Documente Academic

Documente Profesional

Documente Cultură

Combustion Analysis Spark Plug Bore

Încărcat de

sinasayedana0 evaluări0% au considerat acest document util (0 voturi)

41 vizualizări2 pagini6

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest document6

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

41 vizualizări2 paginiCombustion Analysis Spark Plug Bore

Încărcat de

sinasayedana6

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

For decades, the measurement of combus-

tion chamber pressure has been regarded

as the best means for the analysis and de-

velopment of combustion processes. For

relevant and precise measurements, the

measuring equipment must not have any

inuence on the combustion. To achieve

this, time-consuming and expensive in-

dicating bores are needed in the engine,

into which conventional combustion

chamber pressure sensors are inserted.

Another possible solution is measurement

via the spark plug bore, but here there is

the challenge of tting an ignition func-

tion comparable with series spark plugs

as well as a high-quality measurement

function into a conned space. Some-

times even with M14 spark plugs com-

promises in both functions have been

necessary up to now, for smaller types

only solutions with restricted applica-

tion have existed to date. Now, with the

newly-developed spark plug generation

it is possible to carry out highly-precise

cylinder pressure measurements via the

spark plug bore without inuencing the

mixture ignition.

Te new spark plugs are available with

M10 and M12 mounting thread as well

as in various lengths with spark plug heat

ratings of 07, 3, 5 and 7. Te integrated

pressure sensor has a sensitivity of 12

pC/bar and its thermodynamic behavior

is comparable with good, conventionally-

tted sensors.

Longevity and service

From the very beginning, longevity,

product quality and service-friendliness

were given absolute priority. Te sin-

tered-in platinum electrode ensures out-

standing stability as well as an extremely

low deviation of the heat rating in mass

production. Similarly, the platinum-

sheathed earth electrodes (some with

copper cores) were designed for long

service life. In vehicle tests, distances of

up to 30,000 km were covered without

impairment of the ignition and pressure

measurement functions. Tanks to the

modular layout of the measuring spark

plug, it is possible for the user to replace

individual components where often in the

past the complete replacement of a sensor

was necessary. Tus the new product line

contributes signicantly to reducing the

costs of combustion analysis.

Ignition function

In order to create sucient space for the

pressure measuring function, the ceram-

ic insulator had to be greatly reduced in

size in the vicinity of the spark plug shell.

Tus the wall thickness of the ceramic

part and the ignition pin cross-section

are only 40% of the standard dimensions

of M10 spark plugs.

As a result, the optimization of the in-

sulator geometry in simulations and

tests as well as the use of a particularly

shock-resistant ceramic material ensured

the achievement of reliable operation in

excess of 30 kV; in addition, the volt-

age requirement was reduced by approx.

30% compared with standard spark

plugs thanks to the very thin electrodes.

Tus, despite the severe geometric re-

strictions, it was possible to develop an

insulator that ensured sustained ignition

of the mixture even with supercharged

engines.

Figure 1: Novel pressure measuring spark plugs.

Easily recognizable by the round membrane

in the immediate vicinity of the electrode.

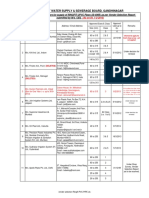

Combustion analysis

via the spark plug bore

In close cooperation with Bosch and AVL, Piezocryst Advanced Sensorics has developed a novel spark plug series with

integrated pressure measurement function for engine design and quality control. The partners have contributed their

respective know-how to this cooperative venture (ignition from Bosch, application from AVL and sensor from Piezocryst).

Special priority was given to the achievement of a high-quality pressure signal without the need for an additional bore in the

engine. For this, completely new design approaches were pursued in order to solve the problems of extreme miniaturization.

Pressure measurement function

Miniaturization without loss of quality

was also the top priority for the integra-

tion of the pressure measurement func-

tion. Tus the membrane was integrated

laterally in the spark plug housing instead

of at the front end in order to achieve suf-

cient membrane area for high sensitivi-

ties and good thermodynamic behavior.

By taking advantage of the so-called

longitudinal eect, the piezoelectric

measuring elements arranged behind it

could be of extremely at design. Due

to the high thermal loading, the measur-

ing elements were made of particularly

temperature-resistant gallium phosphate

monocrystals. Tis material has already

been used in other combustion chamber

pressure sensors and thanks to its high

sensitivity enables a good signal-to-noise

ratio.

Summary

Te innovative measuring spark plugs set

a new standard in engine development

and quality control regarding signal

quality, ignition function and reliability.

Tey enable the implementation of fast,

reliable and highly accurate cylinder

pressure measurements without addi-

tional outlay.

Figure 2: Schematic layout consisting of the insulator top, piezo cable and insulator modules

together as well as the spark plug housing with integrated pressure measurement function.

2007 Piezocryst Advanced Sensorics GmbH

S-ar putea să vă placă și

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.De la EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Evaluare: 3 din 5 stele3/5 (4)

- Gasket FactorsDocument7 paginiGasket Factorsbalumagesh1979100% (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Chemical Engineering Facts at Your Fingertips 2009 and 2010Document39 paginiChemical Engineering Facts at Your Fingertips 2009 and 2010Trevor KanodeÎncă nu există evaluări

- UH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math ModelDocument361 paginiUH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math Modelmanitheaerialfighter100% (1)

- HiraDocument30 paginiHiravijay kumar singhÎncă nu există evaluări

- BPSK SimulinkDocument13 paginiBPSK SimulinkpootommyÎncă nu există evaluări

- Estimation Software For Presure VesselDocument36 paginiEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Solutions For Internal Arc Protection According To IEC 62271-200 in MV SwitchgearDocument5 paginiSolutions For Internal Arc Protection According To IEC 62271-200 in MV Switchgearkyawswarpm100% (1)

- Get More Life From HeatExchangers Sleeving of Tubes PDFDocument4 paginiGet More Life From HeatExchangers Sleeving of Tubes PDFalejandrogrande100% (1)

- Shijo.T.Daniel S5 Mechanical Roll No: 859 REG NO: 11020125Document28 paginiShijo.T.Daniel S5 Mechanical Roll No: 859 REG NO: 11020125sinasayedanaÎncă nu există evaluări

- Structured ProgrammingDocument31 paginiStructured ProgrammingkakaboomÎncă nu există evaluări

- Gestra: Condensate ManualDocument172 paginiGestra: Condensate ManualNavneet PandeyÎncă nu există evaluări

- Gestra Condensate ManualDocument172 paginiGestra Condensate ManualGeorge ClaessenÎncă nu există evaluări

- Topsoe High Flux Steam ReformDocument6 paginiTopsoe High Flux Steam ReformAnissa Nurul BadriyahÎncă nu există evaluări

- Select Expansion Joints ProperlyDocument4 paginiSelect Expansion Joints ProperlySeungmin Paek100% (2)

- Improved Power Plant PerformanceDocument3 paginiImproved Power Plant Performanceshams100% (1)

- Car Hacker'S Handbook Reversing The Can Bus Craig Smith @opengaragesDocument30 paginiCar Hacker'S Handbook Reversing The Can Bus Craig Smith @opengaragessinasayedana0% (1)

- Thermo WaveDocument127 paginiThermo WaveFernando Molina100% (2)

- City Gas Distribution Basics 1584287870 PDFDocument60 paginiCity Gas Distribution Basics 1584287870 PDFDeepak SharmaÎncă nu există evaluări

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe la EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesÎncă nu există evaluări

- Philips Aquatrio FC7070 - 01 Esploso ManualeDocument9 paginiPhilips Aquatrio FC7070 - 01 Esploso ManualeRocco Mangione0% (1)

- Stay CablesDocument22 paginiStay Cablesalex_g00dyÎncă nu există evaluări

- USC Steam Turbine TechnologyDocument17 paginiUSC Steam Turbine TechnologyteijarajÎncă nu există evaluări

- Applying Six Sigma at 3MDocument13 paginiApplying Six Sigma at 3MdchÎncă nu există evaluări

- Speed SensorDocument7 paginiSpeed SensorsinasayedanaÎncă nu există evaluări

- A Complete Analysis of Your Reformer-SynetixDocument9 paginiA Complete Analysis of Your Reformer-SynetixhendraokasÎncă nu există evaluări

- Flyer HSS Tubes Cranes OkDocument4 paginiFlyer HSS Tubes Cranes OkNoman Abu-FarhaÎncă nu există evaluări

- Istp 2015Document7 paginiIstp 2015HERDI SUTANTOÎncă nu există evaluări

- Renewable Energy: Gianluca Coccia, Giovanni Di Nicola, Marco SotteDocument10 paginiRenewable Energy: Gianluca Coccia, Giovanni Di Nicola, Marco Sotteanita galihÎncă nu există evaluări

- Heat Flux Thermocouple MCTDocument2 paginiHeat Flux Thermocouple MCTIziÎncă nu există evaluări

- Ultrasonic Inspection of Pipeline Split-TeesDocument8 paginiUltrasonic Inspection of Pipeline Split-TeesEhab SaadÎncă nu există evaluări

- FULLTEXT01Document8 paginiFULLTEXT01balamuruganÎncă nu există evaluări

- Hunik 2002Document9 paginiHunik 2002Hiwa KhalediÎncă nu există evaluări

- Strain Gauge Sensor PDFDocument12 paginiStrain Gauge Sensor PDFMario Eduardo Santos MartinsÎncă nu există evaluări

- For Review ISTP26 FudhailDocument7 paginiFor Review ISTP26 FudhailHERDI SUTANTOÎncă nu există evaluări

- 00643Document9 pagini00643Sunilkumar ReddyÎncă nu există evaluări

- For Review ISTP26 FudhailDocument7 paginiFor Review ISTP26 FudhailHERDI SUTANTOÎncă nu există evaluări

- Turbine Gas Meter Series iMTM-Q: Fit For Purpose, Fit For Future by InnovationDocument4 paginiTurbine Gas Meter Series iMTM-Q: Fit For Purpose, Fit For Future by InnovationaliÎncă nu există evaluări

- Plug Process Repair Heat Exchangers PDFDocument6 paginiPlug Process Repair Heat Exchangers PDFJOÃO CARLOS SILVAÎncă nu există evaluări

- Energies: CFD Analysis of Regenerative Chambers For Energy Efficiency Improvement in Glass Production PlantsDocument17 paginiEnergies: CFD Analysis of Regenerative Chambers For Energy Efficiency Improvement in Glass Production Plantspuyang48Încă nu există evaluări

- 3d Systems Fluid Flow Ebook Usen 2022 04 15 ADocument16 pagini3d Systems Fluid Flow Ebook Usen 2022 04 15 AOARIASCOÎncă nu există evaluări

- DB Cylinder Pressure Sensor enDocument2 paginiDB Cylinder Pressure Sensor enjulien17Încă nu există evaluări

- Design and Analysis of Engine FinsDocument6 paginiDesign and Analysis of Engine FinsAJAYÎncă nu există evaluări

- CIGRE 2012: 21, Rue D'artois, F-75008 PARISDocument6 paginiCIGRE 2012: 21, Rue D'artois, F-75008 PARISfgdfgdfÎncă nu există evaluări

- Strain GaugesDocument7 paginiStrain GaugesRoss Jay MichelÎncă nu există evaluări

- Medidores Tipo Diafragma SensusDocument12 paginiMedidores Tipo Diafragma SensusRogers Alberto Alvarez GuzmanÎncă nu există evaluări

- Novel Concepts For The Design of Moulds and Equipment For ExpandedDocument8 paginiNovel Concepts For The Design of Moulds and Equipment For ExpandedJOSE GÎncă nu există evaluări

- Topsoe High Flux Steam Reform - AshxDocument6 paginiTopsoe High Flux Steam Reform - AshxAgam HanasichulaÎncă nu există evaluări

- Enhancing The Heat-Transfer Co-Efficient by Using Taguchi Orthogonal ArrayDocument4 paginiEnhancing The Heat-Transfer Co-Efficient by Using Taguchi Orthogonal ArrayinventionjournalsÎncă nu există evaluări

- 2000 Spie - High Reliability Coolers Under Development at Signaal-UsfaDocument9 pagini2000 Spie - High Reliability Coolers Under Development at Signaal-UsfaM. Sadiq. A. PachapuriÎncă nu există evaluări

- Wall Heat Transfer in Gas-Fired Furnaces: Effect of Radiation ModellingDocument12 paginiWall Heat Transfer in Gas-Fired Furnaces: Effect of Radiation ModellingAmir AbbaszadehÎncă nu există evaluări

- SCHOTT Ptr70 Receiver BrochureDocument12 paginiSCHOTT Ptr70 Receiver Brochureiresa_nuratÎncă nu există evaluări

- Optimizing The Design of Splitter TowersDocument6 paginiOptimizing The Design of Splitter TowersZangÎncă nu există evaluări

- How Furnace Model Predictive Control Forecasts Transitions To Enhance Strip Quality and ProductivityDocument12 paginiHow Furnace Model Predictive Control Forecasts Transitions To Enhance Strip Quality and ProductivityJJÎncă nu există evaluări

- 6 Polley Compabloc FDocument5 pagini6 Polley Compabloc FarianaseriÎncă nu există evaluări

- superTube-Brochure Schwank EN-8Document8 paginisuperTube-Brochure Schwank EN-8tijeanlandry7267Încă nu există evaluări

- A NEW Micro-Four-Point Probe Design FOR Zhang, Dong-Nanotechnology Laboratory, SystemsDocument4 paginiA NEW Micro-Four-Point Probe Design FOR Zhang, Dong-Nanotechnology Laboratory, Systemsobalana tosinÎncă nu există evaluări

- DRESSER Turbine Meter Brochure 0712Document8 paginiDRESSER Turbine Meter Brochure 0712ggrapsasÎncă nu există evaluări

- Induction Bends in Material Grade X80Document0 paginiInduction Bends in Material Grade X80Nandhakumaran RajagopalanÎncă nu există evaluări

- GESTRA 20condensate 20manualDocument172 paginiGESTRA 20condensate 20manualjeevanmark100% (1)

- Modeling of Propane-Air Combustion in Meso-Scale Tubes With Wire MeshDocument7 paginiModeling of Propane-Air Combustion in Meso-Scale Tubes With Wire Meshherdi sutanto adigunaÎncă nu există evaluări

- BT3528882893 PDFDocument6 paginiBT3528882893 PDFshashank sharmaÎncă nu există evaluări

- Manufacturing Process Crucible FurnaceDocument6 paginiManufacturing Process Crucible FurnaceCristian MosqueraÎncă nu există evaluări

- GESTRA Condensate ManualDocument172 paginiGESTRA Condensate ManualChirag ShahÎncă nu există evaluări

- Energy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyDe la EverandEnergy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyChristine JuniorÎncă nu există evaluări

- Meraki Datasheet Auto RFDocument1 paginăMeraki Datasheet Auto RFsinasayedanaÎncă nu există evaluări

- Collapsed Radiator Hose ECT Sensors Import Insights: February 2015Document60 paginiCollapsed Radiator Hose ECT Sensors Import Insights: February 2015sinasayedanaÎncă nu există evaluări

- Siemens Turns Focus To Gasoline Injection: Automotive Is One of The Leaders in ThisDocument10 paginiSiemens Turns Focus To Gasoline Injection: Automotive Is One of The Leaders in ThissinasayedanaÎncă nu există evaluări

- CAN Bus Signal Monitoring Using The DL850V: Yokogawa Meters & Instruments CorporationDocument27 paginiCAN Bus Signal Monitoring Using The DL850V: Yokogawa Meters & Instruments CorporationsinasayedanaÎncă nu există evaluări

- Ubicaci N Can Bus7Document32 paginiUbicaci N Can Bus7masquimuchiÎncă nu există evaluări

- Cpre 458/558: Real-Time Systems: Controller Area NetworkDocument27 paginiCpre 458/558: Real-Time Systems: Controller Area NetworksinasayedanaÎncă nu există evaluări

- 1nzfe9Document11 pagini1nzfe9sinasayedanaÎncă nu există evaluări

- Judgment Basis Definitions: If Author Claims First Use of Technology, Is Claim Valid?Document2 paginiJudgment Basis Definitions: If Author Claims First Use of Technology, Is Claim Valid?sinasayedanaÎncă nu există evaluări

- Canbus 150328105928 Conversion Gate01Document45 paginiCanbus 150328105928 Conversion Gate01sinasayedanaÎncă nu există evaluări

- Car Talk Winter Driving Tips: 1. If Your Car Needs Regular Service, Get It Done Now. Nothing's A Big Deal in The SummerDocument6 paginiCar Talk Winter Driving Tips: 1. If Your Car Needs Regular Service, Get It Done Now. Nothing's A Big Deal in The SummersinasayedanaÎncă nu există evaluări

- 0280K00849 702 1Document16 pagini0280K00849 702 1sinasayedanaÎncă nu există evaluări

- BSR NH Circle Jaipur 2016Document103 paginiBSR NH Circle Jaipur 2016vikash kumar50% (4)

- Crankshaft Position (CKP) Sensor: 1F2-12 M161 Engine ControlsDocument6 paginiCrankshaft Position (CKP) Sensor: 1F2-12 M161 Engine ControlsKukuh SeptiantoÎncă nu există evaluări

- Klübersynth UH1 14-151: Product InformationDocument2 paginiKlübersynth UH1 14-151: Product InformationNathanael SuryantoroÎncă nu există evaluări

- CH 1: Materials Used in Pipework & Plumbing FittingsDocument10 paginiCH 1: Materials Used in Pipework & Plumbing FittingsEmad BassemÎncă nu există evaluări

- A9K CatalogueDocument152 paginiA9K CatalogueMohamed SaffiqÎncă nu există evaluări

- GWSSB Vendor List 19.11.2013Document18 paginiGWSSB Vendor List 19.11.2013sivesh_rathiÎncă nu există evaluări

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument15 paginiAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiÎncă nu există evaluări

- Biodegradability of SurfactantsDocument1 paginăBiodegradability of SurfactantsTinnysumardiÎncă nu există evaluări

- Selenium-75 Sources and Source Holders: ApplicationsDocument2 paginiSelenium-75 Sources and Source Holders: ApplicationsTanpreet SinghÎncă nu există evaluări

- Ultra Petronne Interior Supply Corp.: Manufacturer of Light Metal FramesDocument1 paginăUltra Petronne Interior Supply Corp.: Manufacturer of Light Metal Framesjun vincint geleraÎncă nu există evaluări

- Mech 3-Module 1Document41 paginiMech 3-Module 1melkisidick angloanÎncă nu există evaluări

- Distributed PowerDocument3 paginiDistributed PowertibvalÎncă nu există evaluări

- Behringer UB2222FX PRODocument5 paginiBehringer UB2222FX PROmtlcaqc97 mtlcaqc97Încă nu există evaluări

- KST GlueTech 44 enDocument80 paginiKST GlueTech 44 enLeandro RadamesÎncă nu există evaluări

- Face Consultants Limited: Concrete Society'S Technical Report: 4 EditionDocument14 paginiFace Consultants Limited: Concrete Society'S Technical Report: 4 EditionVincent_rko1Încă nu există evaluări

- HARGA REFERENSI B2S PapuaDocument6 paginiHARGA REFERENSI B2S PapuaAbiyoga AdhityaÎncă nu există evaluări

- Circuiting Explained-Water Coils PDFDocument2 paginiCircuiting Explained-Water Coils PDFFrancisÎncă nu există evaluări

- Published Document Guidance On The Use of BS EN 13108, Bituminous Mixtures - Material SpecificationsDocument8 paginiPublished Document Guidance On The Use of BS EN 13108, Bituminous Mixtures - Material SpecificationsCristián JiménezÎncă nu există evaluări

- SemDocument31 paginiSemkaushik4208Încă nu există evaluări

- Rational Suite ToolsDocument47 paginiRational Suite ToolsZatin GuptaÎncă nu există evaluări

- ProceedingsDocument656 paginiProceedingsgkgjÎncă nu există evaluări

- Lesson Plan 2 Road FurnitureDocument4 paginiLesson Plan 2 Road FurnitureShahbaz SharifÎncă nu există evaluări