Documente Academic

Documente Profesional

Documente Cultură

Basic Calculation of A Boost Converter's Power Stage

Încărcat de

xuanvan1303Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Basic Calculation of A Boost Converter's Power Stage

Încărcat de

xuanvan1303Drepturi de autor:

Formate disponibile

V

IN V

OUT

I

IN

I

OUT

C

IN

C

OUT

L

D

SW

Application Report

SLVA372CNovember 2009Revised January 2014

Basic Calculation of a Boost Converter's Power Stage

Brigitte Hauke ......................................................................................... Low Power DC/DC Application

ABSTRACT

This application note gives the equations to calculate the power stage of a boost converter built with an IC

with integrated switch and operating in continuous conduction mode. It is not intended to give details on

the functionality of a boost converter (see Reference 1) or how to compensate a converter. See the

references at the end of this document if more detail is needed.

For the equations without description, See section 8.

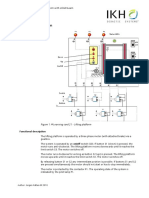

1 Basic Configuration of a Boost Converter

Figure 1 shows the basic configuration of a boost converter where the switch is integrated in the used IC.

Often lower power converters have the diode replaced by a second switch integrated into the converter. If

this is the case, all equations in this document apply besides the power dissipation equation of the diode.

Figure 1. Boost Converter Power Stage

1.1 Necessary Parameters of the Power Stage

The following four parameters are needed to calculate the power stage:

1. Input Voltage Range: V

IN(min)

and V

IN(max)

2. Nominal Output Voltage: V

OUT

3. MaximumOutput Current: I

OUT(max)

4. Integrated Circuit used to build the boost converter. This is necessary, because some parameters for

the calculations have to be taken out of the data sheet.

If these parameters are known the calculation of the power stage can take place.

1 SLVA372C November 2009 Revised J anuary 2014 Basic Calculation of a Boost Converter's Power Stage

Submit Documentation Feedback

Copyright 20092014, Texas Instruments Incorporated

OUT(max)

L

SW(max)

I

I

I = +

2 1 D -

L

MAXOUT LIM(min)

I

I = I (1 D)

2

- -

IN(min)

L

S

V D

I =

f L

IN(min)

OUT

V

D = 1

V

-

Calculate the Maximum Switch Current www.ti.com

2 Calculate the Maximum Switch Current

The first step to calculate the switch current is to determine the duty cycle, D, for the minimuminput

voltage. The minimuminput voltage is used because this leads to the maximumswitch current.

(1)

V

IN(min)

=minimuminput voltage

V

OUT

=desired output voltage

=efficiency of the converter, e.g. estimated 80%

The efficiency is added to the duty cycle calculation, because the converter has to deliver also the energy

dissipated. This calculation gives a more realistic duty cycle than just the equation without the efficiency

factor.

Either an estimated factor, e.g. 80%(which is not unrealistic for a boost converter worst case efficiency),

can be used or see the Typical Characteristics section of the selected converter's data sheet

( Reference 3 and 4).

The next step to calculate the maximumswitch current is to determine the inductor ripple current. In the

converters data sheet normally a specific inductor or a range of inductors is named to use with the IC. So

either use the recommended inductor value to calculate the ripple current, an inductor value in the middle

of the recommended range or, if none is given in the data sheet, the one calculated in the Inductor

Selection section of this application note.

(2)

V

IN(min)

=minimuminput voltage

D =duty cycle calculated in Equation 1

f

S

=minimumswitching frequency of the converter

L =selected inductor value

Nowit has to be determined if the selected IC can deliver the maximumoutput current.

(3)

I

LIM(min)

=minimumvalue of the current limit of the integrated switch (given in the data sheet)

I

L

=inductor ripple current calculated in Equation 2

D =duty cycle calculated in Equation 1

If the calculated value for the maximumoutput current of the selected IC, I

MAXOUT

, is belowthe systems

required maximumoutput current, another IC with a higher switch current limit has to be used.

Only if the calculate value for I

MAXOUT

is just a little smaller than the needed one, it is possible to use the

selected IC with an inductor with higher inductance if it is still in the recommended range. A higher

inductance reduces the ripple current and therefore increases the maximumoutput current with the

selected IC.

If the calculated value is above the maximumoutput current of the application, the maximumswitch

current in the systemis calculated:

(4)

I

L

=inductor ripple current calculated in Equation 2

I

OUT(max)

=maximumoutput current necessary in the application

D =duty cycle calculated in Equation 1

This is the peak current, the inductor, the integrated switch(es) and the external diode has to withstand.

2 Basic Calculation of a Boost Converter's Power Stage SLVA372C November 2009 Revised J anuary 2014

Submit Documentation Feedback

Copyright 20092014, Texas Instruments Incorporated

D F F

P = I V

F OUT(max)

I = I

OUT

L OUT(max)

IN

V

I = (0.2 to 0.4) I

V

( )

IN OUT IN

L S OUT

V V V

L =

I f V

-

www.ti.com Inductor Selection

3 Inductor Selection

Often data sheets give a range of recommended inductor values. If this is the case, it is recommended to

choose an inductor fromthis range. The higher the inductor value, the higher is the maximumoutput

current because of the reduced ripple current.

The lower the inductor value, the smaller is the solution size. Note that the inductor must always have a

higher current rating than the maximumcurrent given in Equation 4 because the current increases with

decreasing inductance.

For parts where no inductor range is given, the following equation is a good estimation for the right

inductor:

(5)

V

IN

=typical input voltage

V

OUT

=desired output voltage

f

S

=minimumswitching frequency of the converter

I

L

=estimated inductor ripple current, see below

The inductor ripple current cannot be calculated with Equation 1 because the inductor is not known. A

good estimation for the inductor ripple current is 20%to 40%of the output current.

(6)

I

L

=estimated inductor ripple current

I

OUT(max)

=maximumoutput current necessary in the application

4 Rectifier Diode Selection

To reduce losses, Schottky diodes should be used. The forward current rating needed is equal to the

maximumoutput current:

(7)

I

F

=average forward current of the rectifier diode

I

OUT(max)

=maximumoutput current necessary in the application

Schottky diodes have a much higher peak current rating than average rating. Therefore the higher peak

current in the systemis not a problem.

The other parameter that has to be checked is the power dissipation of the diode. It has to handle:

(8)

I

F

=average forward current of the rectifier diode

V

F

=forward voltage of the rectifier diode

3 SLVA372C November 2009 Revised J anuary 2014 Basic Calculation of a Boost Converter's Power Stage

Submit Documentation Feedback

Copyright 20092014, Texas Instruments Incorporated

OUT

1 2

FB

V

R = R 1

V

-

FB

2

R1/2

V

R =

I

R1/2 FB

I 100 I

R

1

R

2

I

R1/2

I

FB

V

OUT

V

FB

Output Voltage Setting www.ti.com

5 Output Voltage Setting

Almost all converters set the output voltage with a resistive divider network (which is integrated if they are

fixed output voltage converters).

With the given feedback voltage, V

FB

, and feedback bias current, I

FB

, the voltage divider can be calculated.

Figure 2. Resistive Divider for Setting the Output Voltage

The current through the resistive divider shall be at least 100 times as big as the feedback bias current:

(9)

I

R1/2

=current through the resistive divider to GND

I

FB

=feedback bias current fromdata sheet

This adds less than 1%inaccuracy to the voltage measurement. The current can also be a lot higher. The

only disadvantage of smaller resistor values is a higher power loss in the resistive divider, but the

accuracy will be a little increased.

With the above assumption, the resistors are calculated as follows:

(10)

(11)

R

1

,R

2

=resistive divider, see Figure 2.

V

FB

=feedback voltage fromthe data sheet

I

R1/2

=current through the resistive divider to GND, calculated in Equation 9

V

OUT

=desired output voltage

6 Input Capacitor Selection

The minimumvalue for the input capacitor is normally given in the data sheet. This minimumvalue is

necessary to stabilize the input voltage due to the peak current requirement of a switching power supply.

the best practice is to use lowequivalent series resistance (ESR) ceramic capacitors. The dielectric

material should be X5R or better. Otherwise, the capacitor cane lose much of its capacitance due to DC

bias or temperature (see references 7 and 8).

The value can be increased if the input voltage is noisy.

4 Basic Calculation of a Boost Converter's Power Stage SLVA372C November 2009 Revised J anuary 2014

Submit Documentation Feedback

Copyright 20092014, Texas Instruments Incorporated

OUT(max)

L

OUT(ESR)

I

I

V = ESR +

1 D 2

-

OUT(max)

OUT(min)

S OUT

I D

C =

f V

www.ti.com Output Capacitor Selection

7 Output Capacitor Selection

Best practice is to use lowESR capacitors to minimize the ripple on the output voltage. Ceramic

capacitors are a good choice if the dielectric material is X5R or better (see reference 7 and 8).

If the converter has external compensation, any capacitor value above the recommended minimumin the

data sheet can be used, but the compensation has to be adjusted for the used output capacitance.

With internally compensated converters, the recommended inductor and capacitor values should be used

or the recommendations in the data sheet for adjusting the output capacitors to the application should be

followed for the ratio of L C.

With external compensation, the following equations can be used to adjust the output capacitor values for

a desired output voltage ripple:

(12)

C

OUT(min)

=minimumoutput capacitance

I

OUT(max)

=maximumoutput current of the application

D =duty cycle calculated with Equation 1

f

S

=minimumswitching frequency of the converter

V

OUT

=desired output voltage ripple

The ESR of the output capacitor adds some more ripple, given with the equation:

(13)

V

OUT(ESR)

=additional output voltage ripple due to capacitors ESR

ESR =equivalent series resistance of the used output capacitor

I

OUT(max)

=maximumoutput current of the application

D =duty cycle calculated with Equation 1

I

L

=inductor ripple current fromEquation 2 or Equation 6

5 SLVA372C November 2009 Revised J anuary 2014 Basic Calculation of a Boost Converter's Power Stage

Submit Documentation Feedback

Copyright 20092014, Texas Instruments Incorporated

FB

2

R1/2

V

Value of Resistor Between FB Pin and GND: R =

I

R1/2 FB

Current Through Resistive Divider Newtwork for Output Voltage Setting: I 100 I

D F F

Power Dissipation in Rectifier Diode: P = I V

F OUT(max)

Average Forward Current of Rectifier Diode: I = I

OUT

L OUT(max)

IN

V

Inductor Ripple Current Estimation: I = (0.2 to 0.4) I

V

( )

IN OUT IN

L S OUT

V V V

Inductor Calculation: L =

I f V

-

OUT(max)

L

SW(max)

I

I

Application specific maximum switch current: I = +

2 1 D -

L

MAXOUT LIM(min)

I

Maximum output current of the selected IC: I = I (1 D)

2

- -

IN(mi n)

L

S

V D

Inductor Ripple Current: I =

f L

IN(min)

OUT

V

Maximum Duty Cycle: D = 1

V

-

Equations to Calculate the Power Stage of a Boost Converter www.ti.com

8 Equations to Calculate the Power Stage of a Boost Converter

(14)

V

IN(min)

=minimuminput voltage

V

OUT

=desired output voltage

=efficiency of the converter, e.g. estimated 85%

(15)

V

IN(min)

=minimuminput voltage

D =duty cycle calculated in Equation 14

f

S

=minimumswitching frequency of the converter

L =selected inductor value

(16)

I

LIM(min)

=minimumvalue of the current limit of the integrated witch (given in the data sheet)

I

L

=inductor ripple current calculated in Equation 15

D =duty cycle calculated in Equation 14

(17)

I

L

=inductor ripple current calculated in Equation 15

I

OUT(max)

=maximumoutput current necessary in the application

D =duty cycle calculated in Equation 14

(18)

V

IN

=typical input voltage

V

OUT

=desired output voltage

f

S

=minimumswitching frequency of the converter

I

L

=estimated inductor ripple current, see Equation 19

(19)

I

L

=estimated inductor ripple current

I

OUT(max)

=maximumoutput current necessary in the application

(20)

I

OUT(max)

=maximumoutput current necessary in the application

(21)

I

F

=average forward current of the rectifier diode

V

F

=forward voltage of the rectifier diode

(22)

I

FB

=feedback bias current fromdata sheet

(23)

6 Basic Calculation of a Boost Converter's Power Stage SLVA372C November 2009 Revised J anuary 2014

Submit Documentation Feedback

Copyright 20092014, Texas Instruments Incorporated

:

OUT(max)

L

OUT(ESR)

I

I

Additional Output Voltage Ripple due to ESR V = ESR +

1 D 2

-

OUT(max)

OUT(min)

S OUT

I D

Minimum Output Capacitance, if not given in the data sheet: C =

f V

OUT

OUT 1 2

FB

V

Value of Resistor Between FB Pin and V : R = R 1

V

-

www.ti.com Equations to Calculate the Power Stage of a Boost Converter

(24)

V

FB

=feedback voltage fromthe data sheet

I

R1/2

=current through the resistive divider to GND, calculated in Equation 22

V

OUT

=desired output voltage

(25)

I

OUT(max)

=maximumoutput current of the application

D =duty cycle calculated in Equation 14

f

S

=minimumswitching frequency of the converter

V

OUT

=desired output voltage ripple

(26)

ESR =equivalent series resistance of the used output capacitor

I

OUT(max)

=maximumoutput current of the application

D =duty cycle calculated in Equation 14

I

L

=inductor ripple current fromEquation 15 or Equation 19

7 SLVA372C November 2009 Revised J anuary 2014 Basic Calculation of a Boost Converter's Power Stage

Submit Documentation Feedback

Copyright 20092014, Texas Instruments Incorporated

References www.ti.com

9 References

1. Understanding Boost Power Stages in Switchmode Power Supplies (SLVA061)

2. Voltage Mode Boost Converter Small Signal Control Loop Analysis Using the TPS61030 (SLVA274)

3. Data sheet of TPS65148 (SLVS904)

4. Data sheet of TPS65130 and TPS65131 (SLVS493)

5. Robert W. Erickson: Fundamentals of Power Electronics, Kluwer Academic Publishers, 1997

6. Mohan/Underland/Robbins: Power Electronics, J ohn Wiley &Sons Inc., Second Edition, 1995

7. Improve Your Designs with Large Capacitance Value Multi-Layer Ceramic Chip (MLCC) Capacitors by

George M. Harayda, Akira Omi, and Axel Yamamoto, Panasonic

8. Comparison of Multilayer Ceramic and Tantalum Capacitors by J effrey Cain, Ph.D., AVX Corporation

Spacer

Revision History

Changes from B Revision (July 2010) to C Revision ..................................................................................................... Page

Changed V

IN

to V

OUT

in Figure 2 ........................................................................................................ 4

NOTE: Page numbers for previous revisions may differ frompage numbers in the current version.

Changes from A Revision (April 2010) to B Revision .................................................................................................... Page

Changed I

OUT(max)

x (1D) To: I

OUT(max)

x D in Equation 12 ............................................................................ 5

Changed I

OUT(max)

x (1D) To: I

OUT(max)

x D in Equation 25 ............................................................................ 7

NOTE: Page numbers for previous revisions may differ frompage numbers in the current version.

Changes from Original (November 2009) to A Revision ................................................................................................ Page

Added V

OUT

/V

IN

(Typical) to Equation 6 ................................................................................................ 3

added V

OUT

/V

IN

(Typical) to Equation 19 ............................................................................................... 6

NOTE: Page numbers for previous revisions may differ frompage numbers in the current version.

8 Revision History SLVA372C November 2009 Revised J anuary 2014

Submit Documentation Feedback

Copyright 20092014, Texas Instruments Incorporated

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per J ESD46, latest issue, and to discontinue any product or service per J ESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as components) are sold subject to TIs terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TIs terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license froma third party under the patents or other intellectual property of the

third party, or a license fromTI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different fromor beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harmand take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TIs goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or enhanced plasticare designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLPProducts www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright 2014, Texas Instruments Incorporated

S-ar putea să vă placă și

- Slva372b Basic Calculation of A Boost Converter's Power StageDocument9 paginiSlva372b Basic Calculation of A Boost Converter's Power StagericardoszfÎncă nu există evaluări

- A Practical Guide For The Selection of Power Inductors For DC DC Converters PDFDocument6 paginiA Practical Guide For The Selection of Power Inductors For DC DC Converters PDFŽarko DačevićÎncă nu există evaluări

- Current Mode Slope CompensationDocument11 paginiCurrent Mode Slope CompensationDaniel BiasiÎncă nu există evaluări

- LM25005, LM25010: Buck Regulator Topologies For Wide Input/Output Voltage DifferentialsDocument10 paginiLM25005, LM25010: Buck Regulator Topologies For Wide Input/Output Voltage DifferentialsBejoy ThomasÎncă nu există evaluări

- 7 Segment LED CounterDocument7 pagini7 Segment LED CounterOPie UPieÎncă nu există evaluări

- Chapter 8. Switched-Inductor Supplies With Design Insight and Intuition (Power IC Design)Document29 paginiChapter 8. Switched-Inductor Supplies With Design Insight and Intuition (Power IC Design)Minh Hai RungÎncă nu există evaluări

- Lesson 14 332a.ppsxDocument11 paginiLesson 14 332a.ppsxAKASHPUSHP JOHRIÎncă nu există evaluări

- Common Base Transistor Characteristics PDFDocument2 paginiCommon Base Transistor Characteristics PDFTravis50% (2)

- Introduction To Oscilloscopes and Function GeneratorsDocument5 paginiIntroduction To Oscilloscopes and Function GeneratorsmelfamaniaÎncă nu există evaluări

- Induction Motor Model Example SolutionDocument8 paginiInduction Motor Model Example SolutionJocel GuzmanÎncă nu există evaluări

- Lab 4 Half Wave and Full WaveDocument8 paginiLab 4 Half Wave and Full WaveRashid Rind Rashid Rind100% (1)

- PWM Off-Line Switching Regulator Ics: Str-A6000H SeriesDocument13 paginiPWM Off-Line Switching Regulator Ics: Str-A6000H SeriesAnonymous Lfgk6vygÎncă nu există evaluări

- 21 Lifting Platform Solution ENGDocument4 pagini21 Lifting Platform Solution ENGhaftu gideyÎncă nu există evaluări

- What is north bridge and south bridge architectureDocument5 paginiWhat is north bridge and south bridge architectureRejis SinnerÎncă nu există evaluări

- 12V To 120V DC - DC Converter Using Power Electronics For Higher Efficiency and Reliable OperationDocument23 pagini12V To 120V DC - DC Converter Using Power Electronics For Higher Efficiency and Reliable OperationRaghav ChawlaÎncă nu există evaluări

- Transformer Less POWER SUPPLY REPORTDocument7 paginiTransformer Less POWER SUPPLY REPORTضياء بن احمد الكباري67% (3)

- Simulation of Buck Converter with Synchronous RectifierDocument7 paginiSimulation of Buck Converter with Synchronous RectifierThinh NguyenÎncă nu există evaluări

- LIC Lab ManualDocument65 paginiLIC Lab ManualBala Subramanian0% (1)

- Electrical Machines-IIDocument137 paginiElectrical Machines-IIgnathbl100% (1)

- EJERC TRANSF MONOFASICOS Solut Manual Electric Machinery 4ed ChapmanDocument8 paginiEJERC TRANSF MONOFASICOS Solut Manual Electric Machinery 4ed ChapmanGabriel EduardoÎncă nu există evaluări

- CHAPTER 2 TransformersDocument70 paginiCHAPTER 2 TransformersTom100% (1)

- PIC16F1508 Microcontroller Program DesignDocument22 paginiPIC16F1508 Microcontroller Program DesignThemba MaviÎncă nu există evaluări

- Basic Electronics: Dr. Hemanth C Associate Professor, SENSEDocument50 paginiBasic Electronics: Dr. Hemanth C Associate Professor, SENSEFarhan100% (1)

- Electronics Engineering SyllabusDocument1 paginăElectronics Engineering Syllabuspcjoshi02Încă nu există evaluări

- Transformer - NT PDFDocument108 paginiTransformer - NT PDFReshab Sahoo100% (1)

- Bipolar Junction Transistors (BJTs) ExplainedDocument78 paginiBipolar Junction Transistors (BJTs) ExplainedSebastian LMÎncă nu există evaluări

- Boost DesignDocument4 paginiBoost DesignmuthukumartharaniÎncă nu există evaluări

- Fault-Tolerant Operation of An Open-End Winding Five-Phase PMSM Drive With Short-Circuit Inverter FaultDocument11 paginiFault-Tolerant Operation of An Open-End Winding Five-Phase PMSM Drive With Short-Circuit Inverter Faultmitsui100% (1)

- Single Phase TransformerDocument11 paginiSingle Phase TransformerArijeet MondalÎncă nu există evaluări

- Series Resonant Circuit: Experiment # ECE 312 LDocument4 paginiSeries Resonant Circuit: Experiment # ECE 312 LVan M M GabonÎncă nu există evaluări

- BCD to 7-Segment Decoder Design and ImplementationDocument9 paginiBCD to 7-Segment Decoder Design and ImplementationFAseeh MalikÎncă nu există evaluări

- Analog Circuits and Simulation LabDocument77 paginiAnalog Circuits and Simulation LableevasusanÎncă nu există evaluări

- Buffer AmplifierDocument9 paginiBuffer AmplifierDicky D.M.Încă nu există evaluări

- Experiment 24: The Potentiometer: PurposeDocument6 paginiExperiment 24: The Potentiometer: PurposekirtiÎncă nu există evaluări

- How To Calculate SMPS Transformer - Formula - Electronic CircuitDocument3 paginiHow To Calculate SMPS Transformer - Formula - Electronic CircuitCristian FernandesÎncă nu există evaluări

- Electronics 1 Lab Manual PDFDocument30 paginiElectronics 1 Lab Manual PDFAnonymous 7y7TeR0% (1)

- First Order Active Filters (LPF, HPF) : (A) Low Pass FilterDocument12 paginiFirst Order Active Filters (LPF, HPF) : (A) Low Pass FilterVRÎncă nu există evaluări

- Chapter 7. Switched-Inductor Regulators With Design Insight and Intuition (Power IC Design)Document119 paginiChapter 7. Switched-Inductor Regulators With Design Insight and Intuition (Power IC Design)Minh Hai RungÎncă nu există evaluări

- Experiment 8 Transformer Equivalent CircuitDocument9 paginiExperiment 8 Transformer Equivalent CircuitBrett GallÎncă nu există evaluări

- CH 4 - DC-DC ConvertersDocument52 paginiCH 4 - DC-DC ConvertersTsegau Hagos100% (1)

- Viper 12s Buck Boost ConverterDocument14 paginiViper 12s Buck Boost ConverterelkillyÎncă nu există evaluări

- Hybrid Equivalent For CC TransistorDocument9 paginiHybrid Equivalent For CC TransistorPriya BalakrishnanÎncă nu există evaluări

- Feedback Amplifiers-EDC PDFDocument45 paginiFeedback Amplifiers-EDC PDFanjanaÎncă nu există evaluări

- Unit1 EDCDocument24 paginiUnit1 EDCKarthick Sivakumar ChellamuthuÎncă nu există evaluări

- Microcontroller Based Medicine Reminder PDFDocument55 paginiMicrocontroller Based Medicine Reminder PDFjadhav priti NanaÎncă nu există evaluări

- DC Converter All LecturesDocument29 paginiDC Converter All LecturesHolloGramÎncă nu există evaluări

- Dual Variable Power Supply Project ReportDocument12 paginiDual Variable Power Supply Project ReportHarshvardhan MishraÎncă nu există evaluări

- Major Project Report on 12V Battery Charger FabricationDocument10 paginiMajor Project Report on 12V Battery Charger FabricationDebeshÎncă nu există evaluări

- ELG3311 Solutions for Assignment 1 ProblemsDocument14 paginiELG3311 Solutions for Assignment 1 Problemstesfayregs gebretsadik100% (1)

- Photosynthesis 9700 Biology A-Level RevisionDocument4 paginiPhotosynthesis 9700 Biology A-Level RevisionMehreen SyedÎncă nu există evaluări

- Power SupliesDocument42 paginiPower SupliesCenkGezmişÎncă nu există evaluări

- ECD Lab EEC 752Document17 paginiECD Lab EEC 752juhi99360% (5)

- Goodrive20 Series Inverter Quick Reference GuideDocument122 paginiGoodrive20 Series Inverter Quick Reference GuidejhonnyÎncă nu există evaluări

- L9 Single Phase VSIDocument114 paginiL9 Single Phase VSIPrashant Surana100% (1)

- ADE Lab Manual - Analog Part PDFDocument21 paginiADE Lab Manual - Analog Part PDFJk RinkuÎncă nu există evaluări

- Slva 477 BDocument8 paginiSlva 477 BAnonymous QakmLc3kTIÎncă nu există evaluări

- TI - Boost Converter CalculationDocument10 paginiTI - Boost Converter CalculationyaheyaÎncă nu există evaluări

- Basic Calculation of A Buck Converter's Power Stage: Application ReportDocument8 paginiBasic Calculation of A Buck Converter's Power Stage: Application ReportAli KeyvanÎncă nu există evaluări

- LM5032 INTERLEAVED BOOST CONVERTER DESIGNDocument12 paginiLM5032 INTERLEAVED BOOST CONVERTER DESIGNParvesh GautamÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Altium Designer Viewer PDFDocument6 paginiAltium Designer Viewer PDFxuanvan1303Încă nu există evaluări

- Getting Started With PCB Design PDFDocument34 paginiGetting Started With PCB Design PDFxuanvan1303Încă nu există evaluări

- Tutorial GettingStartedwithPCBDesignDocument55 paginiTutorial GettingStartedwithPCBDesignxuanvan1303Încă nu există evaluări

- LED Driving PDFDocument10 paginiLED Driving PDFxuanvan1303Încă nu există evaluări

- Approval Form For Material Gate Pass 内部出门证: COD Muhammed Thanzeel 8424503 0580281560Document1 paginăApproval Form For Material Gate Pass 内部出门证: COD Muhammed Thanzeel 8424503 0580281560Muhammed ThanzeelÎncă nu există evaluări

- Chapter 2 (A) Total Quality Management PDFDocument44 paginiChapter 2 (A) Total Quality Management PDFSarah AqirahÎncă nu există evaluări

- AS400 Questions and AnswersDocument4 paginiAS400 Questions and Answerssenthilj82Încă nu există evaluări

- PNG Standard Classification (Jan 09)Document124 paginiPNG Standard Classification (Jan 09)Christian BarÎncă nu există evaluări

- SQL Server Migration Offer DatasheetDocument1 paginăSQL Server Migration Offer Datasheetsajal_0171Încă nu există evaluări

- JD TM-DC BSG-MT 1Document2 paginiJD TM-DC BSG-MT 1Anshuman Tiwari 4-Year B.Tech. Mining EngineeringÎncă nu există evaluări

- Project ReportDocument19 paginiProject ReportEr Nandkishor Prajapati86% (7)

- Book To PrintDocument291 paginiBook To PrintIan Untalan67% (6)

- RFP Medical Device Park YeidaDocument53 paginiRFP Medical Device Park YeidaJyoti SwarupÎncă nu există evaluări

- JSA 001 - UG Pipe Fabrication & ErectionDocument14 paginiJSA 001 - UG Pipe Fabrication & ErectionNitish SinghÎncă nu există evaluări

- Tekcon - Spun Piles PropertiesDocument10 paginiTekcon - Spun Piles PropertiesChung Yiung YungÎncă nu există evaluări

- Chapter 02 KendallDocument9 paginiChapter 02 KendallPaolo BagsicÎncă nu există evaluări

- Slaa 116Document21 paginiSlaa 116misaelrodrigoÎncă nu există evaluări

- TWI Control of Welding DistortionDocument12 paginiTWI Control of Welding DistortionClaudia Mms100% (2)

- Eicher Motors Initiating CoverageDocument15 paginiEicher Motors Initiating CoverageNikhil SinghalÎncă nu există evaluări

- Ae 3007a-72-299Document7 paginiAe 3007a-72-299turboshaftÎncă nu există evaluări

- Applied Mould EngineeringDocument10 paginiApplied Mould EngineeringSreedhar Pugalendhi100% (2)

- Characteristics of A Good Management Information SystemDocument6 paginiCharacteristics of A Good Management Information SystemSahil AhujaÎncă nu există evaluări

- Gojo BOQ 2013 ManualDocument40 paginiGojo BOQ 2013 ManualAbel BerhanemeskelÎncă nu există evaluări

- Scheduling Resources and Costs: Chapter EightDocument15 paginiScheduling Resources and Costs: Chapter EightArnór Scribd JónssonÎncă nu există evaluări

- Basic Concept For Electrical DesigningDocument2 paginiBasic Concept For Electrical DesigningJoel RemegioÎncă nu există evaluări

- Ogunranti Abiodun Rasaq: Career SummaryDocument4 paginiOgunranti Abiodun Rasaq: Career SummaryOgunranti RasaqÎncă nu există evaluări

- Vijayanand Travels: VRL Logistics LTDDocument11 paginiVijayanand Travels: VRL Logistics LTDPråbhåkår Ð ÅppûÎncă nu există evaluări

- ES 411 - Eng'g Management SyllabusDocument7 paginiES 411 - Eng'g Management SyllabusJames Adrian Abalde SaboÎncă nu există evaluări

- Chapter 08 Discrete State Process ControlDocument32 paginiChapter 08 Discrete State Process ControlJosé Blanco MendezÎncă nu există evaluări

- Solidworks Composer: Add A New Dimension To Your Technical CommunicationsDocument4 paginiSolidworks Composer: Add A New Dimension To Your Technical CommunicationsNatarajan RamamoorthyÎncă nu există evaluări

- Limj/Goa: 1.1. Atis 1.2. Noise Abatement Procedures 1. GeneralDocument38 paginiLimj/Goa: 1.1. Atis 1.2. Noise Abatement Procedures 1. GeneralPIETROÎncă nu există evaluări

- Archipreneur Insights GuideDocument42 paginiArchipreneur Insights GuideHimanshu KalraÎncă nu există evaluări

- Product Lifecycle Management: UnderstandingDocument20 paginiProduct Lifecycle Management: Understandinganurag_kapila3901Încă nu există evaluări

- Recommender System Based On Customer Behaviour For Retail StoresDocument12 paginiRecommender System Based On Customer Behaviour For Retail StoresPriscila GuayasamínÎncă nu există evaluări