Documente Academic

Documente Profesional

Documente Cultură

C1079PE Heavy Duty Pneumatic Pumps Series 400200

Încărcat de

Angelica DragulescuDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

C1079PE Heavy Duty Pneumatic Pumps Series 400200

Încărcat de

Angelica DragulescuDrepturi de autor:

Formate disponibile

Compression rate:

see table;

Delivery:

see table;

Air driven pressure:

14 bar max.;

Air inlet:

G UNI-ISO 228/1

(3/4 BSP);

Air outlet:

G UNI-ISO 228/1

(3/4 BSP);

Weight:

25-28 Kg.

Caratteristiche

Barrel pumps for oil,

grease and other

corrosive fluids and for

refilling reservoirs and for

centralized plant feeder.

Applications

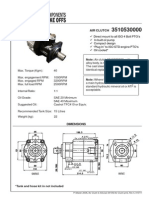

Heavy duty Pneumatic Pumps series 400200

For Oil or Grease and Non-corrosive Fluids

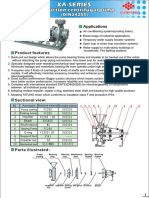

Wide air discharge; to reduce the outlet air temforature drop to a minimum for maximum

efficiency.

Minimum friction; the synthetic rubber air piston slides in a corrosion proof lapped aluminium

cylinder.

Long life seals; accurate assembly, resilience and quality of the materials used, ensure a good seal

for long foriods.

No interruption for adjustment or lubrication; the air motor is sealed, there are no exposed

moving parts.

Maximum life! No seal; the piston and cylinder are of special steel, treated, normalized and

micro-lapped.

Double self alignment joint; with safety spring and square thread.

Sure priming; the base valve is made of hardened steel and ensures a forfect seal.

Forced feed device; makes it possible to feed very hard lubricants into the compression chamber.

Characteristics

Exceptionally strong, powerful and durable

pumps. Suitable for the supply of light, heavy

or fibrous lubricants, even at low

temforatures.

Fits standard commercial drums or large

capacity drums.

Features:

Air supply valve; complete with floating slide,

held on the seat by the air pressure, self

sealing and self cleaning

Positive oforation; a double toggle joint

correctly positions the distribution valve.

Corrosion proof steel rod; is guided to

prevent faulty alignment of the air control

valves, chromium plated hardened and

lapped, to reduce the wear of the seals to a

minimum.

Leghe di

ottima

tenacit

Dimensions

477

1330

238

0 min/99 hours

Modo Off

[S.Min]

Suspend

Heavy duty Pneumatic Pumps series 400200

Hydraulic diagram

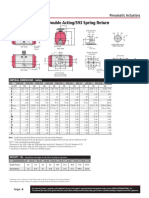

HOW TO ORDER

PUMP ASSY.

PART NO.

AIR MOTOR ONLY

PART NO.

PISTON ROD ONLY

PART NO.

RATIO

TYPE OF

LUBRICANT

DELIVERY AIR

PRESSURE 7

BAR.

400200 400100 400170 40:1 Grease NLGI 2 8 Kg./min.

400300 400100 400155 75:1

Grease NLGI 2

5 Kg./min.

400205 400100 400165 25:1

Grease /oil

1000 cSt.

16 ltr./min.

400210 400100 400160 6:1

Oil 1000 cSt.

28 ltr./min.

ACCESSORIES

PART NUMBER DESCRIPTION

2034950

Exhaust silencer

0400040

Cover for 180 Kg. Drums

SPARES

COMPONENT P. NR. SERVICE KIT P.NR.

Motor

head

400100 2037304

400100 400294

Rod

pumping

400160 for 400210 2037305 for rod pumping

400165 for 400205 2037306 for rod pumping

400170 for 400200 2037307 for rod pumping + motor head

400170 for 400200 400194 gasket for rod pumping

400170 for 400200 2039930 gasket suction piston

400155 for 400300 400195 gasket for rod pumping

400155 for 400300 2034857 for rod pumping + motor head

Order Informations

0 60.000 cicli

1 60.000 cicli

Sensore di ciclo

Z

Z

Z

Z

Contacts

F

F

F

i

i

i

l

l

l

t

t

t

r

r

r

i

i

i

M

M

M

I

I

I

N

N

N

I

I

I

M

M

M

I

I

I

D

D

D

I

I

I

M

M

M

A

A

A

X

X

X

I

I

I

Contatti

ITALY

Dropsa SpA

t. +39 02-250791

f.+39 02-25079767

www.dropsa.com

sales@dropsa.com

ITALY

Dropsa SpA

t. +39 02-250791

f.+39 02-25079767

U.K.

Dropsa (UK) Ltd

t. +44 (0)1784-431177

f. +44 (0)1784-438598

GERMANY

Dropsa GmbH

t. +49 (0)211-394-011

f. +49 (0)211-394-013

FRANCE

Dropsa Ame

t. +33 (0)1-3993-0033

f. +33 (0)1-3986-2636

CHINA

Dropsa Lubrication Systems

(Shanghai) Co.,Ltd

t. +86 (021) 67740275

f. +86 (021) 67740205

U.S.A.

Dropsa Corporation

t. +1 586-566-1540

f. +1 586-566-1541

AUSTRALIA

Dropsa Australia Ltd.

t. +61 (0)2-9938-6644

f. +61 (0)2-9938-6611

BRAZIL

Dropsa Remonlub

t. +55 (0)11-563-10007

f. +55 (0)11-563-19408

C1079PE WK 26/00

www.dropsa.com

sales@dropsa.com

Installation/Oforation

S-ar putea să vă placă și

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- FMC Weco Wing Union CatalogDocument16 paginiFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- Mahindra Cat ScorpioDocument143 paginiMahindra Cat ScorpioAndres Pacheco100% (2)

- Bulldozer d9t CatDocument20 paginiBulldozer d9t CatJuan David JaramilloÎncă nu există evaluări

- Catalog Mud Pump 25864Document24 paginiCatalog Mud Pump 25864agus100% (1)

- Vilter CatalogDocument28 paginiVilter CatalogDang Anh Tuan0% (1)

- WOM Magnum Gate Valve BrochureDocument8 paginiWOM Magnum Gate Valve BrochuresjongejongeÎncă nu există evaluări

- The Weir Direct-Acting Feed Pump - Working InstructionsDe la EverandThe Weir Direct-Acting Feed Pump - Working InstructionsÎncă nu există evaluări

- Oil Free Compressor en PDFDocument24 paginiOil Free Compressor en PDFKiatchai IttivikulÎncă nu există evaluări

- AutoMate Training ModulesDocument12 paginiAutoMate Training ModulesMihai AncutaÎncă nu există evaluări

- Okb Top SeriesDocument4 paginiOkb Top SeriesIrma Pokvić-Ramulj100% (1)

- CP150 SMDocument50 paginiCP150 SMjacklyn ade putra100% (1)

- 06 SCT Extended PDFDocument40 pagini06 SCT Extended PDFSlobodan Antic100% (2)

- KV-S4065CL KV-S4065CW KV-S4065CWCN KV-S4085CL KV-S4085CW KV-S4085CWCNDocument20 paginiKV-S4065CL KV-S4065CW KV-S4065CWCN KV-S4085CL KV-S4085CW KV-S4085CWCNLouis ChenÎncă nu există evaluări

- Valmet 611 DSLDocument57 paginiValmet 611 DSLagrodostavaÎncă nu există evaluări

- York CompressorsDocument6 paginiYork CompressorsFernando HuarocÎncă nu există evaluări

- Catalog URB PDFDocument801 paginiCatalog URB PDFDAN GDFÎncă nu există evaluări

- Mitsubishi Catalogs Manuals PDFDocument6 paginiMitsubishi Catalogs Manuals PDFZulkipli Marasabessy50% (2)

- Burda Primavara 2015Document196 paginiBurda Primavara 2015Angelica Dragulescu94% (36)

- S 28AT XP EXP EngDocument6 paginiS 28AT XP EXP EngpramodtryÎncă nu există evaluări

- Weco Wing UnionsDocument15 paginiWeco Wing Unionsturend0% (1)

- Embroidery BooksDocument19 paginiEmbroidery BooksAngelica Dragulescu100% (1)

- Egger Impeller Brochure PDFDocument10 paginiEgger Impeller Brochure PDFnbharath1988100% (1)

- Cryo Pump PDFDocument0 paginiCryo Pump PDFkanchanabalajiÎncă nu există evaluări

- 2GDocument8 pagini2GGaurav Panditrao UdanshivÎncă nu există evaluări

- SY215C 9 Excavator PDF Valve Throttle (Revisi) PDFDocument93 paginiSY215C 9 Excavator PDF Valve Throttle (Revisi) PDFSohibul AminÎncă nu există evaluări

- Imo Pump 3DDocument6 paginiImo Pump 3DHadi Utomo100% (1)

- Tansmisii CVT Pentru TractoareDocument35 paginiTansmisii CVT Pentru TractoareCochintu RaduÎncă nu există evaluări

- EIM 7 - 8-Module 1Document24 paginiEIM 7 - 8-Module 1Donna Shane ReyesÎncă nu există evaluări

- Partes Motor 444 Aspiracion Natural 9812-0080 PDFDocument112 paginiPartes Motor 444 Aspiracion Natural 9812-0080 PDFDaniel Aguirre83% (6)

- Válvulas Bola SegmentadaDocument12 paginiVálvulas Bola SegmentadarehynaldoÎncă nu există evaluări

- Air System ComponentsDocument6 paginiAir System ComponentsEliasÎncă nu există evaluări

- SAPP Series PumpsDocument2 paginiSAPP Series Pumpssahildhingra100% (1)

- Dokumen - Tips Dv200 Manual Master1Document45 paginiDokumen - Tips Dv200 Manual Master1Fermín Duarte RodríguezÎncă nu există evaluări

- DV100 SMDocument51 paginiDV100 SMjacklyn ade putraÎncă nu există evaluări

- 15 Metal Seated Butterfly ValvesDocument8 pagini15 Metal Seated Butterfly ValvesrajfmcÎncă nu există evaluări

- Antico PPCL Series PDFDocument6 paginiAntico PPCL Series PDFswainpiyush123Încă nu există evaluări

- Anderson Greenwood - Pentair Series 400 Modulating Datasheet PDFDocument4 paginiAnderson Greenwood - Pentair Series 400 Modulating Datasheet PDFSARATH KRISHNAKUMARÎncă nu există evaluări

- Gardner Denver Industrial Blowers TF 140L K202Document8 paginiGardner Denver Industrial Blowers TF 140L K202Aleksandar JočićÎncă nu există evaluări

- RW PDFDocument6 paginiRW PDFnbharath1988Încă nu există evaluări

- Pump Sales WebDocument7 paginiPump Sales WebGermán Soledad MolinaÎncă nu există evaluări

- Air Line AccessoriesDocument4 paginiAir Line AccessoriesZeckÎncă nu există evaluări

- Hoer CT Valve 2Document5 paginiHoer CT Valve 2Tu PhamÎncă nu există evaluări

- Earls Full CatalogueDocument66 paginiEarls Full Catalogueseanu71Încă nu există evaluări

- HH125 Smanual Completed - Master Updated 30-3-06Document41 paginiHH125 Smanual Completed - Master Updated 30-3-06jacklyn ade putra0% (1)

- Bomba de Engranajes Catalogo JOYANGDocument8 paginiBomba de Engranajes Catalogo JOYANGlizbethdiosesÎncă nu există evaluări

- Norgren Catalouge PDFDocument22 paginiNorgren Catalouge PDFjaydee45Încă nu există evaluări

- Book LayoutDocument8 paginiBook LayoutaamenaÎncă nu există evaluări

- Table of Content: Pneumatic ToolsDocument7 paginiTable of Content: Pneumatic Toolsdunareanu_marian8668Încă nu există evaluări

- Norgren N - UK - 1 - 5 - 135 - PRA - 182000 PDFDocument12 paginiNorgren N - UK - 1 - 5 - 135 - PRA - 182000 PDFpichooooÎncă nu există evaluări

- Rotex Pneumatic Cylinder CatalogueDocument4 paginiRotex Pneumatic Cylinder Cataloguekumar ambujÎncă nu există evaluări

- Penta Wet KitDocument44 paginiPenta Wet KitAlexandru Nicu100% (1)

- Reg RedQ Specialy Regulators PDFDocument20 paginiReg RedQ Specialy Regulators PDFDavid SaldarriagaÎncă nu există evaluări

- Mercury Fuel ComponentsDocument7 paginiMercury Fuel ComponentswguenonÎncă nu există evaluări

- Performer X Turbocharging System For 1996-2000 Honda Civic D16Y8 Catalog #1500 Installation InstructionsDocument14 paginiPerformer X Turbocharging System For 1996-2000 Honda Civic D16Y8 Catalog #1500 Installation Instructionsdiaz_almarazÎncă nu există evaluări

- Rotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceDocument36 paginiRotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceSaurav DasÎncă nu există evaluări

- Bomba Hidraulica Sp25Document5 paginiBomba Hidraulica Sp25Javier SumozaÎncă nu există evaluări

- Air Clutch PZBDocument4 paginiAir Clutch PZBRio de MarioÎncă nu există evaluări

- Toyota 5l Engine-Turbo Kit Fitting InstructionsDocument9 paginiToyota 5l Engine-Turbo Kit Fitting Instructionsaqilhad100% (2)

- Technical DetailsDocument100 paginiTechnical Detailsnvkjayanth50% (2)

- Eaton HansenKingDocument80 paginiEaton HansenKingKING COMERCIAL LTDAÎncă nu există evaluări

- Tech Data Sheet ENG-21 Version 2Document3 paginiTech Data Sheet ENG-21 Version 2muhmmadafzal73Încă nu există evaluări

- Technical Bulletin: Valtek Mark One Control ValvesDocument20 paginiTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzÎncă nu există evaluări

- Heavy Duty Actuator - BrochureDocument16 paginiHeavy Duty Actuator - BrochureRedzaÎncă nu există evaluări

- Equipos de Limpieza CATDocument34 paginiEquipos de Limpieza CATHenryMonteagudoParedesÎncă nu există evaluări

- Double Acting and Spring Return Pneumatic Actuators For On/off or Modulating Control of Most Quarter Turn Applications. Output Torques To 2385 NMDocument6 paginiDouble Acting and Spring Return Pneumatic Actuators For On/off or Modulating Control of Most Quarter Turn Applications. Output Torques To 2385 NMTeun HaperenÎncă nu există evaluări

- Gate Valve CataogueDocument4 paginiGate Valve CataogueAditya B. RyantoÎncă nu există evaluări

- Primetech ProfileDocument15 paginiPrimetech Profileask101Încă nu există evaluări

- Ariel JGK and JGT CompressorsDocument5 paginiAriel JGK and JGT CompressorsPablo GutierrezÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- C1079PE Heavy Duty Pneumatic Pumps Series 400200Document2 paginiC1079PE Heavy Duty Pneumatic Pumps Series 400200Angelica Dragulescu100% (1)

- C2017ie-Pompe PN Seria 233000 .Si 234000Document9 paginiC2017ie-Pompe PN Seria 233000 .Si 234000Angelica DragulescuÎncă nu există evaluări

- Grease Guns: K000437: TWIN-LOCK Grease Gun With High Grade Steel Silver FinishDocument3 paginiGrease Guns: K000437: TWIN-LOCK Grease Gun With High Grade Steel Silver FinishAngelica DragulescuÎncă nu există evaluări

- Pompa Pneumatica LOCOPUMPDocument10 paginiPompa Pneumatica LOCOPUMPAngelica DragulescuÎncă nu există evaluări

- Pompa Pneumatica de Transvazare Si UmplereDocument2 paginiPompa Pneumatica de Transvazare Si UmplereAngelica DragulescuÎncă nu există evaluări

- C2201IE HYDCannonpumpDocument13 paginiC2201IE HYDCannonpumpAngelica DragulescuÎncă nu există evaluări

- C2000PE Dragon 06 14Document2 paginiC2000PE Dragon 06 14Angelica DragulescuÎncă nu există evaluări

- C2186PE Ultrasensor DMMDocument2 paginiC2186PE Ultrasensor DMMAngelica DragulescuÎncă nu există evaluări

- C2187PE Ultrasensor DMGDocument2 paginiC2187PE Ultrasensor DMGAngelica DragulescuÎncă nu există evaluări

- Pompa 3413001Document4 paginiPompa 3413001Angelica DragulescuÎncă nu există evaluări

- AutoungatoareDocument1 paginăAutoungatoareAngelica DragulescuÎncă nu există evaluări

- C2123IE LocopumpS2 31 14Document9 paginiC2123IE LocopumpS2 31 14Angelica DragulescuÎncă nu există evaluări

- C2023ie 234700 01 12Document13 paginiC2023ie 234700 01 12Angelica DragulescuÎncă nu există evaluări

- C1020CE - 47 Pompa Pneumatica Seria 3413000Document1 paginăC1020CE - 47 Pompa Pneumatica Seria 3413000Angelica DragulescuÎncă nu există evaluări

- Pompa Dragon 1Document10 paginiPompa Dragon 1Angelica DragulescuÎncă nu există evaluări

- Elpompa 1222000Document2 paginiElpompa 1222000Angelica DragulescuÎncă nu există evaluări

- Accesorii UngereDocument2 paginiAccesorii UngereAngelica DragulescuÎncă nu există evaluări

- C2150PE DragonXDocument2 paginiC2150PE DragonXAngelica DragulescuÎncă nu există evaluări

- B21 HSTDocument342 paginiB21 HSTbatman2054Încă nu există evaluări

- SyllabusDocument2 paginiSyllabusAyush BhadauriaÎncă nu există evaluări

- Evergush Xa en 50hzDocument15 paginiEvergush Xa en 50hzFikry HarzanÎncă nu există evaluări

- Stone India FDocument2 paginiStone India FEr Rajesh Bura0% (1)

- Self-Propelled Lawn Mower Cable RepairDocument2 paginiSelf-Propelled Lawn Mower Cable RepairSaikat SarkarÎncă nu există evaluări

- Diploma Board Examination - December 2020Document2 paginiDiploma Board Examination - December 2020Pradeep AppuÎncă nu există evaluări

- Manual Tecnico Actuador Neumatico Bray S92 93 PDFDocument1 paginăManual Tecnico Actuador Neumatico Bray S92 93 PDFlcs2006mvÎncă nu există evaluări

- Types: Positive Displacement PumpsDocument4 paginiTypes: Positive Displacement PumpsAnonymous hUxOtWChmIÎncă nu există evaluări

- KL150 Detailed SpecsDocument3 paginiKL150 Detailed Specsben100% (1)

- Directional & Control Valves NG10 PDFDocument15 paginiDirectional & Control Valves NG10 PDFJhon NaranjoÎncă nu există evaluări

- DG Faults and Troubleshooting MeasuresDocument6 paginiDG Faults and Troubleshooting MeasuressolomonÎncă nu există evaluări

- LEHM20671-00 - C4.4 Electronic Data SheetDocument3 paginiLEHM20671-00 - C4.4 Electronic Data Sheetkman548Încă nu există evaluări

- 1434532626092-140T Crane MTCDocument38 pagini1434532626092-140T Crane MTCAlok AnandÎncă nu există evaluări

- K38 Series: Diesel Generator SetDocument4 paginiK38 Series: Diesel Generator Setkumar aÎncă nu există evaluări

- K 4700 CSK 5000 CCK 5500 CBK 5000 CSK 6000 CCK 6000 CSK 7500 CCDocument2 paginiK 4700 CSK 5000 CCK 5500 CBK 5000 CSK 6000 CCK 6000 CSK 7500 CCMIGUEL ÁNGEL TOMÉÎncă nu există evaluări

- Kranzle Profijet Catalog-2019 - EN - 16220Document1 paginăKranzle Profijet Catalog-2019 - EN - 16220Music NetÎncă nu există evaluări

- Spark Controlled Compression IgnitionDocument18 paginiSpark Controlled Compression IgnitionLEONARDO DAVINCIÎncă nu există evaluări

- ALUP Largo 31-45 Sales Leaflet EN 6999640400Document2 paginiALUP Largo 31-45 Sales Leaflet EN 6999640400Bosznay ZoltánÎncă nu există evaluări

- Manual (24 Abs 318-360)Document66 paginiManual (24 Abs 318-360)Carlos Manuel de la Hoz Serrano100% (1)