Documente Academic

Documente Profesional

Documente Cultură

Altivar 08

Încărcat de

Marco Hinojosa PahuasiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Altivar 08

Încărcat de

Marco Hinojosa PahuasiDrepturi de autor:

Formate disponibile

English

W9 1623644 01 12 A03

200/240 V

50/60 Hz

Power terminals

AwG

mN

in.lbf

14

8.8

Control terminals

LI4 +15V

(1)

W1

V1

U1

60 mm

W

W1

50

V1

50

U1

50

+15

LI3

200/240 V - 50/60 Hz

LI4

LI2

"Factory setting" circuit diagram

L1

A0 COM LI1

Installation :

- device vertical, 10

- minimum clearance for

cooling :

50 mm around the controller

10 mm in front

A0

AI1

+5V

20

in.lbf

4.4

LI3

0.37 kW - 200 / 240 V

2.2K 1/2W

mN

0.5

LI2

Altivar 08

R1A R1C

1.5

AwG

16

+5

desconecte y espere 1 min.

mm2

Max. torque

LI1

. Avant toute intervention, couper la

puissance, attendre 1 mn.

. Before servicing remove all power,

wait 1 min.

. Vor Eingriff ist das Ger spannungslos zu machen, 1 min warten.

. Prima di intervenire togliere

l'alimentazione, attendere 1 min.

. Antes de intervenir en el variador,

AI1

Max. X-section

MODE

R1C

mm

2.5

Max. torque

COM

Te

1 - Mount the controller

2 - Connect according to the circuit diagram below :

single-phase supply (s - L1 - L2)

motor (U - V - W - s) ensuring that it is connected to a

200/240 V supply

control (1 or 2 operating directions via LI1 and/or LI2)

speed reference, via LI3/LI4 and/or via a potentiometer

on AI1

3 - Power up without giving a run signal

4 - Configure the motor nominal frequency bFr if it is other

than 50 Hz

5 - Adjust, if the factory setting is not suitable :

minimum LSP and maximum HSP speeds

acceleration ACC and deceleration dEC ramps

SP2 and SP3 speeds if necessary for 4 preset speeds

ItH motor thermal protection current

6 - Start : the speed is displayed in Hertz (Hz) for example, for a

3000 rpm / 50 Hz motor : 20 Hz = 1200 rpm

R1A

Max. X-section

Installation stages, "factory setting"

L2

ATV-08HM2

ATV-08HM2X

VVDED398035

Altivar 08

Telemecanique

5V

+

120 mm

Reference

potentiometer

Display frequency reference, if used

M

3

50

3xM4

(1) Fault relay contact, signals the state of the controller remotely (open when

fault present or powered off)

- LI1 : forward

- LI2 : reverse

- LI3/LI4 : 4 preset speeds :

1 = LSP + reference on AI1 (LI3 = 0, LI4 = 0)

2 = SP2 (LI3 = 1, LI4 = 0)

3 = SP3 (LI3 = 0, LI4 = 1)

4 = HSP (LI3 = 1, LI4 = 1)

Setup

I/O specifications

Use the

&

MODE

keys

Example :

bFr

ACC

MODE

{8

MODE

ACC

dEC

Level 1 parameters : normal use

Function

Unit

R1A/R1C : Relay contact

- Min. switching power : 10 mA for a 24 V

- Max. switching power on inductive load (cos 0.3 or L/R = 10 ms) :

2 A for c 250 V or a 30 V

+5 : 5 V, 10 mA max. supply for 2.2 k setpoint potentiometer

AI1 : Analogue input 0 + 5 V impedance 50 k (reconfigurable to 0 + 10 V

or, with 500 resistor in parallel 0/20 mA or 4/20 mA)

A0 : Open collector PWM type analogue output at 1.2 kHz, 10 mA max., output

impedance 1k

COM : 0V common for I/O

LI1, LI2, LI3, LI4 : Logic inputs. Impedance 5 k , 15 V internal supply (11 V to

15 V) or 24 V external supply (11 V to 30 V)

+15 : Supply for logic inputs : 15 V, 100 mA max.

Factory setting

rdY = Stopped : speed controller ready

4{5 = Operating : estimated rotational frequency

Hz

dCb = DC injection braking

bFr

ACC

dEC

LSP

HSP

SP2

SP3

ItH

L2A

= no

L2A

Motor frequency : 50 Hz/60 Hz

(or SPE by modifying Fr5)

Hz

50

Acceleration ramp time

Deceleration ramp time

Low speed

Hz

High speed

Hz

50

2nd preset speed

Hz

3rd preset speed

Hz

25

A

Thermal protection current (= motor rating plate)

ifItH is at max. : ntH (protection disabled) is displayed

Controller In

Access to level 2 parameters (no/YES)

no

L2A

Configuration can only be

modified with controller stopped

To level 2

Adjustment can be modified with

controller stopped or operating

Display

= YES

Level 2 parameters : function extensions

FrH

LCr

ULn

tHd

tHr

UnS

Fr5

to level 1

UFr

CrI

FLG

SLP

Level

1

LI

to level 1

Startup

Alt

Atr

FCS

IdC

tdC

LDC

Function

Unit

Factory setting

Display frequency setpoint

Hz

FrH

Display motor current

Display supply voltage

Display speed controller thermal state (nominal = 100 %, tripping at 118 %)

Display motor thermal state (nominal = 100 %, tripping at 118 %)

Not memorized after loss of supply

Nominal motor voltage (rating plate)

230

Motor rated frequency (to be modified if other than 50 or 60 Hz; 120 Hz max.)

Hz

= bFr

Minimum motor voltage at low frequency

20

IR compensation (adjust the stator resistance of the motor set by Ith)

20

Frequency loop gain. If FLG > 99, nFL (to disable this function may stall the motor when high torque is demanded) is displayed.

Machines with high resistant torque or with high inertia: progressively decreasz the gain from 33 to 0%.

Machines with fast cycles, low resistant torque or low inertia: progressively increase the gain from 33 to 99%.

Again which is set too high may cause instability.

Slip compensation

33

Hz

depends on rating

Configuration of logic inputs :

LI = 2C4 (2-wire control, 2 operating directions, 4 speeds) :

LI = 3C2 (3-wire control, 2 operating directions and 2 speeds) :

- LI1 = forward

- LI1 = stop

- LI2 = reverse

- LI2 = RUN forward - LI3 = RUN reverse

- LI3/LI4 = 4 speeds (1)

- LI4 = 2 speeds (LI4 to 0 : LSP + setpoint AI1,

LI = 3C4 (3-wire control, 1 operating direction and 4 speeds) :

LI4 to 1 : HSP)

- LI1 = stop

LI = 1C4 (2-wire control, 1 operating direction and 4 speeds) :

- LI2 = RUN forward

- LI1 = forward - LI2 = not assigned

- LI3/LI4 = 4 speeds (1)

- LI3/LI4 = 4 speeds (1)

Configuration of input AI1 :

Alt = 5U : 0-5 V (internal supply)

Alt = 0A : 0-20 mA

Alt = 10U : 0-10 V (external supply) Alt = 4A : 4-20 mA

2C4

5U

connect a resistor (500 - 0.25 W)

between terminals AI1 and COM

Automatic restart after fault (no/YES/USF). Function reserved for fans, pumps and conveyors.

If Atr = USF automatic restart is only available for UFS fault

no

Return to factory settings (no/YES)

no

Automatic injection braking current on stop

0.7 controller In

Automatic injection braking time on stop

if tdC = 0 : no braking

if tdC = 21 : Cnt (continuous braking on stop) is displayed

Locking of parameters (no/YES)

if YES : the parameters are visible but cannot be modified except for L2A and LDC

0.5

no

LDC

(1) 4 speeds via LI3/LI4 :

LSP + reference AI1 if LI3 = 0 and LI4 = 0

SP3 if LI3 = 0 and LI4 = 1

SP2 if LI3 = 1 and LI4 = 0

HSP if LI3 = 1 and LI4 = 1

Configuration can only be modified

with controller stopped

Display

Adjustment can be modified with

controller stopped or operating

Diagnostic

Unshielded supply cable

Display

Fault

Remedy

No fault

displayed

Motor doesn't run

although run

command and

speed reference

are OK

After powered-up the drive, the motor runs only

if run commands have been set to zero. If

automatic restart function is enabled (level 2

parameter: Atr), these commands are taken

into account without to be reset before.

When LI = 1C4 or 2C4, set Atr = YES (or USF)

Overvoltage

Change the supply voltage and ensure it is

stable

Undervoltage

Change the supply voltage and ensure it is

stable

Increase the ACC or dEC ramp time

Check the sizing of the motor and of the

speed controller

OSF

Te

USF

OCF

MODE

Motor short-circuit

Check the controller output circuit

(isolation or short-circuit fault)

Internal fault

Switch off.

Try to return to the factory setting (FCS)

If this is unsuccessful, replace the speed

controller

ObF

Overvoltage

on braking

Increase the deceleration ramp time

EMC flange, to be ordered

separately : VW3-A08831

to be fitted to the controller

OHF

Speed controller

overheating

Check the motor load, the ventilation of the

speed controller and the ambient temperature.

Allow to cool before restarting

Lug for

PE conductor

OLF

Motor overload

Check the motor load and the adjustment of

parameter ltH.

Allow to cool before restarting

SCF

Altivar 08

R1A R1C

Metallic

clamps

InF

0.37 kW - 200 / 240 V

2.2K 1/2W

+5V

Unshielded cable

(relay contact)

Overcurrent

AI1

A0 COM LI1

LI2

LI3

LI4 +15V

Switch the speed controller off before restarting

Shielded control cable

Shielded motor cable

- For standard EN55011 class A :

If the speed controller is fixed to machine ground wiring the VW3-A08831

flange is not required, fix the metallic clamps to the machine ground wiring to

connect the shielding.

Automatic restart after the drive trips and coasts to stop, if fault has

disappeared andd if Atr = YES (and Atr = USF, for USF

fault ONLY).

In case of fault is still present, after 6 attempts of resetting in less than

6 minutes, the 6th attempt will stop the drive in freewheel, and fault

code display will flash.

The fault has to be reset by cycling power on the drive.

S-ar putea să vă placă și

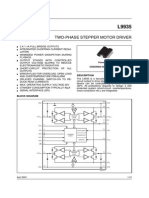

- Two-Phase Stepper Motor Driver: DescriptionDocument19 paginiTwo-Phase Stepper Motor Driver: DescriptionDan EsentherÎncă nu există evaluări

- 3000W Single Output Power Supply: SeriesDocument7 pagini3000W Single Output Power Supply: SeriesAlexander PekarovskiyÎncă nu există evaluări

- Overcurrent Protection Relay FeaturesDocument47 paginiOvercurrent Protection Relay FeaturesmaheshÎncă nu există evaluări

- LTC 7138Document24 paginiLTC 7138MallickarjunaÎncă nu există evaluări

- TB6560 - T4 - V4 4 Axis CNC Dirver Manual and TB6560-T4-V3 4 Axis CNC Dirver Manual 20110510Document16 paginiTB6560 - T4 - V4 4 Axis CNC Dirver Manual and TB6560-T4-V3 4 Axis CNC Dirver Manual 20110510Ersin CelebiÎncă nu există evaluări

- Boost Controller With Power Factor CorrectionDocument14 paginiBoost Controller With Power Factor CorrectionChiseledPrawnÎncă nu există evaluări

- Stepper Motor Controllers: DescriptionDocument12 paginiStepper Motor Controllers: DescriptionGigi TyireanÎncă nu există evaluări

- 3000W Single Output Power Supply Spec SheetDocument6 pagini3000W Single Output Power Supply Spec SheetGrigoriu CodrutaÎncă nu există evaluări

- G1R400 3Document1 paginăG1R400 3epicenterrulezÎncă nu există evaluări

- Voltage Regulator For Generators: Instruction ManualDocument48 paginiVoltage Regulator For Generators: Instruction ManualvjÎncă nu există evaluări

- LM2585Document32 paginiLM2585Anonymous uBxUcNd58Încă nu există evaluări

- Ltc1871ems (LTSX, Frntoluz Welch Allyn)Document36 paginiLtc1871ems (LTSX, Frntoluz Welch Allyn)RICHIHOTS2Încă nu există evaluări

- Ha 13563Document18 paginiHa 13563Danh ProÎncă nu există evaluări

- Lm2596 Simple Switcher Power Converter 150 KHZ 3A Step-Down Voltage RegulatorDocument29 paginiLm2596 Simple Switcher Power Converter 150 KHZ 3A Step-Down Voltage RegulatorJuliano GriguloÎncă nu există evaluări

- 1fázisú Frekvenciaváltó, 3fázisú Frekvenciaváltó, Inverter Katalógus KatalógusDocument10 pagini1fázisú Frekvenciaváltó, 3fázisú Frekvenciaváltó, Inverter Katalógus Katalóguses64u4Încă nu există evaluări

- Variador User HandyDocument6 paginiVariador User HandyDavid S. Valenzuela Portillo100% (2)

- IC-ON-LINE - CN sm34063 3672826Document8 paginiIC-ON-LINE - CN sm34063 3672826Anonymous KuTQvYTuÎncă nu există evaluări

- DeviceCraftDCmotorController 1015BDocument24 paginiDeviceCraftDCmotorController 1015BbetortitaÎncă nu există evaluări

- LM3478 High Efficiency Low-Side N-Channel Controller For Switching RegulatorDocument22 paginiLM3478 High Efficiency Low-Side N-Channel Controller For Switching RegulatorVinoth Kumar RajendranÎncă nu există evaluări

- M542Document3 paginiM542xhaneriÎncă nu există evaluări

- A3953 DatasheetDocument12 paginiA3953 DatasheetMohan RajÎncă nu există evaluări

- Altivar 71 Quick Reference Guide - en - T8843pd0601ep r0Document2 paginiAltivar 71 Quick Reference Guide - en - T8843pd0601ep r0محمد دانشÎncă nu există evaluări

- Receptor Satélite Fortecstar Lifetime UltraDocument28 paginiReceptor Satélite Fortecstar Lifetime UltraHugo Roberto RibeiroÎncă nu există evaluări

- Variflex2 RVEF - Datasheet - EnGDocument8 paginiVariflex2 RVEF - Datasheet - EnGPepe ChampiiÎncă nu există evaluări

- 25 A 20Document9 pagini25 A 20s_barriosÎncă nu există evaluări

- MEH449 - Application GuideDocument12 paginiMEH449 - Application GuideChintan AcharyaÎncă nu există evaluări

- LM5020 100V Current Mode PWM Controller: General Description FeaturesDocument13 paginiLM5020 100V Current Mode PWM Controller: General Description FeaturesAlonso CoradoÎncă nu există evaluări

- AN7554Document22 paginiAN7554Corban MihaiÎncă nu există evaluări

- L9235F - Car Alternator Voltage RegulatorDocument11 paginiL9235F - Car Alternator Voltage Regulatorlongtrandang5867Încă nu există evaluări

- LM2596S ADJ Power Converter RegulatorDocument31 paginiLM2596S ADJ Power Converter RegulatorCadet RaparivoÎncă nu există evaluări

- Lock Out Relay PDFDocument10 paginiLock Out Relay PDFshaikhsajid242Încă nu există evaluări

- Alternator Regulator With LIN: Advance InformationDocument31 paginiAlternator Regulator With LIN: Advance InformationDario Gomez100% (1)

- Carlo Gavazzi Level RelayDocument5 paginiCarlo Gavazzi Level RelayPeter CalvoÎncă nu există evaluări

- 150Khz, 3A PWM Buck DC/DC Converter Features General DescriptionDocument12 pagini150Khz, 3A PWM Buck DC/DC Converter Features General Descriptionpaulmx13Încă nu există evaluări

- Telemecanique Altivar 16 ATV16U72N4Document33 paginiTelemecanique Altivar 16 ATV16U72N4Tezontepec De Aldama HidalgoÎncă nu există evaluări

- BM2596Document9 paginiBM2596Anton AdrianÎncă nu există evaluări

- APW7159ADocument23 paginiAPW7159AVoicu AdrianÎncă nu există evaluări

- LM 297Document12 paginiLM 297Monika JhaÎncă nu există evaluări

- Mach Cong Suat Cau H - Lmd18200Document14 paginiMach Cong Suat Cau H - Lmd18200hieuhuech1Încă nu există evaluări

- F2-08SIM Input Simulator D2-08NA-1 AC InputDocument10 paginiF2-08SIM Input Simulator D2-08NA-1 AC InputVladimir Aliro Quezada CidÎncă nu există evaluări

- Single Ended Active Clamp/Reset PWM: Features DescriptionDocument16 paginiSingle Ended Active Clamp/Reset PWM: Features Descriptioncatsoithahuong84Încă nu există evaluări

- Fan 7314Document14 paginiFan 7314Kamal NonekÎncă nu există evaluări

- Come Disc Excitation SystemDocument33 paginiCome Disc Excitation Systemkra_amÎncă nu există evaluări

- p632 Testing Procedure of Tranformer Diffrential Protection PDFDocument14 paginip632 Testing Procedure of Tranformer Diffrential Protection PDFJawad AmjadÎncă nu există evaluări

- Furnace Micro Controller 2438 Operational - Manual PDFDocument21 paginiFurnace Micro Controller 2438 Operational - Manual PDFjaidev dewanganÎncă nu există evaluări

- LM2596 LM2596 SIMPLE SWITCHER Power Converter 150 kHz3A Step-Down Voltage RegulatorDocument33 paginiLM2596 LM2596 SIMPLE SWITCHER Power Converter 150 kHz3A Step-Down Voltage RegulatorFremont Navarro GottliebÎncă nu există evaluări

- A4954 DatasheetDocument9 paginiA4954 DatasheetAngly1959Încă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Exercises in Electronics: Operational Amplifier CircuitsDe la EverandExercises in Electronics: Operational Amplifier CircuitsEvaluare: 3 din 5 stele3/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Analog Circuit Design Volume Three: Design Note CollectionDe la EverandAnalog Circuit Design Volume Three: Design Note CollectionEvaluare: 3 din 5 stele3/5 (2)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe la EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsEvaluare: 3.5 din 5 stele3.5/5 (6)

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1De la EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Evaluare: 4.5 din 5 stele4.5/5 (3)

- 110 Waveform Generator Projects for the Home ConstructorDe la Everand110 Waveform Generator Projects for the Home ConstructorEvaluare: 4 din 5 stele4/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlDe la EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlEvaluare: 5 din 5 stele5/5 (1)

- DS DL05 06 PLC PDFDocument102 paginiDS DL05 06 PLC PDFwahyu yuliantoÎncă nu există evaluări

- Guide About Tcpip Connections Between Pcs and Siemens PlcsDocument11 paginiGuide About Tcpip Connections Between Pcs and Siemens Plcsnathan_allgrenÎncă nu există evaluări

- ConfigurationExample x7 V11d2 SinamicsV60 enDocument40 paginiConfigurationExample x7 V11d2 SinamicsV60 enAnonymous YfCPPhri8lÎncă nu există evaluări

- Contadores Rapidos Siemens S7-1200Document24 paginiContadores Rapidos Siemens S7-1200mauro100% (1)

- CQM1Document541 paginiCQM1humbertocanales_chÎncă nu există evaluări

- infoPLC Net 109759822 GRAPH TIAPortal V15 V1.0 en PDFDocument42 paginiinfoPLC Net 109759822 GRAPH TIAPortal V15 V1.0 en PDFCristian LleraÎncă nu există evaluări

- Manejo de Recetas en s7-1200Document45 paginiManejo de Recetas en s7-1200John Freddy Monroy JaimesÎncă nu există evaluări

- S7-1200 HMI Time Sync HowTo e PDFDocument18 paginiS7-1200 HMI Time Sync HowTo e PDFRoberto Matheus JuniorÎncă nu există evaluări

- PidTemp MultiZone DOC V10 enDocument62 paginiPidTemp MultiZone DOC V10 enDzinh TuongÎncă nu există evaluări

- Quality Assurance Through Weighing, Controlling and Logging (Set 6)Document56 paginiQuality Assurance Through Weighing, Controlling and Logging (Set 6)LÊ Hải NAMÎncă nu există evaluări

- S7 1200 SMS DOC V13 enDocument78 paginiS7 1200 SMS DOC V13 enLuiyi Lazcano MontalvoÎncă nu există evaluări

- Process Data Acquisition and Monitoring: SIMATIC S7-1200 FW V4.2, STEP 7 V15.1 (TIA Portal)Document55 paginiProcess Data Acquisition and Monitoring: SIMATIC S7-1200 FW V4.2, STEP 7 V15.1 (TIA Portal)Samir SabicÎncă nu există evaluări

- Siemens S71200-1500Document126 paginiSiemens S71200-1500justinÎncă nu există evaluări

- Connecting A S7-1500 To A SQL DatabaseDocument27 paginiConnecting A S7-1500 To A SQL DatabaseGlauco SantiagoÎncă nu există evaluări

- Replace FB LGF - Timerswitch: Step 7 (Tia Portal)Document3 paginiReplace FB LGF - Timerswitch: Step 7 (Tia Portal)Marco Hinojosa PahuasiÎncă nu există evaluări

- Color Television Chassis: Block Diagrams, Test Point Overview, and Waveforms Circuit Diagrams and PWB LayoutsDocument34 paginiColor Television Chassis: Block Diagrams, Test Point Overview, and Waveforms Circuit Diagrams and PWB Layoutsochacino22Încă nu există evaluări

- Moving PTO Positioning Axes of An S7-1200 As IO Device Centrally From An IO ControllerDocument30 paginiMoving PTO Positioning Axes of An S7-1200 As IO Device Centrally From An IO ControllerMarco Hinojosa PahuasiÎncă nu există evaluări

- InfoPLC Net Tiatips by Mister Automation enDocument84 paginiInfoPLC Net Tiatips by Mister Automation enMarco Hinojosa PahuasiÎncă nu există evaluări

- A5E31238908A-02 SIWAREX WP231 GHB en en-USDocument182 paginiA5E31238908A-02 SIWAREX WP231 GHB en en-USKingkataKA AutomationÎncă nu există evaluări

- Installation Guide for lemonPOS POS SoftwareDocument4 paginiInstallation Guide for lemonPOS POS SoftwareHenry HubÎncă nu există evaluări

- EM24DINDSDocument14 paginiEM24DINDSJavaprima Dinamika AbadiÎncă nu există evaluări

- A Cranial Approach To Sinus Congestion: By, Nathan Widboom D.ODocument31 paginiA Cranial Approach To Sinus Congestion: By, Nathan Widboom D.ONancyÎncă nu există evaluări

- Hocketts Features of Human Language Zed and JasDocument41 paginiHocketts Features of Human Language Zed and JasRechelle Marmol100% (1)

- Chapter 7, 8, 9Document11 paginiChapter 7, 8, 9Rubilyn IbarretaÎncă nu există evaluări

- Trainee Accountant Job DescriptionDocument5 paginiTrainee Accountant Job DescriptionNelly PilcoÎncă nu există evaluări

- 5 Nighttime Image Enhancement Using A NewDocument7 pagini5 Nighttime Image Enhancement Using A NewNithish CenaÎncă nu există evaluări

- Manual For Master Researchpproposal - ThesisDocument54 paginiManual For Master Researchpproposal - ThesisTewfic Seid100% (3)

- A Psychologist Explains Why Everyone Is Suddenly On TiktokDocument3 paginiA Psychologist Explains Why Everyone Is Suddenly On TiktokImen ImenÎncă nu există evaluări

- Project Proposal ApprovedDocument2 paginiProject Proposal ApprovedRonnel BechaydaÎncă nu există evaluări

- Manual Cisco - DPC3925Document106 paginiManual Cisco - DPC3925HábnerTeixeiraCostaÎncă nu există evaluări

- Application Sheet: Series CW SeriesDocument2 paginiApplication Sheet: Series CW SerieskamalÎncă nu există evaluări

- I-Plan Marketing List On Installments 11-Aug-23Document10 paginiI-Plan Marketing List On Installments 11-Aug-23HuxaifaÎncă nu există evaluări

- Lembar Kerja Lap Keu - Tahap 1Document4 paginiLembar Kerja Lap Keu - Tahap 1Safana AuraÎncă nu există evaluări

- Attaei PDFDocument83 paginiAttaei PDFHandsomē KumarÎncă nu există evaluări

- Environment Health: European Research OnDocument73 paginiEnvironment Health: European Research OnDaiuk.DakÎncă nu există evaluări

- Saturn Engine Compression Test GuideDocument7 paginiSaturn Engine Compression Test GuideManuel IzquierdoÎncă nu există evaluări

- 04 Vendor Registration TrainingDocument16 pagini04 Vendor Registration TrainingAhmad Ramin AbasyÎncă nu există evaluări

- Sujit Kumar Rout, Rupashree Ragini Sahoo, Soumya Ranjan Satapathy, Barada Prasad SethyDocument7 paginiSujit Kumar Rout, Rupashree Ragini Sahoo, Soumya Ranjan Satapathy, Barada Prasad SethyPrabu ThannasiÎncă nu există evaluări

- Medical ParasitologyDocument33 paginiMedical ParasitologyAlexander Luie Jhames SaritaÎncă nu există evaluări

- Final VeganDocument11 paginiFinal Veganapi-314696134Încă nu există evaluări

- Komatsu PC01-1 (JPN) 14001-Up Shop ManualDocument217 paginiKomatsu PC01-1 (JPN) 14001-Up Shop Manualhaimay118100% (2)

- Gen-6000-0mh0/0mhe Gen-6000-0mk0 Gen-6000-0ms0/0mse Gen-7500-0mh0/0mhe Gen-8000-0mk0/0mke Gen-8000-0ms0/0mseDocument26 paginiGen-6000-0mh0/0mhe Gen-6000-0mk0 Gen-6000-0ms0/0mse Gen-7500-0mh0/0mhe Gen-8000-0mk0/0mke Gen-8000-0ms0/0mseAhmed Khodja KarimÎncă nu există evaluări

- Chapter 2 (Teacher)Document19 paginiChapter 2 (Teacher)ajakazÎncă nu există evaluări

- Iso 9117-3 2010Document10 paginiIso 9117-3 2010havalÎncă nu există evaluări

- Toyota-HiAce 2011 EN Manual de Taller Diagrama Electrico 4fdf088312Document4 paginiToyota-HiAce 2011 EN Manual de Taller Diagrama Electrico 4fdf088312Oscarito VázquezÎncă nu există evaluări

- Unit 6 ( CONSTRUCTION OF THE FLEXIBLE PAVEMENT )Document19 paginiUnit 6 ( CONSTRUCTION OF THE FLEXIBLE PAVEMENT )Zara Nabilah87% (15)

- Procurement of Railway Infrastructure Projects - ADocument15 paginiProcurement of Railway Infrastructure Projects - ADan NanyumbaÎncă nu există evaluări

- VPN Risk Report Cybersecurity InsidersDocument20 paginiVPN Risk Report Cybersecurity InsidersMaria PerezÎncă nu există evaluări