Documente Academic

Documente Profesional

Documente Cultură

Lean Manufacturing Implementation - The Main Chalenges and Barriers

Încărcat de

Eduardo Castrillón0 evaluări0% au considerat acest document util (0 voturi)

82 vizualizări8 paginiLean manufacturing, lean enterprise, lean production, or often simply "lean", is a practice that considers the expenditure of resources for any goal other than the creation of value for the end customer. This paper reveals to the challenges and barriers to be faced and overcome while implementing lean concept.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentLean manufacturing, lean enterprise, lean production, or often simply "lean", is a practice that considers the expenditure of resources for any goal other than the creation of value for the end customer. This paper reveals to the challenges and barriers to be faced and overcome while implementing lean concept.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

82 vizualizări8 paginiLean Manufacturing Implementation - The Main Chalenges and Barriers

Încărcat de

Eduardo CastrillónLean manufacturing, lean enterprise, lean production, or often simply "lean", is a practice that considers the expenditure of resources for any goal other than the creation of value for the end customer. This paper reveals to the challenges and barriers to be faced and overcome while implementing lean concept.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

41

ISSN 1822-6760. Management Theory and Studies for Rural Business

and Infrastructure Development. 2013. Vol. 35. No. 1. Scientific Journal.

LEAN MANUFACTURING IMPLEMENTATION: THE MAIN CHALENGES

AND BARRIERS

Ramun iarnien, Milita Vienaindien

Kaunas University of Technology

Lean manufacturing, lean enterprise, lean production, or often simply "Lean", is a practice

that considers the expenditure of resources for any goal other than the creation of value for the end

customer to be wasteful, and thus a target for elimination. Lean can be described at different levels

of abstraction: it can be defined as a philosophy, as a set of principles and as bundles of practices.

The paper reveals to the challenges and barriers to be faced and overcome while implementing lean

concept. Research method is the analysis and synthesis of scientific literature, logical, comparative

and graphic representation. On the base of analysis, authors of this paper present major implementa-

tion barriers.

Keywords: barriers, implementation, lean manufacturing, principles.

JEL classification: M11, L23, M54.

Introduction

The term "Lean" was coined by a research team working on international auto

production and it reflects the waste reduction nature of the Toyota production system

and contrasts it with the craft and mass forms of production (Womack, 1991). Later

Lean was defined by G. Howell (2001) as Give customers what they want, deliver

it instantly with no waste.

Manufacturing companies have been faced with increasing amounts of pressure

from customers and competitors in the past couple of decades. Customers have higher

expectations from their purchases, and manufacturers can meet these expectations by

increasing a products quality, reducing delivery time, and minimising product costs

or a combination of the three (George, 2002). This has forced the manufacturing

industry to implement new production strategies to enhance their competitiveness in

the global market place (Chena, 2010).

More than 20 years foreign scientists are discusing about lean manufacturing,

lean principles implementation, and tools and techniques. Results of its retrospective

analysis draw attention to such names as: J. P. Womack (1991, 1996), M. Imai

(1997), G. Howell (2001), M. George (2002), P. Hines et al. (2004), Z. Radnor and

R. Boaden (2008), S. P. Vendan and K. Sakthidhasan (2010), J. C. Chena et al.

(2010). The main barriers to lean implementation have been researched by: N. Bhatia

and J. Drew (2007), Z. Radnor and P. Walley (2008), L. Brando de Souza (2009),

H. M. Alinaitwe (2009), L. Brando de Souza and M. Pidd (2011), R. iarnien and

M. Vienaindien (2012), M. F. Bollbach (2012) and the others.

Though lean manufacturing has been widely recognised for its effectiveness in

continuously improving productivity, product quality, and on-time delivery to cus-

tomers; although a lot of companies started implementing lean concept, according to

42

S. Bhasin and P. Burcher (2006), only 10 percent or less of the companies succeed in

implementing lean manufacturing practices.

Despite significant studies and works on Lean manufacturing, this field has

struggled with a lack of clarity about why Lean implementation is not so successful

and what main barriers it faces with.

The problem is what are the main challenges and barriers for lean manufactur-

ing implementation and what measures could be taken to facilitate it.

The purpose of this paper is to identify the main challenges and barriers to

Lean implementation.

Research methodology. The analysis of scientific literature enabled to dis-

close the essence and importance of Lean concept. Synthesis of scientific literature

allowed finding out the core principles of Lean manufacturing. Scientific literature

was systemized and summarized by applying the logical, comparative and graphic

representation. On the base of conducted analysis and synthesis, two groups people

related barriers and organizational barriers were identified and reccomendations

how to overcome them presented.

The results of this research can be useful for scientists analizing this topic from

theoretical and empirical perspective, and for practicians implementing lean concept

in business.

The Essence of Lean Concept

Lean manufacturing was first implemented by Toyota Corporation in response

to the mass-production model. When engineers at Toyota researched mass-production

systems, they discovered that their mass-production model, which eliminated

changeover time by using one machine for each part, was not optimally efficient

(Toyota Production System).

They discovered that machines downstream were sitting idle until the specific

part the machine made was required for production. These idle machines contributed

to waste in the process. Therefore, the engineers from Toyota created a lean manufac-

turing system. This system focused on the continuous identification and elimination

of waste. As a result, the Toyota Production System (TPS) used fewer resources than

mass production. Organisations have found that, by identifying and removing waste,

as well as implementing key lean tools, they can continuously improve their produc-

tivity, increase quality, and become more cost effective (Imai, 1997).

Long production runs, big backlogs and long lead times are fast becoming op-

erating styles of the past. Flexibility and quick response must become the norm. The

driving force behind this need is customers who increasingly expect short lead times

for products configured exactly as specified and delivered on time, every time. The

trend of quick-response, no excuses delivery has put many manufacturers in the un-

comfortable position of having to conform or lose business to a competitor who has

developed short cycle time capabilities. To meet competitive requirements and reduce

costs, many manufacturers are turning to lean manufacturing techniques to drastically

cut cycle time and increase their competitive edge (Vendan, 2010).

43

Lean production can be described at different levels of abstraction: it can be

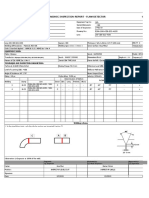

defined as a philosophy, as a set of principles and as bundles of practices (see fig-

ure 1). For instance, Womack et al. (1996) define Lean production as a business and

production philosophy that shortens the time between order placement and product

delivery by eliminating waste from a products value stream.

Figure 1. Different levels of Lean concept

There are many views of what constitutes Lean thinking. Although most peo-

ple recognize its roots in the Toyota production system, there has been considerable

development of the concept over time, with J. P. Womack and D. T. Jones (1996) re-

garded by most as the originators of the term. According to J. P. Womack (2002), the

five core principles of Lean, based on an underlying assumption that organizations

are made up of processes, are:

specify the value desired by the customer;

identify the value stream for each product providing that value and challenge

all of the wasted steps;

make the product flow continuously;

introduce pull between all steps where continuous flow is impossible;

manage towards perfection so that the number of steps and the amount of

time and information needed to serve the customer continually falls (see figure 2).

1.

Figure 2. The five core principles of Lean

LEAN

44

Subsequent development of the approach (Hines, 2004) differentiates between

Lean at a strategic level focusing on the principles, and at an operational level focus-

ing on the tools and techniques (Radnor, 2008).

Challenges and Barriers in Lean Implementation

There are some challenges which still face the implementation of Lean and

which to date still have not been fully addressed. Z. Radnor et al. (2006) depict the

following three issues that organizations face with:

the people issue understanding the effect and gaining buy-in of the indi-

vidual particularly when there is a dilemma that persuading people to embark on the

lean journey, where the last stop may be their own removal or reassignment isnt

easy;

the process issue understanding which processes are applicable for lean

tools and techniques;

the sustainability issue how to ensure that lean becomes more than another

set of tools but becomes an inherent way of working.

Slightly different classification presents M. F. Bollbach (2012); he discloses

the social and the technical barriers to Lean implementation: high employee turnover,

weak supplier performance, market conditions, lack of Lean knowledge, intercultural

communication, and work styles.

Summarizing N. Bhatia and J. Drew (2007), Z. Radnor and R. Boaden (2008),

Z. Radnor and P. Walley (2008), L. Brando de Souza (2009), H. M. Alinaitwe

(2009), L. Brando de Souza and M. Pidd (2011), R. iarnien and M. Vienaindien

(2012) and M. F. Bollbach (2012), authors of this paper maintain that classification of

barriers into social and technical is more acceptable. But technical barriers mostly

depend on the organization. Thus, authors highlight two types of barriers: people re-

lated barriers and organizational barriers. The list of main barriers to successful Lean

implementation is presented in table.

Presented classification of barriers to Lean implementation is very overall.

Barriers can differ depending on the sector of economy and specific company. It can

be said that every case of lean concept implementation is more or less unic. And

companies face with some variety of barriers. According to the authors of this paper

possition, some general recommendations could be suggested.

Firstly, one of the major mistakes and reasons of unsuccessful implementing of

lean concept is focusing on tools and techniques instead of sufficient consideration to

personally related issues. It is very important to ensure eficient trust, human motiva-

tion and commitment at the organization among all the levels of employees.

45

Table. The main barriers of Lean implementation

Type of Barriers Evidence

People related

Resistance to change

Implementing lean production often demands a sig-

nificant change in an organization's attitude, which

can be very challenging if an organization is not

well slated to deal with the changes.

Perception and lack of

knowledge

Lack of understanding of lean knowledge, principles

and techniques among managers and employees.

Identity of improvement

team members

Often made up of those willing to get involved, ra-

ther than those who should do so.

Poor communication

The over-use of jargon and the lack of a clear mes-

sage to staff.

Organizational

Compartmentalization

The fragmentation into functional and professional

silos imposes a major and functional barrier to the

flow of customers, goods and information.

Hierarchy and Cultural

issues

Based on the hierarchy of staff and the way man-

agement roles are allocated, it typically become a

barrier for any improvement but this is care and also

frequent roles especially important when lean is in-

troduced.

High Cost of Implemen-

tation and lack of re-

sources

Implementing lean often means completely disman-

tling previous physical plant setups and systems.

The purchase of efficient machinery and training

employees can add considerably to companies pay-

roll expenses.

Weak link between im-

provement programmes

and strategy

Lean improvement programs are not incorporated

into companys strategy.

Data collection and per-

formance measurement

It is necessary to show progress and to assess the ef-

fectiveness of the different changes, tools and tech-

niques that are implemented.

Secondly, despite the fact that some authors describe lean in different levels of

abstraction philosophy, set of principles and bundles of practices there should be

very close interaction between them. Lean as a philosophy must be clearly under-

stood and rated at the top managerial level, maintained through the main principles

and implemented using different tools and techniques.

Thirdly, one more recommendation is that lean improvement programs have to

be incorporated into the companys strategy.

Conclusions

1. Summarizing scientific literature, Lean manufacturing can be described at

different levels of abstraction: it can be defined as a philosophy, as a set of principles

and as bundles of practices.

2. According to the conducted analysis the following five core principles of

Lean can be identified:

specific value to the customer;

value stream mapping wastes elimination;

46

continuous improvement;

continuous flow;

and pull driven systems.

3. The analysis of scientific literature revealed that various authors emphasize

slightly different barriers and challenges to lean manufacturing implementation. Part

of them depict social and the technical barriers, while the others highlight barriers re-

lated with people issue, process issue, and sustainability issue.

4. Authors of this paper suggest classification of barriers into two groups:

people related barriers and organizational barriers.

5. General recommendations to facilitate lean manufacturing implementation

process could be suggested: focusing on people and personally related issues; close

interaction between lean as a philosophy, set of principles and bundles of practices;

incorporation of lean improvement programs into the overall companys strategy.

References

1. Alinaitwe, H. M. (2009). Prioritising Lean Construction Barriers in Uganda's Construc-

tion Industry // Journal of Construction in Developing Countries. Vol. 14, No. 1.

2. Bhasin, S., Burcher, P. (2006). Lean Viewed as a Philosophy // Journal of Manufacturing

Technology Management. No. 17 (1).

3. Bhatia, N., Drew, J. (2007). Applying Lean production to the public sector // McKinsey

Quarterly. No. 3.

4. Bollbach, M. F. (2012). Country specific barriers to implementing Lean production sys-

tems in China. http://hdl.handle.net/2134/10094 [2013 01 20].

5. Brando de Souza, L. (2009). Trends and approaches in lean health care // Leadership in

Health Services. No. 22 (2).

6. Brando de Souza, L., Pidd, M. (2011). Exploring the barriers to lean health care imple-

mentation // Public Money & Management. No. 31 (1).

7. Chena, J. C., Lib, Y., Shadyc, B. D. (2010). From value stream mapping toward a

lean/sigma continuous improvement process: an industrial case study // International Journal of

Production Research. Vol. 48, No. 4.

8. iarnien, R., Vienaindien, M. (2012). Lean manufacturing: theory and practice // Eco-

nomics and management. No. 17 (2).

9. George, M. (2002). Lean Six Sigma: Combining Six Sigma quality with Lean speed.

New York: McGraw-Hill.

10. Hines, P., Holweg, M., Rich, N. (2004). Learning to evolve: a review of contemporary

Lean thinking // International Journal of Operations and Production Management. No. 10 (24).

11. Howell, G. (2001). Introducing Lean Construction: Reforming Project Management.

Report Presented to the Construction User Round Table (CURT). Lean Construction Institute.

12. Imai, M. (1997). Gemba Kaizen: A common sense, low cost approach to manage-

ment. New York: McGraw-Hill.

13. Radnor, Z., Boaden, R. (2008). Editorial: Lean in Public Services Panacea or Para-

dox? // Public Money & Management. No. 1 (28).

14. Radnor, Z., Walley, P., Stephens, A., Bucci, G. (2006). Evaluation of the Lean Ap-

proach to Business Management and its Use in the Public Sector. Edinburgh: The Scottish Gov-

ernment.

15. Radnor, Z., Walley, P. (2008): Learning to Walk Before We Try to Run: Adapting

Lean for the Public Sector // Public Money & Management. No. 28 (1).

47

16. Vendan, S. P., Sakthidhasan, K. (2010). Reduction of Wastages in Motor Manufactur-

ing Industry // Jordan Journal of Mechanical and Industrial Engineering. Vol. 4. No. 5.

17. Womack, J. P. (2002). Lean Thinking: Where Have We Been and Where Are We Go-

ing? // Forming & Fabricating. Lean Manufacturing Special Insert.

18. Womack, J. P., Jones, D. T. (1996). Lean Thinking: Banish Waste and Create Wealth

in your Corporation. New York: Simon & Schuster.

19. Womack, J. P., Jones, D. T., Roos, D. (1991). The Machine that Changed the World:

The Story of Lean Production. New York: Harper Collins.

PAGRINDINIAI TAUPIOS GAMYBOS DIEGIMO IKIAI IR BARJERAI

Ramun iarnien, Milita Vienaindien

Kauno Technologijos Universitetas

Santrauka

Taupi gamyba (angl. Lean) ar taupi mon yra taupios vadybos filosofija ir praktika, utikri-

nanti produkt gamyb ir paslaug teikim minimaliomis snaudomis, nuostoli mainim, lanks-

tum bei nuolatin tobuljim. Tai didesn vert vartotojui, naudojant maiau resurs ir taip gyjant

didesn konkurencin pranaum. Lean gali bti traktuojama iais abstrakcijos lygiais: kaip filoso-

fija, kaip princip rinkinys ir praktik bei ranki visuma. Straipsnio tikslas ianalizavus mokslin

literatr, identifikuoti pagrindinius ikius ir klitis diegiant Lean koncepcij. Tyrimo metodo-

logija paremta mokslins literatros lyginamja analize ir sinteze bei grafiniu vaizdavimu. Remian-

tis atlikta analize straipsnio autoriai pateikia pagrindinius Lean koncepcijos gyvendinimo prakti-

koje barjerus ir rekomendacijas kaip sumainti j neigiam poveik.

Raktiniai odiai: barjerai, diegimas, principai, taupi gamyba.

JEL kodai: M11, L23, M54.

Copyright of Management Theory & Studies for Rural Business & Infrastructure Development is the property

of Management Theory & Studies for Rural Business & Infrastructure Development and its content may not be

copied or emailed to multiple sites or posted to a listserv without the copyright holder's express written

permission. However, users may print, download, or email articles for individual use.

S-ar putea să vă placă și

- ATF Guide on Firearm Import MarkingDocument32 paginiATF Guide on Firearm Import MarkingEduardo CastrillónÎncă nu există evaluări

- ATF Guide on Firearm Import MarkingDocument32 paginiATF Guide on Firearm Import MarkingEduardo CastrillónÎncă nu există evaluări

- 6S Visual Management - Draft-6!7!07 J RubioDocument62 pagini6S Visual Management - Draft-6!7!07 J RubiommakhanÎncă nu există evaluări

- A Model For Sustainable Operational Excellence Trrough Knowledge ManagementDocument216 paginiA Model For Sustainable Operational Excellence Trrough Knowledge ManagementEduardo CastrillónÎncă nu există evaluări

- Lean As A PhilosophyDocument17 paginiLean As A PhilosophyfabriiiÎncă nu există evaluări

- The Power of Positive Psychology for Improving Lean Six SigmaDocument6 paginiThe Power of Positive Psychology for Improving Lean Six SigmaEduardo CastrillónÎncă nu există evaluări

- BB - Lean Six Sigma in Services - ALL PagesDocument13 paginiBB - Lean Six Sigma in Services - ALL PagesNinh Manh LeÎncă nu există evaluări

- Going Lean: Professor Peter Hines & David TaylorDocument54 paginiGoing Lean: Professor Peter Hines & David Taylorwides7Încă nu există evaluări

- Analysis of Investor Behavior in An Artificial Stock MarketDocument33 paginiAnalysis of Investor Behavior in An Artificial Stock MarketEduardo CastrillónÎncă nu există evaluări

- 7 WasteDocument19 pagini7 WasteKushagra SharmaÎncă nu există evaluări

- Itp Stage Gate OverviewDocument29 paginiItp Stage Gate OverviewCicero ZanoniÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Securing Obligations Through Pledge and MortgageDocument4 paginiSecuring Obligations Through Pledge and MortgagePrincessAngelaDeLeon100% (1)

- Ecma L1221BR3 PD02 05172016Document2 paginiEcma L1221BR3 PD02 05172016Anil JindalÎncă nu există evaluări

- PACL Lodha Commette Final NOTICE of SALE With Property DetailsDocument4 paginiPACL Lodha Commette Final NOTICE of SALE With Property DetailsVivek Agrawal100% (2)

- Applying Graph Theory to Map ColoringDocument25 paginiApplying Graph Theory to Map ColoringAnonymous BOreSFÎncă nu există evaluări

- Dice Resume CV Narendhar ReddyDocument5 paginiDice Resume CV Narendhar ReddyjaniÎncă nu există evaluări

- 01 Lab ManualDocument5 pagini01 Lab ManualM Waqar ZahidÎncă nu există evaluări

- JVW 110Document2 paginiJVW 110Miguel Leon BustosÎncă nu există evaluări

- Inventory of Vacant Units in Elan Miracle Sector-84 GurgaonDocument2 paginiInventory of Vacant Units in Elan Miracle Sector-84 GurgaonBharat SadanaÎncă nu există evaluări

- RPH Sains DLP Y3 2018Document29 paginiRPH Sains DLP Y3 2018Sukhveer Kaur0% (1)

- UMC Florida Annual Conference Filed ComplaintDocument36 paginiUMC Florida Annual Conference Filed ComplaintCasey Feindt100% (1)

- Gulfco 1049 MaxDocument5 paginiGulfco 1049 MaxOm Prakash RajÎncă nu există evaluări

- Pantone and K100 Reverse White MedicineDocument16 paginiPantone and K100 Reverse White MedicinepaanarÎncă nu există evaluări

- Doohap supplier and customer segmentationDocument2 paginiDoohap supplier and customer segmentationPriyah RathakrishnahÎncă nu există evaluări

- Sine and Cosine Exam QuestionsDocument8 paginiSine and Cosine Exam QuestionsGamer Shabs100% (1)

- Coca Cola Live-ProjectDocument20 paginiCoca Cola Live-ProjectKanchan SharmaÎncă nu există evaluări

- CSIR AnalysisDocument1 paginăCSIR Analysisசெபா செல்வாÎncă nu există evaluări

- Vortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimDocument7 paginiVortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimhiraÎncă nu există evaluări

- Pakistan Affairs Current Affairs 2016 MCQSDocument3 paginiPakistan Affairs Current Affairs 2016 MCQSMuhammad MudassarÎncă nu există evaluări

- Ôn tập và kiểm tra học kì Tiếng anh 6 ĐÁP ÁNDocument143 paginiÔn tập và kiểm tra học kì Tiếng anh 6 ĐÁP ÁNThùy TinaÎncă nu există evaluări

- AP Biology Isopod LabDocument5 paginiAP Biology Isopod LabAhyyaÎncă nu există evaluări

- Chapter 27 Protists I. Evolution of EukaryotesDocument7 paginiChapter 27 Protists I. Evolution of EukaryotesNadeem IqbalÎncă nu există evaluări

- Method Statement Pressure TestingDocument15 paginiMethod Statement Pressure TestingAkmaldeen AhamedÎncă nu există evaluări

- New Pacific Timber v. Señeris, 101 SCRA 686Document5 paginiNew Pacific Timber v. Señeris, 101 SCRA 686Ishmael AbrahamÎncă nu există evaluări

- Vestax VCI-380 Midi Mapping v3.4Document23 paginiVestax VCI-380 Midi Mapping v3.4Matthieu TabÎncă nu există evaluări

- High Volume InstrumentDocument15 paginiHigh Volume Instrumentcario galleryÎncă nu există evaluări

- Entrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Document35 paginiEntrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Ameen KolachiÎncă nu există evaluări

- Chapter 4 and 5 - For StudentsDocument6 paginiChapter 4 and 5 - For Studentsdesada testÎncă nu există evaluări

- 4mb1 02r Que 20220608Document32 pagini4mb1 02r Que 20220608M.A. HassanÎncă nu există evaluări

- Kamera Basler Aca2500-20gmDocument20 paginiKamera Basler Aca2500-20gmJan KubalaÎncă nu există evaluări

- Ut ProcedureDocument2 paginiUt ProcedureJJ WeldingÎncă nu există evaluări