Section A - Customer DataDocument2 paginiEngine Generator Set Inspection Checklist: Section A - Customer Datasri_lntÎncă nu există evaluări

- LAVT & NGR Cubicles Pre & Commissioning Activities Including Tools RequiredDocument2 paginiLAVT & NGR Cubicles Pre & Commissioning Activities Including Tools Requiredrhoney0120% (1)

- Introduction To FACTS: Alternating Current Transmission System (FACTS) Devices in Power Grids. FACTS AllowDocument4 paginiIntroduction To FACTS: Alternating Current Transmission System (FACTS) Devices in Power Grids. FACTS AllowsameekshaÎncă nu există evaluări

- New QBhve3yearDocument29 paginiNew QBhve3yearArun SelvarajÎncă nu există evaluări

- PS7203-Advanced Power System ProtectionDocument6 paginiPS7203-Advanced Power System ProtectionntrimurthuluÎncă nu există evaluări

- Commission HV Underground CablesDocument12 paginiCommission HV Underground CablesisukuruÎncă nu există evaluări

- SS04 CH01 - 48V BDT Transducer SAT FormatDocument74 paginiSS04 CH01 - 48V BDT Transducer SAT FormatshameemindiaÎncă nu există evaluări

- National Grid: Checklist For Commissioning of Oil-Immersed Power TransformerDocument8 paginiNational Grid: Checklist For Commissioning of Oil-Immersed Power TransformerSanthosh Kumar VinayagamÎncă nu există evaluări

- Power Elecronics: Unit 1:: QuestionsDocument8 paginiPower Elecronics: Unit 1:: QuestionsMonishaahÎncă nu există evaluări

- GTU BE Semester VII Exam Advanced Power SystemsDocument1 paginăGTU BE Semester VII Exam Advanced Power SystemsChintan PatelÎncă nu există evaluări

- R o Y o B oDocument6 paginiR o Y o B oloffycrazeÎncă nu există evaluări

- DCRP Written Test QuestionsDocument1 paginăDCRP Written Test QuestionsSiva NandhamÎncă nu există evaluări

- Testing and Commissioning ProceduresDocument8 paginiTesting and Commissioning Proceduresbhukya lachiramÎncă nu există evaluări

- Schematic Wiring Diagram GuideDocument6 paginiSchematic Wiring Diagram GuideramyapothurÎncă nu există evaluări

- Current Transformer Testing SWP: 1. Purpose and ScopeDocument9 paginiCurrent Transformer Testing SWP: 1. Purpose and ScopeDEADMANÎncă nu există evaluări

- QUESTIONBANK EcadDocument19 paginiQUESTIONBANK EcadVarsha WaingankarÎncă nu există evaluări

- The Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDocument10 paginiThe Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDaily FunÎncă nu există evaluări

- Surge ArresterDocument7 paginiSurge ArresterNilesh MahajanÎncă nu există evaluări

- OCEFDocument2 paginiOCEFmmsaÎncă nu există evaluări

- LV Test Plan - ErgonDocument1 paginăLV Test Plan - ErgonrezadÎncă nu există evaluări

- Static VAR Compensation (SVC)Document2 paginiStatic VAR Compensation (SVC)Vedant KulkarniÎncă nu există evaluări

- Tinh Dong Ngan Mach Va Ton That Co TaiDocument3 paginiTinh Dong Ngan Mach Va Ton That Co TaiNga VũÎncă nu există evaluări

- FACTS devices control power flowsDocument1 paginăFACTS devices control power flowsRojaÎncă nu există evaluări

- Electromagnetic Fields Temperature: BurdenDocument2 paginiElectromagnetic Fields Temperature: BurdenBashaÎncă nu există evaluări

- Ts Based All StandardsDocument12 paginiTs Based All Standardsanjes1Încă nu există evaluări

- Electrical Interview QuestionsDocument3 paginiElectrical Interview QuestionsबिपुलकुँजÎncă nu există evaluări

- EE2351 PSA 2marks 2013 - 2Document15 paginiEE2351 PSA 2marks 2013 - 2Vijay RajuÎncă nu există evaluări

- TransformerDocument6 paginiTransformerrasheed313Încă nu există evaluări

- Interview Questions-1Document12 paginiInterview Questions-1aryasaurabh54Încă nu există evaluări

- Test Procedure CVT Bus 1 Phase R & TDocument4 paginiTest Procedure CVT Bus 1 Phase R & TLeonardo layÎncă nu există evaluări

- LV Switchgear Dielectric TestsDocument2 paginiLV Switchgear Dielectric TestswaseemsamsodienÎncă nu există evaluări

- 9 LorDocument2 pagini9 LorThameemul BuhariÎncă nu există evaluări

- SP0518Document15 paginiSP0518NgigiDanielÎncă nu există evaluări

- Knowledge is "Real Power": Introduction to Power QualityDe la EverandKnowledge is "Real Power": Introduction to Power QualityÎncă nu există evaluări

- 220V DCDocument15 pagini220V DCsekhar_ntpcÎncă nu există evaluări

- NTPC SIMHADRI 400kV Line Bay CommissioningDocument17 paginiNTPC SIMHADRI 400kV Line Bay Commissioningabhinav_baishwarÎncă nu există evaluări

- Triple Driver IC with Thermal MonitoringDocument6 paginiTriple Driver IC with Thermal MonitoringOlga PlohotnichenkoÎncă nu există evaluări

- Method Statement For AC PANELDocument6 paginiMethod Statement For AC PANELkamilÎncă nu există evaluări

- Apl 5336Document20 paginiApl 5336FlavianoSilvaÎncă nu există evaluări

- Honda - 1988-1991 Civic WiringDocument4 paginiHonda - 1988-1991 Civic Wiringkd6aaj100% (1)

- Damage To Bottom Ash Handling SysDocument6 paginiDamage To Bottom Ash Handling SyssanjeevchhabraÎncă nu există evaluări

- Format For Feeder Cable 48 - 42Document1 paginăFormat For Feeder Cable 48 - 42sanjeevchhabraÎncă nu există evaluări

- D1300009 Sheet 1Document1 paginăD1300009 Sheet 1sanjeevchhabraÎncă nu există evaluări

- Format For Feeder Cable 48 - 42Document1 paginăFormat For Feeder Cable 48 - 42sanjeevchhabraÎncă nu există evaluări

- Commission Coal Feeders at NTPC Simhadri PlantDocument8 paginiCommission Coal Feeders at NTPC Simhadri PlantsanjeevchhabraÎncă nu există evaluări

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDocument4 paginiGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraÎncă nu există evaluări

- High Axial Shift in Turbine, 210 MW Unit, 02-03 PDFDocument1 paginăHigh Axial Shift in Turbine, 210 MW Unit, 02-03 PDFsanjeevchhabraÎncă nu există evaluări

- Aux Steam SystemDocument14 paginiAux Steam Systemsanjeevchhabra100% (1)

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDocument4 paginiGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraÎncă nu există evaluări

- Sample Construction Methodology For Civil WorksDocument6 paginiSample Construction Methodology For Civil WorksRotsen Kho YuteÎncă nu există evaluări

- Failure of Rotary Flow Divider PDFDocument8 paginiFailure of Rotary Flow Divider PDFsanjeevchhabraÎncă nu există evaluări

- Frequent Tripping of VFD On BUSHOG - JUN10 PDFDocument2 paginiFrequent Tripping of VFD On BUSHOG - JUN10 PDFsanjeevchhabraÎncă nu există evaluări

- Heavy Deposit in Raidant Roof Tube PDFDocument5 paginiHeavy Deposit in Raidant Roof Tube PDFsanjeevchhabraÎncă nu există evaluări

- X79 PDFDocument2 paginiX79 PDFsanjeevchhabraÎncă nu există evaluări

- Design of Iec 61850 Based Substation Automation SystemsDocument8 paginiDesign of Iec 61850 Based Substation Automation Systemsİsmail KayahanÎncă nu există evaluări

- Develop Project Charter CaseDocument25 paginiDevelop Project Charter Casesanjeevchhabra100% (1)

- Maintenance PlanDocument35 paginiMaintenance PlansanjeevchhabraÎncă nu există evaluări

- 02 ACSR ZEBRA ConductorDocument37 pagini02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- Auto Transformerr4 PDFDocument54 paginiAuto Transformerr4 PDFsanjeevchhabraÎncă nu există evaluări

- Guaranteed Technical Parameters:: Inhibited Insulating OilDocument2 paginiGuaranteed Technical Parameters:: Inhibited Insulating Oilsanjeevchhabra100% (1)

- Substation SpecDocument143 paginiSubstation Specsanjeevchhabra100% (2)

- Bidding FormsDocument104 paginiBidding FormssanjeevchhabraÎncă nu există evaluări

- 03 1 TS (vOL II) Sec IIISurvey (Part I)Document39 pagini03 1 TS (vOL II) Sec IIISurvey (Part I)sanjeevchhabraÎncă nu există evaluări