Documente Academic

Documente Profesional

Documente Cultură

(3374 3377) Icmct14

Încărcat de

Tushar SarkarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

(3374 3377) Icmct14

Încărcat de

Tushar SarkarDrepturi de autor:

Formate disponibile

International Journal of ChemTech Research

CODEN (USA): IJCRGG ISSN : 0974-4290

Vol.6, No.6, pp 3374-3377, Aug-Sep 2014

ICMCT-2014 [10

th

12

th

March 2014]

International Conference on Materials and Characterization Techniques

Optical and Structural Characterizations of ZnO Thin Films

Fabricated by SILAR Method via Sulphate Route

R.Radha

1

*, A.Sakthivelu

1

, D.Pradhabhan

1

, C.Ravichandiran

3

,

S.Murugesan

2

, E.Mohandas

2

and P.Geethadhevi

3

1,3

PG & Research Department of Physics, Periyar.E.V.R College, Trichy, India,

2

Materials Synthesis and Structural Characterization Division, PMG, IGCAR,

Kalpakkam, India.

*Corres.author: radhasudeep2013@gmail.com

Abstract: The ZnO thin films were prepared on cleaned glass substrates by SILAR deposition technique using

Zn (CH

3

COO)

2

and Na

2

S

2

O

3

as precursor solution with deposition cycles of 25, 50 and 75. The prepared

samples were annealed in air. The ZnO thin films are prepared from source of sulphate precursor route followed

by decomposition at 450

C annealing which leads to the properties changes. The prepared thin films were

characterized for their structural, micro structural and optical properties by XRD, FESEM and UV-Visible

spectroscopy. The XRD analysis shows that the prepared samples are polycrystalline and it exhibits hexagonal

structure. The morphology of the ZnO thin films characterized by FESEM revealed that the film consisted of

mixture of nanoparticles and the EDAX results showed the presence of ZnO in the prepared thin films. The

optical properties of the deposited films were characterized by UV-VIS and FTIR spectrometry. The paper will

discuss the preparation methods and results of ZnO thin films by SILAR method.

Keywords: ZnO; Nano crystalline thin film; SILAR deposition method.

1. Introduction

Zinc oxide (ZnO) is one of the most prominent binary II-VI semiconductor compounds, it is an n-type

Semiconductor of hexagonal (wurtzite) structure [1].Thin films of ZnO have been prepared by different

researchers using various techniques such as spray pyrolysis [2], physical vapour deposition [3], chemical

vapour deposition [4], sputtering [5], solgel method [6] and Successive Ionic Layer Adsorption and Reaction

(SILAR) [7] method. The SILAR technique involves multiple dipping of a substrate in cationic and anionic

precursors. In addition to its simplicity, SILAR also has a number of advantages: a) it offers extremely easy

way to dope, b) operating at room temperature c) no power requirements. The thin films and nanoparticles of

ZnO used in several applications, such as in dye sensitized solar cell [8],gas sensors [9], and light emitting

diodes [10].

2. Experimental

ZnO thin films were deposited by SILAR method on well cleaned glass substrate (6cm x 1.25cm x

1mm) using 0.1 mol Zinc acetate ((CH

3

COO)

2

Zn

.

2H

2

O) with 0.1 mol NaOH used as source of cationic

R.Radha et al /Int.J. ChemTech Res.2014,6(6),pp 3374-3377. 3375

precursor solution and sodium thiosulfate (Na

2

S

2

O

3

.5H

2

O) used as the source of anionic precursor solution. The

SILAR deposition cycles were repeated and carried out for 25, 50 and 75 times separately to get the three

desired films. The prepared films were dried at room temperature for 2 hours and then annealed in air at 450

o

C

for 3 hours which leads to the properties changes. Optical characterizations of the films were carried out using a

Unico UV-2102PCS spectrophotometer. The structural properties of the films were characterized by XPERT-

PRO X-ray powder diffractometer (CuKa radiation, 0.15418 nm). Surface morphology was characterized by

FE-SEM 6701 F (Resolution 6 xlac).

3. Results and Discussion

1 0 2 0 3 0 4 0 5 0 6 0 7 0

00

5 0

1 0 0

1 5 0

2 0 0

2 5 0

3 0 0

3 5 0

(

2

0

0

)

(

1

0

3

)

(

1

1

0

)

(

1

0

2

)

(

1

0

1

)

(

0

0

2

)

(

1

0

0

)

F 7 5

F 5 0

F 2 5

I

n

t

e

n

s

i

t

y

(

a

.

u

)

2 t h e t a ( d e g . )

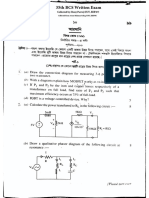

Fig. (1) XRD pattern of ZnO thilms prepared for various (25, 50 and 75) deposition cycles.

Figure 1 shows X-ray diffraction pattern of ZnO thin films prepared at three different deposition cycles

of 25, 50 and 75. The XRD pattern shows hump around 25 two theta corresponds to amorphous glass substrate,

the sharp peaks are entire characteristic of the hexagonal ZnO wurtzite structure according to JCPDS card file

No. 36-1451. No other peaks are observed, suggesting that only single-phase ZnO has formed. The lattice

parameter values, a and c, have been calculated for 25,50 and 75 deposition cycles from their accurately

determined two theta positions with UNITCELL least minimisation code (11).

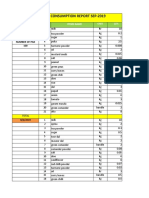

Fig.2 shows the variation of (a) lattice parameters with the deposition cycles and (b) crystallite size and

micro strain with the deposition cycles.

Lattice parameter values, a and c are in good agreement with the reported standard values (JCPDS No.

36-1451). The standard ZnO lattice parameters were a=3.250 and c=5.207 (12). The lattice parameter of

50 cycles of dipping sample almost well agreed with standard ZnO lattice parameter, whereas the other two

samples show either low in a parameter or high in c parameter. The average crystallite size of the SILAR

deposited ZnO thin films has been calculated using Scherer formula[13] shown in equation (1) and the average

lattice strain has been calculated using Stokes Wilson equation [14] shown in equation (2). The FWHM values

of the samples were derived from their highest intensity peak broadening by pseudo-voigt peak fitting.

Crystallite size D

ave

= 094/ cos, ----- (1) and Micro Strain = /4tan ----- (2)

a

b

F25 F50 F75

3.244

3.245

3.246

3.247

3.248

3.249

3.250

3.251

3.252

(a)

(c)

DIPPING

L

a

t

t

i

c

e

,

a

(

A

)

5.190

5.195

5.200

5.205

5.210

L

a

t

t

i

c

e

,

c

(

A

)

20 30 40 50 60 70 80

46

48

50

52

54

56

Dipping Cycles

C

r

y

s

t

a

l

l

i

t

e

S

i

z

e

(

n

m

)

0.0022

0.0023

0.0024

0.0025

0.0026

0.0027

0.0028

Crystallite Size (nm)

Micro Strain

M

i

c

r

o

S

t

r

a

i

n

a

b

R.Radha et al /Int.J. ChemTech Res.2014,6(6),pp 3374-3377. 3376

Where D

ave

is the mean crystallite size, is the average micro strain (d/d), the full width at half maximum of

the diffraction line, the angle of diffraction, and the wavelength of the X-ray radiation. The crystallite sizes

obtained were ~ 47 nm, 54 nm and 56 nm for deposition cycles 25, 50 and 75 respectively.

Fig.3 (a) and (b) shows the FESEM and their EDAX spectra of ZnO films by SILAR method for 25

dippings, 50 dippings and 75 dippings

Field Emission Scanning Electron Microscope (FESEM) images and their corresponding EDAX

spectra of ZnO films deposited for different deposition cycles 25,50 and 75 are shown in figures 3(a) and (b)

and (c). The size distribution of grains appears to be less homogenous for 25 deposition cycles, which shows

distinguished micro flower shape composed with self-aligned prismatic nanoparticles and grown film not fully

covered the substrate. An organized change occurs in the structure from micro-flower nanostructure to a less

uniform surface with closely attached nano particles in 50 and 75 deposition cycles. Agglomeration of nano

particles also seems to be present in the certain region on the ZnO film surface. The EDAX results of the ZnO

thin film clearly indicated the chemistry of the film. It was observed that the UV-Visible transmittance of the

film was high in 25 deposition cycles. The optical band gap of the films were calculated using Tauc plot

method ((h)

2

against h) and found to be 3.01eV for 25 deposition cycles, 3.31ev for 50 deposition cycles

and 3.22 eV for 75 deposition cycles respectively.

4. Conclusions

ZnO nanocrystalline thin films have been synthesized by SILAR method using zinc acetate and sodium

thiosulfate. The XRD analysis reveals that ZnO is crystalline nature and in hexagonal structure, with the

nanoparticles of size in the range of ~47-56 nm. The result of UV-Vis. spectrum shows that prepared ZnO thin

films have UV absorption ability. EDAX analysis of the prepared ZnO thin films confirms that the samples are

composed of Zn and O without any impurity. SEM micrograph witnesses the samples consist of regular and

almost spherical shape particles at higher deposition cycles and the films are homogeneous and well covered to

the substrate. The data presented here concludes that in SILAR method, the number of deposition cycles plays

an important role in fabrication of good quality ZnO nanocrystalline thin films and also determining the particle

size.

5. References

1. A Mang, K Reimann and St Rubenacke, Solid State Commun. 94, 251 (1995)

2. Ayouchi R, Leinen D, Martn F, Gabas M, Dalchiele E and Ramos-Barrado J R 2003 Thin Solid Films

426 68

3. Kouam J, Ait-Ahcene T, Plaiasu A G, Abrudeanu M, Motoc A, Beche E and Monty C 2008 Solar

Energy 82 226

4. Wang X H, Li R B and Fan D H 2011 Appl. Surf. Sci. 257 2960

5. Zhang Zhonghai, Hossain Md Faruk, Arakawa Takuya and Takahashi Takakazu 2010 J. Hazard. Mater.

176 973

6. Yakuphanoglu Fahrettin 2010 J. Alloys Compd. 507 184

7. X.D. Gao, X.M. Li, W.D. Yu, J. Solid State Chem. 177 (2004) 3830.

8. Wu Jih-Jen, Chen Guan-Ren, Yang Hung-Hsien, Ku Chen-Hao and La Jr-Yuan 2007 Appl. Phys. Lett.

90 213109

9. Chen Jin, Li Jin, Li Jiahui, Xiao Guoqing and Yang Xiaofeng 2011 J. Alloys Compd. 509 740

10. Kim K, Horwitz J S, Kim W H, Makinen A J, Kafafi Z H and Chrisey D B 2002 Thin Solid Films 420

421 539.

11. T J B Holland and S A T Redfern "Unit cell refinement from powder diffraction data: the use of

regression diagnostics". Mineralogical Magazine 61 (1997) 65-77.

12. Abrahams, S., Bernstein, J. Acta Crystallogr, Sec. B 25, 1233 (1969)

a

b

R.Radha et al /Int.J. ChemTech Res.2014,6(6),pp 3374-3377. 3377

13. Maleki M, Ghamsari M Sasani, Mirdamadi Sh. and Ghasemzadeh R 2007 Semicond. Phys. Quant.

Electron. Optoelectron. 10 30.

14. Ajaya Kumar Singh, Swati Mehra, Gautam Sheel Thool.European Chemical Bulletin 2013, 2(8), 518-

523.

*****`

S-ar putea să vă placă și

- Wu 2016Document8 paginiWu 2016Tushar SarkarÎncă nu există evaluări

- Assignment (2) Problem (1) : Selected Topics in Communications EngineeringDocument1 paginăAssignment (2) Problem (1) : Selected Topics in Communications EngineeringTushar SarkarÎncă nu există evaluări

- Zant Ye 2004Document132 paginiZant Ye 2004Tushar SarkarÎncă nu există evaluări

- Time Varyng Field LectureDocument11 paginiTime Varyng Field LectureSarwar Hosen SimonÎncă nu există evaluări

- Solution Manual Optical Fiber Communication 3rd EdDocument6 paginiSolution Manual Optical Fiber Communication 3rd EdTushar SarkarÎncă nu există evaluări

- Electromagnetic WaveDocument15 paginiElectromagnetic WaveTushar SarkarÎncă nu există evaluări

- ElectrostaticsDocument64 paginiElectrostaticsTushar Sarkar0% (1)

- Calculation Problems and Short Questions From Old Exams. Solutions and AnswersDocument110 paginiCalculation Problems and Short Questions From Old Exams. Solutions and AnswersTisha KhatriÎncă nu există evaluări

- Bengali Sign Language Recognition Using Deep Convolutional Neural NetworkDocument5 paginiBengali Sign Language Recognition Using Deep Convolutional Neural NetworkTushar SarkarÎncă nu există evaluări

- An Effective Learning and Teaching Model For Programming LanguagesDocument25 paginiAn Effective Learning and Teaching Model For Programming LanguagesTushar SarkarÎncă nu există evaluări

- Lect5-Optical Fibers 2Document134 paginiLect5-Optical Fibers 2trlp1712100% (1)

- Calculation Problems and Short Questions From Old Exams. Solutions and AnswersDocument110 paginiCalculation Problems and Short Questions From Old Exams. Solutions and AnswersTisha KhatriÎncă nu există evaluări

- Ad Notice 2017-18Document5 paginiAd Notice 2017-18Tushar SarkarÎncă nu există evaluări

- BK 7 CH 10Document16 paginiBK 7 CH 10Tushar SarkarÎncă nu există evaluări

- NWPGCL Ae BuetDocument6 paginiNWPGCL Ae BuetTushar SarkarÎncă nu există evaluări

- 35th BCS Electrical Wriitten Question-1 PDFDocument4 pagini35th BCS Electrical Wriitten Question-1 PDFTushar SarkarÎncă nu există evaluări

- Open Positions at UConnDocument1 paginăOpen Positions at UConnTushar SarkarÎncă nu există evaluări

- Newspaper Adm Notice 2017 18Document1 paginăNewspaper Adm Notice 2017 18Tushar SarkarÎncă nu există evaluări

- Final Brochure Evening 2017-18-2Document2 paginiFinal Brochure Evening 2017-18-2Tushar SarkarÎncă nu există evaluări

- 976Document5 pagini976Tushar SarkarÎncă nu există evaluări

- Bepza - 2016Document6 paginiBepza - 2016Tushar SarkarÎncă nu există evaluări

- Recruitment Exam Question Sample Telecom SectorDocument3 paginiRecruitment Exam Question Sample Telecom SectorTushar SarkarÎncă nu există evaluări

- IolugDocument26 paginiIolugTushar SarkarÎncă nu există evaluări

- Middle Tennessee State University Graduate Registration and Other Fees Summer 2016Document1 paginăMiddle Tennessee State University Graduate Registration and Other Fees Summer 2016Tushar SarkarÎncă nu există evaluări

- Application FormDocument2 paginiApplication FormTushar SarkarÎncă nu există evaluări

- Circular URP1Document4 paginiCircular URP1Tushar SarkarÎncă nu există evaluări

- Accepted Paper ListDocument6 paginiAccepted Paper ListTushar SarkarÎncă nu există evaluări

- Transmission Lines and Measurement of Their Characteristics: by Lloyd Butler VK5BRDocument11 paginiTransmission Lines and Measurement of Their Characteristics: by Lloyd Butler VK5BRTushar SarkarÎncă nu există evaluări

- SaborDocument8 paginiSaborTushar SarkarÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- NRF Nano EthicsDocument18 paginiNRF Nano Ethicsfelipe de jesus juarez torresÎncă nu există evaluări

- 2019 06 28 PDFDocument47 pagini2019 06 28 PDFTes BabasaÎncă nu există evaluări

- Potato Storage and Processing Potato Storage and Processing: Lighting SolutionDocument4 paginiPotato Storage and Processing Potato Storage and Processing: Lighting SolutionSinisa SustavÎncă nu există evaluări

- Chapter 2 and 3 ImmunologyDocument16 paginiChapter 2 and 3 ImmunologyRevathyÎncă nu există evaluări

- Jeremy A. Greene-Prescribing by Numbers - Drugs and The Definition of Disease-The Johns Hopkins University Press (2006) PDFDocument337 paginiJeremy A. Greene-Prescribing by Numbers - Drugs and The Definition of Disease-The Johns Hopkins University Press (2006) PDFBruno de CastroÎncă nu există evaluări

- Soil SSCDocument11 paginiSoil SSCvkjha623477Încă nu există evaluări

- Minyak Atsiri Sereh WangiDocument4 paginiMinyak Atsiri Sereh Wangicindy paraditha kasandraÎncă nu există evaluări

- Guides To The Freshwater Invertebrates of Southern Africa Volume 2 - Crustacea IDocument136 paginiGuides To The Freshwater Invertebrates of Southern Africa Volume 2 - Crustacea IdaggaboomÎncă nu există evaluări

- Soal UAS Bahasa Inggris 2015/2016: Read The Text Carefully! Cold Comfort TeaDocument5 paginiSoal UAS Bahasa Inggris 2015/2016: Read The Text Carefully! Cold Comfort TeaAstrid AlifkalailaÎncă nu există evaluări

- Answers To Your Questions About Circumcision and HIV/AIDSDocument2 paginiAnswers To Your Questions About Circumcision and HIV/AIDSAlex BrownÎncă nu există evaluări

- Solar Refrigeration: Prepared by M.DevakumarDocument21 paginiSolar Refrigeration: Prepared by M.DevakumarEasy StudyÎncă nu există evaluări

- Itrogen: by Deborah A. KramerDocument18 paginiItrogen: by Deborah A. KramernycÎncă nu există evaluări

- Revision Ror The First TermDocument29 paginiRevision Ror The First TermNguyễn MinhÎncă nu există evaluări

- BV Lesson Plan 4Document3 paginiBV Lesson Plan 4api-252119803Încă nu există evaluări

- Libro Resumenes 2012Document735 paginiLibro Resumenes 2012fdobonat613100% (2)

- Phardose Lab Prep 19 30Document4 paginiPhardose Lab Prep 19 30POMPEYO BARROGAÎncă nu există evaluări

- Long Term Effects of Surgically Assisted Rapid Maxillary Expansion Without Performing Osteotomy of The Pterygoid PlatesDocument4 paginiLong Term Effects of Surgically Assisted Rapid Maxillary Expansion Without Performing Osteotomy of The Pterygoid PlatesAngélica Valenzuela AndrighiÎncă nu există evaluări

- WWW Spectrosci Com Product Infracal Model CVH PrinterFriendlDocument3 paginiWWW Spectrosci Com Product Infracal Model CVH PrinterFriendlather1985Încă nu există evaluări

- Service Bulletins For Engine Model I0360kb.3Document6 paginiService Bulletins For Engine Model I0360kb.3Randy Johel Cova FlórezÎncă nu există evaluări

- Pe 3 Syllabus - GymnasticsDocument7 paginiPe 3 Syllabus - GymnasticsLOUISE DOROTHY PARAISO100% (1)

- Leather & Polymer - Lec01.2k11Document11 paginiLeather & Polymer - Lec01.2k11Anik AlamÎncă nu există evaluări

- Installing Touareg R5 CamshaftDocument1 paginăInstalling Touareg R5 CamshaftSarunas JurciukonisÎncă nu există evaluări

- Brief RESUME EmailDocument4 paginiBrief RESUME Emailranjit_kadalg2011Încă nu există evaluări

- Basics of Fire SprinklerDocument21 paginiBasics of Fire SprinklerLeo_1982Încă nu există evaluări

- Daily Staff Food Consumption Reports Sep-2019Document4 paginiDaily Staff Food Consumption Reports Sep-2019Manjit RawatÎncă nu există evaluări

- Management of Preterm LaborDocument2 paginiManagement of Preterm LaborpolygoneÎncă nu există evaluări

- Congenital Flexural Deformity in CalfDocument6 paginiCongenital Flexural Deformity in CalfBibek SutradharÎncă nu există evaluări

- SanMilan Inigo Cycling Physiology and Physiological TestingDocument67 paginiSanMilan Inigo Cycling Physiology and Physiological Testingjesus.clemente.90Încă nu există evaluări

- Drug-Nutrient Interaction in Prescriptions ForDocument7 paginiDrug-Nutrient Interaction in Prescriptions ForRafika DitaÎncă nu există evaluări

- Ec Declaration of Conformity: W1/35 KEV KIRK - Protective Gloves - Cathegory IIDocument3 paginiEc Declaration of Conformity: W1/35 KEV KIRK - Protective Gloves - Cathegory IICrystal HooverÎncă nu există evaluări