Documente Academic

Documente Profesional

Documente Cultură

TC Controlling Analog and Digital Trains Together

Încărcat de

chrisfletcher52Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TC Controlling Analog and Digital Trains Together

Încărcat de

chrisfletcher52Drepturi de autor:

Formate disponibile

29 J anuary 2013 Rev 2.

0

2

Die Preiten Bahn a PC controlled Model Railway

By Chris Fletcher

Abstract

Just after Christmas we completed system testing of our model railway and this event

represents the successful conclusion to a project that started 4 years ago. This paper

is intended to describe technical details in the design and implementation of the

Preiten Bahn.

Even though the Preiten system is specifically designed to permit Conventional

(Analog) and Digital (DCC) Model Trains to operate on the same layout, the report

covers many theoretical and practical aspects applicable to any PC controlled Model

Railway. Such subjects are

Electronic Design

Planning

Power distribution

Cabling

Data Preparation (for Freiwalds TrainController

TM

)

System Testing

The Analog hardware is marketed by Oaktree Systems LLC under the name of

Railroad Control Interface (RCI) This hardware is described in some detail.

The DCC Command Station is manufactured by Digitrax and Mobile decoders come

from a variety of sources including MTH, ESU, Lenz etc.

Other peripheral Hardware such as Mini-Boosters, DC/DCC Switches and Occupancy

Detectors are home built for reasons explained in the paper.

In the past, when one talks of mixing DCC and DC together the warnings from all

quarters sounded: Dont Do It, you will destroy your equipment! Of course I took

this seriously and researched the failure circumstances to design protection systems

against accidental bridging of DC and DCC. These problems can be enumerated as

follows

1. Voltage Doubling across DCC decoder input

2. Overload Currents in One Rail Only

3. Different DC and DCC Supply voltages may cause Feedback through intrinsic

Protection Diodes in H-Bridges.

4. Some DCC sound decoders include large capacitors on their input circuitry

which falsely trigger overload protection circuits.

Disclaimer

The Equipment described here works well

on my System. I take NO Responsibility for

its correct functioning anywhere else!

Chris Fletcher

3

Contents

1 INTRODUCTION .................................................................................................. 6

1.1 HISTORY ........................................................................................................................................ 6

1.2 I WENT DOWN MANY WRONG PATHS! ................................................................................................ 6

1.3 ACKNOWLEDGEMENTS .................................................................................................................... 7

1.4 IS IT ECONOMICAL? ........................................................................................................................ 7

1.5 COPY RIGHT ................................................................................................................................... 8

1.6 REFERENCES ................................................................................................................................. 8

2 GENERAL PRINCIPLES ..................................................................................... 9

2.1 WHY PC CONTROL ? ...................................................................................................................... 9

2.1.1 Manual Control .................................................................................................................9

2.1.2 Automatic Control .......................................................................................................... 10

2.1.3 Analog and Digital Traffic together ................................................................................ 10

3 TC OPERATION ................................................................................................ 10

3.1 ALLOCATION OF BLOCKS .............................................................................................................. 10

3.2 BLOCKS, SECTIONS AND ROUTES ................................................................................................. 11

3.3 SPECIAL CONSIDERATIONS FOR ANALOG SYSTEMS ....................................................................... 13

3.4 LOGICAL BLOCK POLARITY IN ANALOG SYSTEMS .......................................................................... 15

3.5 SCHEDULES ................................................................................................................................. 16

3.6 SIGNALING ................................................................................................................................... 17

3.7 ENGINES (SEE FIG. 12) ................................................................................................................. 19

3.7.1 Analog Engines ............................................................................................................. 19

3.7.2 Digital Engines ............................................................................................................... 19

3.8 SIMULTANEOUS ANALOG/DIGITAL OPERATION .............................................................................. 20

3.9 RUNNING ENGINES SMOOTHLY ACROSS BLOCK BOUNDARIES. ....................................................... 21

3.10 TRAFFIC CAPACITY AND BUS ARRANGEMENTS (SEE FIG. 14) ......................................................... 22

3.10.1 COM Ports ..................................................................................................................... 22

3.10.2 Traffic Capacity of the RCI Equipment .......................................................................... 23

4 PROBLEMS WITH MULTIPLE POWER SUPPLIES ......................................... 27

4.1 ACCIDENTAL BRIDGING OF ANALOG AND DIGITAL BLOCKS (SEE FIG. 17) ....................................... 27

4.2 VOLTAGE DOUBLING (SEE FIGS. 18, 19) ........................................................................................ 27

4.3 OVERLOAD CURRENT ON ONE SIDE ONLY ...................................................................................... 29

4.4 UNDETECTED O/L CURRENTS THROUGH PROTECTION DIODES IN H-BRIDGE CIRCUITS ..................... 30

4.5 IN-RUSH CURRENTS WITH SOME SOUND DECODERS ...................................................................... 31

4.6 LIMITATIONS APPLIED TO ANALOG ENGINES RUNNING UNDER TRAINCONTROLLER

TM

...................... 32

5 HARDWARE ...................................................................................................... 33

5.1 SYSTEM REQUIREMENTS ............................................................................................................... 33

5.2 PRODUCTION OF PCB CARDS AND THE EAGLE CAD SYSTEM ........................................................ 33

6 COMMERCIALLY AVAILABLE HARDWARE ................................................... 34

6.1 THE RAILROAD CONTROL INTERFACE, RCI .................................................................................... 34

6.2 MICRO PROCESSOR CONTROLLED THROTTLE CARD CBC-8R ........................................................ 35

6.2.1 CBC8 Features .............................................................................................................. 35

6.2.2 Card Addressing ............................................................................................................ 37

6.2.3 Commands and Responses for the CBC-8R Card ....................................................... 37

6.3 THE MINI-INPUT-OUTPUT CARD IO-24 ........................................................................................... 40

6.3.1 Features ........................................................................................................................ 40

6.3.2 Card Addressing ............................................................................................................ 41

6.3.3 Commands and Responses for IO-24 ........................................................................... 41

6.4 THE INPUT OUTPUT CARD IO-48 ................................................................................................... 44

6.4.1 Features ........................................................................................................................ 44

6.4.2 Card Addressing ............................................................................................................ 45

6.4.3 Commands and Responses for IO-48 ........................................................................... 45

6.5 THE RCI BUS SYSTEM .................................................................................................................. 48

4

6.5.1 Bus Wiring ..................................................................................................................... 48

6.5.2 Poling ............................................................................................................................. 49

6.6 DIGITRAX HARDWARE ................................................................................................................... 50

6.6.1 The Command Station/Booster DCS 100 ..................................................................... 50

6.7 USB LOCONET INTERFACE PR3 ................................................................................................... 51

7 HOME-BUILT HARDWARE ............................................................................... 52

7.1 A HOME-BUILT OCCUPANCY DETECTOR ........................................................................................ 52

7.1.1 Principles ....................................................................................................................... 52

7.1.2 The DC-DCC Switch (4) card ........................................................................................ 52

7.2 THE DCC MINI-BOOSTER ............................................................................................................. 54

7.2.1 Features ........................................................................................................................ 55

7.3 THE TORTOISE UNIT ..................................................................................................................... 58

8 IMPLEMENTATION ........................................................................................... 60

8.1 PHYSICAL CONSTRUCTION ............................................................................................................ 60

8.2 PLANNING .................................................................................................................................... 64

9 MOUNTING AND CABLING THE WHOLE SYSTEM ........................................ 65

9.1 THE BOARD PANELS .................................................................................................................... 65

9.2 BOARD INTERCONNECTIONS ......................................................................................................... 67

9.2.1 Solution Specific for New RCI IO-48 Board................................................................... 67

9.2.2 Solutions for other Equipment Cases ............................................................................ 68

9.2.3 Existing Main Boosters .................................................................................................. 68

9.3 CABLING ...................................................................................................................................... 68

9.4 POWER SUPPLY AND DISTRIBUTION .............................................................................................. 69

10 DATA CONFIGURATIONS ............................................................................ 73

10.1 BLOCK DATA (FIG. 63, 64, 65)...................................................................................................... 74

10.2 ROUTE DATA (SEE FIG. 66) ........................................................................................................... 79

10.3 TURNOUTS (SEE FIG. 67) .............................................................................................................. 81

10.3.1 Turnout .......................................................................................................................... 82

10.3.2 Double Slips .................................................................................................................. 82

11 TEST TOOLS ................................................................................................. 84

11.1 CABLE TEST TOOL ....................................................................................................................... 84

11.2 RCITEST PROGRAM ...................................................................................................................... 84

11.3 THE PRICOM DCC POCKET TESTER .............................................................................................. 87

11.4 VERSA-TAP DEVICE ...................................................................................................................... 87

11.5 TEST AND MONITOR FACILITIES BUILT INTO TC .............................................................................. 89

11.5.1 Dr. Railroad ................................................................................................................... 89

11.5.2 Inspector ........................................................................................................................ 90

11.5.3 The TC Explorer Window .............................................................................................. 90

11.5.4 Detailed Messages ........................................................................................................ 92

11.5.5 The Simulator ................................................................................................................ 93

12 SYSTEM TESTING ........................................................................................ 94

12.1 INSTALLING THE DRIVERS ............................................................................................................. 94

12.2 CHECK BUS COMMUNICATIONS AND BASIC CARD FUNCTIONS ........................................................ 97

12.3 RUN TRAINCONTROLLER .............................................................................................................. 98

12.4 FINAL CONFIGURATION OF TURNOUTS AND DOUBLE SLIPS ........................................................... 100

12.4.1 Electro Frog wiring ....................................................................................................... 100

12.4.2 Output Configuration ................................................................................................... 101

12.5 RAIL POLARITY........................................................................................................................... 102

12.5.1 Analog Wiring .............................................................................................................. 102

12.5.2 Check Occupancy indicators ....................................................................................... 102

12.5.3 DCC Polarity ................................................................................................................ 103

12.6 SYSTEM TESTING COMPLETE ...................................................................................................... 103

13 ALL ABOUT SCHEDULES ......................................................................... 104

13.1 TYPES OF SCHEDULES ................................................................................................................ 104

5

13.1.1 Single Schedule ONE Start to ONE Destination ...................................................... 104

13.1.2 Multi Schedule SEVERAL Starts to SEVERAL Destination ..................................... 104

13.1.3 Shunting Schedules NO Starts or Destinations ....................................................... 104

13.2 CREATION OF SCHEDULES .......................................................................................................... 104

13.2.1 By picking from the Block Diagram ............................................................................. 104

13.2.2 Use of AutoTrain .......................................................................................................... 108

13.3 INTERLINKING OF SCHEDULES ..................................................................................................... 110

13.3.1 Schedule Successors .................................................................................................. 110

13.3.2 Calling Schedules via Operations Lists ....................................................................... 110

13.4 SETTING UP A MULTI-SCHEDULE ................................................................................................. 111

14 TRAIN DATA AND SPEED PROFILING ...................................................... 114

14.1 TEST TRACK .............................................................................................................................. 114

14.2 ANALOG ENGINES ...................................................................................................................... 115

14.3 DIGITAL ENGINES ....................................................................................................................... 116

14.4 SPEED PROFILING ...................................................................................................................... 118

14.4.1 Adjusting Creep speed .............................................................................................. 118

14.4.2 Determining Speed Profile .......................................................................................... 118

Appendix A Conversion Tables.120

6

1 Introduction

1.1 History

I have been interested in 0 Gauge Model Railways since Childhood in Germany. At

the ripe age of 6 I inherited from my older brother a Mrklin 3 rail AC trainset E

44 engine and some coaches and trucks. This passion has stayed with me until

today and also infected my son from an early age. We started seriously in 1976

and Preiten Bahn is our 7

th

layout. Layout No. 5 was electronically controlled, but

was of the hard wired logic type ie. not computer controlled. Work commitments

since 1985 prevented any further work in the hobby until my retirement in 2005. In

1999 I became aware of RR&Co TrainController

TM

(TC) and RCI, CTI hardware.

Since I had a fairly large collection of analog engines conversion to DCC was

costly and problematical. Any serious work, however, had to wait until my full

retirement and the construction of layout No. 6 in 2006. For economic reasons I

finally chose the RCI system of hardware. Layout No. 6 was TC controlled (V 5.8)

and ran small numbers of DC controlled trains. Change of personal circumstances

(shifting to a new home) in 2009 motivated construction of layout No. 7, also

known as the Preiten Bahn (derived from our address), where my work with TC

and RCI continued. Until May 2012 Preiten Bahn was functioning in analog mode

only and the wiring had become a complete Birds-nest For the last 7 months I

introduced mounting of all boards on 8 panels, which necessitated a complete

rewiring. During construction of layouts No. 6 and 7, I went down many blind alleys

and took many wrong turns, mostly because of insufficient understanding of the

system principles behind the facilities offered. Today those problems are mostly

solved (with help from see acknowledgements) and therefore I thought other Model

Railroaders could benefit from some of my experiences.

1.2 I went down many wrong paths!

On the way I ran into the following difficulties

1. The Back EMF of Motors confuses the single occupancy indicator per block

on the CBC8 card, i.e. intermittently it indicates unoccupied. In this case TC

loses control and trains come to rest two blocks further on as unknown

locos.

2. Initially I thought I could provide a CBC8 outlet per Section in a block and

combine several in one super block. This was a false assumption and you

cannot start a brake ramp in one block and have a stop marker in another. All

markers apply to the one block only and therefore 2 or 3 occupancy detectors

are required in One Block.

3. With analog trains the current sensing occupancy indicators do not indicate

when the engines are stationary. Therefore the inbuilt indicator on the CBC8

is still required to detect stationary trains.

4. The comments in the TC manual about special DCC connection on RCI cards

apply to the TD4 card which has not been available for some years and was

replaced by the CBC8 (but without DCC connection).

5. For satisfactory operation DCC supply voltage must be 4 to 5 Volts higher

than Analog supply voltage, which brings its own problems when bridging

occurs between the two.

6. Command and Feedback Buses must be separated; otherwise traffic capacity

is limited to about two trains simultaneously running.

7. A special Mini-Booster had to be developed to handle general short circuit

conditions (even ignoring filter capacitor charging currents) as well as short

circuits to CBC8 outputs.

8. DCC type Occupancy Indicators such as BDL168 DO NOT work for Analog

Running and therefore I had to develop my own.

7

1.3 Acknowledgements

This is the conclusion of a 4-year Project and I am very happy with the outcome. A

few thank-you notes are appropriate.

My first Thank-You must go to my friend Vladimir Grbac who virtually did all the

physical work associated with the construction of the Preiten Bahn. He did everything

from erecting the room (after excavation), building the bench work, laying roadbed

and track, up to much of the wiring.

My very artistic architect son David however infused Preiten Bahn with its character:

He created the mountains, backdrops, tunnel entrances and ballast along the track.

My heartfelt thanks go particularly to him. Susanne Heim in Germany built most of

the houses on the layout and these buildings are an absolute delight. My good friend

J oseph Schweikl in Germany has built some of my best engines and my thanks go

to him also.

On the technical side I am indebted to Mr. Charles L Davis, President of Oaktree

Systems, LLC for his good advice and assistance. During my research into problems

with bridging DC and DCC together, I received much help from Mark Gurries.

Much help was also received from members of the TrainController

TM

Forum

particularly from Otto Berg von Linde, Jrgen Freiwald, Bob Wright, Jeremy Brandon

and many others.

I am indebted also to Lubos Domalip, Jan Marvan and the PragOclub who produced

some 40 odd German Light signals which look phantastic.

1.4 Is it Economical?

Here is a comparison of number and types of boards required for the Preiten Bahn

(64 Blocks) now and if I was to implement it with pure DCC equipment

Combined Analog/Digital Installation

CBC8 Boards Qty 8

DC/DCC Switches Qty 16

Mini-Boosters Qty 16

IO-24 Boards (Turnouts) Qty 8

IO-48 Boards (DC/DCC Switch Operation & Signals) Qty 8

PSX-AR (Auto Reverse) Qty 2

DCS 100 (5 Amp) Command Station Qty 1

PR3 Computer Interface Qty 1

RS 485 Interfaces (RCI and SmartHand) Qty 5

Pure DCC Installation

BDL 168 Boards and Mounting Boards Qty 9

PM-42 Boards Qty 9

DS 64 Boards (Turnouts) Qty 11

SE8C Boards and Mounting Boards (Signals) Qty 4

PSX-AR (Auto Reverse) Qty 2

DCS 200 (8 Amp) Command Station Qty 1

PR3 Computer Interface Qty 1

8

RS 485 Interface (SmartHand) Qty 1

Additional Loco Decoders (3 Amp) Qty 20 approx.

Depending on the number of additional loco decoders you need the Pure DCC

Installation is probably more economical than the combined Analog/Digital system.

Analog Operation also suffers from several limitations as outlined in 4.6.

On the other hand not every loco is convertible to digital for a number of reasons

I have a number of Tank engines (some Brass) which do not have enough

space for the decoders.

A friend of mine has a number of collector items which he would not want to

touch in any case.

Some of the smaller scales such as N and Z scale do not readily lend

themselves to conversion.

The choice is then to run the analog vehicles on your layout alongside digital locos

(albeit with limitations) or relegating them to the shelf to be looked at only.

I have heard of a number of club set-ups that have some weekends set aside for pure

analog running, while other users with digital equipment do their running on different

weekends. A change-over switch must accomplish the different connections. The

system described here would allow all users to run all trains All the Time!

I did some trial PCB layouts (to the limit of my EAGLE license - 160 x 100 mm Max)

and could establish that DC-DCC switch, cut-down IO-48 and Mini-Booster could be

combined into one board. Perhaps this would enhance the economic situation of

the combined system. Since this involves knowledge of proprietary firmware this is

clearly a question for RCI (or anyone else) to develop such a thing.

1.5 Copy Right

The information contained herein, insofar as it is not also contained in any of the

references in 1.6, is my copy right. However I dont mind if any of this information is

being used by anyone, except that I would like to be quoted in such a case.

1.6 References

Document Website

1. TrainController V7.0 G Users Guide www.freiwald.com/pages/download.htm

2. +SmartHand V7.0 Manual www.freiwald.com/pages/download.htm

3. CBC-8R Users Manual www.oaktreesystems.com

4. IO-24 Users Manual www.oaktreesystems.com

5. IO-48 Users Manual www.oaktreesystems.com

6. Digitrax Super Chief Manual www.digitrax.com/ftp/superchief.pdf

7 Open DCC website www.opendcc.org/index_e.html

9

2 General Principles

2.1 Why PC Control ?

Fig. 1 PC control of a Model Railway

At the beginning one should ask the following question: Why have a PC controlled

Model Railway? For my part I wanted the following three basic functions (See Error!

Reference source not found.) fulfilled.

1. Driving, where the system should be able to control the speed and direction

of the motor within a model engine. The traverse of a layout should be carried

out safely i.e. different engines should not collide with each other! Therefore

the whole system is divided into blocks where normally only one train (engine)

is permitted to be in one block at the one time. The exception are consists

where several engines pull the one train.

2. Feedback of position. In order to steer an engine adequately from one block

to another on a layout, the control program must be continually updated as to

the actual position of the train on the layout, ie. in which block the train is

currently located. A Feedback Mechanism must thus be provided.

3. Switching. For an engine to reach its destination, it is implied that the path

through the station yards etc. must also be set up correctly. For this reason

switching functions are provided which can set turnouts to the correct position

as well as move (show) signals in the correct aspect.

2.1.1 Manual Control

Traditionally model trains were driven from Power CABs which were switched to

different parts of a layout via sometimes quite complex CAB switching arrangements.

RR&Co

Command

Station

& Booster

Mobile

Decoder

Block b

Mobile

Decoder

Block b

Occupancy

Detector

Digital Engine

Block a Block a

Analog Engine

Stationary

Locomotive

Decoder

Accessory

Decoder

Automatic

Control

Manual

Control

Switching PC Interface (DCC)

RS 485 Interface

10

It is clear that generally a single operator can control only up to 2 trains

simultaneously. Thus, without PC control, a layout has to be set up for a particular

path and then 2 trains (half the main line apart) are driven from the same power pack.

As long as both trains move at approximately the same speed they will stay apart and

continue running. Such running lacks life and to me is boring! Many clubs operate

layouts with several operators, who hand trains over from one operator to another by

CAB switching. This is fun but is not very suitable for a single operator like myself.

Thus, I hoped to benefit from a PC controlled system, particularly when several trains

are running automatically, I can drive a particular engine with a hand held controller

and have a signaling system available to do this safely. Equally when friends are

visiting they can have a handheld controller each and drive their individual train (of

course obeying the signals displayed on their handhelds).

2.1.2 Automatic Control

From the above it is clear that the PC system should run as many trains as possible

(in my case this seems to be 7 with 14 blocks in the main line). This certainly puts life

into the system my son commented the other day: there are little maggots crawling

out of all sorts of holes! In the end, watching an automatic layout is also boring and

that is why I would like to run some trains manually within the automatic background

traffic.

2.1.3 Analog and Digital Traffic together

Often I can hear the question: Can I run my conventional engine on a digital layout?

The short answer is: Yes, but only one engine at a time (stretched 0 facility), but

other traffic is severely restricted. Add to this that many of us Modelers are on in

years and lack the inclination or the necessary electronics skills to convert their

prized models to digital operation. With 0 Gauge I am ok, but the smaller the scale,

the more difficult the job becomes (Z-scale is very, very difficult!).

In my case I was confronted with converting some 80 engines to digital working or

running only the digital vehicles and leaving the others in their boxes or on the shelf!

TC offered a solution to run both so I went this way! In the long run I will probably

convert all my good locomotives to DCC and leave the rest DC controlled (see also

section 1.4 Is it Economical?)

3 TC Operation

3.1 Allocation of Blocks

To enable TC to steer locos across the system, it is necessary to define the whole

track layout in terms Blocks, such that positions of all trains may be known to TC at

all times. Blocks are generally required to hold one train to the exclusion of all

others. A block is usually a piece of track insulated at both ends (if current sensing

occupancy detectors are used). It should be long enough to hold the longest train

you have operating on your system and NOT include any Turnouts or Crossings. It

can be rather disastrous when turnouts are being switched under a moving train! The

Turnout Ladder in Fig. 2 (shown in Grey) is made up of Routes Only and in a Pure

Digital system is undetected.

11

3.2 Blocks, Sections and Routes

Fig. 2 Blocks, Sections and Routes

Any Block can be subdivided into several Sections which may be set up for

purposes such as Start Braking (Brake Marker) or Stop Here etc. They are merely

pieces of isolated track which are being supplied through different Occupancy

Detectors. Sections are pieces of track situated in the ONE Block (adjacent to each

other).

Blocks are interconnected by Routes which may be only 1 2 mm long or include a

whole undetected section of track as shown in Fig. 2. Routes may include Turnouts

or Double Slips but Trains Never Stop there.

In Summary we note

The whole layout is divided into blocks where each block is a length of track

partitioned off the general system by incorporating at least one occupancy

indicator which indicates to TC whether this block is occupied or not.

Trains may only stop in Blocks

Blocks may NOT contain Turnouts, Slips or Crossings

Blocks should normally be long enough to accommodate the longest train.

However this rule can be broken with TC V7.0 Gold and later, where train

length can protect the end of a long train by not releasing the previous block.

Blocks are interconnected with routes where routes are seen to contain all the

switches or crossings.

12

Fig. 3 Block Allocation for DCC

Fig. 3 shows the block allocation for the Demo layout delivered with the TC software.

The layout is organized for a digital control system and obeys the above rules exactly.

Each block (light blue, green and red) is a piece of track separated at both ends from

the rest of the system. Switches are shown in dark grey and are not part of any block.

They can be connected to the Track Bus with or without occupancy detection. Thus

the switches are part of routes which interconnect the blocks.

Fig. 4 shows how this layout is drawn manually in TC as a Switchboard Diagram.

Each block is represented by a rectangle with signal lamps at each end. The signal

lamp can be displayed as a 2, 3 or 4 aspect light signal (set in the block editor). This

signaling scheme merely regulates the traffic between the blocks and does NOT

represent any particular prototypical signaling scheme. The signaling scheme works

irrespective whether actual signals are Installed on the layout or NOT. I made a bad

error a couple of years ago where I defined physical addresses in TC V5.8 without

any cards connected. This rendered the whole system inoperable.

Fig. 4 Representation in a Switchboard Diagram in TC

At any time while the Switchboard Diagram is being drawn TC automatically

calculates a Dispatcher (Block-) Diagram as shown in Fig. 5 showing all blocks and

13

routes but no other parts of the switchboard diagram. The user has NO Control over

this process and this enforces the Block Allocation Rules mentioned above i.e.

turnouts are not part of blocks. All routes are traced and the block diagram is

continually kept in synchronism with the switchboard diagram.

Fig. 5 Automatically calculated Dispatcher Diagram

3.3 Special Considerations for Analog Systems

For Analog Operation, however, a problem presents itself: Every piece of track

derives its power from the decoder allocated to the particular block. This includes

all turnouts, double slips and crossings, which must therefore be part of a block. If

you want to force the block diagram to accept a new block for that reason you have to

turn off automatic diagram calculation first and then edit the block diagram with the

new routes. If you do this, tracing of all routes is turned off and you must trace ALL

routes manually. This is definitely NOT Recommended.

Fig. 6 Block Allocation for Analog System

14

For an analog systems the rules can be bent a little i.e. switches can be included

in a block by connecting them at the ENDS. Fig. 6 indicates how the Demo layout can

be adapted for analog operation. In such a case the switchboard diagram and

dispatcher diagram remain the same as shown in Fig. 4 and 5. In most cases this

arrangement would suffice.

In some situations special arrangements have to be made, as shown in Fig. 7.

Fig. 7 Creation of Switch Islands

Such ladders of double slips occur in two places in the main yard of the Preiten Bahn

and these Islands cannot be handled by the method outlined in Fig. 6. Jrgen

Freiwald suggested relays that make temporary connections between the island and

one or other succeeding block. These relays (labeled xx Entry) are operated when

particular routes are seized (in either direction).

For example, assume a train on a schedule is to proceed from block 72 to block 45.

The process continues as follows

1. The train has entered block 72 from the left and would stop there if the path

ahead is not clear.

2. A condition for seizure of any route in this complex is that all 5 relays must be

released.

3. Assuming the condition 2. is true and block 45 is unoccupied the route 72 > 45

is seized and relay 45 Entry is operated. This connects power from block 45 to

the island and 45 is marked occupied as soon as the train enters the island.

4. Under this condition any other train waiting to enter the island from blocks 75 >

77 must continue to wait because relay 45 Entry is operated.

5. The relays would be released once the route is released. Sometimes this

could occur when the train is still situated on the island. Therefore I have

added a delay of 5 seconds to the release time of all relays which ensures that

the island is cleared under all normal circumstances.

6. Once the train is safely running in block 45 relay 45 Entry is released after 5

seconds and the island is available for the next train.

With such an arrangement no additional blocks are required and the standard block

diagram calculations can stand.

There can be other solutions to such problems which do not involve relays. Jeremy

Brandon suggested a solution whereby the double slips can be divided into their

constituent Right Hand Turnouts and a switchboard diagram with an additional block

in the middle of the island can be produced. This solution would not require the

15

connecting relays but the resultant switchboard diagram would not look like the real

situation.

If simultaneous analog and digital operation is required block allocations according to

the above methods are still required.

3.4 Logical Block Polarity in Analog Systems

With digital systems such as DCC the power is supplied as AC i.e. there are

continuous polarity reversals on the track. This AC power, apart from being decoded,

is rectified in the decoder and then applied to the motor with a polarity depending on

the Content of the Command. The phase of the DCC signal does not affect the

direction of the train.

With analog systems the polarity on the track is directly applied to the motor and the

standard is that +ve to the right hand rail (and ve to the left hand rail) will move the

engine in that direction i.e. in the direction where the positive rail is on the right hand

side. If you now turn the engine around and apply the same polarity the engine still

runs in the same direction even if the tender is leading i.e. the engine runs

backwards.

We can say that the block has a Logical Forward Direction if +ve is applied to the

right hand rail). That is in an Analog System the Block has a logical forward direction

and not the engine.

Fig. 8 Logical Polarity of Blocks

Fig. 8 gives an example of a Double Track main line with a station consisting of

blocks 1 3. Every block is allocated a logical forward direction as shown by the

arrows. How you allocate the logical forward direction probably depends on what

prototypical railway you are modeling. In the USA or Continental Europe trains run

normally on the right hand track and Forwards is implied by the direction of the black

arrows in Fig. 8 as shown. If you are modeling trains in British countries and Sweden,

16

trains run on the left and Logical Forward would be in the opposite direction. Of

course this is up to the owner of the layout (I have a friend who runs British and

American trains side by side on the left track).

The main thing is that you decide the Logical Forward direction for each

block. If you have a bi-directional track you must decide which direction is logically

Forward and an engine moving the other way is then considered to be running

backwards irrespective how it is facing!

To describe these Attributes to blocks in TC a check box Reversed Polarity is

provided in the Connection window of the Block Data. TC is designed at present so

that an Unchecked Reversal box indicates that the Logical Forward direction is

from West to East, or North to South. If the Logical Forward direction is East to West

or South to North the box should be Checked.

From the above it follows that in Stationary Decoder Systems Polarities should be

adjusted as follows

1. On a printout of the Dispatcher diagram mark in arrows indicating the logical

forward direction of each block.

2. Set the Reversed Polarity check boxes to suit.

3. Wire the whole layout in a consistent way ie. connect the +ve terminal of the

decoder to the right hand rail of the block track looking in the forward direction.

It would be wise that you determine the +ve terminal first by wiring and testing

electrically (running an engine) on one block.

4. Put a train on the track inside of the block.

5. Assign an engine to a block (where you start testing the whole layout).

6. Make sure the engine image in the block symbol is heading in the Logical

Forward direction.

7. Select the engine in the train window.

8. Drag the speed slider in the train window to the right (forward).

9. If the actual train on the layout is now moving in the Logical Forward

direction the polarity of the block is Correctly adjusted.

10. If the engine moves in the opposite direction you must Reverse the Physical

wire connection between the decoder and the track.

Please note that an incorrectly wired block may be corrected for running, using the

Reversal check boxes but Brake or Stop Markers in these blocks will be ignored. It

is therefore imperative that the reversal checkboxes are checked as per the above

and then the physical wiring is arranged to suit.

3.5 Schedules

It is clear from the preceding sections that many and varied commands are necessary

to run a train from one Block to another

The path ahead must be checked to be available

Signal Aspects must be set

Turnouts and Slips must be set to the correct position

Trains must be started up in the correct way ie. Momentum etc. must be

applied.

Under way Speed must be controlled according to Break and Stop Markers

etc.

TC provides two Flexible and Easy Methods of specifying this multitude of commands

By using AutoTrain

17

In this case you need to specify the Start and End Blocks for your schedule

and otherwise delete any blocks from the schedule if you dont want to include

them in the search. This process can be iterative ie. you can order a path

search, abandon it if unsuitable, change the conditions and order another

search. When satisfied you can edit the schedule data and save it.

By picking items from the block diagram. This process is more laborious as

you have to pick every block and route you want in the schedule from the

dispatcher diagram.

Fig. 9 Operation Of A Schedule

Fig. 9 explains the operation of a Schedule in a much abbreviated way. The Schedule

has been recorded to move the engine (BR 64), currently located in the Start Block

04, backwards through either Blocks 38 or 37 to the Destination Block 47. The

operations on Blocks (Status enquiry etc.), would be carried out in TC memory rather

than the hardware, but for simplicity the latter has been presented.

More detailed information on how a particular schedule is operating can be found in

the Detailed Message display available in TC.

Schedules may be called from

The schedule list in the Dispatcher Diagram

Push Buttons on the switchboard

From Time Table using the Fast Clock

From Other Schedules either as successors or via Start/End Operations

3.6 Signaling

Every model railway system needs prototypical working signals to give it realism. I

was fortunate that Lubos Domalip and the boys of the PragOclub produced for me

some 40 German signals (1969 variety). To drive them I had to develop a series of

daughter boards to be plugged into the IO-48 boards.

18

Fig. 10 German Hp Signal Interface

The daughter board contains 2 x 4 Aspect Signal circuits and each is connected to the

actual light signal via an 8-wire flat telephone cable. Each of the 8 wires is connected

Fig. 11 The German Hp Signaling System (1969)

19

to a separate LED in the signal. At the foot of each signal I have installed another little

board where the 8 wires coming in on a RJ45 jack are connected to screw terminals.

The actual LED wires coming from the Hauptsignal on top of the base board

terminate there.

The various Signal interfaces (including a 3 aspect American circuit developed by

RCI) and their connections are shown in Fig. 11.

TC provides an internal signaling system at the exit of each block which emulates

some parts of the Hp system and can be used to drive light or semaphore devices via

suitable interfaces.

TC also provides definable independent signal interfaces which can use the internal

signals as triggers in combination with other conditions (like occupancy) to modify the

Signal Aspects. In Fig. 11 I have shown how I intend to derive the operation of the

Advance Signals (Vorsignal) using the internal signals of the next block and other

conditions in a defined signal block. At this stage this is all theory as I have yet to

install the actual signals and try all this.

There is also a discrepancy between the internal signaling system and its prototype in

that in the real system the signal goes to red as soon as a train has gone past. In TC

this does not happen until later. I will probably define independent signal blocks for all

signals when I am more up to speed with this.

3.7 Engines (see Fig. 12)

3.7.1 Analog Engines

Analog Engines are Conventional locomotives that have no decoders mounted in

them. The Motor Outputs of Stationary Decoders are now connected to the track

section through the Occupancy Detectors. Otherwise there is no Real Difference in

principle to Mobile Decoders. In this case every section of track must belong to a

block and therefore is supervised as to occupancy through the individual block. The

Stationary locomotive decoders are mounted beneath the track boards and are fixed.

They are connected to the command station (the PC running TC) via a Command

bus, which we will call the Analog Command Bus. The TC Program running in a PC

is the Command Station and no separate CS or Booster is required.

3.7.2 Digital Engines

Digital locos each contain a digital receiver (Mobile decoder) connected between

the motor and the track contactors. In this case a special Command Station (in this

case Digitrax DCS100 (or DCS200) is required. The command station is connected

to the PC via a Digital Command Bus (in this case LocoNet wires 1, 6). In the

digital configuration the PC does Not Act as a Command Station but as a CAB,

such as DT402.

20

3.8 Simultaneous Analog/Digital Operation

Fig. 12 Combined DC/DCC Operation

The Analog Command Bus in the case of RCI is the Balanced 4-wire RS 485 Bus

where different pairs are used for transmission and reception of signals i.e. the Bus is

Bi-Directional and can be used for both Commands and Feedback. In my system

RCI bus A is only used for Loco Driving (ie. connects to CBC8 cards), RCI bus B is

the Feedback Bus for occupancy detectors (connects to IO-48 cards), while RCI bus

C only connects to RCI Accessory Cards IO-24 for Turnout control.

The Digital Command Bus is in my case implemented in Digitraxs LocoNet

Technology wires 1 & 6 only and these are used for Forward Loco Driving

Commands (Standard NMRA DCC packets). Of course TC communicates with the

DCS100 command station via wires 3 & 4 as for all other LocoNet devices.

Each Block is allocated a change over relay on the DC/DCC switch card. In its

released position the relay connects the particular stationary decoder to the track of

the block. An analog engine is marked in its Train Data as No Connection and if the

block is reserved for such an engine the relay is left released and the engine is

controlled via the stationary decoder. A DCC equipped engine on the other hand is

marked with Address Data in its train data. When a block is reserved for this type of

engine the block data specifies a particular On-Off switch in the Digital Power

field. This On-Off switch operates the DCC Enable relay for the block and the track is

connected to the Digital Command Bus.

Because of the voltage drop experienced in mobile decoders the DCC track power

has to be run at about 5V more than the analog power here called CBC power. If the

stationary decoders were powered from the same supply as the DCC boosters the

motors would probably be damaged. On the Preiten Bahn we are running CBC power

at 19V and DCC power at 24V.

21

DC engines can only be reached within the block where they are marked as being

situated, while DCC engines can be reached anywhere on the layout provided the

DCC Enable relay is operated.

Engines are tracked in TC which means that TC knows at all times which loco is

situated in what block.

In the scenario shown in Fig. 10 a digital Engine A moves from Block X to Block Y,

thus enabling analog Engine B to enter Block X. Then Engine A is moved out of

Block Y thus enabling Engine B to move from Block X to Block Y.

The Stationary Decoders are connected permanently to their particular blocks and

this arrangement is called Static Assignment of blocks.. The RCI System of

hardware is more suited for this mode of operations.

To save on numbers of stationary decoders it is possible to connect blocks through

relay contacts with particular decoders. This application of Stationary Decoders is

called Dynamic Assignment to blocks. In this case, when the block is reserved for a

particular analog engine, TC selects the decoder already connected to that engine

in the previous block in preference to another free device with access to this block.

The CTI hardware is more suited for Dynamic Assignment.

TC supports both Static and Dynamic Assignment and the choice is probably an

economic one: Static Assignment means more decoders while Dynamic

Assignment means more relay switches (and accessory decoders to drive them!).

I have employed Static decoder allocation in my system, but I know that one of my

friends uses Dynamic Allocation with CTI hardware and is certainly happy with this.

3.9 Running engines Smoothly across Block Boundaries.

Fig. 13 Running Analog Engines smoothly across Block Boundaries

Digital engines can be addressed from the Command Station while situated

anywhere on the layout. However from the above discussion it is clear that Analog

engines can only be addressed through the specific block where the engine is

located. This means that when an Analog engine reaches the end of a block the

stationary decoder of the next block must be Powered Up before the engine can

continue. Thus if you try and run an Analog engine from one block to the next

22

without a Schedule the engine would stop momentarily until TC (via train tracking)

decides which the next block actually is. The engine would Hick across each block

boundary which is quite unsatisfactory. Thus the block ahead must always be

Prepared before the Analog engine reaches the boundary. This implies that for

Analog Running a path needs to be defined in TC which is done via setting up a

Schedule. Fig. 13 shows how all engine commands are also repeated towards the

next block ahead, thus ensuring that the analog engine runs smoothly across Block

Boundaries.

Within Shunting Schedules a whole area of blocks is reserved for the one engine

ie. no other engine can be situated on any block in the defined area. If the engine is

analog, then the driving commands are repeated to ALL blocks within the area.

3.10 Traffic Capacity and Bus Arrangements (see Fig. 14)

3.10.1 COM Ports

The following 7 USB connected ports are used on the Preiten Bahn

1. COM 10 connects LocoNet via a PR3 interface to the Command Station and

all 16 Mini-Boosters ie. 16 Power Districts of 4 Blocks each. TC simulates

DT402 driving commands towards CS. DCS100 formats all NMRA packets

and transmits these on LocoNet wires 1 & 6 towards the Mini-Boosters.

A UP5 panel has been included in LocoNet to allow plugging in of a DT402 for

DCC only testing.

2. COM 4 (RCI-A) handles all Analog Driving Commands on the Main System.

TC puts out approx. 100 Speed Commands per second which compares well

with the capacity of the DCC system (120 packets per second). The only

Feedback TC receives on this bus is CBC Overload and Occupancy of

stationary engines. It is inconsequential if this information is delayed

somewhat (due to driving commands)

3. COM 7 (RCI-B) carries all Feedback replies on the main system (2 occupancy

indicators per block). This traffic is handled via 8 IO-48 cards which equates to

a poling cycle duration of 80 mS, ie. any engine entering a block anywhere

would be noticed within 40 mS on the average. A 0-Gauge engine travelling at

scale speed of 120 Kph moves 2.8 cm in 40mS. In terms of accuracy this can

be safely ignored. The occasional output command for setting signals and

DCC enable relays will also not make much difference.

4. COM 9 (RCI-C) handle all 8 IO-24 cards which in turn set the 42 tortoise

switch machines. This load is not likely to exceed 1 2 turnout settings per

second.

5. COM 3 (RCI-D) connects one CBC8 card only. This card is connected to a

Tram system, where 2 tram vehicles run back and forth between the ends of

an 8 block tram system. This system only uses the in-built occupancy

detectors in the CBC8 card and therefore could not be connected to RCI-A.

6. COM 6 is the SmartHand Control Bus as recommended by RR&Co.

7. COM 8 connects a Versa-Tap monitoring device (Stratus Engineering) which

can be plugged into any of the RS485 buses to record the traffic there.

23

Fig. 14 Peripheral Buses on the Preiten Bahn System

3.10.2 Traffic Capacity of the RCI Equipment

With analog systems TC (running in a PC) is the command station itself and TC

provides its own timing structure which ensures 100 commands are sent per second

on any RCI bus (see Fig. 12). The RCI cards at 38,400 Baud, actually can handle

up to 300 commands per second but 100 commands per second per bus is not much

slower than the total DCC command station capacity and is more than adequate.

With a poling type master-slave system in contrast to an Event driven bus, there will

be a period of uncertainty regarding the actual point of recognition with respect to the

point of physical contact by the engine with the particular track section. I have

assumed that the requirement for recognition of an engine entering a block be one

engine length (35 cm for 0 Gauge). If we further assume that an engine entering a

block at full scale speed, must be recognized within less than half the average

length of an engine then a maximum polling cycle time can be calculated as follows

120 kph = 33 m per Sec.

33 m per Sec / 45 = 73 cm per Sec approx. ( for 0 Gauge)

Length of Engine = 35 cm approx

Maximum allowable period of uncertainty = 230 mS

From this we can calculate the maximum number of IO-24,48 cards that may be

scanned on one RCI bus. It is assumed that no Output commands are sent on these

(Polling) buses.

230 mS / Polling Command Time (10 mS) = 23 commands per polling cycle

This would limit the number of cards on one polling bus to about 23 maximum (see

Fig. 12). On the Preiten Bahn I have used the following maximum bus load

For Output Command Handling 10 Max CBC8 cards (8 actually used)

24

For Feedback via Polling Replies 15 Max IO Cards (8 actually used)

On the Preiten Bahn with 8 x IO-48 cards on RCI Bus B, TC can recognise arrival of

an engine (35cm long) in 4% of 73 cm i.e. 3 cm (average between 0 and 6).

A Poling Cycle Start every 230 mS (with 23 cards) would guarantee recognition of an

engine traveling at full scale speed, within quarter of the length (on the average) of

one engine (period of uncertainty is 0 to 0.5 the length of an engine).

Fig. 15 Ultimate Analog/Digital System 320 Blocks

The example shown in Fig. 15 illustrates how 320 blocks (2.1 occupancy indicators

per block) can be accommodated on 9 RCI buses using 40 CBC8 cards and 75 IO-

48,24 cards. The poling cycles in the above cases would be 15 x 10 mS long i.e.

much less than the 230 mS required.

320 blocks seems a very large system and can be regarded as the upper limit of an

Analog/Digital System. Such a system would probably also require a very fast PC. On

LocoNet there is a limitation of 20 devices such as Mini-Boosters on one bus.

Therefore the arrangement in Fig. 15 would require 80 Mini-Boosters (1 per 4 blocks).

In such a case 4 o 5 LocoNet Repeaters, LNRP, would also be required.

Calculating it out 320 blocks would require the following cards

CBC8 40

IO-48 40

IO-24 35 ??

Mini-Boosters 80

DC/DCC switches 80

25

Of course, I have NOT made measurements on a Maximum System. On the

Preiten Bahn (64 blocks) I have operated up to 7 trains simultaneously (Main Line =

14 Blocks). Clearly the limitation is the number of blocks in the Main Line.

Fig. 16 shows a sample of the bus exchanges between TC and CBC8 cards as an

analog engine moves through blocks 16 and 18 on the Preiten Bahn. The sequences

were recorded on a Versa-Tap device but the comments are typed in by me.

MM/DD/YY hh:mm:ss.ms.us DTE(hex) DCE(hex) Comment

05/27/10 18:03:03.731.372 013000ffce

05/27/10 18:03:03.748.962

4030000070

05/27/10 18:03:03.750.299 4030000070

05/27/10 18:03:03.768.991

41500ecad5

Set Speed in Block 18 =

Forward 74

05/27/10 18:03:03.770.359 41

05/27/10 18:03:03.778.747

41500acad1

Set Speed in Block 16 =

Forward 74

05/27/10 18:03:03.780.087 41

05/27/10 18:03:03.788.539

4130000071

05/27/10 18:03:03.789.877 4130a000d1

05/27/10 18:03:03.798.359

41500ecad5

Set Speed in Block 18 =

Forward 74

05/27/10 18:03:03.799.702 41

05/27/10 18:03:03.809.975

41500acad1

Set Speed in Block 16 =

Forward 74

05/27/10 18:03:03.811.315 41

05/27/10 18:03:03.819.964

4330000073

05/27/10 18:03:03.821.304 43300f007c

05/27/10 18:03:03.838.993

4430000074

05/27/10 18:03:03.840.333 4430300044

05/27/10 18:03:03.849.945

4530000075

05/27/10 18:03:03.851.282 4530000075

05/27/10 18:03:03.868.912

81300000b1

05/27/10 18:03:03.870.242 81300000b1

05/27/10 18:03:03.878.940

41500ec9d6

Set Speed in Block 18 =

Forward 73

05/27/10 18:03:03.880.281 41

05/27/10 18:03:03.889.928

41500ac9d2

Set Speed in Block 16 =

Forward 73

Fig. 16 RCI Bus Communication Sequence

26

DTE is sent by the Data Terminal Equipment ie. the CBC8 while DCE is sent be the

Data Circuit Terminating Equipment ie. the RS485 bus interface attached to the

PC. Note the 5 Byte replies for the poling commands and the 1 Byte reply for the

Output commands.

27

4 Problems with multiple Power Supplies

4.1 Accidental Bridging of Analog and Digital Blocks (See Fig. 17)

If you ask people whether you can connect analog DC and DCC together you get

the Common Wisdom reply: Dont Do It !! Around the model railway circles

stories about Blown-Up Decoders and Boosters etc. abound. I therefore

researched the reasons for these claims in order to find ways to prevent Harm.

Fig. 17 Accidental DC to DCC Bridging

4.2 Voltage Doubling (see Figs. 18, 19)

Fig, 18 shows one scenario of how Two Supplies can be connected In Series by

bridging the gap on one side of the track. It is assumed that the outputs from the two

H-Bridges are Out of Phase at that instant. This would cause doubling of the

voltage on the track in certain places as shown (Wayne Roderick has explained this

on http://www.tslrr.com/common.htm). If a mobile decoder happened to be sitting

across a part with 30 - 40 V connected to the input, it will in all probability be

destroyed. Since this is an effect of excess voltage the damage will occur without

any overload current flowing thus no circuit breaker is going to be tripped. The

problem would occur in every case where multiple power supplies are used in

different adjoining blocks in the system,

If the negative poles of the DC supply to all H-Bridges are connected together via a

strong Common, the Booster Common, Voltage Doubling is eliminated (see Fig. 15).

Bridging the gap would cause the two out of phase outputs to be short-circuited

together causing tripping of the overload protection. Most manufacturers of Digital

Model Railway equipment strongly recommend this common. Similarly in all situations

where more than one supply is involved the existence of this common should be

checked to prevent damage later.

28

Fig. 18 Voltage Doubling

Fig. 19 Voltage Doubling is eliminated by Common

29

4.3 Overload Current on one Side only

Digital control equipment for model railways such as circuit breakers are generally

designed to protect the equipment against short circuits across the track.

Therefore no protection is afforded if the overload current occurs in one leg only.

Assuming one H-Bridge produces DC pulses and the other DCC reversals, heavy

overload currents may occur which are not necessarily detected. If two H-Bridge

outputs are out of phase and connected together on one side, the Overload current

Must be sensed in one H-Bridge circuit or the other (see Fig. 20). This will only be

true if the OL detectors are in all H-Bridges on the Same Side ie. the Negative Side

in Fig. 20 or on Both sides (as in CBC8). In Wolfgang Kufers Mini-Booster (based on

L6203) described here the overload detector is on the Negative Side and this

circuitry is external to the chip. Other Mini-Booster circuits have been designed which

are based on LMD 18200 which contain On-Chip circuitry on the Positive Side. I

have NO knowledge what arrangements have been made in commercially available

Boosters from eg. Digitrax, NCE (Lenz), or CTI. These questions need to be

answered if you want to mix Digital and Analog operations. In my case, I am

using CBC8 which is safe with anything on the DCC side (see Fig. 21)

Fig. 20 Overload Current on ONE side only

Fig. 18 shows that the old CBC8 card can be operated with All Types of Boosters

irrespective of their protection arrangements: If you are using the old CBC8 card in a

mixed analog/digital system the Overload Protection (and therefore disconnection of

power up to 2 seconds will operate in every case cross bridging. However DCC circuit

breakers (such as PM42) are still required to isolate power districts in case of short

circuits across the DCC track.

Fig. 21 Overload Currents with CBC8

Chuck Davis from RCI has informed me that he is developing a new CBC8 card

because the TLE5205 central component in the old one is no longer available. This

card will have overload protection (I >2 Amps) on the negative side and is therefore

safe with the Mini-Booster described here but not with everything like the old card.

30

Fig. 22 explains what can happen if two H-Bridges (with OL Protection on Different

sides) Collide.

Fig. 22 Big Problems if two H-Bridges with different Protection COLLIDE

!!!

This condition will only occur in mixed DC and DCC situations since the DCC

outputs are constantly reversing while the DC output connects to positive only.

Therefore one of the protection circuits will operate and disconnect power from both

rails.

I found a circuit using the LMD18200 on the following website:

http://home.cogeco.ca/~rpaisley4/CircuitIndex.html but, of course, I have no

experience with this device.

4.4 Undetected O/L currents through Protection Diodes in H-Bridge circuits

All H-Bridge motor drive circuits have intrinsic protection diodes included in the same

chip. These diodes protect the output transistors against back emf spikes. If a

voltage differential exists between two H-Bridges which have been connected

together a heavy current may flow through the protection diode to the other supply

as shown in Fig. 23. This current would not be detected by the H-Bridge Protection

circuit and even if the chip was disabled it would not break the current. Most circuit

breakers open one leg only on overload because they are designed to protect against

short circuits across the track.

Fig. 23 Feedback through Protection Diodes

31

This problem can be overcome by connecting a diode in series with the lower

voltage supply as shown in Fig. 24. In my case I have connected a 10 Amp diode in

series with each CBC8 card.

Fig. 24 Series Diode eliminates Feedback

In Summary

1. Stationary Decoders with Protection on BOTH sides can interwork with

ALL kind of Boosters (Mini or Main). In this case Circuit Breakers are only

provided for short circuits across the track.

2. Stationary Decoders with Protection on the NEGATIVE side can

interwork with Mini-Boosters with Protection on the NEGATIVE side (like

the one described in Fig. 39.

3. Stationary Decoders with Protection on the POSITIVE side can only

interwork with Mini-Boosters with Protection on the POSITIVE side (eg.

LMD18200 based).

4. In ALL OTHER Combinations you are courting DISASTER!

4.5 In-Rush Currents with some Sound Decoders

Many of the DCC sound decoders contain large Filter Capacitors which need to be

charged up at decoder initialization. This causes the protection circuitry in some H-

Bridges to operate falsely before the Capacitors are charged up. This is a well-known

problem which some DCC decoder manufacturers like ESU have tackled. However

there are many decoders with this problem and Boosters or Mini-Boosters need to

take account of the condition. It is assumed that a delay of 30 40 mS is sufficient for

this condition.

Fig. 25 Problem with In-Rush currents in some sound decoders

32

If we include a delay of 40 mS, based on a CR network in the Mini-Booster circuit, we

get an additional problem if DC collides with DCC. Since DCC constantly reverses

every 50 or 100 micro seconds The Overload Current is chopped every half cycle

of the DCC output. If a single delay circuit of some milliseconds was added to the

circuit, the delay would be restarted for every half cycle and therefore would never

expire. Both H-Bridges would probably be destroyed in this case. The Mini-

Booster described here takes care of the situation as described in 7.2

4.6 Limitations Applied to Analog Engines running under TrainController

TM

Analog i.e. DC controlled trains are subject to a number of limitations as follows

1. Engine control is limited to Speed and Direction Change.

2. No extra Functions are available such as Whistle Blowing or Flashing Lights.

3. No Sound Functions are available. However 4D Sound should work

Normally

4. No Back-emf compensation is applicable since stationary decoders can only

be Tuned to the Block and not the Engine.

5. Speed Calibrations must be done for the whole train not just the engine.

Virtual Markers are Unreliable. I have used Physical Contact Indicators

everywhere (2 or 3 per block).

6. Running without Defined Path (i.e. no defined schedule) is Not Possible.

Since schedules operate strictly One Way, shunting across block boundaries

is not really possible. Shunting Schedules generally do work but must be

applied to specific Roads where no block is reserved for another engine.

7. Pushing trains containing Resistive Wheel Sets ahead of the engine is only

possible within a shunting schedule ie. you cannot do it within a normal

schedule. The need for resistive wheel sets has been eliminated in TC Gold

because it calculates (from train length) when to release the previous block.

From the above it is obvious that conversion of Analog Engines to Digital Operation

has Many Advantages. However Analog Operation allows automatic running of your

conventional locos where conversion is not possible or desired. Friends can run their

analog engines on my system amongst my trains running automatically. This means

they have to follow the signal indications given on SmartHand which is a lot of

fun!

33

5 Hardware

Clearly not all problems encountered in the project can be solved using commercially

available equipment and therefore some Boards had to be specially designed and

built for my system.

5.1 System Requirements

In summary the requirements for my system were as follows =

1. Provide Stationary Decoders for Analog operation

2. Provide for Strict Separation of buses carrying Driving Commands and

Feedback

3. Provide access to the Digital Command (Track) Bus when required (relay

method)

4. Allow for Separate Power Feed (different voltages) to the digital and analog parts

of the system

5. Allow Safe Bridging of any currently analog and currently digital blocks

6. Provide a delay in tripping of the overload protection to cover the In-Rush

Current in some sound decoders.

7. Provide Overload Detection with automatic reset

8. Provide remote indication of Overload in TC.

5.2 Production of Pcb cards and the EAGLE CAD System

I purchased a Hobbyist license for Eagle which allows me to lay out multilayer Pcbs

up to the size of 100 x 160 mm. I am also obliged to design boards only for the Hobby

and not monetary gain. I therefore cannot produce and sell any boards. However I am

making the EAGLE files available which anyone can take to a Pcb manufacturer who

will accept designs as EAGLE files. I certainly had no trouble in finding such a

company in Melbourne. So anyone wanting to build such a system can get the boards

manufactured for themselves. I only got the blank printed boards made and built them

up myself but the company would also have built the boards at extra cost..

34

6 Commercially available Hardware

In this section I am describing the Analog equipment from RCI in more detail since I

assume that DCC technology and operation is well known.

6.1 The Railroad Control Interface, RCI

RCI is a series of peripheral cards which may be connected to a PC via a

Communications Network based on the RS485 Bus. The cards contain considerable

intelligence because of their on-board micro controllers and TrainController

TM

is

designed to interwork with them.

Fig. 26 Railroad Control Interface - System Overview

The System is designed and marketed by Oaktree Systems LLC and is intended to

run a model railway directed by Control Software in a PC or even a custom made

Hardware Controller. Fig. 26 shows the arrangement and TrainController

TM

is

designed to interwork with this hardware.

Fig. 26 includes the main cards available in the system and the controller (here the

PC) manipulates the cards via a set of commands and replies which are specific to

the RCI system.

All cards conform to the RCI command format which consists of 5 bytes (fixed length)

in each packet -

Command (PC to Card): AAAAAAAA CCCCCCCC DDDDDDDD dddddddd Check

Where AA.A is the card address

CCC is the Command Code

DDD is the first Data Byte

dd.d is the 2

nd

Data Byte

Check is a Checksum of all other bytes.

Polling Response AAAAAAAA CCCCCCCC XXXXXXXX YYYYYYYY Check

(5 Byte Acknowledge)

Where AA.A is the card address

CCC is the Command Code received by card

XXX is the first Data Byte

YYY is the 2

nd

Data Byte

Check is a Checksum of all other bytes.

Control

Software

USB to

RS485 IF

Computer Block

Control

CBC-8

To 8 Blocks

IO-24

1 2 8 1 2 16

Inputs Outputs

1 8

IO-48

1 2 16 1 2 32

Inputs Outputs

1 2 16 1 2 32

Outputs Outputs

O-48

RCI Bus (RS 485)

35

Output Response AAAAAAAA (only the address is sent back in the

response)

(1 Byte Acknowledge)

Note that NO card can initiate a message, it can merely respond to a command.

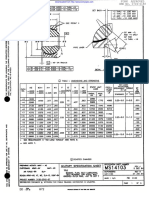

6.2 Micro Processor controlled Throttle Card CBC-8R

The CBC-8R is a Microprocessor Controlled peripheral card which serves to

control

8 Analog Blocks. At this stage I would like to emphasize that this card drives analog

trains only and has No Connection to DCC. The TC Manual describing Dual

Control of Analog and Digital engines, refers to another Track Driving Card, TD4

which was able to connect DCC signals upon receiving a special command. The TD4

card is currently out of production.

6.2.1 CBC8 Features

Control of 8 Blocks where each block controller includes a 96 Step PWM

Speed Control and a Voltage Sensing single Occupancy Detector. Blocks

may be independently controlled from the PC.

As with all digital motor drive circuits CBC-8R uses a so-called H-Bridge

Integrated circuit (type TLE 5205). This circuit is applied to the track 9.8 mS

after the start of the power cycle. The CBC8R card runs to a 10 mS power

cycle and maximum power is applied when the speed step applied is 95%.

Fig. 27 shows how a sensing circuit is applied after 9.8 mS, at a time when the

power is switched off. The sensing circuit is built into the H-Bridge output

circuit of TLE 5205 and checks for continuity through < 10K resistance

(minimum current detected is 0.7 mA).

Fig. 27 Occupancy Detection in CBC-8R

This occupancy detector has the advantage that is will respond to the

presence of Stationary Vehicles. All other detectors require some power to

be applied to the track, which is OK for DCC, but is a problem for Analog

Track Feeding.

The disadvantage is that the detector is sensitive to back emf pulses from the

motor i.e. it may not detect a vehicle when back emf pulses are High. The

other problem is that occupancy indication is signaled back from the CBC-8R

card via the RCI bus while loco driving commands are sent forward. When I

had more than two trains operating in a group of blocks polling replies were

15 V

Speed Step =50%

Speed Step =95% (Max)

5 mS 9.5 mS 9.8 mS

10 mS

0

Occupancy

Detector

applied

36

not received by TC for 0.5 seconds or more and trains got lost to the system.

We will see later how this problem was overcome.

Another disadvantage is that the CBC-8R card only provides one occupancy

detector per block while Analog locos usually require at least 2 (Brake