Documente Academic

Documente Profesional

Documente Cultură

2 Narayana CHT

Încărcat de

sarabjitsgDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2 Narayana CHT

Încărcat de

sarabjitsgDrepturi de autor:

Formate disponibile

Thursday, November

12, 2009

1

The Presentation on

Benchmarking Benchmarking Benchmarking Benchmarking

at

PETROFED Workshop on Energy Management

& Efficiency Improvement in the Oil & Gas

Sector by CSS Narayana, Centre for High

Technology

13th Nov09, New Delhi

WELCOME

WELCOME

TO

TO

Thursday, November

12, 2009

2

Presentation Overview

Introduction

Energy consumption, conservation & optimization

Performance Evaluation & Benchmarking how critical?

Performance Evaluation of PSU Refineries by CHT

Global Benchmarking Methodologies

Potential identified

Opportunities for performance improvement

Way forward

Thursday, November

12, 2009

3

Refining Capacity

132.4

148.9

240.9

127.3

116.9

127.3

105.4

99.4

158.9

89.9

94.3

94.3

82.0

33.0

33.0

43.5

33.0

27.0

0

50

100

150

200

250

2003 2004 2005 2006 2007 2012

Capacity of Indian Refineries, MMTPA

Total Capacity

PSU Refineries

Pvt. Refineries

Thursday, November

12, 2009

4

SIKKIM

GOA

MUMBAI

MANGALORE

KOCHI

CHENNAI

VISHAKHAPATNAM

HALDIA

MATHURA

KOYALI

BONGAIGAON

GUWAHATI

DIGBOI

NUMALIGARH

PANIPAT

NARIMANAM

BARAUNI

BHATINDA

JAMNAGAR

RIL 33 & 29

12.0

5.5

MRPL 9.69

7.5

9.5

1.0

7.5

12.0

8.0

6.0

3.0

0.65

1.0

2.35

6.0

13.7

BINA

PARADEEP

REFINERY

EXISTING

North

South

East

West

Current Processing

Capacity

PROPOSED LEGEND LEGEND

Vadinar

20 MMTPA

35.19 MMTPA

19 MMTPA

74.9 MMTPA

Nameplate Capacities in

MMTPA 10

6

Tons/Yr

Indian Refining Capacity

ESSAR 10.5 & 3.5

Total Capacity

=178 MMTPA

9.0

BPCL

IOCL

HPCL

KADALUR

Nagarjuna 6.0

ONGC

Thursday, November

12, 2009

5

Indian Refineries

19 refineries 17 PSUs & 2 Private

Present refining capacity of 178 MMTPA much higher than

product demand of 133.4 MMTPA

Focus shifted from maximization of middle distillates to

market driven economics more secondary units

Stringent Envn. Norms, fuel quality compliance & improved

performance key for survival

Evolving Refinery Configurations highly complex &

integrated with Petrochemicals / Power plants to up-grade

bottom of the barrel for maximize profitability

Thursday, November

12, 2009

6

Need for Energy Conservation

~45% of our energy needs met by oil & gas sector alone

Energy accounts for ~40% operating costs in HC Sector

Fuel consumption & HC Loss: 7-10% of crude processed

Energy conservation and environmental protection are two

sides of the same coin

Higher Energy Efficiency & better management play vital

role in leveraging profit margins

Hence, Optimizing internal energy consumption is the key

The endeavour should be towards optimizing

energy consumption and not minimization.

Thursday, November

12, 2009

7

Energy consumption

Is manifested thru following attributes

Direct fuel in Heaters/Boilers/GTGs

Indirect fuel to raise Steam

Steam & Power for Equipment drive

Cooling Water circulation

Refinery energy consumption is calculated based

on consumption of each of these attributes

To generate Power

Thru STG

To meet Process req.

Thursday, November

12, 2009

8

375

380

386

367

362

385

350

355

360

365

370

375

380

385

390

395

400

0

3

-

0

4

0

4

-

0

5

0

5

-

0

6

0

6

-

0

7

0

7

-

0

8

0

8

-

0

9

Average Industry Energy & Loss Consumption (Mbtu/bbl)

Thursday, November

12, 2009

9

Specific Energy Consumption Trend

76

82

81

74

71

69

65

67

69

71

73

75

77

79

81

83

85

0

3

-

0

4

0

4

-

0

5

0

5

-

0

6

0

6

-

0

7

0

7

-

0

8

0

8

-

0

9

Average Industry Specific Energy & Loss Consumption (Mbtu/Bbl/NRGF)

Thursday, November

12, 2009

10

Performance Evaluation

Why needed ?

It is an on-going process to assess the present operation

of a refinery against best in the world w.r.t. to KPIs such as

Capacity utilization

Energy & HC Loss Management

Yield & processing

Human Resources & other Asset Management

Maintenance Performance, Reliability & Availability

Financial Performance

Environmental Performance

and identify the scope and further improve the operational

performance.

Thursday, November

12, 2009

11

Performance Evaluation

How Critical ?

Globalization

Corporate mergers & formation of JVs

Oil & Gas Sector is a truly global & highly competitive industry

Value added product at acceptable cost

Market driven cost profits under pressure spiraling input costs

Ever increasing energy costs & Security

Dismantling of APM

Fluctuating Operating Margins - need to reduce operating costs

Challenges ahead in processing Heavy & Sour Crudes

Stringent Fuel Quality & Environment Norms

Performance evaluation helps to take corrective measures

to bridge the identified gaps to improve bottom-line &

finally be at par with global standards

Thursday, November

12, 2009

12

Refinery Performance evaluation

Tools for improvement

Benchmarking the ongoing search for best practices that produces the ongoing search for best practices that produces the ongoing search for best practices that produces the ongoing search for best practices that produces

superior performance when adopted and implemented superior performance when adopted and implemented superior performance when adopted and implemented superior performance when adopted and implemented

Effective tool to improve Effective tool to improve Effective tool to improve Effective tool to improve , productivity, quality, profitability and , productivity, quality, profitability and , productivity, quality, profitability and , productivity, quality, profitability and

other such dimensions of performance that determine other such dimensions of performance that determine other such dimensions of performance that determine other such dimensions of performance that determine

competitiveness competitiveness competitiveness competitiveness

Is the first step on the improvement cycle Is the first step on the improvement cycle Is the first step on the improvement cycle Is the first step on the improvement cycle

Identifies the opportunities for improvement Identifies the opportunities for improvement Identifies the opportunities for improvement Identifies the opportunities for improvement

Helps to measure success achieved in bridging gaps identified Helps to measure success achieved in bridging gaps identified Helps to measure success achieved in bridging gaps identified Helps to measure success achieved in bridging gaps identified

Maintains stimulus for continuous improvement Maintains stimulus for continuous improvement Maintains stimulus for continuous improvement Maintains stimulus for continuous improvement

Thursday, November

12, 2009

13

Why Benchmark?

Collects data and verifies the

KPIs that you rely on

Establishes solid cornerstone

to build corporate strategy

Measures progress towards

your Vision

Identifies opportunities for

improvement

Improvement

Cycle

Thursday, November

12, 2009

14

Performance Forces

Driving Forces Driving Forces

Biases Biases

Lack of Lack of

Challenge Challenge

Crises Crises and and

Interruption Interruption

Vision Vision

Knowledge Knowledge

Purpose Purpose

Organization Organization

Initiative Initiative

Recognition Recognition

Benchmarking Benchmarking

Focus Focus

Inappropriate Inappropriate

Goals Goals

Non Non- -Involvement Involvement

in Goal Setting in Goal Setting

Resisting Forces Resisting Forces

Unrealistic Unrealistic

Expectations Expectations

Risk Risk

Aversion Aversion

Neglect Neglect

Indecision Indecision

Upward Upward

Delegation Delegation

Leadership Leadership

Technology Technology

and Tools and Tools

Listening Listening

Training Training

and Mentoring and Mentoring

Planning Planning

and Goals and Goals

Networking Networking

Valid Valid

Information Information

Disorganization Disorganization

Fragmentation Fragmentation

Inflexibility Inflexibility

Poor Poor

Coaching Coaching

Inadequate Inadequate

Information Information

Labor Labor

Conflict Conflict

Regulation Regulation

or Subsidization or Subsidization

Office Politics Office Politics

and Red Tape and Red Tape

Invisible Invisible

Errors Errors

Inadequate Inadequate

Capital Capital

Weak Weak

Organizational Organizational

Sensing Sensing

Conflicting Conflicting

Priorities Priorities

Competition Competition

Collaboration Collaboration

Innovation Innovation

Strong Decision Making Strong Decision Making

and Risk Taking and Risk Taking

Accountability Accountability

Downward Downward

Delegation Delegation

Alignment Alignment

of Values of Values

World World- -Class Class

Thursday, November

12, 2009

15

P

e

r

f

o

r

m

a

n

c

e

P

e

r

f

o

r

m

a

n

c

e

G

a

p

s

G

a

p

s

P

r

a

c

t

i

c

e

s

P

r

a

c

t

i

c

e

s

G

a

p

s

G

a

p

s

O

r

g

a

n

i

z

a

t

i

o

n

a

l

O

r

g

a

n

i

z

a

t

i

o

n

a

l

O

w

n

e

r

s

h

i

p

O

w

n

e

r

s

h

i

p

Capturing the Potential within

Three Legs of the Stool

The Why

The What

The How

Thursday, November

12, 2009

16

Peer groups members

Are approximately your size

Are in your market area

Have a similar configuration

Customized Gap Analysis

Understanding Performance Gaps is key to Performance

Improvement

Performance gaps will be assessed using customized peer

groups

Thursday, November

12, 2009

17

Performance Evaluation & Benchmarking

Important!

Age or type of technology employed not taken into account

Why? refineries undergo continuous maintenance &

upgrading

So, age/technology of unit bear no resemblance to original

Obvious that old unit/technology may be less efficient w.r.t.

energy consumption or product yield/quality is an

inescapable fact, the performance gap is real & economics

of closing the gap should be evaluated.

Thursday, November

12, 2009

18

Energy Benchmarking & Targeting

CHT conducted Energy Benchmarking & Targeting of PSU

Refineries in 96 97 in association with EIL

20% Gap between actual energy consumption &

Benchmark identified for most of the Units. Corrective

measures taken to reduce the gap.

CHT along with EIL conducts regular Audits to reduce gap

between actual vis--vis Target Performance

CHT repeated Energy Benchmarking through EIL in 2003

Thursday, November

12, 2009

19

Performance Evaluation by CHT

CHT regularly carries out Internal Benchmarking of PSU

refineries w.r.t. major areas of operation impacting

profitability - as part of Performance Evaluation

The major parameters of performance benchmarked

include

1. Crude Tput,

2. Distillate Yield

3. Product Pattern

4. Energy Consumption

5. Fuel & Loss

6. HC Loss

7. Refinery overall Capacity Utilization (primary & secondary)

8. Plant Mechanical Availability (considers s/d details)

Thursday, November

12, 2009

20

Performance Evaluation by CHT

CHT introduced new Energy Factors for Process units in

2002-03, to reflect the technological advances over the

years

Energy Factor indicates intensity of Energy Consumption

of a process units vis--vis CDU

Similarly, new method for benchmarking Overall Refinery

Capacity Utilization taking utilization of into consideration

both primary & secondary units has started in 2004-05

This reflects actual scenario compared to earlier practice

of comparing only the capacity utilization of CDU only

Thursday, November

12, 2009

21

Benchmarking at Global Level

No data base on performance of global refineries readily

available in public domain

Objective is to develop valid industry performance criteria

to facilitate evaluation of refineries vis--vis others in that

region

International agencies such as SA, BP, KBC, SGSI, etc

carry out performance evaluation studies

Thursday, November

12, 2009

22

SA Benchmarking Studies

As advised by the Expert Committee constituted (to

identify gaps in technology in Indian refineries) by

MOP&NG in 1995, various refineries participated in

benchmarking studies

Refineries participated in International studies carried out

bi-annually by M/s Solomon Associates

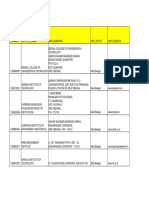

Year Refineries participated

1989 CPCL,IOCL (J), (M), (H)

1996 IOCL(J),(M),(H),BPCL,HPCL(M),(V),KRL,CPCL

1998 BPCL

2000 CPCL

Thursday, November

12, 2009

23

SA Benchmarking Studies

Major Key Performance Areas & Parameters are:

Performance Areas Parameters of measure

Capacity Utilization Equivalent Distillation

Capacity (EDC)

Capacity Utilization

Processing Efficiency Index

Energy Energy Intensity Index (EII)

Manpower Personal Index

Maintenance Cost Maintenance Index

Turnaround Index

Operating Expenses Cash Operating Index

Net Margin Net Margin Index

Thursday, November

12, 2009

24

SA Benchmarking Studies

EDC Equivalent Distillation Capacity

EDC concept helps for comparing performance

between refineries of different size & configuration

(Normalization)

EDC = (Configuration Factor * design unit

capacity)

Capacity Utilization is a function of EDC

Thursday, November

12, 2009

25

SA Benchmarking Studies

Energy Efficiency

The energy efficiency of a refinery is measured in terms of

Energy Intensity Index (EII), which is given by

EII = [(Actual energy consumption / Standard energy

consumption)] x 100

Standard energy consumption signifies target energy

consumption reasonably achievable if the refining

operation is optimal

Thursday, November

12, 2009

26

BP Energy Benchmarking Studies

BP carries out Energy Management Studies based on

utility parameters Steam, Power, Fuel & CW

Computes Energy Performance Index (EPI)

Actual Energy Consumption

EPI = ____________________________ X 100

Guideline Energy Consumption

A tool to judge relative unit performance w.r.t. Benchmark

Thursday, November

12, 2009

27

KBC Energy Benchmarking Studies

Approach considers overall refinery as a system and

studies integration between Process & Energy Systems

Developed Best Technology (BT) Energy Consumption

Norms Benchmarks for evaluating refinery performance

ENCON Programme considers Energy Costing & Plant

Yield Performance and results in economically justifiable

consumption level set by actual economic environment

Thursday, November

12, 2009

28

Shell Benchmarking of PSU Refineries

Modules

Energy and Hydrocarbon Loss Management

Human Resource Management

Maintenance performance, Reliability and Availability

Optimisation

Environmental Performance

Financial Performance

Boundaries of The Review

Standard Refinery (fuel + Lube Units) Operations,

Maintenance, Management and Projects

Includes Head Office Support functions

Excludes Terminals, Supply and Distribution, Packaging

Plants, Community Facilities (township, hospital, etc)

Thursday, November

12, 2009

29

Shell Benchmarking of PSU Refineries

Peer Groups comparison

Peer Groups Refineries are divided into Peer Groups on the

basis of Region and/or on the basis of the Refinery Complexity.

An additional Indian Peer group has been included in this study.

Three regional Peer Groups considered Asia Pasific (EAS),

Europe (EUR) and North & South America (NSA)

The refinery complexity Peer Groups in order of increased

complexity are

Hydro-skimming (HSK)

Thermal Cracking (TCR)

Small Complex (SCP)

Medium Complex (MCP)

Large Complex (LCP)

Very Large Complex (VLCP)

Thursday, November

12, 2009

30

NSP Count - 2004

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

100.0

1 2 3 4 5 6 7 8 9

1

0

1

1

1

5

1

6

1

8

1

9

2

0

2

1

2

2

2

5

2

6

3

0

3

1

3

5

3

6

3

7

4

0

4

1

4

2

4

3

4

5

4

6

4

7

4

8

4

9

5

0

5

1

5

2

5

3

5

4

5

5

5

6

5

7

5

8

HSK TCR

Small Complex Plant Medium Complex Plant

LCP VLCP

Indian PSU Refineries are classified as

Small or Medium Complex Type

N

o

r

m

a

l

S

h

i

f

t

P

o

s

i

t

i

o

n

(

N

S

P

)

Thursday, November

12, 2009

31

Intake relative to Complexity high for many sites

Barrels of Intake

0

25,000

50,000

75,000

100,000

125,000

150,000

175,000

200,000

225,000

P

r

o

c

e

s

s

i

n

g

I

n

t

a

k

e

k

b

b

l

/

y

r

.

Small Complex Plant Medium Complex Plant

HSK TCR LCP VLCP

HSK TCR

Small Complex Plant Medium Complex Plant

Thursday, November

12, 2009

32

The CEL system built as per this diagram

Process Units

Cooling Water

System

Flare

CEL

Energy

Loss

Generation

Consumption

Ocean

Refinery

Storage & Handling

Sundries

Process

Energy allowances

for Process units

Mass Balance to

close

Energy balance to

close

Thursday, November

12, 2009

33

Performance Evaluation & Benchmarking

Energy & Hydrocarbon Loss Management

Site CEL Index

Overall site Energy & Loss performance Indicator

CEL Index = Actual Energy Consumed + HC loss

_________________________________ X 100

Allowance for (Energy + HC loss)

Thursday, November

12, 2009

34

Energy & Loss Performance - CEL

80

100

120

140

160

180

200

220

1 2 3 4 5 6 7 8 9

1

0

1

2

1

3

1

6

1

8

1

9

2

4

2

5

2

7

2

8

2

9

3

0

3

1

3

2

3

4

3

7

3

9

4

0

4

1

4

4

4

5

4

6

4

7

4

8

4

9

5

0

5

1

5

2

5

3

5

4

5

5

5

6

5

7

5

8

HSK TCR SCP MCP LCP VLCP

C

E

L

I

n

d

e

x

.

CEL Index SBR 2003

improvement in Energy and Loss was noted

SBR = Shell Benchmarking Reference

Thursday, November

12, 2009

35

Refinery Energy and Loss Performance vs.

Regional Peers

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

2003 2004

Thursday, November

12, 2009

36

Strengths and Weaknesses

Strength

Many process units are near world average efficiency

Three sites (IOC M, IOC J & NRL) rank highly on a

regional basis for Energy. Others have included upgrades

since 2003/4

Good Generation efficiency for sites with Gas Turbines

Energy conservation disciplines well advanced

Opportunities

Older units offer scope to improve but will require

investment. Geography of site could limit these opportunities

Lower capacity utilisation has an effect on energy efficiency.

Site wide energy optimisation gaps caused by sequential

site development

Ocean losses needs attention

Thursday, November

12, 2009

37

Refinery Products Analysis

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

1

2

3

4

56

78

9

1

0

1

1

1

2

1

31

4

1

5

R

e

g

R

e

f

%

w

t

o

n

P

r

o

d

u

c

t

s

Gas LPG Gasolines + Naphtha Jet + Kero Gasoils Residue + Fuel Oil Base Oil + Bitumen +Wax Coke Other Fuel + Loss

Regional Target Mogas + Kero

Regional Target Distillate Yield

Thursday, November

12, 2009

38

Refinery Product Breakdown 2004/5

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Regional

Peer

Group

28.0

30.0

32.0

34.0

36.0

38.0

40.0

Gas & LPG Gasolines & Solvents Kerosene Gasoils Fuel Oil & Residue Lubes, Wax & Bitumen Coke, Sulphur & Misc Fuel & Loss Feedstock API

Thursday, November

12, 2009

39

Margin Performance comparison

On an Import parity basis Gross Margins improved by

210% between 2003/4 and 2004/5

By comparison Regional Marker Gross Margins improved

by between 230 and 290%

Key constraints on Gross Margin potential

Indian Market is skewed towards Gasoil and away from Jet and

Gasoline

Refineries are constrained to their regional market within India

No outlets for premium quality products

Lack of conversion capacity means that Distillates are derived from

Crude which yield low value Fuel Oil and other components

Little or no outlets for Chemical Feedstock or export of fuels

Thursday, November

12, 2009

40

Margin Potential & Opportunities

Further increase conversion capacity & reduce FO

Strategically replace Naphtha as fuel with NG and develop

aromatics and premium gasoline

Upgrade HCUs for increased LPG Yields

Continue to develop supply chain infrastructure, port

capacity, crude and product pipelines

Quality improvements not just in response to

Environmental drives but also product differentiation

Develop refinery-petrochemicals interfaces

Export potential for low cost refineries (< $1/bbl) with good

supply logistics. (note product quality risk)

Thursday, November

12, 2009

41

Margin Issues to tackle

Relative lack of Residue Upgrading reduces margin

Significant margin loss due to prevailing product market

structure

Currently little or no product premium available

Crude diet relatively fixed compared to actions taken by

peers

Some process units, e.g. HCU, may not be performing at

optimum

Thursday, November

12, 2009

42

Energy Benchmarking - results

2

10

3 3

8

4

1

9

5

2

7

6

Tercile 1 Tercile 3 Tercile 1 Tercile 3 Tercile 1 Tercile 3 Tercile 1 Tercile 3

Energy Consumption of Indian Refineries Vs APC & Global Peers

APC: Indian 15 & total 39 Global: Indian 15 & total 62

03-04 APC 04-05 APC 03-04 GBL 04-05 GBL

Thursday, November

12, 2009

43

Potential areas of improvement

Steam & Power Imbalance

Poor Insulation

Optimising Hydrogen consumption

High Steam Losses

High handling loss due to TTL dispatch

Piece-meal augmentation of Refining Capacity

Inadequate dissemination of ENCON measures being implemented

Lack of information on KPIs of Pace- setters in public domain

Energy Management Systems not fully evolved at some places

Lack of quality vendors (Poor workmanship)

Thursday, November

12, 2009

44

Energy Mgmt & Improvement

Efficient Management, best practices operation &

preventive maintenance measures requiring little or low

investment could save ~10% energy

Develop Action Plan based on successfully implemented

ENCON Schemes elsewhere

Implementation of these measures would help Indian Oil &

Gas Industries improve their Energy Efficiency &

Conservation levels

Savings in energy conservation would in future be

required from both cost cutting as well as conserving eco-

system

This will also help reduce GHG emissions and thus

protect our eco-system

Thursday, November

12, 2009

45

Limitations/barriers to improve Energy Efficiency

Lack of awareness at the operator level for acute need for

Conservation opportunity value lost due to inefficiency

No continuous display in DCS of key operating

parameters & their impact on margin (Thermal Efficiency of

Heaters/Boilers, etc)

Slow decision making ENCON Projects have to compete

for approval with other projects like Margin Improvement &

Environmental Issues

Absence of a dedicated & separate ENCON Cell at many

places

Existing award scheme for suggesting energy

improvement techniques need to be made attractive

Thursday, November

12, 2009

46

Maintenance Benchmarking results

1

6

8

1

8

6

1

5

9

5

9

1

0

10

Ter ci l e

1

Ter ci l e

2

Terci l e

3

Terci l e

1

Ter ci l e

2

Terci l e

3

Terci l e

1

Ter ci l e

2

Terci l e

3

Ter ci l e

1

Ter ci l e

2

Terci l e

3

Position of 15 PSU refineries in various Terciles for 2003-04 & 2004-05

APC - Asia Pacific Region & GBL - Global refineries

03-04 APC 04-05 APC 03-04 GBL 04-05 GBL

Thursday, November

12, 2009

47

Refinery Reliability key for sustainability

75

80

85

90

95

100

1 2 3 4 5 6 8 9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

3

0

3

1

3

2

3

3

3

4

3

5

3

7

3

8

4

2

4

8

4

9

5

0

5

3

5

6

5

7

5

8

%

M

a

i

n

t

a

i

n

e

d

A

v

a

i

l

a

b

i

l

i

t

y

.

Thursday, November

12, 2009

48

Potential identified from Benchmarking

Energy and Loss Management area Energy is

the single largest controllable cost.

Maintained Availability Unavailability is one of

the largest controllable loss of Income for the

sites.

Unplanned Downtime Unreliable plant also

leads to loss of Income and adds costs.

Supply Chain Optimization External market

impact on plant utilization. Supply chain

optimization is of lower priority than the items

above.

Thursday, November

12, 2009

49

Way Forward

Efficient energy use cornerstone for sustenance

Implementation of ENCON Measures

Overall site heat integration

Optimize utilities generation GT based CPPs

Key is sustainable Availability & Reliability improvement

to go for best operating practices, constantly assess the

impact of unit non-availability

Synergy with Petrochemicals & Power Plants

Upgrade Bottom of the Barrel wisely for profit margin

Increase conversion capacity

Reducing Carbon foot print I.e. Greenhouse Gas Emissions

Zeal to operate close to Benchmarks helps create

competition in excellence

Benchmark & target the systems regularly

Thursday, November

12, 2009

50

World is changing More Rapidly than we can

Comprehend or fully Analyze!

Let us explore & catch up fast.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Hidrl1 PDFDocument7 paginiHidrl1 PDFRajesh Kumar100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Antena TelnetDocument4 paginiAntena TelnetMarco PiambaÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Pityriasis VersicolorDocument10 paginiPityriasis Versicolorketty putriÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- NCP - Major Depressive DisorderDocument7 paginiNCP - Major Depressive DisorderJaylord Verazon100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Canoe Matlab 001Document58 paginiCanoe Matlab 001Coolboy RoadsterÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Winter CrocFest 2017 at St. Augustine Alligator Farm - Final ReportDocument6 paginiWinter CrocFest 2017 at St. Augustine Alligator Farm - Final ReportColette AdamsÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The cardioprotective effect of astaxanthin against isoprenaline-induced myocardial injury in rats: involvement of TLR4/NF-κB signaling pathwayDocument7 paginiThe cardioprotective effect of astaxanthin against isoprenaline-induced myocardial injury in rats: involvement of TLR4/NF-κB signaling pathwayMennatallah AliÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The RBG Blueprint For Black Power Study Cell GuidebookDocument8 paginiThe RBG Blueprint For Black Power Study Cell GuidebookAra SparkmanÎncă nu există evaluări

- Pg2022 ResultDocument86 paginiPg2022 ResultkapilÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Sakui, K., & Cowie, N. (2012) - The Dark Side of Motivation - Teachers' Perspectives On 'Unmotivation'. ELTJ, 66 (2), 205-213.Document9 paginiSakui, K., & Cowie, N. (2012) - The Dark Side of Motivation - Teachers' Perspectives On 'Unmotivation'. ELTJ, 66 (2), 205-213.Robert HutchinsonÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Eloy-Stock English Full PDFDocument0 paginiEloy-Stock English Full PDFR.s. WartsÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Toeic: Check Your English Vocabulary ForDocument41 paginiToeic: Check Your English Vocabulary ForEva Ibáñez RamosÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Kiritsis SolutionsDocument200 paginiKiritsis SolutionsSagnik MisraÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Student Exploration: Inclined Plane - Simple MachineDocument9 paginiStudent Exploration: Inclined Plane - Simple MachineLuka MkrtichyanÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Applications SeawaterDocument23 paginiApplications SeawaterQatar home RentÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Amount of Casien in Diff Samples of Milk (U)Document15 paginiAmount of Casien in Diff Samples of Milk (U)VijayÎncă nu există evaluări

- Rifle May 2015 USADocument72 paginiRifle May 2015 USAhanshcÎncă nu există evaluări

- Buried PipelinesDocument93 paginiBuried PipelinesVasant Kumar VarmaÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Rom 2 - 0-11 (En)Document132 paginiRom 2 - 0-11 (En)Mara HerreraÎncă nu există evaluări

- WBDocument59 paginiWBsahil.singhÎncă nu există evaluări

- Quiz 140322224412 Phpapp02Document26 paginiQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- English Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiDocument4 paginiEnglish Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiMutiara siwa UtamiÎncă nu există evaluări

- Design of Penstock: Reference Code:IS 11639 (Part 2)Document4 paginiDesign of Penstock: Reference Code:IS 11639 (Part 2)sunchitk100% (3)

- Fire Protection in BuildingsDocument2 paginiFire Protection in BuildingsJames Carl AriesÎncă nu există evaluări

- Quarter 1 - Module 1Document31 paginiQuarter 1 - Module 1Roger Santos Peña75% (4)

- Bolt Grade Markings and Strength ChartDocument2 paginiBolt Grade Markings and Strength ChartGregory GaschteffÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Perancangan Crushing Plant Batu Andesit Di PT Nurmuda Cahaya Desa Batujajar Timur Kecamatan Batujajar Kabupaten Bandung Barat Provinsi Jawa BaratDocument8 paginiPerancangan Crushing Plant Batu Andesit Di PT Nurmuda Cahaya Desa Batujajar Timur Kecamatan Batujajar Kabupaten Bandung Barat Provinsi Jawa BaratSutan AdityaÎncă nu există evaluări

- Interlocking Block TechnologyDocument15 paginiInterlocking Block TechnologyChaula Trivedi100% (5)

- postedcontentadminuploadsFAQs20for20Organization PDFDocument10 paginipostedcontentadminuploadsFAQs20for20Organization PDFMohd Adil AliÎncă nu există evaluări

- Speech On Viewing SkillsDocument1 paginăSpeech On Viewing SkillsMera Largosa ManlaweÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)