Documente Academic

Documente Profesional

Documente Cultură

Earth Mat Design For HV and Ehv Substation

Încărcat de

Raja RamachandranTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Earth Mat Design For HV and Ehv Substation

Încărcat de

Raja RamachandranDrepturi de autor:

Formate disponibile

EARTHING MAT DESIGN FOR HV & EHV SUBSTATIONS

1. INTRODUCTION

Earthing is essential wherever electricity is generated, transmitted and distributed

or user, to ensure safety and proper operation of the electrical system. It is well that the

earthing systems are intended to protect equipment and personnel in and around the

substation from the dangerous over voltage. An effective earthing system depends on

various factors like resistivity of surface layer of soil, duration and magnitude of fault

current, maximum safe current that a human body can tolerate and the permissible earth

potential rise that may take place due to fault current. Earthing in a substation effective

means to obtain and maintain low resistance value for providing easy path for flow of

fault currents and unbalance current flow through neutral. Design of proper equipment

for electrical substation grounding is important from the safety consideration of

personnel and equipment.

or the actual design of earth mat for a !" # E!" $ub%stations, a few numbers

of complicated formulae are involved. or arriving at step potential and touch potential to

be well within the safe limit for the given soil condition, area of the substations, fault

current and duration of fault current. An optimum design of earth mat can be arrived at

only by trial and error method repeating the calculation many numbers of times.

2. PURPOSE OF SUB-STATION EARTHING SYSTEM

&he ob'ect of an earthing system in a sub%station is to provide under and around the

sub%station a surface which shall be at a uniform potential and near (ero or absolute

earth potential as possible. &he provision of such a surface of uniform potential under

and around the sub%station ensures that no human being in the sub%station is sub'ect to

shock or in'ury on the occurrence of a short circuit or development of other abnormal

conditions in the equipment installed in the yard. &he primary requirements of a good

earthing system in sub%stations are)

a. It should stabili(e circuit potentials with respect to ground and limit the overall

potential rise.

b. It should protect life and property from over%voltage

c. It should provide low impedance path to fault currents to ensure prompt and

consistent operation of protective devices during ground faults.

- 1 -

d. It should keep the maximum voltage gradient long the surface inside and around

the sub%station within safe limits during ground faults.

3. EARTHING SYSTEM

*.+ &he earthing system meeting the above requirements comprises an earthing mat

buried hori(ontally at a depth of about half%a metre below the surface of the ground

and ground rods at suitable points. All the non%current carrying parts of the

electrical equipment in sub%station are connected to the earthing mat. ,nder the

normal conditions, the ground rods contribute little towards lowering the ground

resistance. !owever, these are helpful in lowering mesh potential and maintaining

low values of resistance under all weather conditions.

*.- &he earth mat is connected to the following in a sub%station)

a. &he neutral point of each system through its own independent earth.

b. Equipment framework and other non%current carrying parts.

c. All extraneous metallic frameworks not associated with equipment.

d. &he earth point of .ightning Arreasters, /apacitive "oltage &ransformers,

/oupling /apacitors and the lightning down conductors in the sub%station

through their permanent independent earth electrode.

e. $ub%station fence.

*.* &he earthing system installation shall strictly comply with the requirements of latest

edition of Indian Electricity 0ules, relevant Indian $tandards and Applicable /odes of

1ractices.

4. PARAMETERS AFFFECTIVE THE DESIGN OF EARTHING MAT

$everal variable factors are involved in the design of earthing mat conductor.

&herefore, earthing mat for each sub%station has to be designated individually usually.

&he earthing mat has to be designated for the site conditions to have low overall

impedance and a current carrying capacity consistent with the fault current magnitude.

&he parameters listed below influence the design of earthing mat)

a. 2agnitude of fault current

b. Duration of fault

c. $oil resistivity

d. 0esistivity of surface material

e. $hock duration

- 2 -

f. 2aterial of earthing mat conductor and

g. Earthing mat geometry

5. DESIGN PROCEDURE:

&he following steps are involved in the design of earthing mat)

a. &he sub%station layout plan should be finali(ed before the design of earthing mat

is taken up. rom the proposed layout of the sub%station, determine the area to

be covered by the earthing mat.

b. Determine the soil resistivity at the sub%station site. &he resistivity of the earth

varies within extremely wide limits, between + and +3,333 ohmmeters. &he

resistivity of the soil at many station sites has been found to be non%uniform.

"ariation of the resistivity of the soil when depth is more predominant as

compared to the variation with hori(ontal distances. 4ide variation of resistivity

with depth is due to stratification of earth layers. In some sites, the resistivity

variation may be gradual, where stratification is not abrupt. A highly refined

technique for the determination of resistivity of homogeneous soil is available. &o

design the most economical and technically sound grounding system for large

stations, it is necessary to obtain accurate data on the soil resistivity and on its

variation at the station site. 0esistivity measurements at the site will reveal

whether the soil is homogeneous or non%uniform. In case the soil is found

uniform, conventional methods are applicable for the computation of earth

resistivity. 4hen the soil is found non%uniform, either a gradual variation or a

two%layer model may be adopted for the computation of earth resisivity.

&he resistivity of earth varies over a wide range depending on its moisture

content. It is therefore, advisable to conduct earth resistivity tests during the dry season

in order to get conservative results.

6.MEARUREMENT OF EARTH RESISTIVITY:

6.1Te! "#$%!&#':

In the evaluation of earth resistivity for sub%station and generating stations,

atleast eight test directions shall be chosen from the center of the station to cover the

whole site. &his number shall be increased for very large station sites.

6.2P(&'$&)*e Te!:

- 3 -

4enner5s four%electrode method is recommended for these types of field

investigations. In this method, four electrodes are driven into the earth along a straight

line at equal intervals. A current is passed through the two outer electrodes and the

earth as shown in igure + and the voltage difference ", observed between the two inner

electrodes. &he current flowing into the earth produces an electric field proportional to

its density and to the resistivity of the soil. &he voltage " measured between the inner

electrodes is therefore proportional to the field. /onsequently, the resistivity will be

proportional to the ratio of the voltage to current i.e. 0. &he following equation holds for)

6$70

p 8 %%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% ..9 :+;

-$ $

+ < %%%%%%%%%%%%%%% % %%%%%%%%%%%%%%%

=$

-

< =6e

-

=$

-

< =e

-

4here

p 8 0esistivity of soil in ohm%metre

$ 8 Distance between two successive electrodes in metres

0 8 0atio of voltage to current or electrode resistance in ohms

E 8 Depth of burial of electrode in meters

If the depth of burial of the electrodes in the ground is negligible compared to the

spacing between the electrodes, then

p 8 -7$0 .9. :-;

6.3Te! P(#$e+,(e:

At the selected test site, in the chosen direction, four electrodes are driven into

the earth along a straight line at equal intervals, $. the depth of the electrode in the

ground shall be of the order of +3 to +> cm. &he megger is placed on a steady and

approximately level base, the link between terminals 1+ and /+ opened and the four

electrodes connected to the instrument terminals as shown in igure +. An appropriate

range on the instrument is thus selected to obtain clear readings avoiding the two ends

of the scale as far as possible. &he readings are taken while turning the crank at about

+*> rev ? min. 0esistivity is calculated by substituting the value of 0 thus obtained in the

Equation :-;. In case where depth of burial is more than +?-3

th

of spacing, Equation :+;

should be used instead of :-;.

- 4 -

-.De!e(.&'e !/e M%0&.,. G(#,'+ F%,*! C,((e'!:

ault current at the sub%station is determined from the system studies. A

correction factor is applied to the fault current thus determined to take care of the future

growth of the system. "alue of this correction factor is usually of the order of +.- to +.>.

!owever, in practice 63@A for 633 k" system and *+.>@A for --3?+*- k" systems are

generally adopted for design purpose.

-.1 D,(%!&#' #1 F%,*!:

or the design of earth mat, the practices regarding assumption of duration of

fault differ from country to country. &hus in the ,$$0, the duration of fault is assumed

as 3.- second. In the ,$A, it is assumed as 6.3 seconds, which is equal to the duration

on which the short time rating of the switchgear is based. In India, the short time rating

of most of the equipment is based on +.3%second duration of fault. &herefore, +.3

second may be adopted as the duration of fault in the calculations to determine the si(e

of conductor for earthing mat. or the purpose of determining the safe step and mesh

- 5 -

potentials duration of 3.> second may be adopted. !owever, it may be ensured on the

basis of the protective gear and protective schemes provided in each case that fault is

cleared in the period not exceeding of 3.> seconds. 4here the fault clearing time

exceeds 3.> seconds, this duration may be taken equal to fault cleaning time.

2.De!e(.&'e !/e &3e #1 $#'+,$!#( 1#( e%(!/ .%!:

$i(e of conductor based on thermal stability) &he si(e of conductor for earthing

mat based on thermal stability is determined with help of approximate formula as per

IEEE A3%+BAC given below)

or welded 'oints A8+-.*3 DIsq.mm, for bolted 'oints A 8 +>.+* DI sq.mmm.

4here A 8 area of conductor

I 8 rms value of fault current in @A.

Assuming duration of fault current as +.3 sec.

4.Me$/%'&$%* R,55e+'e #1 C#'+,$!#(:

rom the consideration of mechanical ruggedness, and easy installation. &he

maximum width to thickness ratio of steel flats for ground mat conductor should be E.>

such that thickness of the flat is not less than * mm. Fround mat conductor comprising

steel rod having a diameter not less than > mm. &he standard si(es of conductor as per

I$) +E*3 G +BAB are as follows)

a.

+3 x C mm

-

b.

*3 x C mm

-

c.

>3 x C mm

-

d.

>3 x A mm

-

e.

E> x +- mm

-

f.

-3 x C mm

-

g.

63 x C mm

-

h.

C3 x C mm

-

i.

C> x A mm

-

4.1C#((#&#':

Hn average steel corrodes about six times as fast as copper when placed in soil. &he

extent of corrosion depends upon the properties of soil. 2any times, soil has conflicting

properties, some of which indicate that the soil is corrosive and other indicates the

opposites. Despite this, a very fair degree of correlation has been found between

electrical resistivity of soil and corrosion.

- 6 -

16.De!e(.&'e !/e M%0&.,. G(&+ C,((e'!:

&he design value of the maximum grid current :IF; is given by the following equation)

IF 8 /1DIg

4here Ig 8 2aximum grid current in Amperes

D 8 Decrement factor for the entire duration of fault

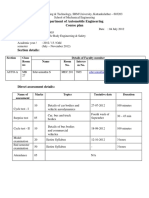

&ypical values of D are given in the following table.

F%,*! D,(%!&#' 7S8 De$(e.e'! F%$!#( DF

3.33A +.C>

3.+ +.->

3.-> +.+3

3.> or more +.3

/1 ) /orrective pro'ection factor for the relative increase of fault currents during the

station life span. or (ero future growth of the system, /1 8 +.

Ig) $f:*Io;

4here

*Io) rms. "alue of the symmetrical ground fault current in Ampere

$f ) /urrent division factor relating to the magnitude of fault current to that of its

portion flowing between the earthing mat and surrounding earth.

S1 & +e)e'+e'! #' !/e 1#**#9&'5 )%(%.e!e(:

a. .ocation of fault

b. 2agnitude of station earthing mat resistance

c. Iuried pipes and cables in the vicinity of or directly connected, or both, to the

station earthing system.

d. Hverhead ground wires or neutral conductors.

In the absence of full details regarding exact system configuration of which the

substation form a part, at the design stage, it will be fairly accurate to adopt a value of

3.> for $f to determine the fault current that flows through the grid to remote earth.

16.1 Re&!&:&!; #1 S,(1%$e "%;e( 7

8:

/rushed rock is used as a surface layer in substations for the following reasons)

a. It provides high resistivity surface layer

b. It serves as impediment to the movement of reptiles and thereby helps in

minimi(ing the ha(ards, which can be used by them.

- 7 -

c. It prevents the formation of pools of oil in the event of leakage of oil from oil

insulated and oil cooled electrical equipment.

d. It discourages the growth of weeds

e. It helps retention of moisture in the underlying soil and thus helps in maintaining

the resistivity of sub%soil at lower value.

f. It discourages running of persons in the substations and saves them from the risk

of being sub'ected to possible high step potentials.

In tropical countries like India, where the population of reptiles is large, it is

advantageous to surround the electrical equipment and the structures supporting

conductors by a surface layer of about +3cm of crushed rock up to a distance of about

two meters in all directions. $uch surface layer around the metallic equipment and

structures, besides minimi(ing the ha(ards caused by reptiles, provides a high resistivity

layer below the feet of human beings approaching the equipment ? structures and

enables them to withstand higher touch potentials. If step potential without crushed rock

is well within safe limits, it is not necessary to spread crushed rock over the complete

substation area. !owever, if it exceeds the safe limits crushed rock of +> to -3mm si(e

may be spread to cover the earth in the entire substation area.

If the type of rock to be used is known the lower value of resistivity for that type of rock

may be adopted in the design. Htherwise, in conformity with the design practices

followed by most of the electric utilities, an average resistivity value of *,333 Hhm%metre

may be adopted for the purpose of earthing mat design.

11.De!e(.&'e !/e !#*e(%<*e !#,$/ %'+ !e) )#!e'!&%*

&he values of these potentials depend on the body weights, thickness and

resistivity of surface layer and duration of shock current.

A preliminary earth mat arrangement is developed on the basis of an assumed

spacing between two parallel conductors. In this arrangement a continuous conductor

should be assumed as surrounding the substation and the conductor within it should be

located at reasonably uniform spacing parallel to each other along the rows of the

structures, equipments etc. rom the arrangement so arrived at the number of parallel

and cross conductors and the total length of conductor constituting the earth mat are

determined for use in the further design calculations.

&he values of the expected maximum mesh and step potentials are calculated

with the help of the following formulae.

Etouch 8 :+333 <+.> /g :hg@;g; 3.++C?ts

- 8 -

Estep 8 :+333 <C/g :hg@;g; 3.++C?ts

4here,

/g 8+ for crushed rock resistivity equal to that of soil resistivity. If crushed rock

resistivity does not equal to soil, reference may be made in figure.- for obtaining the

value of /g

@ 8 %g? <g

g 8 0esistivity of surface layer in ohm G metre

8 0esistivity of soil in ohm G metre

ts 8 Duration of shock current flow in seconds

hg 8 $urface layer thickness in metre

/g 8 reduction factor for derating the normal value of surface layer resistivity determined

as follows. /g 8+ for crushed stone resistivity equal to soil resistivity

h 8 depth of earth mat conductor in metres

d 8 diameter of earth mat conductor in metres

Em 8 @m @i Ig ? . "olts

@i 8 /orrective factor which accounts for the increase in current density in the grid

extremities

8 3.C>C < 3.+E- n

Ig 8 2aximum grid current in Amperes.

@m 8 +?- JIn KD

-

?+Chd < :d<-h;

-

?ADd % h?6dL <@ii ? @h G In A? :-n%+;M

@ii 8 + for grids with earthing rods along the perimeter or for rods in that mat corners as

well as along the perimeter and throughout the grid area.

@h 8 + < h?hg

8 $oil resistivity in ohm G metre

hg 8 + metre :reference depth of earth mat;

d 8 $pacing between parallel conductors in metres

n 8 nAnI for calculating Em

nA 8 &he number of parallel conductors in transverse direction

- 9 -

nI 8 &he number of parallel conductors in longitudinal direction

. 8 .c < .t for earth mat without earth rods or with only a few rods located within the mat

but away from the perimeter

8 .c<+.+>. for earth mat with ground rods predominantly along the perimeter

.c 8 &otal earth mat conductor length in metre

.r 8 &otal earthing rod length in metre

$tep potential Estep 8 @s @i .g?. "olts

4here @i 8 3.C>C < 3.+E-n

and @ 8 +? J+?-h < +?D<h < +?D :+%3.>

n%-

;M

., h and D being the same as defined earlier and n being larger of nA and nI for

calculating Es.&he value of expected mesh voltage and step voltage should be

determined for the following conditions in the order indicated below)

a. 4ithout ground rods

b. 4ith uniformly distributed ground rods

- 10 -

c. 4ith ground rods only in the perimeter

If the computed value of mesh voltage is less than the tolerable touch voltage,

the design of earth mat is completed. !owever, if the computed mesh voltage is

exceeding the tolerable touch voltage the design will require inclusion of ground rods or

revision. $imilarly, the computed step voltage should also be less than the tolerable step

voltage. If either the step or touch voltage is found to exceed the tolerable voltages, the

earth mat design will have to be revised by including additional earthing rods, earth mat

depth reducing spacing etc. Additional earthing rod shoud be provided at the base of

lightning arresters and transformer neutrals.

or ground mat depths less than 3.-> metres) &he value of the sub station

grounding resistance in uniform soil can be estimated by means of the following formula.

0g 8 ?6 ?A <?.

4here 0g 8 station ground resistance in ohms

8 Average earth resistivity in ohm metre

A 8 area under earth mat in square metres

. 8 the total length of buried conductors in metres

or ground mat depth between 3.-> and -.> metres) &he station ground resistance for

ground mat with ground rods is determined with the $chwar( formula given below)

0g 8 K+?. <+?-3A J+< +?+<h-3?AML

12.C#'$*,&#'

rom this paper, it could be seen that for the proper and an optimum design of

earth mat for an !"?E!" substation can be arrived at only by trial and error method

repeating the calculation many numbers of times. Iut manual calculation is a time

consuming process, wherein software iterates the calculation by changing parameter like

spacing between earth conductors, number of earth electrodes. In order to arrive at the

optimum design of earth mat so that for a given substation, the attainable level of step

potential, touch potential and earth resistance is well within the tolerable value for the

given soil condition, area of the substations, fault current and duration of fault current.

- 11 -

S-ar putea să vă placă și

- Learn Mandarin Chinese: Most Popular Chinese Tales With AnimalsDocument65 paginiLearn Mandarin Chinese: Most Popular Chinese Tales With AnimalseChineseLearning100% (6)

- Concepts of EarthingDocument6 paginiConcepts of EarthingKonda SrinivasÎncă nu există evaluări

- DC System DesignDocument6 paginiDC System DesignTukaram Pawar100% (1)

- Underground-Sprayed Concrete BrochureDocument12 paginiUnderground-Sprayed Concrete BrochureEngTamerÎncă nu există evaluări

- Earthing Concepts SummaryDocument9 paginiEarthing Concepts SummaryarinnotesÎncă nu există evaluări

- MD1-0-E-505!06!00001 Generator Transformer Sizing CalculationDocument19 paginiMD1-0-E-505!06!00001 Generator Transformer Sizing Calculationtvpham12350% (2)

- 132kv Malana Ekd-Section-Rev01 ModifiedDocument1 pagină132kv Malana Ekd-Section-Rev01 ModifiedannuvyasÎncă nu există evaluări

- SafeGrid Reference ManualDocument16 paginiSafeGrid Reference Manualrajarao1234Încă nu există evaluări

- 41-24 - Design of Earthing SystemsDocument121 pagini41-24 - Design of Earthing SystemsPrasad RaviproluÎncă nu există evaluări

- Earthing Calculation For Substation BuildingDocument3 paginiEarthing Calculation For Substation Buildingajaz8429Încă nu există evaluări

- Best Practices - Earthing Installations - Myths & FactsDocument43 paginiBest Practices - Earthing Installations - Myths & FactskapilÎncă nu există evaluări

- EHV HV Cable Sheath EarthingDocument20 paginiEHV HV Cable Sheath EarthingSachinÎncă nu există evaluări

- Earthing SystemDocument22 paginiEarthing Systemashokparikh100% (2)

- 21 - GIS Earthing PDFDocument11 pagini21 - GIS Earthing PDFwaqas_a_shaikh4348Încă nu există evaluări

- Substation Earthing by JGNDocument49 paginiSubstation Earthing by JGNrupamÎncă nu există evaluări

- Earth Mat Design GeneralDocument62 paginiEarth Mat Design GeneralShah AlamÎncă nu există evaluări

- Lecture On Metallurgical BalancesDocument14 paginiLecture On Metallurgical BalancesVladimir LopezÎncă nu există evaluări

- AGPT04I-09 Guide To Pavement Technology Part 4I Earthworks MaterialsDocument47 paginiAGPT04I-09 Guide To Pavement Technology Part 4I Earthworks MaterialsLeandroÎncă nu există evaluări

- CBIP-Desgn of Earth Mat For HV SSDocument31 paginiCBIP-Desgn of Earth Mat For HV SSSantosh Kumar83% (6)

- A554-15 Standard Specification For Welded Stainless Steel Mechanical TubingDocument8 paginiA554-15 Standard Specification For Welded Stainless Steel Mechanical TubingChuthaÎncă nu există evaluări

- 765 KV Substn Design ChallangesDocument8 pagini765 KV Substn Design ChallangesDipak Bandyopadhyay100% (2)

- STATCOMDocument5 paginiSTATCOMVenkateshÎncă nu există evaluări

- Ground Grid SizingDocument65 paginiGround Grid SizingMohan SaravanaÎncă nu există evaluări

- Gas Insulated Substation Grounding System Design Using TheDocument6 paginiGas Insulated Substation Grounding System Design Using Theraghavendran raghuÎncă nu există evaluări

- CdegsDocument6 paginiCdegsChristopher PerkinsÎncă nu există evaluări

- THESISDocument44 paginiTHESISRowena Shaira AbellarÎncă nu există evaluări

- Earthing Protection BKM 7103Document8 paginiEarthing Protection BKM 7103Utku Can KılıçÎncă nu există evaluări

- Standard Safety Practices Manual PDFDocument350 paginiStandard Safety Practices Manual PDFsithulibraÎncă nu există evaluări

- Earth Mat Design 33-11KV SSDocument5 paginiEarth Mat Design 33-11KV SSDipak BandyopadhyayÎncă nu există evaluări

- Earthing Mat Design Calculation SheetDocument15 paginiEarthing Mat Design Calculation Sheetmaddy100% (1)

- NGR - Ohm Calc Trafo 5MVA-20kVDocument6 paginiNGR - Ohm Calc Trafo 5MVA-20kVbarukomkssÎncă nu există evaluări

- Bus Switching Configurations in Air Insulated Substations AISDocument5 paginiBus Switching Configurations in Air Insulated Substations AISArnel Pascual LaquindanumÎncă nu există evaluări

- Earthmat Calculations For WTG HT YardDocument3 paginiEarthmat Calculations For WTG HT YardSanthosh KumarÎncă nu există evaluări

- CT Requirements - Summary - Rev 3p2 - 090121 - ABB Relays - New - v0p5Document20 paginiCT Requirements - Summary - Rev 3p2 - 090121 - ABB Relays - New - v0p5goalex100% (1)

- Substation EarthingDocument6 paginiSubstation Earthingjpsridhar100% (1)

- Voltage Dip CalculationDocument69 paginiVoltage Dip CalculationCalvert WongÎncă nu există evaluări

- Grounding: Egbodor Peter UwhubetineDocument18 paginiGrounding: Egbodor Peter UwhubetineEgbodor Peter100% (1)

- Page 1 of 4 Why Your Capacitor Bank Should Be Left UngroundedDocument4 paginiPage 1 of 4 Why Your Capacitor Bank Should Be Left UngroundedArunava BasakÎncă nu există evaluări

- NGR PDFDocument4 paginiNGR PDFmanicheÎncă nu există evaluări

- NGR SizingDocument14 paginiNGR SizingSibolis Naburju0% (1)

- Earthing System Calculation For Steel Factory Substation 132 11kV 40MVADocument29 paginiEarthing System Calculation For Steel Factory Substation 132 11kV 40MVAsahli medÎncă nu există evaluări

- Knowledge is "Real Power": Introduction to Power QualityDe la EverandKnowledge is "Real Power": Introduction to Power QualityÎncă nu există evaluări

- Test Intensiv Engleza 5Document30 paginiTest Intensiv Engleza 5Simona Singiorzan90% (30)

- Microbiology QuestionsDocument5 paginiMicrobiology QuestionsNaeem AminÎncă nu există evaluări

- Chapter 17 - NT PWC SDM Substation Layouts and Facilities - Outdoor Section Rev 2 - 17-1-2012Document12 paginiChapter 17 - NT PWC SDM Substation Layouts and Facilities - Outdoor Section Rev 2 - 17-1-2012Punit RatnaniÎncă nu există evaluări

- Razevig Method DSLPDocument19 paginiRazevig Method DSLPsunny171083_901235920% (2)

- Trfo Voltage DropDocument74 paginiTrfo Voltage DropshivvaramÎncă nu există evaluări

- Gas Insulated Switchgear and GIS Substation Essentials1Document4 paginiGas Insulated Switchgear and GIS Substation Essentials1Mishra Sanjib0% (1)

- 25 KV Equipment Sizing Calculationv5 - PDFDocument56 pagini25 KV Equipment Sizing Calculationv5 - PDFAbhas Gupta100% (2)

- Street Lighting Design Guide and Department Standard Specification 6 EditionDocument19 paginiStreet Lighting Design Guide and Department Standard Specification 6 EditionOvidiu ChirvaseÎncă nu există evaluări

- Earthing Calculation - V - 0.2Document18 paginiEarthing Calculation - V - 0.2Ravishankar.AzadÎncă nu există evaluări

- Earth Mat Designing of SubstationDocument7 paginiEarth Mat Designing of Substationraghu008Încă nu există evaluări

- IEEE 1850 GroundGridCalcsDocument11 paginiIEEE 1850 GroundGridCalcsaabts1413Încă nu există evaluări

- NGR Sizing Calculation As Per IEEE 32Document3 paginiNGR Sizing Calculation As Per IEEE 32Soumya MukherjeeÎncă nu există evaluări

- Earthing ReportDocument8 paginiEarthing ReportkhandelwalaÎncă nu există evaluări

- Chemical Earthing PDFDocument28 paginiChemical Earthing PDFbkmsingh196895% (19)

- Chemical Earthing SpecDocument2 paginiChemical Earthing Specaajkal12321100% (1)

- Gas Insulated Substation GIS Versus Air Insulated Substation AIS - Electrical Engineering PortalDocument8 paginiGas Insulated Substation GIS Versus Air Insulated Substation AIS - Electrical Engineering PortalAnonymous ggwJDMh8Încă nu există evaluări

- SS Earthing Mat Design 22 8 12Document7 paginiSS Earthing Mat Design 22 8 12Vishal ThakurÎncă nu există evaluări

- EHVHV Underground Cable Sheath Earthing Part 12Document5 paginiEHVHV Underground Cable Sheath Earthing Part 12rajfab100% (1)

- Selective Coordination Breaker Application ChartDocument5 paginiSelective Coordination Breaker Application Charthanner90Încă nu există evaluări

- Ring EarthingDocument3 paginiRing EarthingJibin J VargheseÎncă nu există evaluări

- Main Components of Electrical Substation: Incoming LineDocument10 paginiMain Components of Electrical Substation: Incoming LineShiv Kumar Verma100% (1)

- CVT - EMVTS ComparisionDocument1 paginăCVT - EMVTS ComparisiondseshireddyÎncă nu există evaluări

- Substation GroundingDocument19 paginiSubstation GroundingDev SwainÎncă nu există evaluări

- GP223 Design of Earthing Mat For High Voltage Sub-StationDocument34 paginiGP223 Design of Earthing Mat For High Voltage Sub-StationsreejitvpÎncă nu există evaluări

- Poor Grounding Contributes To Downtime But A Lack of Good Grounding Is Also Dangerous and Increases The Risk of Equipment FailureDocument5 paginiPoor Grounding Contributes To Downtime But A Lack of Good Grounding Is Also Dangerous and Increases The Risk of Equipment FailureSTG INSTRUMENTÎncă nu există evaluări

- Earthingconcepts 091106084814 Phpapp02Document48 paginiEarthingconcepts 091106084814 Phpapp02Aurimas ZavarskisÎncă nu există evaluări

- Thermodynamics - SunilDocument5 paginiThermodynamics - SunilRaja RamachandranÎncă nu există evaluări

- Non Traditional Machining TechniquesDocument4 paginiNon Traditional Machining TechniquesRaja RamachandranÎncă nu există evaluări

- Theory of Automotive EnginesDocument7 paginiTheory of Automotive EnginesRaja RamachandranÎncă nu există evaluări

- Vehicle Body EnggDocument6 paginiVehicle Body EnggRaja RamachandranÎncă nu există evaluări

- Department of Automobile Engineering Course PlanDocument4 paginiDepartment of Automobile Engineering Course PlanRaja RamachandranÎncă nu există evaluări

- Sources and Types of Municipal Solid WastesDocument2 paginiSources and Types of Municipal Solid WastesRaja RamachandranÎncă nu există evaluări

- Lesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Document3 paginiLesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Raja RamachandranÎncă nu există evaluări

- Video 8Document2 paginiVideo 8Raja RamachandranÎncă nu există evaluări

- CE1205 Lesson PlanDocument2 paginiCE1205 Lesson PlanRaja RamachandranÎncă nu există evaluări

- CE1008 Lesson PlanDocument3 paginiCE1008 Lesson PlanRaja RamachandranÎncă nu există evaluări

- CE1008 Lesson PlanDocument3 paginiCE1008 Lesson PlanRaja RamachandranÎncă nu există evaluări

- CE1006 Lesson PlanDocument2 paginiCE1006 Lesson PlanRaja RamachandranÎncă nu există evaluări

- Faculty Name: Sucheta Panda: Total Number of Hours 48Document1 paginăFaculty Name: Sucheta Panda: Total Number of Hours 48Raja RamachandranÎncă nu există evaluări

- Video 9Document1 paginăVideo 9Raja RamachandranÎncă nu există evaluări

- Veer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-PT&HTDocument4 paginiVeer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-PT&HTRaja RamachandranÎncă nu există evaluări

- Lesson Plan Subject Name-Robotics and Flexible Manufacturing Systems Branch-Production Engineering Subject Code-BPE 2802 Semester - 8Document2 paginiLesson Plan Subject Name-Robotics and Flexible Manufacturing Systems Branch-Production Engineering Subject Code-BPE 2802 Semester - 8Raja RamachandranÎncă nu există evaluări

- Veer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-Transport PhenomenaDocument3 paginiVeer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-Transport PhenomenaRaja RamachandranÎncă nu există evaluări

- Lesson Plan: Veer Surendra Sai University of TechnologyDocument4 paginiLesson Plan: Veer Surendra Sai University of TechnologyRaja RamachandranÎncă nu există evaluări

- Lesson Plan Subject Name-Automation & Numerical Control Machines Branch-Production Engineering Subject Code - BPE 2701 Semester - 7Document2 paginiLesson Plan Subject Name-Automation & Numerical Control Machines Branch-Production Engineering Subject Code - BPE 2701 Semester - 7Raja RamachandranÎncă nu există evaluări

- Video PDFDocument2 paginiVideo PDFRaja RamachandranÎncă nu există evaluări

- Lesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6Document2 paginiLesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6Raja RamachandranÎncă nu există evaluări

- Lesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Document2 paginiLesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Raja RamachandranÎncă nu există evaluări

- Naskah Drama Beauty and The BeastDocument39 paginiNaskah Drama Beauty and The BeastAyu Rose75% (4)

- My 6-Step Plan For Diagnosing & Managing The Pruritic DogDocument6 paginiMy 6-Step Plan For Diagnosing & Managing The Pruritic DogAnonymous TDI8qdYÎncă nu există evaluări

- Comsol ProfileDocument4 paginiComsol ProfilePrashant KumarÎncă nu există evaluări

- GNM SyllabusDocument4 paginiGNM SyllabusVinay SinghÎncă nu există evaluări

- "Automatic Tyre Pressure Inflation System": Bachelor of TechnologyDocument41 pagini"Automatic Tyre Pressure Inflation System": Bachelor of Technologymd washiqeÎncă nu există evaluări

- Distribution System ReliabilityDocument8 paginiDistribution System Reliabilityabera alemayehuÎncă nu există evaluări

- Craig - 4353 TX CobraDocument3 paginiCraig - 4353 TX CobraJorge ContrerasÎncă nu există evaluări

- V260 Control ValveDocument12 paginiV260 Control ValvenwabukingzÎncă nu există evaluări

- Routes of Medication AdministrationDocument2 paginiRoutes of Medication AdministrationTracy100% (6)

- DEMU COUP - Leviat - 17 1 EDocument28 paginiDEMU COUP - Leviat - 17 1 EJianhua WuÎncă nu există evaluări

- Apexification Using Different Approaches - Case Series Report With A Brief Literature ReviewDocument12 paginiApexification Using Different Approaches - Case Series Report With A Brief Literature ReviewIJAR JOURNALÎncă nu există evaluări

- Curicullum Vitae Hendri Zand Franxiscus LahaguDocument3 paginiCuricullum Vitae Hendri Zand Franxiscus LahaguSepta Yudistira Inggil PambudiÎncă nu există evaluări

- Minor Losses ExperimentDocument4 paginiMinor Losses ExperimentRaj GuptaÎncă nu există evaluări

- B.ing Wajib - XI IPA1-2Document3 paginiB.ing Wajib - XI IPA1-2iwan fals NurjaniÎncă nu există evaluări

- CMC 2023 Senior Category Question BankDocument5 paginiCMC 2023 Senior Category Question BankNikita AgrawalÎncă nu există evaluări

- Scientific Method - AssessmentDocument13 paginiScientific Method - AssessmentA.BensonÎncă nu există evaluări

- EN 14103 - ThermoDocument4 paginiEN 14103 - ThermoLuciana TrisnaÎncă nu există evaluări

- International SubcontractingDocument2 paginiInternational SubcontractingCatherine JohnsonÎncă nu există evaluări

- Environmental Science 15th Edition Miller Solutions Manual DownloadDocument20 paginiEnvironmental Science 15th Edition Miller Solutions Manual DownloadBrett Bunch100% (20)

- Taenia SoliumDocument40 paginiTaenia SoliumBio SciencesÎncă nu există evaluări

- Supergene High Yield Introgressed Hybrid Oil Palm MalaysiaDocument16 paginiSupergene High Yield Introgressed Hybrid Oil Palm MalaysiaYangSern Lim100% (13)