Documente Academic

Documente Profesional

Documente Cultură

Cylinder Design Standards

Încărcat de

terigaliyan0 evaluări0% au considerat acest document util (0 voturi)

200 vizualizări8 paginiwewe

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLS, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentwewe

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

200 vizualizări8 paginiCylinder Design Standards

Încărcat de

terigaliyanwewe

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

Standard Description

General Register Notes

American and Canadian

ASME VIII Div 1 Pressure Vessels

CTC 8WC Welded steel cylinder with porous filling

DOT 2P Non-refillable

DOT 3A

Seamless steel cylinder with a water capacity not over 1,000

pounds (453 kg) and a service pressure of at least 150 psig

(1.03MPa)

DOT 3AA

DOT 3AA/TC3AAM-139

Seamless steel cylinder with a water capacity of not over 1,000

pounds (453 kg) and a service pressure of at least 150 psig

(1.03Mpa)

DOL 3AL

DOT 3AL/TC-3ALM

Seamless aluminum cylinder with a maximum water capacity of

1000 pounds (453 kg) and minimum service pressure of 150

psig. (1.03Mpa)

DOT 3B

Seamless steel cylinder with a water capacity of not over 1,000

pounds (453 kg) and a service pressure of at least 150 psig

(1.03 MPa) to not over 500 psig (3.44 MPa).

DOT 3E

Seamless steel cylinder with an outside diameter not greater

than 2 inches (50 mm) nominal, a length less than 2 feet (600

mm) and a service pressure of 1,800 psig (12.4 MPa).

DOT 4AA 480

Welded steel cylinder having a water capacity not over 1,000

pounds (453 kg) water capacity and a service pressure of 480

psig. (3.3 MPa)

DOT 4B

Welded or brazed steel cylinder with longitudinal seams that

are forged lap-welded or brazed and with water capacity not

over 1,000 pounds (453 kg) and a service pressure of at least

150 psig (1.03 MPa) but not over 500 psig (3.44 MPa).

DOT 4BA

Welded or brazed steel cylinder either spherical or cylindrical in

shape, with a water capacity of 1,000 pounds or less and a

service pressure of at least 225 and not over 500 psig.

DOT 4BW

Welded or brazed steel cylinder either spherical or cylindrical in

shape, with one circumferential seam and a water capacity of

1,000 pounds (453 kg) or less and a service pressure of at

least 225 psig (1.5 MPa) and not over 500 psig (3.44 MPa).

DOT 4E

Welded aluminium cylinder with a water capacity of not over

1,000 pounds (453 kg) and a service pressure of at least 225

psig (1.5 MPa) to not over 500 psig (3.44 MPa).

DOT 4L A DOT 4L cylinder is a fusion welded insulated cylinder with a

water capacity not over 1,000 pounds (453 kg) water capacity

and a service pressure of at least 40 psig (0.27 MPa) but not

greater than 500 psig (3.44 MPa).

DOT 8 Seamless cylinders with a service pressure of 250 psig (1.7

MPa) with porous fillings for acetylene.

Approved Cylinder Standards

1. This register shows cylinder standards that may be used for newly manufactured cylinders. A cylinder can only be

manufactured or imported into New Zealand if it is designed to a standard that appears on this list.

2. Where a cylinder standard has been withdrawn by the respective standards authority the standard should not

appear on this list. If you are aware of an anomaly, please contact ERMA NZ.

DOT 8AL Seamless steel cylinder with a service pressure of 250 psig

(1.7 MPa). The attachment of heads by welding or by brazing

by dipping process and a welded circumferential body seam is

authorized. Longitudinal seams are not authorized.

DOT 39 Non-refillable seamless, welded, or brazed cylinder with a

service pressure not to exceed 80 percent of the test pressure.

Spherical pressure vessels are authorized

DOT-SP 6517 Welded steel cylinders based on DOT 4BW for acetylene

DOT-SP 6668 Insulated welded cylinders based on DOT 4L with a water

capacity of 100 pounds (45.36 kg)

DOT-SP 7235 Fibre reinforced compressed gas cylinders conforming to DOT

FRP-2

DOT-SP 7542 Welded steel cylinders based on DOT 4BW with porous filling

for acetylene

DOT-SP 8725 Fibre reinforced plastic, hoop-wrapped aluminium cylinders

conforming to DOT FRP-2 for transportation of certain non-

liquefied compressed gases

DOT-SP 9634 Fibre reinforced plastic full composite cylinders conforming to

DOT FRP-1

DOT-SP 10227 Cryogenic cylinders for liquid oxygen based on DOT 4L

DOT-SP 10915 Fully wrapped carbon-fibre reinforced aluminium lined cylinders

conforming to DOT CFFC

DOT-SP 10945 Fully wrapped carbon fibre reinforced aluminium lined cylinders

based on DOT CFFC

DOT-SP 11953 Welded steel cylinder based on DOT 4BW for non-liquefied

and liquefied compressed gases

Australian & New Zealand

AS 1777-2005

Aluminium cylinders for compressed gases Seamless

0.1kg to 130kg

AS/NZS 1841.1-2007 Portable fire extinguishers- General requirements

AS/NZS 1841.2-2007

Portable fire extinguishers - Specific requirements for water

type extinguishers

AS/NZS 1841.3-2007

Portable fire extinguishers - Specific requirements for wet

chemical type extinguishers

AS/NZS 1841.4-2007

Portable fire extinguishers - Specific requirements for foam

type extinguishers

AS/NZS 1841.5-2007

Portable fire extinguishers - Specific requirements for powder

type extinguishers

AS/NZS 1841.6-2007

Portable fire extinguishers - Specific requirements for carbon

dioxide type extinguishers

AS/NZS 1841.7-2007

Portable fire extinguishers - Specific requirements for

vaporizing liquid type extinguishers

AS/NZS 1841.8-2007

Portable fire extinguishers - Specific requirements for non-

rechargeable type extinguishers

AS 22782000

Metal aerosol dispensers of capacity 50 mL to 1000 mL

inclusive

AS 2468-1989

Steel cylinders for compressed gases Brazed 0.1 kg to 11

kg

AS 2469-2005

Steel cylinders for compressed gases Welded two-piece

construction 0.1 kg to 150 kg

AS 2470-2005

Steel cylinders for compressed gases Welded three-piece

construction with longitudinal joint 11 kg to 150 kg

AS 2527-2006 Cylinders for dissolved acetylene

AS 2764 - 2002 FRP Hoop Wrapped 0.1kg - 130kg

AS 2875-1995

Alloy steel cylinders for compressed gases Seamless 0.1

kg to 500 kg

AS 3577-2006

Steel cylinders for compressed gases Welded 150 kg to

500 kg

British

BS 5045-2:1989

Transportable gas containers. Specification for steel containers

of 0.5 L up to 450 L water capacity with welded seams

BS 5045-7:2000

Transportable gas containers. Specification for seamless steel

gas containers of water capacity 0.5 L up to 15 L for special

portable application

BS 5045-8:2000

Transportable gas containers. Specification for seamless

aluminium alloy gas containers of water capacity 0.5 L up to 15

L and up to 300 bar charged pressure at 15C for special

portable application

BS EN 1964-1:2000

Transportable gas cylinders. Specification for the design and

construction of refillable transportable seamless steel gas

cylinders of water capacities from 0,5 litre up to and including

150 litres. Cylinders made of seamless steel with a value of

less than 1100 MPa

BS EN 1964-2:2001 Transportable gas cylinders. Specification for the design and

construction of refillable transportable seamless steel gas

cylinders of water capacities from 0,5 litre up to and including

150 litres. Cylinders made of seamless steel with a value of

1100 MPa and above

BS EN 1975:2000

Transportable gas cylinders. Specification for the design and

construction of refillable transportable seamless aluminium

and aluminium alloy gas cylinders of capacity from 0,5 litre up

to 150 litre

BS EN 12862:2000 Transportable gas cylinders. Specification for the design and

construction of refillable transportable welded aluminium alloy

gas cylinders

EN

EN 3 Portable Fire Extinguishers

EN 12245 (as amended

by ERMA COP)

Fully Wrapped Composite Cylinders

EN 13110 - 2002 Welded Aluminium LPG Cylinders

84/526/EEC

Seamless unalloyed aluminium and aluminium alloy gas

cylinders with capacity between 0.5 to 150 litres

EN 417

Non-refillable metallic gas cartridges for liquefied petroleum

gases, with or without a valve, for use with portable appliances.

Construction, inspection, testing and marking

EN 12862:2000

Transportable gas cylinders. Specification for the design and

construction of refillable transportable welded aluminium alloy

gas cylinders

ISO

ISO 9809-1:1999

Cylinders of seamless steel of tensile strength less than

1100Mpa

ISO 9809-2:2000

Cylinders of seamless steel of tensile strength greater than or

equal to 1100Mpa

ISO 11119-1 (As

amended by ERMA

approved code of

practice)

Gas Cylinders of composite construction Specification and

test methods Part 1: Hoop wrapped composite gas cylinders.

Notes

Acetylene

LPG, to 787 ml, id to 80mm

SCUBA

SCUBA

SCUBA

Acetylene

Approved Cylinder Standards

1. This register shows cylinder standards that may be used for newly manufactured cylinders. A cylinder can only be

manufactured or imported into New Zealand if it is designed to a standard that appears on this list.

2. Where a cylinder standard has been withdrawn by the respective standards authority the standard should not

appear on this list. If you are aware of an anomaly, please contact ERMA NZ.

Acetylene

US Department of Transportation permit expires 31 May 2010

Refer to ERMA approved code of practice HSNOCOP7-1

US Department of Transportation permit expires 31 December

2010

US Department of Transportation permit expires 31 May 2010

US Department of Transportation permit expires 31 August

2010

US Department of Transportation permit expires 31 December

2010

US Department of Transportation permit expires 31 May 2010

US Department of Transportation permit expires 30 November

2009

US Department of Transportation permit expires 28 February

2010

US Department of Transportation permit expires 30 September

2009

See R24 of the Hazardous Substances (Compressed Gases)

Regulations 2004

Declared obsolescent by Standards Australia

Acetylene

See R11 of the Hazardous Substances (Compressed Gases)

Regulations 2004

Supersedes B114

Partially replaced by BS EN 13322-1:2003

Together with BS EN 1964-1:2000 supersedes BS 5045-

1:1982.

Replaces BS 5045-3:1984

Replaces withdrawn standard BS 5045-1:1982

This standard must be used in accordance with the ERMA

approved Gas Cylinders of Composite Construction Designed

to EN 12245:2009

Identical to BS EN 12862

0.5 litre up to and including 150 litres

0.5 litre up to and including 150 litres

This standard must be used in accordance with the ERMA

approved Code of Practice for Gas Cylinders of Composite

Construction Designed to ISO 11119-1

S-ar putea să vă placă și

- Cylinder Design StandardDocument12 paginiCylinder Design StandardasadrasoolÎncă nu există evaluări

- Cylinder Design Standards WSNZDocument5 paginiCylinder Design Standards WSNZjamilÎncă nu există evaluări

- Guide to Requalifying Gas CylindersDocument13 paginiGuide to Requalifying Gas CylindersEmran UmerÎncă nu există evaluări

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Document1 paginăRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhÎncă nu există evaluări

- BS en 876-1995 PDFDocument12 paginiBS en 876-1995 PDFMalik khurram shahzadÎncă nu există evaluări

- EIGA - Doc 79-19 - Cylinder Retest StationsDocument11 paginiEIGA - Doc 79-19 - Cylinder Retest StationsDidier GiraldoÎncă nu există evaluări

- INTERNATIONAL MARITIME ORGANIZATION REVISED STANDARDSDocument17 paginiINTERNATIONAL MARITIME ORGANIZATION REVISED STANDARDSislima50% (2)

- Tools Threading MachineDocument20 paginiTools Threading MachinedayglisÎncă nu există evaluări

- 49 CFR 178.61 Cylinder Specification RequirementsDocument7 pagini49 CFR 178.61 Cylinder Specification RequirementsFarhan AliÎncă nu există evaluări

- Airgas Cylinder Info ChartsDocument3 paginiAirgas Cylinder Info ChartsDaniel VelasquezÎncă nu există evaluări

- BS341.3 Cylinder Valve Connections GuideDocument2 paginiBS341.3 Cylinder Valve Connections GuideDUONG TRANÎncă nu există evaluări

- Propane MsdsDocument8 paginiPropane MsdssalcabesÎncă nu există evaluări

- Bandlock2 LiteratureDocument2 paginiBandlock2 LiteraturelaiminhtheÎncă nu există evaluări

- ms123-2 2011preDocument5 paginims123-2 2011preKimi KononÎncă nu există evaluări

- Galvosil 15680 Data SheetDocument2 paginiGalvosil 15680 Data Sheetn00b1810Încă nu există evaluări

- NF 16101 Explained PDFDocument8 paginiNF 16101 Explained PDFhammouche_soufianeÎncă nu există evaluări

- BS 534-1990Document26 paginiBS 534-1990Kenji LauÎncă nu există evaluări

- BS EN 1333-2006 法兰及其接缝.管道部件.PN的定义和选择Document6 paginiBS EN 1333-2006 法兰及其接缝.管道部件.PN的定义和选择gdj1973Încă nu există evaluări

- Gas CylindersDocument9 paginiGas CylindersSanj.etcÎncă nu există evaluări

- Mil HDBK 695d Change 2Document45 paginiMil HDBK 695d Change 2dhoo_babyÎncă nu există evaluări

- BS en Iso 11114-1 1998Document50 paginiBS en Iso 11114-1 1998Anonymous 1ykzuaxWgYÎncă nu există evaluări

- Iso 11439 2013Document15 paginiIso 11439 2013Hernán Enrique Díaz EchauriÎncă nu există evaluări

- ISO - 15156-1 - 2009 - Technical Circular - 1 - 2014-01-27Document4 paginiISO - 15156-1 - 2009 - Technical Circular - 1 - 2014-01-27manuelazo78Încă nu există evaluări

- Ped 2014 - 68 - EuDocument96 paginiPed 2014 - 68 - EuperycabralÎncă nu există evaluări

- Directive 75-324-EEC ADDDocument10 paginiDirective 75-324-EEC ADDGordan SanticÎncă nu există evaluări

- Iso 11439 2013 en PDFDocument11 paginiIso 11439 2013 en PDFDhirajRathore100% (1)

- Gas Hydrate Tutorial: Crystal Structures and PropertiesDocument134 paginiGas Hydrate Tutorial: Crystal Structures and PropertiesGinoÎncă nu există evaluări

- (PDF) BS EN 1440-2008+A1-2012 LPG Equipment and AccessoriesDocument4 pagini(PDF) BS EN 1440-2008+A1-2012 LPG Equipment and AccessoriesJulian RapushiÎncă nu există evaluări

- BS en 13575 2012 PDFDocument32 paginiBS en 13575 2012 PDFPedro LuizÎncă nu există evaluări

- Approval Standard For Centrifugal Fire Pumps (Horizontal, End Suction Type)Document25 paginiApproval Standard For Centrifugal Fire Pumps (Horizontal, End Suction Type)saifahmed7100% (1)

- Iso 91 2017Document22 paginiIso 91 2017anitagissellatapiaÎncă nu există evaluări

- API 6D - 6A - 607 - BS5351 BALL VALVE: Lanus Industries LLC USADocument61 paginiAPI 6D - 6A - 607 - BS5351 BALL VALVE: Lanus Industries LLC USANagendra SunkariÎncă nu există evaluări

- Gas Industry Standard: GIS/F12:2007Document21 paginiGas Industry Standard: GIS/F12:2007Yousefi76Încă nu există evaluări

- Understanding Ped For Asme VesselsDocument33 paginiUnderstanding Ped For Asme VesselsRamakrishnan SrinivasanÎncă nu există evaluări

- En1564-1 2017Document4 paginiEn1564-1 2017Dan PopaÎncă nu există evaluări

- Triple Eccentric Metal Seated ValvesDocument4 paginiTriple Eccentric Metal Seated ValvesFelipe Gamboa GálvezÎncă nu există evaluări

- Aluminium en AW 6082Document3 paginiAluminium en AW 6082doshi78Încă nu există evaluări

- Ihc S 500Document2 paginiIhc S 500hk089Încă nu există evaluări

- Din en 1320-1996Document18 paginiDin en 1320-1996edcam13Încă nu există evaluări

- BS en Iso 13769-2009Document30 paginiBS en Iso 13769-2009Vasko MandilÎncă nu există evaluări

- Vecom - Japanese BlackDocument2 paginiVecom - Japanese Blackdiaccessltd_17172961Încă nu există evaluări

- Iso 13349-2010Document50 paginiIso 13349-2010rohitshukla23Încă nu există evaluări

- Dosh DocumentsDocument5 paginiDosh DocumentsmohdmasriÎncă nu există evaluări

- NR 23 Fire ProtectionDocument8 paginiNR 23 Fire ProtectionVítor Andrade SoaresÎncă nu există evaluări

- Failure of CNG CylinderDocument4 paginiFailure of CNG Cylindermuki10Încă nu există evaluări

- WEBINAR: Ballast Water Management - Be Ready For The Discharge Standard D-2Document32 paginiWEBINAR: Ballast Water Management - Be Ready For The Discharge Standard D-2sukhjit78Încă nu există evaluări

- Water Quality Testing FactorsDocument2 paginiWater Quality Testing Factorsroman66350% (2)

- ISO ListDocument22 paginiISO ListAbhimanyu BagalÎncă nu există evaluări

- SEALINE Catalog 2021Document20 paginiSEALINE Catalog 2021ddÎncă nu există evaluări

- BS 5045-2 Transportable Gas ContainersDocument48 paginiBS 5045-2 Transportable Gas Containerspgltu0% (1)

- EI 1590 Specifications and Qualification Procedures For Aviation Fuel Microfilters130515015011Document34 paginiEI 1590 Specifications and Qualification Procedures For Aviation Fuel Microfilters130515015011Ing. Gilberto Velásquez C.Încă nu există evaluări

- TGBS Open Day 2021 Fleet Management InsightsDocument40 paginiTGBS Open Day 2021 Fleet Management Insightsahmad aimanÎncă nu există evaluări

- Span TS 3004Document49 paginiSpan TS 3004Muhamad FarhanÎncă nu există evaluări

- Tank Mangement API RP 2350 PDFDocument17 paginiTank Mangement API RP 2350 PDFfarhanÎncă nu există evaluări

- 49 CFR Ch. I (10-1-01 Edition) 173.34: 173.34 Qualification, Maintenance and Use of CylindersDocument13 pagini49 CFR Ch. I (10-1-01 Edition) 173.34: 173.34 Qualification, Maintenance and Use of Cylindersleunamsayan100% (1)

- Conder Separator Brochure NewDocument8 paginiConder Separator Brochure Newednavilod100% (1)

- A338 Steel StandardDocument2 paginiA338 Steel StandardguilhermehsssÎncă nu există evaluări

- WKS 17 Cylinder Design Standards Withdrawn June 2023 v2Document6 paginiWKS 17 Cylinder Design Standards Withdrawn June 2023 v2Marley GomezÎncă nu există evaluări

- Ansi-Valve Body Material SelectionDocument3 paginiAnsi-Valve Body Material SelectionsatthukotienÎncă nu există evaluări

- Starline Firesafe Ball ValveDocument6 paginiStarline Firesafe Ball ValvePhornlert WanaÎncă nu există evaluări

- 236d ElectricalDocument4 pagini236d ElectricalJavier CaceresÎncă nu există evaluări

- PROSIS Part Information: 8/3/2011 1020038 20060 EC700B LC Volvo 10001-212/100 Cylinder Block 8279230Document3 paginiPROSIS Part Information: 8/3/2011 1020038 20060 EC700B LC Volvo 10001-212/100 Cylinder Block 8279230Power MobileÎncă nu există evaluări

- Solar Water Heaters Guidelines V1 Aug 2019Document49 paginiSolar Water Heaters Guidelines V1 Aug 2019Mile DjordjevicÎncă nu există evaluări

- Dead loads and gravity framing designDocument3 paginiDead loads and gravity framing designYURITZI MARTINEZ CUELLARÎncă nu există evaluări

- 7 - In. Posiset Thru-Tubing Plug (2 / - In. Od) : Description FeaturesDocument1 pagină7 - In. Posiset Thru-Tubing Plug (2 / - In. Od) : Description Featureshamed1725Încă nu există evaluări

- Syllabus WELDING TECHNOLOGY R2017Document2 paginiSyllabus WELDING TECHNOLOGY R2017CHANDRAPRAKASHÎncă nu există evaluări

- B8 PPT Composites MT14 20nov14Document86 paginiB8 PPT Composites MT14 20nov14Rasagya MishraÎncă nu există evaluări

- ME Engine Shows Real Fuel Savings: DieselfactsDocument16 paginiME Engine Shows Real Fuel Savings: DieselfactsKamal WanniarachchiÎncă nu există evaluări

- The Piping Engineering WorldDocument4 paginiThe Piping Engineering WorldHrishikesh PatilÎncă nu există evaluări

- Parts Cataloque 2006Document47 paginiParts Cataloque 2006keesÎncă nu există evaluări

- "DOL Starter": Submitted byDocument10 pagini"DOL Starter": Submitted byKartik InamdarÎncă nu există evaluări

- Control Cables PDFDocument28 paginiControl Cables PDFPandurang NalawadeÎncă nu există evaluări

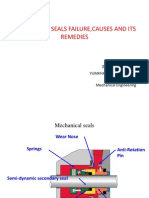

- MECHANICAL SEALS FAILURE CAUSESDocument26 paginiMECHANICAL SEALS FAILURE CAUSESFaruque Khan Yumkhaibam100% (6)

- Eni Blasia S 220Document2 paginiEni Blasia S 220Fajar EkoÎncă nu există evaluări

- Piping Drawings Basics: Mr. T. N. GopinathDocument39 paginiPiping Drawings Basics: Mr. T. N. Gopinathhirenkumar patel100% (1)

- AE240 Notes Early-Airfoil-Development-Handout-1Document5 paginiAE240 Notes Early-Airfoil-Development-Handout-1mohamedÎncă nu există evaluări

- Bending and Transverse TensionDocument23 paginiBending and Transverse TensionAsghar Hussain ShahÎncă nu există evaluări

- LS Circuit IntroductionDocument18 paginiLS Circuit IntroductionMuhammad DaniÎncă nu există evaluări

- Split Case LRDocument8 paginiSplit Case LRmartin.rubenÎncă nu există evaluări

- Kic API X70Document8 paginiKic API X70Ivan SilveiraÎncă nu există evaluări

- Rigid Pavement Thesis 3Document12 paginiRigid Pavement Thesis 3san htet aungÎncă nu există evaluări

- Curriculam Vitae: Mohamed Ibrahim.mDocument4 paginiCurriculam Vitae: Mohamed Ibrahim.mAzizul AnwarÎncă nu există evaluări

- General Online QuestDocument80 paginiGeneral Online QuestPankaj PooniaÎncă nu există evaluări

- Gallic 16 Engels Hld23 TornoDocument47 paginiGallic 16 Engels Hld23 TornoAdrian Macaya100% (1)

- Hyster j2 2 3 5xnDocument12 paginiHyster j2 2 3 5xnBraveBoy JalloÎncă nu există evaluări

- B149.03 02-En PDFDocument4 paginiB149.03 02-En PDFIndra MishraÎncă nu există evaluări

- Manual RT760EDocument159 paginiManual RT760EJonathan Velasco Arce100% (2)

- Di Pipes AuhDocument22 paginiDi Pipes AuhMaged SamirÎncă nu există evaluări

- QSL9 Series PDFDocument4 paginiQSL9 Series PDFAnonymous 3RS6JNcÎncă nu există evaluări