Documente Academic

Documente Profesional

Documente Cultură

Zenoah G230PU Petrol Engine

Încărcat de

Jarkko Puustinen0 evaluări0% au considerat acest document util (0 voturi)

281 vizualizări4 paginiThis document provides instructions for operating and maintaining the G230PU engine model. It can be used in airplanes, helicopters, or boats depending on the specific model. The summary is as follows:

The document outlines safety precautions and instructions for mounting the engine, selecting the appropriate propeller/rotor/screw propeller for the application, fuel mixing ratios, starting and stopping procedures, carburetor adjustment, break-in process, and basic servicing instructions. Precautions are given to not modify parts and to use genuine replacement parts. Starting and operating instructions vary slightly depending on the application - airplane, helicopter, or boat.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document provides instructions for operating and maintaining the G230PU engine model. It can be used in airplanes, helicopters, or boats depending on the specific model. The summary is as follows:

The document outlines safety precautions and instructions for mounting the engine, selecting the appropriate propeller/rotor/screw propeller for the application, fuel mixing ratios, starting and stopping procedures, carburetor adjustment, break-in process, and basic servicing instructions. Precautions are given to not modify parts and to use genuine replacement parts. Starting and operating instructions vary slightly depending on the application - airplane, helicopter, or boat.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

281 vizualizări4 paginiZenoah G230PU Petrol Engine

Încărcat de

Jarkko PuustinenThis document provides instructions for operating and maintaining the G230PU engine model. It can be used in airplanes, helicopters, or boats depending on the specific model. The summary is as follows:

The document outlines safety precautions and instructions for mounting the engine, selecting the appropriate propeller/rotor/screw propeller for the application, fuel mixing ratios, starting and stopping procedures, carburetor adjustment, break-in process, and basic servicing instructions. Precautions are given to not modify parts and to use genuine replacement parts. Starting and operating instructions vary slightly depending on the application - airplane, helicopter, or boat.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

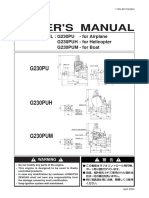

OWNER'S MANUAL

MODEL : G230PU - for Airplane

G230PUH - for Helicopter

G230PUM - for Boat

G230PU

G230PUH

G230PUM

April 2002

1155-93110(204)

Do not modify any parts of the engine.

This engine is designed to be used to Radio

controlled products.

In case any modification by customer, KOMATSU

ZENOAH shall not bear any responsibility from

the damage caused by such modification.

Keep ignition system well maintained.

WARNING

1. Propeller for airplane

The recommended prop sizes are as shown in the table bellow.

This engine with a standard muffler produces the maximum

output when the engine is running at about 10,000rpm. Be sure

to use a propel l er whi ch makes the engi ne speed

approximately 7,000~9,500rpm while the airplane is flying.

[ NOTE ]

When mounting the spinner, set a pin on the hub with more

than 3mm of diameter, thus preventing slipping.

2. Rotor for helicopter

Adjust the rotor-pitch to obtain 9,000~10,000 rpm of the engine

at full throttle operation.

3. Screw Propeller for boat

The exhaust system (e.g., muffler) is not equipped with as

standard. When you select the exhaust system for the engine,

check how many the engine speed (rpm) is required when the

maximum output is generated by using the muffler you select.

And then decide the appropriate the screw propeller that would

meet such engine speed (rpm) that the muffler required.

In general, standard size of the screw propeller (Surface prop

type) are as follows:

1. SAFETY PRECAUTIONS

2. MOUNTING G230PU

3. PROPELLER, ROTOR & SCREW PROPELLER

4. FUEL

5. OPERATION

Make sure that the G230PU is mounted on the aircraft grade

pl ywood wi th more than 6mm of thi ckness or a mount of

equivalent strength and is firmly fixed with 4 bolts.

[ NOTE ]

1. Be sure to set flat washers or metal plate on the reverse side of

the mount to prevent bolts from sinking into the mount. Before

be sure to check for loose bolts.

2. Since the engine is equipped with a float-less carburetor with a

diaphragm pump, the direction of cylinder and position of fuel

tank can be freely selected .

Hand flip start

Since the G230PU is equipped with the ultra compact C.D.I. type

flywheel magneto ignition system, it should be started according

to the following procedure;

8 The magneto system of G230PU is designed in such a way

that when the exhaust port is closed by the piston, that is, when

the compression stroke starts (Refer to Fig. 1-A), sparks are

never produced on spark plug no matter how fast the propeller

may be flipped. Be sure to quickly flip the propeller when the

edge of magnet on the rotor is approaching the coil (Fig. 1-B).

It means that the propeller should be quickly flipped about 90

degrees in crank angle before the compression is about to

start.

How to Start the Engine

1. For Airplane

a. FiII the fuel tank with the fuel.

b. Choke the engine and turn the propeller a few times until the

fuel appears at the carburetor.

c. Set the throttle valve at the idle position or at the position

slightly open from the idle position. Quickly flip the propeller

in the counterclockwise direction according to the procedure

described above. Flip the propeller a few times. Then the

engine starts.

2. For Helicopter & Boat

a. Fill the fuel tank with the fuel.

b. Push the priming bulb upper the carburetor until fuel appears

in the priming bulb.(for Helicopter)

c. Choke the engine and open the throttle valve approximately

1/3~1/2 of the full open position.

d. Quickly pull the starter cord when the initial explosion is

heard.

e. When the initial explosion is heard, open the choke, set the

throttle valve at the idle position or at the position slightly

open from the idle position and quickly pull the starter cord a

few more times. Then the engine starts.

[ NOTE ]

Be sure to open the choke when the initial explosion is heard.

When the choke is opened, be sure to close the throttle valve

3. If the rubber joint is placed between the engine and the body

for anti-vibration, check if the rubber is too week and select the

proper hardness of the rubber, in order to avoid the unexpected

vibration under operating engine RPM zone.

Note carefully that if the engine is vibrated at idling, then the

i dl i ng RPM i s l i kel y to get unstabl e due to overfl ow at

carburetor by the vibration.

4. Coat the bolts for muffler with anti-looser (e.g., Locktite or

equivalent).when assembling.

This manual describes the engine. For its mounting and

control, see the instruction manual for the model airplane,

helicopter and boat.

Each engine is designed for use on each model airplane,

helicopter and boat. If it is used for any other purpose, we

cannot be responsible for its reliability or safety.

Use genuine parts for replacement.

Check the propeller, rotor and screw propeller every time.

If it is damaged, replace it with a new one.

If the propeller (or the rotor or the screw propeller) hit

something while the engine is in operation, immediately

stop the engine and check it.

Start the engine on a flat surface without pebble stones.

Never modify the fIywheeI.

Check the fIywheel. If it is damaged, replace it with a new

one.

When mixing the fuel, or operating the engine, carry it out

in a well-ventilated place.

Magnet

Coil

Fig.1-A Fig.1-B

Diameter Pitch ( in.)

18 6, 16 8 ~ 10

Diameter ( mm )

65 ~ 75

Pich ratio ( mm )

1.9 ~ 1.4

Mix gasoline and 2-stroke oil at a mixing ratio of 25 ~ 40 :1.

[ NOTE ]

1. Be sure to use a gasoline-resistant fuel piping. (Do not use any silicon rubber tube).

2. Never use any alcohol fuel or alcohol added fuel, or the rubber part in the carburetor will be damaged.

6. CARBURETOR ADJUSTMENT

7. ENGINE BREAK-IN

8. SERVICING

to a position near the idle position before starting the next flipping

(If the engine is started while the throttle is wide open, a great

thrusting force is produced, which is very dangerous).

Be sure to wear a thick glove when flipping the propeller. Use all

fingers, except thumb, for the flipping operation.

How to Stop the Engine

For stopping the engine, the black lead wire from the coil should be

grounded to the engine body, or the throttle valve should be closed

completely.

The carburetor is provided with 3 adjust screws which are set to

the best (approximately) positions by our company, but they may

need a l i ttl e adj ustment dependi ng on the temperature,

atmospheric pressure (altitude), etc. of the area where the engine

is used. Start the engine without making any adjustments. Make

readjustments only when the engine shows any mal-functioning.

1. Standard opening of each needle as follows;

Low speed needle: 1

1

/8

1

/4

High speed needle: 1

3

/8

1

/4

Idle Screw: Turning this screw clockwise increases the idling

R.P.M. Turning it counterclockwise decreases the

idling R.P.M

Low speed needle: This is the fuel adjust screw (not the air

screw). Turning this needle clockwise makes the

mixture gas leaner and turning it counterclockwise

makes it richer.

High speed needle: Turning this needle clockwise makes the

mixture gas leaner and turning it counterclockwise

richer. Set this needle at a position which is 1/4

open from the maximum R.P.M. position while the

airplane is on ground.

[ NOTE ]

1. Do not tighten the High and Low Speed needles too firmly.

2. When the unit has just started and the engine is not warm

enough, there may be insufficient acceleration and the engine

may be stopped. Be sure to perform idling before operation.

No specific break-in is required. The engine is gradually broken-in as it is used and the output is also increased gradually.

The engine can be disassembled or reassembled without any

specific difficulties, but be careful of the following matters;

a. For disassembling, the special tools shown in the parts list are

required in addition to the general tools. Be sure to use a new

gasket when the crankcase and cyl i nder have been

disassembled.

b. Removing rotor

1. Screw in the stopper (P/N 3350-96220) in place of the spark

plug. Then turn the rotor counterclockwise until the piston

touches the stopper. Take care it can cause damage to the

piston or connecting rod if the stopper is not screwed in to

the bottom.

2. Loosen and remove the rotor securing nut.

3. Remove the rotor by using the puller (P/N 1490-96101). Do

not hit on the crankshaft by a hammer, that can increase the

runout of the shaft.

c. Assembling crankcase

1. Apply grease on the oil seal lips and oil on the bearing.

2. Assemble the crankshaft with a new gasket.

3. When both front and rear crankcases are tightened, the

portion of gasket protruding on the cylinder mounted surface

should be cut off with a knife until the gasket becomes flush

with the cylinder mounted surface.

d. Assembling piston

Before assembling the piston, apply the oil on the small end

bearing and piston, and set the piston ensuring that the arrow

mark on the top of piston is directed toward the direction of

exhaust port.

e. Assembling cylinder

1. Coat the oil on the inner surface of cylinder.

2. The piston is provided with a knock pin which stops the

piston ring from turning. Set the splitted section of piston ring

at the knock pin and assemble the cylinder ensuring not to

break the piston ring.

f. Adjusting air gap of coil.

The air gap of coil should be adjusted to 0.3 mm (0.01").

g. Adjusting ignition time.

Thi s engi ne wi th the poi nt-l ess C.D.I. type requi res no

adjustments of ignition time.

Low Speed needle High Speed needle

Idle Screw

H

L

KILL SWITCH

BLACK LEAD

RED LEAD

ENGINE BODY EARTH

9. SPECIFICATIONS

Specifications are subject to change without notice.

MODEL ZENOAH G230PU ZENOAH G230PUH ZENOAH G230PUM

PURPOSE Airplane Helicopter Boat

TYPE Air cooled Water cooled

DISPLACEMENT 22.5cc

BORE STROKE 32mm 28mm

COMPRESSION RATIO 8.6 : 1

MAXIMUM OUTPUT 1.95PS/10500rpm [ 1.80PS/10500rpm ] 2.25PS/11000rpm

OPERATING ENGINE SPEED 2000~10000rpm 3000~11000rpm 3500~15000rpm

IGNITION SYSTEM CDI type Flywheel magneto

CARBURETOR WALBRO WA197A WALBRO WA167A WALBRO WA167A

AIR CLEANER Dry type

STARTING Hand flip Recoil starter

FUEL 2-cycle oil pre-mixed gasoline ( Mix ratio 25~40:1 )

SPARK PLUG NGK BMR7A or CHAMPION RCJ4

DRY WEIGHT [ 8 with standard muffler ] 1.42Kg [ 81.58Kg ] 1.49Kg [ 81.65Kg ] 1.45Kg

Q' ty per unit

PU PUH PUM Description Parts No.

Index

No.

Q' ty per unit

PU PUH PUM Description Parts No.

Index

No.

Index Qty

No. Parts No. Description /Unit

Index Qty

No. Parts No. Description /Unit

Index Qty

No. Parts No. Description /Unit

Index Qty

No. Parts No. Description /Unit

1 1148-12112 CYLINDER 1 1 0

2 1160-12111 CYLINDER 0 0 1

3 1160-12210 JACKET 0 0 1

4 07851-00515 JOINT 0 0 2

5 07000-03038 O RING 338 0 0 1

6 1160-12320 O RING 1.519.5 0 0 1

7 1160-12330 BOLT M38 0 0 2

8 1140-13121 GASKET CYL 1 1 1

9 3310-12281 BOLT M520 4 4 4

10 1140-13151 GASKET INSU 1 1 1

11 1148-13161 INSULATOR 1 1 1

12 3330-14121 GASKET CARB 1 2 1

1155-21101 CRANKCASE COMP 1 1 1

13 8 CRANKCASE (R) 1 1 1

14 8 CRANKCASE (F) 1 1 1

15 2629-21130 PIN 3 3 3

16 1140-21141 GASKET CASE 1 1 1

17 2169-21210 SEAL 12227 1 1 1

18 1155-21240 BEARING 2 2 2

19 04065-02812 RING SNAP 1 1 1

20 06034-06001 BEARING 1 1 0

21 1850-21220 SEAL OIL 0 0 1

22 01252-30530 BOLT M530 4 4 4

23 5600-41111 PISTON 1 1 1

24 1100-41210 RING PISTON 2 2 2

Head Office : 1-9 Minamidai, Kawagoe-city,

Saitama, 350-1192 Japan

Phone: (+81)492-43-1117 Fax: (+81)492-43-7197

Printed in Japan

25 1101-41310 PIN PISTON 1 1 1

26 1260-41320 RING SNAP 2 2 2

27 5500-41410 BEARING 1 1 1

28 1101-41340 WASHER THRUST 2 2 2

29 1155-42000 CRANKSHAFT C 1 1 1

30 1155-74110 PLATE MOUNT 1 1 1

31 0262-10516 SCREW CM516 3 3 3

32 1650-43230 NUT 1 0 0

33 1160-75210 PULLEY 0 1 1

34 1861-75101 RECOlL ASSY 0 1 1

35 0263-30414 SCREW M414 0 4 4

36 1000-43240 KEY 1 1 1

37 1140-43250 SHIM 0~2 0~2 0~2

38 2629-71210 COIL SO (GRAY) 1 0 0

39 1160-71211 COIL SO (RED) 0 1 1

40 2629-71311 COIL IG 1 1 1

41 0263-30414 SCREW M414 2 2 2

42 2629-72210 CAP PLUG (BLACK) 1 0 0

43 2850-72110 CAP PLUG (RED) 0 1 1

44 1400-72121 SPRING 1 1 1

45 0260-30422 SCREW M422 2 2 2

46-1 1148-73120 SPARKPLUG BMR7A 1 0 0

46-2 1155-73120 SPARKPLUG RCJ4 0 1 1

47 0263-90550 SCREW M550 2 0 2

48 0263-30555 SCREW M555 0 2 0

49 1142-83110 SPACER 510I.6 2 0 2

50 1751-82002 AIRCREANER 0 1 0

51 1145-81002 CARBURETOR 197A 1 0 0

52 1148-81002 CARBURETOR 167A 0 1 1

53 0263-90520 SCREW M5X20 2 2 2

54 1155-71110 ROTOR 1 1 1

55-1 1155-15110 MUFFLER 1 0 0

55-2 1148-08010 MUFFLER 0 1 0

56 1140-13141 GASKET MUFF 1 2 0

57-1 01252-30550 BOLT M550 2 0 0

57-2 01252-30560 BOLT M560 0 2 0

58-1 0263-30408 SCREW M48 1 0 0

58-2 0263-90416 SCREW M416 0 1 0

59 1152-43260 HUB 1 0 0

60 1152-43281 STUD 1 0 0

61 1152-43290 WASHER HUB 1 0 0

62 3350-53410 NUT 1 0 0

63 3350-96220 STOPPER (OPT) 1 1 1

64 1490-96101 PULLER ASSY (OPT) 1 1 1

65 1110-91320 SOCKET 1 1 1

66 1145-15412 SPACER 0 1 0

67 1158-15420 SPACER 0 1 0

68 1101-96220 ROD-A (OPT) 1 1 1

Q' ty per unit

PU PUH PUM Description Parts No.

Index

No.

10. PARTS LIST

PUH, PUM PU

[ NOTE ]

The parts indicated 8 in the part number column are supplied as an

assembly. No individual part available.

1 1145-81002 CARBURETOR ASSY

2 3306-81380 SCREEN 1

3 2630-81120 PUMP COVER 1

4 3330-81130 SCREW 1

5 3304-81140 GASKET, pump 1

6 1172-81150 DIAPHRAGM, pump 1

7 3310-81311 VALVE, inlet 1

8 3310-81280 METERING COVER 1

9 3310-81230 METERING LEVER 1

10 3310-81250 PIN 1

11 3310-81240 SCREW 1

12 2670-81270 SPRING 1

13 3310-81260 DIAPHRAGM ASSY 1

14 3310-81290 GASKET, metering 1

15 1491-81160 SPRING 1

16 1148-81171 NEEDLE 1

17 3350-81380 SPRING 1

18 2630-81330 SCREW 1

19 1148-81371 SHAFT ASSY 1

20 2670-81410 SPRING 1

21 1148-81390 RING 1

22 3310-81360 SCREW 1

23 1282-81340 THROTTLE VALVE 1

24 3310-81351 SCREW 4

25 3080-81320 SPRING 1

26 1148-81331 H NEEDLE 1

27 1480-81420 PLUG, welch 1

28 1790-81430 PLUG 1

29 3304-81440 RING 1

30 3304-81450 SCREEN 1

31 3304-81910 GASKET KIT 1

32 3304-81920 DIAPHRAM KIT 1

1 1148-81002 CARBURETOR ASSY

2 3306-81380 SCREEN 1

3 2630-81120 PUMP COVER 1

4 3310-81130 SCREW 1

5 3304-81140 GASKET, pump 1

6 1172-81150 DIAPHRAGM, pump 1

7 3310-81311 VALVE, inlet 1

8 1751-81520 METERING COVER 1

9 3310-81230 METERING LEVER 1

10 3310-81250 PIN 1

11 3310-81240 SCREW 1

12 1751-81510 PRIMER PUMP 1

13 2670-81270 SPRING 1

14 3310-81260 DIAPHRAGM ASSY 1

15 1790-81210 BODY ASSY 1

16 1751-81470 GASKET, metering 1

17 3350-81380 SPRING 1

18 2630-81330 SCREW 1

19 1148-81371 SHAFT ASSY 1

20 2670-81410 SPRING 1

21 1148-81390 RING 1

22 3310-81360 SCREW 1

23 1282-81340 THROTTLE VALVE 1

24 1148-81530 SCREW 4

25 3080-81320 SPRING 1

26 1148-81331 H NEEDLE 1

27 1491-81160 SPRING 1

28 1148-81171 NEEDLE 1

29 1480-81420 PLUG, welch 1

30 1790-81430 PLUG 1

31 3304-81440 RING 1

32 3304-81450 SCREEN 1

33 2630-06010 GASKET KIT 1

34 3304-81920 DIAPHRAM KIT 1

S-ar putea să vă placă și

- Briggs & Stratton Engine Manual, Model 90000/100000Document80 paginiBriggs & Stratton Engine Manual, Model 90000/100000zwhgÎncă nu există evaluări

- CV Carb TuningDocument7 paginiCV Carb Tuningmark_dayÎncă nu există evaluări

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocument13 paginiAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyÎncă nu există evaluări

- Honda Self Propel Mower - HRU215Document31 paginiHonda Self Propel Mower - HRU215StuartÎncă nu există evaluări

- Carburetor AdjustmentsDocument4 paginiCarburetor Adjustmentsconimec0% (1)

- Carbtune PDFDocument22 paginiCarbtune PDFndmvillocilloÎncă nu există evaluări

- Fluid IzationDocument37 paginiFluid Izationmehtab hussainÎncă nu există evaluări

- Ford CarbDocument27 paginiFord Carbsmcdonald2536100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- Super Tigre ManualDocument32 paginiSuper Tigre ManualtamanogÎncă nu există evaluări

- Operators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 TractorsDocument44 paginiOperators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 Tractorsfundreamer1Încă nu există evaluări

- Manual ParamotorDocument39 paginiManual ParamotorJose Ramon100% (1)

- PerforationDocument45 paginiPerforationCatur Nila Pratiwi75% (4)

- 1.9l 4-Cylinder Turbo DieselDocument26 pagini1.9l 4-Cylinder Turbo Dieselfloresf5100% (1)

- Compressor WabcoDocument6 paginiCompressor Wabcoruben_cruz_34Încă nu există evaluări

- A Lubricant Is A Substance Introduced To Reduce Friction Between Moving SurfacesDocument5 paginiA Lubricant Is A Substance Introduced To Reduce Friction Between Moving SurfacesMudasar JavedÎncă nu există evaluări

- Manual Motor Fuji 50Document12 paginiManual Motor Fuji 50Jorge Guerra SepulvedaÎncă nu există evaluări

- Testing and Adjusting Cat 3412 SN 3fzDocument21 paginiTesting and Adjusting Cat 3412 SN 3fzEd Calhe100% (11)

- Fouling Factor TEMADocument2 paginiFouling Factor TEMAIynulF.OmarÎncă nu există evaluări

- Bomba de Lodos BH 800 PDFDocument36 paginiBomba de Lodos BH 800 PDFJose Barrero0% (1)

- OBMDocument7 paginiOBMmmohsinaliawan100% (1)

- Manuel CJ750 M1 M1MDocument27 paginiManuel CJ750 M1 M1MFerrousstateÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Chap 4Document43 paginiChap 4adrien_ducaillouÎncă nu există evaluări

- MEROXDocument16 paginiMEROXai_25109275% (4)

- Torque Converter C-300 OWI - Service ManualDocument12 paginiTorque Converter C-300 OWI - Service Manualaldino020203100% (3)

- 100 Yer Pe Yss 0048Document19 pagini100 Yer Pe Yss 0048Cherukunnon JubuÎncă nu există evaluări

- r185nm ManualDocument36 paginir185nm Manualjohnysonycum100% (2)

- B&W Overfire AirDocument4 paginiB&W Overfire AirJose Lorenzo ToralÎncă nu există evaluări

- Manufacturers in Oil and Gas Industry EgyptDocument107 paginiManufacturers in Oil and Gas Industry Egyptsachin0% (1)

- Boiler DesignDocument12 paginiBoiler DesignRAMKUMAR40% (5)

- BCS Two Wheel Tractors Owners Manual PDFDocument20 paginiBCS Two Wheel Tractors Owners Manual PDFAngelescuO100% (2)

- Flash and Fire Point TestDocument7 paginiFlash and Fire Point TestAisyah Ibrahim89% (18)

- Air Liquide Technology HandbookDocument22 paginiAir Liquide Technology Handbooksohail1985100% (2)

- Production of Biodiesel CHEM PROJECTDocument17 paginiProduction of Biodiesel CHEM PROJECTNayera H. Elsaady100% (1)

- ZENO2012 AAaa G620PU, G620PU-1Document8 paginiZENO2012 AAaa G620PU, G620PU-1Martin Leonardo Arias PazÎncă nu există evaluări

- Zenoah 3366 G620PUDocument8 paginiZenoah 3366 G620PUMuhammad Indra RespatiÎncă nu există evaluări

- Owner'S Service ManualDocument20 paginiOwner'S Service ManualShayne BrittonÎncă nu există evaluări

- Zenoah G230PU Petrol Engine PDFDocument4 paginiZenoah G230PU Petrol Engine PDF6KILLER100% (1)

- NGH 38Document6 paginiNGH 38Jose Angel Guitart GonzalezÎncă nu există evaluări

- Owner'S Manual Model: G320PUM Model Code: 967289101: For Radio Control BoatDocument28 paginiOwner'S Manual Model: G320PUM Model Code: 967289101: For Radio Control BoatStevenÎncă nu există evaluări

- Every 500 Hours MaintenanceDocument7 paginiEvery 500 Hours Maintenancerolandaaprian9Încă nu există evaluări

- .46NX Evolution Engine: User GuideDocument7 pagini.46NX Evolution Engine: User GuideJuan Camilo GarciaÎncă nu există evaluări

- Evolution Engines ManualDocument6 paginiEvolution Engines Manualamalraj1005100% (1)

- Dleg0020 Manual v1 1Document24 paginiDleg0020 Manual v1 1Edgar Alexander Grisales VallejoÎncă nu există evaluări

- DLE 30 ManualDocument24 paginiDLE 30 ManualKang YAyanÎncă nu există evaluări

- XTM 21 ManualDocument6 paginiXTM 21 ManualCristian Luis ChenuÎncă nu există evaluări

- sm01b PDFDocument19 paginism01b PDFvette512Încă nu există evaluări

- At 502 at 504 OM 4 LubricationDocument2 paginiAt 502 at 504 OM 4 LubricationConrado Pinho Junior100% (1)

- GT17 Instruction ManualDocument3 paginiGT17 Instruction ManualJose Angel Guitart GonzalezÎncă nu există evaluări

- 1966 FORD MUSTANG Valve-Lash-Adjustment - CopieDocument2 pagini1966 FORD MUSTANG Valve-Lash-Adjustment - CopieLudo BarthelemyÎncă nu există evaluări

- Advance Workshop Exam SolvedDocument41 paginiAdvance Workshop Exam SolvedVinesh ThulasyÎncă nu există evaluări

- Thunder Tiger - +-+PRO-21+og+28BX-RP+bilmotorDocument4 paginiThunder Tiger - +-+PRO-21+og+28BX-RP+bilmotorPeter JoselitoÎncă nu există evaluări

- Leiten - Manual - Escarificador Masalta MC8Document11 paginiLeiten - Manual - Escarificador Masalta MC8bqbovercon2Încă nu există evaluări

- 2BK Carb-ManualDocument2 pagini2BK Carb-Manualfildan211Încă nu există evaluări

- Merry Tiller ManualDocument10 paginiMerry Tiller ManualJonathan GridleyÎncă nu există evaluări

- Clutch ManualDocument16 paginiClutch ManualCO BDÎncă nu există evaluări

- PowerPro Gas EngineDocument16 paginiPowerPro Gas Enginefrostserv6019Încă nu există evaluări

- RCGF Engine Operations ManualDocument8 paginiRCGF Engine Operations ManualricalvarengaÎncă nu există evaluări

- Dleg0085 ManualDocument24 paginiDleg0085 ManualEdgar Alexander Grisales VallejoÎncă nu există evaluări

- 60d1a18b-cb42-4fc3-a01c-49c9b37f5594Document8 pagini60d1a18b-cb42-4fc3-a01c-49c9b37f5594Tarso BrasilÎncă nu există evaluări

- 1E48F-E EngineDocument31 pagini1E48F-E EnginePatrik ArvhultÎncă nu există evaluări

- Dodge Ram A/C Compressor ClutchDocument7 paginiDodge Ram A/C Compressor ClutchKkbhuvan KkÎncă nu există evaluări

- Carburator - Ideal ProblemDocument4 paginiCarburator - Ideal ProblemfuggaÎncă nu există evaluări

- Mac Minarelli Gas TwinDocument6 paginiMac Minarelli Gas TwinAndrew SpiropoulosÎncă nu există evaluări

- Calibracion de ValvulasDocument3 paginiCalibracion de ValvulasJose FavaÎncă nu există evaluări

- Gasoline Engine Owners Maunal For H2I2Document16 paginiGasoline Engine Owners Maunal For H2I2antÎncă nu există evaluări

- Stiga Multiclip ManualDocument8 paginiStiga Multiclip ManualdubbydubbyÎncă nu există evaluări

- Ondemandware - Staticsites Horizon Us SiteSites Horizon masterdefaultManualsDLEG0020 Manual ENDocument24 paginiOndemandware - Staticsites Horizon Us SiteSites Horizon masterdefaultManualsDLEG0020 Manual ENpaulo_gallina_2Încă nu există evaluări

- Chotia-460 NewManualDocument8 paginiChotia-460 NewManualErin LassleyÎncă nu există evaluări

- 1324 1624 1824 Owners Manual 6 4 08Document64 pagini1324 1624 1824 Owners Manual 6 4 08Miguel LopÎncă nu există evaluări

- Cca 23 634 5Document4 paginiCca 23 634 5Guillermo FormosoÎncă nu există evaluări

- Jet Kit InstallDocument2 paginiJet Kit InstallmihaisimoÎncă nu există evaluări

- MANUAL Mini MotoDocument13 paginiMANUAL Mini MotoEdgardo ContrerasÎncă nu există evaluări

- Hyundai Exel 89 1.5l.mantenimientoDocument18 paginiHyundai Exel 89 1.5l.mantenimientoAlexander cesar neyra sotoÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Design Report 1Document31 paginiDesign Report 1arif arifinÎncă nu există evaluări

- Basic Occupational Safety and HealthDocument78 paginiBasic Occupational Safety and HealthShan AdriasÎncă nu există evaluări

- Chap 1 CREDocument24 paginiChap 1 CREtuansyafiqÎncă nu există evaluări

- Developmnet 10 - 2 - 3Document8 paginiDevelopmnet 10 - 2 - 3Garry SandhuÎncă nu există evaluări

- Daily Fuel Expense (Recovered)Document4 paginiDaily Fuel Expense (Recovered)ankit sharmaÎncă nu există evaluări

- WP II Demand Forecast Report FINAL RevisionDocument139 paginiWP II Demand Forecast Report FINAL RevisionSalih Ahmed ObeidÎncă nu există evaluări

- Petroleum Applications: Application and Installation GuideDocument28 paginiPetroleum Applications: Application and Installation GuideVictor NunezÎncă nu există evaluări

- Norme Antincendio Internazionali-1Document4 paginiNorme Antincendio Internazionali-1Bogdan-Grigore Branisteanu-AlbulescuÎncă nu există evaluări

- Industrial ProcessDocument64 paginiIndustrial Processgm0047Încă nu există evaluări

- Taller CombustionDocument1 paginăTaller CombustionAlexanderCáceresCalderón100% (1)

- Unit 1 Introduction To Automobile Engineering: StructureDocument6 paginiUnit 1 Introduction To Automobile Engineering: StructureJai Kumar KaushilÎncă nu există evaluări

- Whitfield Traditions Pellet Stove ManualDocument40 paginiWhitfield Traditions Pellet Stove ManualMr. MorganÎncă nu există evaluări

- Oil Burner Refractory FailureDocument2 paginiOil Burner Refractory FailureKamal ArabÎncă nu există evaluări

- 5-mp Separator PDFDocument1 pagină5-mp Separator PDFquangÎncă nu există evaluări