Documente Academic

Documente Profesional

Documente Cultură

DP2 Process Design Guidelines With Example Storage Tank Design

Încărcat de

NicholasBeresford0 evaluări0% au considerat acest document util (0 voturi)

156 vizualizări4 paginig

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentg

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

156 vizualizări4 paginiDP2 Process Design Guidelines With Example Storage Tank Design

Încărcat de

NicholasBeresfordg

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

Process Engineering Design Project 2014

University of Queensland Page 1 of 4

CHEE4001 Process Engineering Design Project

Equipment Process Design Guidelines

The following guidelines and accompanying indicative examples gives further details of

expectations for the Design Package 2. The following considerations should be given (some

as basis some as design outcomes) to the following equipment types. Others not mentioned

here follow a similar pattern.

Common items to all:

Operating and design T, P

Inflows and Outflows

Choice of materials of construction (Carbon steel (CS), alloy steel (low temperatures),

stainless steel, concrete, plastic, fiberglass, ) and basis (low temperature, corrosion

resistance etc.). Give grade of steel or material.

1. Tanks and vessels

Capacity required and basis (e.g. residence time (s), (days) etc.)

Approximate required aspect ratio (length to height/diameter)

Type of tank (horizontal, vertical, spherical, in-ground, open, ) and why.

Actual dimensions (diameter, length, height, ). Use standard pressure ends if

applicable (see C&R chapter 13 or industry literature)

2. Heat Exchangers (Process, reboilers, condensers, preheaters, coolers etc)

Target temperatures

Stream description for both fluids or for cooling, heating medium

Type of exchanger to be used (S&T fixed tubesheet, floating, U, Plate exchanger).

Justification on choice.

Pressure drops

Overall heat transfer coefficient. Fouling considerations.

Estimated transfer area

S&T exchangers: Approximate length and diameter of shell. (see tubesheet layout table)

Sketch of unit may be useful if it is a non-standard exchanger.

3. Columns, Towers, Absorbers, Strippers,

Major stream flows

Product purity specifications

Type of column (distillation, stripper, absorber etc.)

Type of internals (trays and type sieve, valve; packing random, structured)

Overall height (tray spacing and sump + headspace), diameter (based on % flooding

point)

Pressure drop

Separation efficiency and number of actual separation stages

Process Engineering Design Project 2014

University of Queensland Page 2 of 4

4. Compressors and (non-combustion) turbines

Type of compressor/turbine.

You need to identify the power consumed/produced. This will be the input into your

capital cost.

The number of stages required and the inter-stage temperatures and pressures.

Inter-stage cooling is done by a distinct HX (this is a separate unit operation) which

needs streams to facilitate the cooling and a design.

5. Pumps

Type of pump

The power requirements of the pump estimated from operating pressures, reasonable

estimates of pumping head/losses and pump efficiency.

No sizing required.

Process Engineering Design Project 2014

University of Queensland Page 3 of 4

Example of Storage Tank Process Design

NOTE: This is an example only. Much of the data below is wrong! Do not use, refer to your

own reputable sources. You report does not need to look like this.

X.X TK-521

Equipment Item: Unsymmetric dimethylhydrazine (UDMH) storage tank

Equipment design basis:

240 tonnes of UDMH must be stored for full load to launch vehicle.

The vessel must be a sealed pressure vessel for this toxic and flammable material.

Design Information:

Storage facility will be to be covered and contents maintained at 5 C by circulation to

external heat exchange.

Operating temperature range of tank is 5 C to 50 C. 50 C is the maximum is in the case

of long term refrigeration failure based on maximum temperature on record (ref)).

Maximum storage pressure at 1200 kPa(g) which is UDMH vapour pressure at 50 C (ref).

Horizontal cylindrical tank chosen as most appropriate in terms of layout and reduced

elevation for flammable storage (ref). [this may go in team section]

Preformed torispherical tank ends to be used, since pressure < 15 bar. [this may go in

team section]

Approximate aspect ratio to be 9:1 to 18:1 which is the recommended ratio for pressure

vessels (ref). [this may go in team section]

Allow 10% ullage for contents (ref) and 10% overpressure allowance (ref). [this may go

in team section]

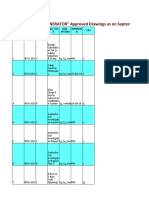

Table X.X Summary of TK-521 design

Variable/Specification Value Units Comment/Justification

Internal Volume 335 m

3

Orientation Horizontal -

Overall Length 32.5 m

Internal Diameter 3658 mm

Min/Max Design Temp 5/50

o

C

Design Pressure 1342 kPa(g)

Material of Construction ANSI 316 SS Required for corrosion resistance to UDMH (ref)

Design Inlet Flow 10 kg/s Production capacity (section X.Y)

Design Outlet Flow 18 kg/s Refuelling rate (section (X.Y)

Design HX flow 0.1 kg/s HX-201 calculation in section X.Y

Notes:

1. Covering required

2. Insulation to be installed to reduce ambient heat ingress and external condensation.

Note:

- The bit shaded in grey are details and required for DP3 only.

- If I had lots of similar tanks, I may do one section on tanks and put all the tanks in a single

table. Reduce repetition for you own and your readers sanity!

Process Engineering Design Project 2014

University of Queensland Page 4 of 4

Appendix A. TK-521 Design Calculations

(completed by Ian Cameron)

General Details

Capacity = 240 tonnes

Liquid density = 791 kg/m

3

(ref)

Tank volume = fluid volume + 10 % ullage = 1.1240/0.791 = 335 m

3

Design temperature = 50 C

Approximate sizing

Approximate vessel dimensions (start with Australia Pressure Vessel Heads Pty Ltd Hot

Pressed Code Ends Data Sheet)

Choose torispherical ends = 3658 mm ID (initial choice)

Volume in ends = 24.575 m

3

= 9.15 m

3

Volume in shell = 335 9.15 = 325.9 m

3

Shell length = 325.9/cross sectional area = 325.9/(3.14(3.658)

2

/4)

= 31.03 metres (falls in acceptable L/D)

Overall vessel length = 31.03 (shell) + 2*(0.681+0.076) (heads) = 32.54 metres

Design conditions

Static head in vessel = gh = 7919.813.6 / 1000 kPa = 27.9 kPa

Operating pressure = 1200 kPa(g)

Maximum design pressure = (1200 + 27.9) kPa(g) + 10% = 1277.91.1 = 1350 kPa(g)

Nozzles (for detailed design, DP3)

Optimal pipe sizes calculated as per example in Appendix Y (Sinnott 2005):

Inlet Outlet Cooling in/out

Flow (kg/s) 10 18 0.1

Calc size (mm) 73 99 12

Size (mm) 80 100 20

Near ambient temperature and a design pressure of 13.5 bar, mean a PN of 20 is suitable for

all nozzles on this vessel (AS4331).

S-ar putea să vă placă și

- Shortcut Design of Pressure Storage TankDocument2 paginiShortcut Design of Pressure Storage TankmsengÎncă nu există evaluări

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De la EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Evaluare: 3.5 din 5 stele3.5/5 (3)

- Pressure Vessels: Avoid Costly Design MistakesDocument8 paginiPressure Vessels: Avoid Costly Design Mistakesmarcel linaÎncă nu există evaluări

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationDe la EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationÎncă nu există evaluări

- Basic Design CalculationsDocument6 paginiBasic Design Calculationsmulusewbelay86Încă nu există evaluări

- New TameDocument8 paginiNew Tameabdibedasa86Încă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Storage TankDocument4 paginiStorage TankniezajanepatnaÎncă nu există evaluări

- Process Heat Transfer: Principles, Applications and Rules of ThumbDe la EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbEvaluare: 4.5 din 5 stele4.5/5 (11)

- Interview Question.Document7 paginiInterview Question.PankajDhobleÎncă nu există evaluări

- Vessel DesignDocument28 paginiVessel DesignDinda Naiya AzhariÎncă nu există evaluări

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe la EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesEvaluare: 3.5 din 5 stele3.5/5 (3)

- 21Document101 pagini21Udaivir YadavÎncă nu există evaluări

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDe la EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsEvaluare: 4 din 5 stele4/5 (6)

- Pressure Vessel Costly MistakeDocument11 paginiPressure Vessel Costly MistakearjayÎncă nu există evaluări

- Process Plant Design: Heinemann Chemical Engineering SeriesDe la EverandProcess Plant Design: Heinemann Chemical Engineering SeriesEvaluare: 3.5 din 5 stele3.5/5 (11)

- Vessel VolumesDocument72 paginiVessel VolumesPaula RiveraÎncă nu există evaluări

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe la EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceEvaluare: 5 din 5 stele5/5 (1)

- Final Acoustic Enclosure PresentationDocument48 paginiFinal Acoustic Enclosure PresentationsartajyadÎncă nu există evaluări

- A Guide to Ship Repair Estimates in Man-hoursDe la EverandA Guide to Ship Repair Estimates in Man-hoursEvaluare: 4.5 din 5 stele4.5/5 (5)

- ME 4226 Heat Exchanger Compiled WconclusionDocument26 paginiME 4226 Heat Exchanger Compiled Wconclusionhamish888Încă nu există evaluări

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsDe la EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsÎncă nu există evaluări

- Agitated Vessel Heat Transfer DesignDocument3 paginiAgitated Vessel Heat Transfer Designvasudevanrv9405Încă nu există evaluări

- Southern Marine Engineering Desk Reference: Second Edition Volume IDe la EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IÎncă nu există evaluări

- Agitated Vessel Heat Transfer Design PDFDocument3 paginiAgitated Vessel Heat Transfer Design PDFmrariffÎncă nu există evaluări

- Chapter One: 1.1) Introduction of Pressure VesselDocument55 paginiChapter One: 1.1) Introduction of Pressure VesselAbenezer BirhanuÎncă nu există evaluări

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ADe la EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AEvaluare: 5 din 5 stele5/5 (1)

- Tank Design and DetailingDocument17 paginiTank Design and DetailingFuatÎncă nu există evaluări

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDe la EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsÎncă nu există evaluări

- Tks 3245 Perancangan Alat ProsesDocument38 paginiTks 3245 Perancangan Alat Prosesfadhillah ivanÎncă nu există evaluări

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsDe la EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsÎncă nu există evaluări

- Storage Tanks: For RefineriesDocument10 paginiStorage Tanks: For RefineriesSiddharth Sridhar100% (1)

- Pressure VesselDocument91 paginiPressure VesselFiza100% (4)

- Pressure Vessel Training ModuleDocument40 paginiPressure Vessel Training ModuleIdil Fitri100% (1)

- How To Use HTRI For Shell & Tube Exchanger DesignDocument38 paginiHow To Use HTRI For Shell & Tube Exchanger Designirshaad_s88% (17)

- Chapter One: Introdution To ProjectDocument21 paginiChapter One: Introdution To Projectabiy balkewÎncă nu există evaluări

- Design of Pressure Vessel For Nitrogen Gas StorageDocument15 paginiDesign of Pressure Vessel For Nitrogen Gas StorageprabhaakarÎncă nu există evaluări

- Jacketed Vessel DesignDocument5 paginiJacketed Vessel Designfunkkkky100% (1)

- Chapter 6 - Mechanical DesignDocument121 paginiChapter 6 - Mechanical DesignohoreyÎncă nu există evaluări

- Jacketed Vessel DesignDocument5 paginiJacketed Vessel DesignfunkkkkyÎncă nu există evaluări

- Pressure Vessel Design TemplateDocument3 paginiPressure Vessel Design TemplateRamachandran Venkatesh0% (1)

- Storage TanksDocument62 paginiStorage Tankstoychom2013Încă nu există evaluări

- Equipment DesignDocument88 paginiEquipment DesignbigbossÎncă nu există evaluări

- Design of A Heat Exchanger Using HTRI - World Wide SimulationDocument5 paginiDesign of A Heat Exchanger Using HTRI - World Wide Simulationwisnu_220267% (3)

- Vessels LDocument34 paginiVessels LMohammed.abudi1996Încă nu există evaluări

- Design of Vertical Pressure VesselsDocument15 paginiDesign of Vertical Pressure VesselsMohit SinghÎncă nu există evaluări

- The Outside Diameter As Their Nominal DiameterDocument75 paginiThe Outside Diameter As Their Nominal Diameterngutor100% (2)

- Vessel VolumesDocument71 paginiVessel VolumesAnonymous a4Jwz14W100% (1)

- Notes For Spreedsheet Calculator SoftwareDocument8 paginiNotes For Spreedsheet Calculator SoftwareniginpÎncă nu există evaluări

- Stress Analysis of Piston Using Pressure Load and Thermal LoadDocument8 paginiStress Analysis of Piston Using Pressure Load and Thermal LoadInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Mme20120400001 99189738 PDFDocument5 paginiMme20120400001 99189738 PDFAnimesh JainÎncă nu există evaluări

- Design HeatexchangerDocument15 paginiDesign HeatexchangerMayurMahajan100% (1)

- Storage Tanks CalculationsDocument21 paginiStorage Tanks Calculationsjimallen21288% (26)

- CHEVRON Shell and Tube Exchanger Component Design ConsiderationsDocument42 paginiCHEVRON Shell and Tube Exchanger Component Design Considerationsbabak mir80% (5)

- Heat ExchangersDocument14 paginiHeat ExchangersPrateek JainÎncă nu există evaluări

- Design Practices - DrumsDocument32 paginiDesign Practices - Drumsagarwalashwin32100% (2)

- Brochure ES-220 UHP Electric Skids PDFDocument2 paginiBrochure ES-220 UHP Electric Skids PDFvenky4025Încă nu există evaluări

- Item Code Item Name Item Class Brand Model Code Warehouse Group Warehouse Code Location Code Sales Price Available QtyDocument8 paginiItem Code Item Name Item Class Brand Model Code Warehouse Group Warehouse Code Location Code Sales Price Available Qtyrahmat agungÎncă nu există evaluări

- Lecture No: 10 (Lubrication in I.C.E) : 10.1 Function of Lubricating SystemDocument5 paginiLecture No: 10 (Lubrication in I.C.E) : 10.1 Function of Lubricating Systemمصطفى العباديÎncă nu există evaluări

- Fabrication of Turbocharger For Two Wheeler: Ahir Nischal A, Sofia Ali A, Darshan S Shah, Sneh R PrajapatiDocument8 paginiFabrication of Turbocharger For Two Wheeler: Ahir Nischal A, Sofia Ali A, Darshan S Shah, Sneh R PrajapatiDeepak sutarÎncă nu există evaluări

- Scan Plan (PAUT) For Taper Joints and K WeldsDocument4 paginiScan Plan (PAUT) For Taper Joints and K WeldsRamakrishnan AmbiSubbiahÎncă nu există evaluări

- Keckley Float ValvesDocument15 paginiKeckley Float ValvesWagner LimaÎncă nu există evaluări

- (BOOK NO. 13) - (18) - SG-D-08 - Primary Heat Transport System - (OTHER)Document83 pagini(BOOK NO. 13) - (18) - SG-D-08 - Primary Heat Transport System - (OTHER)pratip_bÎncă nu există evaluări

- Conveyor BeltDocument31 paginiConveyor BeltsmendozaÎncă nu există evaluări

- Design of A Lever Safety ValveDocument10 paginiDesign of A Lever Safety ValveAbhijith Sanker100% (1)

- 2p36907 SwivelDocument42 pagini2p36907 SwivelIFI ARGENTINA S.A.Încă nu există evaluări

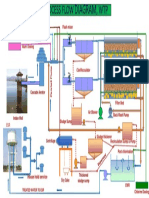

- WTP Process DiagramDocument1 paginăWTP Process DiagramKumar AbhishekÎncă nu există evaluări

- Phase Changes Phase DiagramDocument24 paginiPhase Changes Phase DiagramNicolette BingtanÎncă nu există evaluări

- Valves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Document34 paginiValves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Oscar CalaÎncă nu există evaluări

- 1996-2001 Fuso FH Service Manual PDFDocument1.652 pagini1996-2001 Fuso FH Service Manual PDFoutback_fred100% (4)

- MR810 Torsional Rigidity and Beaming Stiffness Test Procedure 8.14Document4 paginiMR810 Torsional Rigidity and Beaming Stiffness Test Procedure 8.14Maduka SmartÎncă nu există evaluări

- ElectronoobsDocument5 paginiElectronoobsTaufiq QurahmanÎncă nu există evaluări

- XTRACT Calculul Unui Perete de B.ADocument1 paginăXTRACT Calculul Unui Perete de B.AHDu13Încă nu există evaluări

- Quasiturbine EngineDocument16 paginiQuasiturbine Engineapi-238832008100% (1)

- Flex Separation System - S and P - Operating Instructions - 2014Document51 paginiFlex Separation System - S and P - Operating Instructions - 2014Centrifugal SeparatorÎncă nu există evaluări

- Dive Scubapro - Mk2+, Mk2 - Maintenance ProcedureDocument4 paginiDive Scubapro - Mk2+, Mk2 - Maintenance ProceduremanonpomÎncă nu există evaluări

- Komal Kumar Mallick PDFDocument2 paginiKomal Kumar Mallick PDFKomal KumarÎncă nu există evaluări

- Din HandbooksDocument9 paginiDin HandbooksTalha DikenÎncă nu există evaluări

- Retentor Din 3760Document13 paginiRetentor Din 3760Marcelo Godinho BatistaÎncă nu există evaluări

- ROHR2fesu FeaturelistDocument20 paginiROHR2fesu FeaturelistJohan ConradieÎncă nu există evaluări

- Fluids Homework 5 - SolutionsDocument4 paginiFluids Homework 5 - SolutionsJulian MichaelÎncă nu există evaluări

- DRG ListDocument272 paginiDRG ListVijay PalÎncă nu există evaluări

- Bomba A2fo Bosch RexrothDocument3 paginiBomba A2fo Bosch RexrothHIDRAFLUIDÎncă nu există evaluări

- Example 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Document6 paginiExample 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Imran SaikatÎncă nu există evaluări

- Superhero ExampleDocument8 paginiSuperhero Exampleapi-343241309Încă nu există evaluări

- Format WPQDocument2 paginiFormat WPQAkash Singh TomarÎncă nu există evaluări

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDe la EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionEvaluare: 4.5 din 5 stele4.5/5 (3)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDe la EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseEvaluare: 4.5 din 5 stele4.5/5 (51)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItDe la EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItEvaluare: 4 din 5 stele4/5 (25)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDe la EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisEvaluare: 4 din 5 stele4/5 (2)

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataDe la EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataÎncă nu există evaluări

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CDe la EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CÎncă nu există evaluări

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDe la EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionÎncă nu există evaluări

- The Laws of Thermodynamics: A Very Short IntroductionDe la EverandThe Laws of Thermodynamics: A Very Short IntroductionEvaluare: 4.5 din 5 stele4.5/5 (10)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersDe la EverandBulk Material Handling: Practical Guidance for Mechanical EngineersEvaluare: 5 din 5 stele5/5 (1)

- Safety Theory and Control Technology of High-Speed Train OperationDe la EverandSafety Theory and Control Technology of High-Speed Train OperationEvaluare: 5 din 5 stele5/5 (2)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)De la EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Evaluare: 4 din 5 stele4/5 (12)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsDe la EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongÎncă nu există evaluări

- Mechanical Vibrations and Condition MonitoringDe la EverandMechanical Vibrations and Condition MonitoringEvaluare: 5 din 5 stele5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)