Documente Academic

Documente Profesional

Documente Cultură

Guide to restraining concrete panels and beams

Încărcat de

Stuart Edwards0 evaluări0% au considerat acest document util (0 voturi)

384 vizualizări18 paginiVicroads guide for load restraint for concrete panels and beams.

Titlu original

Vicroads Guide to Restraining Concrete Panels & Beams

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentVicroads guide for load restraint for concrete panels and beams.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

384 vizualizări18 paginiGuide to restraining concrete panels and beams

Încărcat de

Stuart EdwardsVicroads guide for load restraint for concrete panels and beams.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 18

keeping victorians connected

Guide to restraining concrete panels and beams

JANUARY 2013

Introduction

Safe loading of vehicles and restraint of loads are important in preventing

injury to people and damage to property. These help to prevent:

the load sliding forward into the truck cabin with serious risks to the driver;

the load falling from the vehicle onto other vehicles or pedestrians;

the load becoming unstable in a way that creates risk when unloading

the vehicle;

drivers and riders having to swerve to avoid fallen items; and

vehicles overturning because of the load shifting while cornering

or changing lanes.

At the very least, it avoids possible disruption to trafc ow.

As an owner and/or driver of a heavy vehicle and as a loader on consignor

you are responsible for ensuring that any load carried by your vehicle is safely

loaded and restrained. This means that the load:

must not be placed in a way that makes the vehicle unsafe or unstable;

must be secured so that it is unlikely to fall or to be dislodged from

the vehicle;

must be restrained by an appropriate method.

Any method of restraint used must comply with Section F (1) of the

Load

Restraint Guide - Second Edition

. This section of the guide details the

performance standards that any restraint system must meet. The guide also

provides information on the principles of restraining loads, requirements for

positioning loads, how to secure loads, and technical information and ratings

on various methods of restraint.

Information in this booklet on restraining concrete panels and beams

is in addition to other relevant information contained in the second edition

of the

Load Restraint Guide 2004

, plus industry standards listed on page 10

of this document.

This booklet describes some of the best ways of transporting concrete panels

and bridge beams.

The adequacy of a particular method of loading and restraint depends on a

large number of factors, and persons using this guide must ensure that the

methods used meet the above standards. VicRoads disclaims liability

for incorrect use of this information.

Every efort has been made to ensure that the information in this booklet

is correct at the time of publication.

The information contained

in this booklet should

be used as a guide only.

Operators should implement

loading and load restraint

procedures that comply with

the performance standards on

page 186 of the Load Restraint

Guide and are prepared in

accordance with Section I

of the Load Restraint

Guide - Second Edition.

3

Why loads move

The following factors can cause movement

of any load that is not adequately restrained:

impacts in minor crashes;

sudden braking, accelerating;

sharp cornering;

adverse road camber;

hilly or rough road surfaces; and/or

wind and airow over the vehicle.

General principles for loading and

restraining of concrete panels

1. Choose a suitable vehicle for the load

Vehicles with low loading decks (drop-deck, step-deck, low loader trailers)

are recommended for all large and high panels. These vehicles lower the

centre of gravity of the load, improving vehicle stability. They also provide

solid blocking of the load against the goose neck. Concrete panels should

be blocked at their front to stop any forward movement.

Vehicles should have properly designed anchor points often capable

of anchoring more than one restraint, especially at the front of the

loading oor.

2. Position and place the load

Keep the load weight evenly spread along the vehicle centre line,

with the centre of gravity as low as possible.

3. Select suitable restraint equipment

Concrete panels on-edge require certied A-frames for support. These

frames must be designed with sufcient strength for the application and

must be adequately restrained on the vehicle, both when laden or unladen.

Tie-down lashings are normally chain or webbing. They should be selected

on the basis of the required minimum pre-tension and lashing capacity (LC)

for the application. Suitable chains include 8 mm or 10 mm transport chain

tensioned with turnbuckle type tensioners. Suitable webbing is 50 mm

tensioned with hand ratchets or truck winches.

4. Check lashings after loading

After commencing a journey the load may settle and shift a little, which can

cause the lashings to loosen. Drivers should check the load and the restraint

tension shortly after commencing the journey. The number of checks that

should be made depends on many factors including the size and shape of

panels being carried as well as the condition of road being travelled.

Refer to 6.7.3 - Support Frames in The National Code of Practice for Precast

Tilt Up and Concrete Elements in Building Construction (Feb 2008) (Aust Govt

- Aust Safety and Compensation Council).

Square timbers are best

for supporting the load

Timbers on edge can roll

forward under braking

releasing all restraint

Correct, at support

Incorrect

4344 is the Aust Std No,

4 represents 4000 kg LC

A typical webbing tag with

required markings, as per

Aust Standard 4380

All load restraints must meet

and comply with Aust Standards

6.7.3 Support frames

Frames used to support concrete elements during transportation whether an integral part

of the transport vehicle or an add-on, need to be designed to withstand loads and forces

which may act on the system during loading, transportation and unloading.

A frame system that is not an integral part of the transport vehicle or trailer should be

adequately secured and be capable of withstanding any forces applied during loading,

transportation and unloading. The loading of vehicles must comply with the National

Transport Commissions Load Restraint Guide. This includes the certication of support

frames by a suitably qualied and approved engineer.

Particular care needs to be taken during loading and unloading of concrete elements from

frames to ensure the support frames remain stable at all stages.

44

Lashings

The minimum LC specications for lashings used for restraining

concrete panels are shown in Table 1 below.

Table 1 - Recommended lashings

Size Minimum recommended Lashing Capacity (LC)

Webbing 50 mm 2,500 kg

Transport Chain

1

8 mm 3.8 tonnes

Transport Chain

1

10 mm 6 tonnes (4.5 t with grab hooks)

Transport Chain

1

13 mm 9 tonnes (6.7 t with grab hooks)

1 Australian Standard AS/NZS4344

The 10 mm and 13 mm chains can be used as safety chains around

the front of the load. Normally a safety chain should provide 7.5 tonnes

of additional restraint for a 25 tonne load (0.8 - 0.5 g from tie-down).

An 8 mm looped chain at 30 to horizontal has a capacity of 3.8 t x

2 x 75% x cos 30 = 4.9 tonnes. A 10 mm chain has 7.8 tonnes lashing

capacity or (LC) and a 13 mm chain has 11.7 tonnes lashing capacity.

Dunnage

Support timbers should be made from hardwood and be a minimum

of 100 mm x 100 mm.

Dunnage timber should be in good condition and free of defects

such as splits and knots.

5

Recommended methods: Using A-frames for carrying

concrete panels

A-frames can be individual units or a set of frames made into one large unit.

Either way, the units themselves must be secured to the vehicle.

It is recommended that A-frames be attached to the deck by positive

methods using suitable bolts, pins or twist-locks. Chaining or clamping

sideways is not recommended, but if used, there should be adequate

friction between the frame and the vehicle deck, using rubber load mat or

timber contact surfaces. Chain and clamps should apply downward force

on the A-frames to increase friction forces.

Ensure that the A-frames have a suitably qualied engineer and approved

engineered design and are not twisted or carried on an uneven oor,

otherwise the load may rock and move. Refer to National Code of Practice

- Certication of Support Frames.

Each frame to carry unit ID numbers.

A-Frame rated positive locating bolts if

chained twist-locks on cross-bearers, preferred

High friction rubber recommended

to prevent steel on steel contact

Figure 1, Typical A-frame on a step-down trailer

A-frame secured with rated forward

blocking pad and high-friction rubber pad

twist-locked in place.

A-frame braced and secured by chains with

high friction rubber pads under the frames

and a rated blocking pad at the front.

Forward blocking pad

Forward blocking pad

High friction

rubber pads

Twist-lock

6

Walkway

and steps

Where panels are carried on a at top trailer without any blocking from a

goose neck or headboard, additional restraint is usually required. A safety

chain should be placed around the front edge of a load (see Figure 2).

These chains should have a minimum lashing capacity of at least 25 per

cent of the weight of the load if angled at less than 30 to the horizontal.

For example:

a 25 tonne load requires an additional 7.5 tonnes of restraint above

sideways and rearwards restraint forces. A 10 mm transport chain

at 30 provides 7.8 tonnes and has a lashing capacity of 6 tonnes

a 15 tonne load requires an additional 4 tonnes of restraint above

sideways and rearwards restraint forces. An 8 mm transport chain

at 30 provides 4.9 tonnes and has a lashing capacity of 3.8 tonnes.

Figure 2, Safety chains example: 4 chains with 2 front chains

independently holding each panel.

The safety chain should be positioned two thirds of the way

up the load and angled not more than 30 to the horizontal.

Top corner protectors

under each chain

High friction matting is

recommended when

using steel on steel

Suggested alternative is to

use a moveable blocking

frame at front of panels.

Note that some panel weight

is resting on the frame base.

Figure 3, Restraining panels on an A-frame using a at top trailer

Angle

30

o

- 35

o

7

Safety Chain

2/3rds high

Figure 4, Restraining panels on a rear-tilt frame on a at top trailer.

To ensure the safety chain does not slip during transport, the use of

a pedestal or a small frame is recommended (see Figures 2 and 4).

Alternatively a strap support over the top of the load can be used as

shown in Figure 3.

Figure 5, An example of a frame at the front of at panels. Safety Chain around the

blocking frame as well as the load resting on the frame base.

8

Carrying at slabs

Concrete panels carried at should be supported on the deck and on other

panels on square timber bearers or rectangular bearers placed on the long

side at (see Figure 6).

Corner protectors should be used under the chains to prevent movement

and damage to the panels.

The number of bearers required is dependent on the type of concrete panels

being carried. Lashings should be applied at each bearer position.

Safety Chain 2/3rds high

Note some load weight

is on blocking frame.

Figure 6, Restraining panels horizontally when using a at top trailer

9

General principles for loading and restraining

of concrete beams

Choose a suitable vehicle for the load

It is very important that the vehicle combination selection is based on

an accurate beam load weight. Final selection must be supported by

manufacturers engineering certication that meets all performance criteria that

may be encountered for permit travel. Individual dolly groups and frames to be

marked with unit ID numbers, load capacities using welded or plated markings.

Depending on the actual beam weight, vehicle conguration must be set up

for appropriate axle group mass limits under permit. The vehicle platform/

low loader/dolly support strength ratings are required for each of these

components and must take into account all particular travel turn angles that

may be encountered will need to be reassessed as being t for service by VASS

engineers or a person with approproate skills and experience as approved

by VicRoads. Additional information can be found in the WorkSafe Victoria

Construction and Erection of Bridge Beams Industry Standard April 2004

(see page 10 of this document).

1. Position and placement of the load

Beam support bolsters must have a certied load ratings document

that covers all likely force angles that may be encountered during travel

including loading and unloading sites. Whilst the loaded vehicle beam

centre of gravity (CoG) is always kept as low as possible it is recommended

at least one static roll threshold (SRT) calculation be conducted for each

beam group type and weight. A copy to be carried on the vehicle and to

be made available on request by police or enforcement ofcers. A certied

load restraint system must be implemented. Suitably competent persons

must be engaged to conduct an assessment of the loads being carried

and certify the load restraint system in accordance with Section I of the

Load Restraint Guide. Certication must be obtained and carried with the

vehicle carrying the load and be readily available for inspection by police or

enforcement ofcers.

2. Certied restraint system and equipment

Concrete beams of varying weights (30t 100t and over) require a

well calculated and a fully assessed load restraint method. Critical

areas for detailed attention include the beam support bolster material

(friction available), lashing chains sizes with lashing capacities to

match load weight (8 mm 10 mm 13 mm are typical sizes).

Annual chain strength safety checks are recommended (see tagged

example right). Attention to load tie-down points is important.

Alternatively all restraint equipment is to be checked in accordance

with Section H of the LGR.

Bolster design, hi-tensile strength steel, load support area, high friction

surfaces, sharp corners and known lashing pretensions are critically

important details that require accurate assessment. Ratchet or sliding

lever turnbuckles are recommended in lieu of regular chain dogs to more

reliably attain consistent pre-tension levels (This is for reducing manual

handling injury risk).

3. Load and lashings check after loading and before travel

Before commencing travel, all ttings, connections, brake hoses, steering

mechanism and equipment, connections are required to be thoroughly

checked. For relatively complex and high risk loading of this nature, it is

recommended that a comprehensive pre-start checklist for the particular

vehicle conguration is made available for suitably qualied responsible

person and the driver to sign of on before a load leaves on its journey.

Consider double-dogging

makes for even clamping

Ensure the load weight

and centre of gravity has

been accurately calculated

Always use or consider high

friction materials at support pad.

These must be blocked or adjusted

to t rmly against the beam

Correct designs must allow

hooks and chains to easily go

through beam restraint holes

and without sharp hole edges

and be clear of beam lifting lugs

4344 is the Aust Std No.,

13.0 represents 13000 kg LC

10

Extendable trailer loading of beams

Restraining beams on a at top or extendable trailers. Prevent movement

by always using sound and square timbers of say 200 mm x 200 mm.

A suitable load blocking system is often a worthwhile approach if available.

Always consider double-dogging. This ensures best load clamping

over right-angle edges of loads.

Blocking frame is a good

option Safety Chain 2/3rds high

Angle 30

o

Sound square timbers -

150 x 150 or 200 x 200mm

Double articulated loads

Total load dynamic braking forces on a turntable require total restraint

and or blocking capacity to be adequate for the load weight to the

level required to meet the LR Performance Standards. Where possible

use large blocking pins or bolt the turntable to the low loader oor.

Place some high friction rubber between steel on steel surfaces

such as a turntable shown on page 11.

WorkSafe Victoria Construction and Erection of Bridge Beams Industry

Standard April 2004. Sections 5 and 6 refer to Handling, Storage and

Transportation. The Aust Standard AS 3850 for Concrete Tilt Panels.

National Code of Practice for Precast, Tilt-up and Concrete Elements

in Building Construction Feb 2008 - (Australian Govt Safety and

Compensation Council).

Low loader and steerable (with operator)

Recommend to bolt or use locking pins

to locate and secure the turntable bolster

This set-up must have suff icient strength

to hold the load and the dolly weight

Dual-positive locking steerable

11

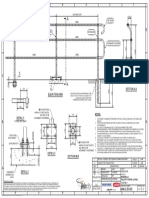

Drawbar self-steerable rear dolly combination

Ensure the beam manufacturer has at least 4 tie-down holes of adequate

diameter at each end of beams over 25t. The holes should also be able to

accommodate suitable chain corner protectors.

Always ensure lashing chains, hooks and tensioners are in a good

serviceable condition. Double check the total load weight, load point

friction and total lashing capacity for all new loads.

Always use positive locking pins in all connecting points. Most spring

clips fail after repeated use and can vibrate and fall out. Couplings must

incorporate a positive locking mechanism together with a separate means

of retaining this mechanism in the locked position. The locking mechanism

must be readily veriable by visual examination.

Vertical lock-nut or padlock

Example

only

Secondary

Positive slide lock

Primary

Non-rotating pin

Heavy vertical pins are recommended with high tensile locking bolts

tted with lock-nuts or a padlock.

An alternative telescopic drawbar design as used in the logging industry.

The drawbar uses a regular positive locking heavy vehicle tow coupling.

If support base is

narrow then a rear

facing outrigger is

recommended.

Distance rearwards from the centre

transverse pivot pins to rearmost

edge of the support plate.

The above distance should not be

less than the height above these

pivot points.

Front of vehicle

12

Inspection and maintenance of vehicles and trailers

A daily pre-trip inspection checklist procedure must be implemented to ensure

the vehicle combination are in safe and roadworthy condition for transporting

loads. Inspections should also include assessment of the load restraints tted

to the load. Preventative maintenance programs must be in place to ensure

all vehicles are regularly inspected and maintained by qualied mechanics

in accordance with the manufacturers design specications for the vehicle/

trailer units maintenance. Documented evidence of the inspections and regular

preventative inspection and maintenance of vehicles/trailers must be obtained

and records kept.

Summary - dos and donts

Drivers

Do Check you have adequate packing and protectors for the load.

Do Remember larger panels require individual lashings.

Do Remember that the size, height and position of your load will afect

the handling of your vehicle.

Do Check your load before moving of and during the trip. Remember

it is difcult and dangerous for a driver to correct any load shift

during the trip.

Do Remember that loads can settle and shift during a journey, allowing

lashings to slacken.

Do Check your load every time you remove or add a load item.

Do Check the load after any sharp manoeuvre or emergency braking.

Dont

Move your vehicle if any part of your load is not correctly restrained.

Dont Take risks. Always ensure you have sufcient chains of known

strength and that these are in good condition.

Consignors

Consignors should ensure panels/beams are adequately cured

and strong enough for transport, including being tightly restrained.

Remember to advise drivers if any panels/beams for despatch are

tted with a lifting hole or have top markings requiring them to

be carried in the up position.

Advise the driver what the weight of the load is as well as the average

item/panel weight to ensure regulation axle weights are not exceeded.

Ensure pre-start inspections are carried out with good lighting

and visibility.

Chain Check Tag

13

Best practice referenced documents - Industry

standards and guidance information

Worksafe industry standards

Construction and erection of bridge beams and pre-cast

and tilt-up concrete for buildings

These documents set out industrywide guidelines for establishing and

maintaining a safe working environment wherever precast concrete or steel

beams are being used to construct bridges and panels for buildings. These

industry-standards provide practical advice about the safe design, manufacture,

transportation and erection of bridge beams, panels and associated precast

concrete elements.

The bridge beam document sets out seven sections covering employer

responsibilities, design for construction, manufacture, handling and storage,

transportation, cranage and erection of the beams. The tilt-up document

also refers in detail to the same or similar basic transport communication

and planning responsibilities as summarized below.

Transportation

1. Before shop drawings are prepared, element sizes and transportability

should be reviewed to conrm that the proposed loads are able to be safely

transported to the site and be safely erected.

2. Precast elements should not be transported until the concrete is adequately

cured & authorised as being ready for lifting & transport by having reached

its design strength. This is typically 3 days for panels and 7 days for beams,

but can vary if design strength testing has been carried out.

3. Prior to transport consideration should be given to bearing assemblies

on the beams, location of support and lifting points at specied

bearing positions.

4. Transport load restraint methods must comply with the National Load

Restraint Performance Standards with all equipment and anchor points

strong enough to hold the load. The restraint system should be certied,

checked and inspected for serviceability before travel.

5. Site delivery consultation and preplanning requires good co-operation

between all the various parties involved.

6. Transport vehicle position will be directed by the erector as required and

could need to be stabilised prior to releasing the load restraints when the

crane commences the lift.

7. Restraints should not be removed until the crane takes an initial weight

of the panel or beam.

8. Under no circumstances should a vehicle be moved without the

load being secured in the appropriate manner.

These WorkSafe industry-standard documents provide much practical

advice and also refer to some 30+ other safety codes and related standards

documents covering concrete panels and beams.

14

National Code of Practice and Australian Standard 3850

Tilt-up concrete panels

The Australian Safety and Compensation Council (ASCC) are instruments of an

advisory nature, except where a law other than the Australian Workplace Safety

Standards Act 2005, makes them mandatory. The National standards objective

is to protect persons from hazards associated with this construction work. High

risk construction work as dened in the national standards includes Tilt-up and

Precast concrete construction work. The standard sets out the requirements

for both OHS Management Plans and Safe Work Method Statements referred

to in this National Code. All the illustrations and guidance in this document

primarily relate to the safe handling of wall panels, however some of the

guidance information in the code is also appropriate for precast concrete

beams, columns and slabs.

Key item examples

1. Safe Design, Handling, Storage, Transportation, On-Site Pre-fabrication

Erection and Demolition.

2. Duty holder responsibilities are described in the context of National,

State and Territory laws.

3. Clients, designers and erectors have a responsibility to consult with

all parties to ensure that safety matters are considered and all hazards

identied and managed.

4. Person with control of the construction project/work - has a responsibility

to protect the health and safety of all persons that maybe afected by

the construction work. This requires information relating to hazard

identication, risk assessment and risk control processes to be compiled

and recorded.

5. Person with control is to ensure adequate consultation with all persons

engaged in every aspect of the construction project, assessment of risks

and methods used to control those risks.

15

6. Handling, storage and transport - with proper preplanning, the handling

of concrete elements can be minimized. The transporter should be made

aware of the all site-specic hazards posed in the transporting of any

concrete items.

a. Storage approval and written instructions should be obtained

from an engineer.

b. Crane selection - communication with the person in control, crane

supplier, erection engineer and prefabricator must consult. Written

procedures including a risk assessment for setting up and dismantling

the crane for the weight to be lifted, the proximity of power lines, and

ground support conditions to be covered. Advice on safe procedures

and good practice for loading and unloading is also set out.

c. Transport - transportation must be undertaken according to State

and Territory requirements as well as relevant Australian standards.

Clear access to site, local streets/roads, plus checks for diferential

road camber that can induce torsional loads in long concrete elements

and may need to be considered. Specic design aspects afecting

transportation including the stability of long and/or unusually shaped

elements during transportation and the concrete strength required for

transportation. Route selection, travel time, trafc volumes to delivery

site, vehicle combination engineers report and permit approvals.

d. Load restraint and load support methods - and transport vehicle or

combination vehicle needs to be designed to withstand the loads and

forces that may act on the system during loading, transportation and

unloading. It is imperative that the load is adequately restrained, secured

and capable of withstanding any forces applied during loading, transport

and unloading. This includes a certication of the vehicle and support

frames by a suitably qualied and approved transport engineer which is

normally covered by the permit to travel process approval requirements.

7. General preplanning - it is vital to all aspects of the transport, loading,

restraint, loaded travel in an approved manner at approved times, correct

load restraint, system pre-check and good safety and maintenance

procedures are in place at all times. Good honest communication and

timely planning with all parties involved will ensure a satisfactory and

safe outcome.

16

VicRoads over-dimensional and over-mass permit

application - example requirements

1. Vehicle details registered owner/operator, address, vehicle make, trailer

/dolly/jinker registration number, tyres per axle, distance between axles,

gross mass of each axle group, tire sizes and ply ratings and overall width

of each axle group. To be in properly maintained and roadworthy condition.

This includes each of the component units of a vehicle combination.

2. Load detail size of article proposed to be carried - length, width

and mass in kgs.

3. Engineering certication permit vehicle combination selection must

be supported by manufacturers engineering certication covering the

vehicle platform/low-loader/dolly/jinker support strength ratings for each

component taken into account and all travel performance criteria that may

be encountered (Individual dolly/jinker groups and frames to be marked

with unit ID numbers/load capacities using welded or marked plates).

Typically a VASS engineer or a person with appropriate skills and experience

as approved by VicRoads must complete this certication. In the case of

some particular loads with a high centre of gravity (CoG) additional static

roll threshold (SRT) calculations may be required for such a load.

4. Overall dimensions of vehicle and load, including empty travel.

5. Load Restraint certication whilst this requirement may not be

required for all loads, critical loads such as concrete beams require

a fully assessed and certied load restraint method that must be

carried on the permit vehicle.

6. Denitions

Permit vehicle means the vehicle combination issued a permit.

Operator means a person in whose name the permit is issued.

Regulations means the road safety (vehicles) regulations 2009.

7. Operator and vehicle driver responsibility to be aware of regulations e.g.

load restraint, posted mass and dimension limits, travelling under overhead

structures or bridges, distance between vehicles, low visibility, travel speeds,

warning devices, regulations requiring permission of other authorities

e.g. rail, tram, electricity and telecommunications for overhead wires travel

permissions. When a vehicle height exceeds 4.8 m under tram wires and

5 m under railway wires, non-conductive skid rails must be attached to

the top of the load.

8. Assessing routes the operator and driver must be satised that a route

assessment has been completed and the permit vehicle can travel along

safely. In particular there must be sufcient clearance under wires,

structures, trees and sufcient ground clearance at rail level crossings.

9. Local road authorities permissions are required from the appropriate

municipal councils before a permit vehicle travels on undeclared (local)

roads outside the Melbourne and Geelong urban areas. The operator must

obtain permission from the City of Melbourne for any travel in the central

business district of Melbourne City.

10. Travel times Metropolitan area are not to commence before 1am.

Variations are only considered for approval following a detailed written

application for exceptional circumstances that would not reduce road

safety in any way.

Rural area permit condition travel is restricted to daylight hours only.

Variation to permit travel times is strictly limited and can only be considered

with full and comprehensive detail of the reasons for a variation. Issues such as

trafc volumes, street lighting, travel width, road width, the speed of the permit

vehicle and the geographic region terrain are all critical.

17

Further information

For detailed information refer to the Load Restraint Guide - Second Edition.

Copies of the Load Restraint Guide - Second Edition are available from the

National Transport Commission website: ntc.gov.au

Further enquiries

For further enquiries, contact VicRoads Transport Safety Services staf.

VicRoads Region Area Phone Address

Metro North West Metropolitan

Melbourne,

north-west

of the Yarra River

9302 8400 Pearcedale Parade

Broadmeadows

Vic 3047

Metro South East Metropolitan

Melbourne,

south-east of the

Yarra River

9881 8862 12 Lakeside Drive

Burwood Vic 3151

Eastern Warragul,

Leongatha,

Traralgon, Sale,

Bairnsdale, Genoa

5135 3037 87 Princes Way

Morwell Vic 3840

Northern Seymour, Kyneton,

Bendigo, Echuca,

Swan Hill, Charlton

5434 5000 57 Lansell Street

Bendigo Vic 3550

North Eastern Yea, Manseld,

Wodonga, Cobram,

Shepparton

5761 1888 50 Clarke Street

Benalla Vic 3672

South Western Geelong, Colac,

Warrnambool,

Portland, Hamilton

5225 2578 180 Fyans Street

South Geelong

Vic 3220

Western Bacchus Marsh,

Ballarat, Ararat,

Horsham, Mildura

5333 8779 88 Learmonth

Road Ballarat

Vic 3350

V

R

P

I

N

0

2

9

0

3

0

2

.

1

3

A

u

t

h

o

r

i

s

e

d

a

n

d

P

u

b

l

i

s

h

e

d

b

y

V

i

c

R

o

a

d

s

,

6

0

D

e

n

m

a

r

k

S

t

r

e

e

t

K

e

w

V

i

c

t

o

r

i

a

3

1

0

1

.

keeping victorians connected

For further information please phone 13 11 71

or visit vicroads.vic.gov.au

S-ar putea să vă placă și

- Belt Tensioners Crucial RoleDocument3 paginiBelt Tensioners Crucial RoleAnonymous YLfOYKGzÎncă nu există evaluări

- Air Brake System Operation and TroubleshootingDocument65 paginiAir Brake System Operation and Troubleshootingعبدالغني القباطي100% (2)

- Warn Guide To WinchingDocument15 paginiWarn Guide To WinchingDeddy RimawanÎncă nu există evaluări

- My Funniest FunniesDocument208 paginiMy Funniest FunniesRunningghostÎncă nu există evaluări

- Owner'S Manual: Installation, Operation, Maintenance & PartsDocument152 paginiOwner'S Manual: Installation, Operation, Maintenance & PartsJose RamosÎncă nu există evaluări

- Ffiigghhttiinngg W Wiitthh DD OoggssDocument2 paginiFfiigghhttiinngg W Wiitthh DD OoggssmysticpaganÎncă nu există evaluări

- Chapter 7-STEERING System (EngineeringDuniya - Com)Document22 paginiChapter 7-STEERING System (EngineeringDuniya - Com)mukesh3021Încă nu există evaluări

- Air Brake ManualDocument94 paginiAir Brake Manualfreeemeee.now130Încă nu există evaluări

- Sumitomo Cranes - Wind Speeds - LetterDocument1 paginăSumitomo Cranes - Wind Speeds - LetterStuart EdwardsÎncă nu există evaluări

- Crane Signals: Association of Carriers & Equipment Lessors, IncDocument24 paginiCrane Signals: Association of Carriers & Equipment Lessors, Incecko markÎncă nu există evaluări

- Wheel AlignmentDocument45 paginiWheel AlignmentViswajith Vm100% (1)

- Sifapp 3 - 07112018Document94 paginiSifapp 3 - 07112018Anonymous 9VohZYTMÎncă nu există evaluări

- QUICKLY ACCESS WINDOWS TOOLS AND APPSDocument31 paginiQUICKLY ACCESS WINDOWS TOOLS AND APPSbraca957Încă nu există evaluări

- JHG-2-002-3 Temporary Work Design Rev 5 (230810)Document6 paginiJHG-2-002-3 Temporary Work Design Rev 5 (230810)Stuart EdwardsÎncă nu există evaluări

- Plan For Bacani Bridge (RCDG)Document15 paginiPlan For Bacani Bridge (RCDG)Glyn A. BrinquezÎncă nu există evaluări

- Audio Car Radio Stereo Wire DiagramDocument21 paginiAudio Car Radio Stereo Wire Diagramsavoaia.constantinÎncă nu există evaluări

- Discreet, Fast and Secure Delivery: Buy The Best Pure OnlineDocument2 paginiDiscreet, Fast and Secure Delivery: Buy The Best Pure OnlineCruise JobsÎncă nu există evaluări

- Standard Hand Signals For Controlling Crane OperationsDocument5 paginiStandard Hand Signals For Controlling Crane OperationsSergio Mario Valdez Acosta100% (1)

- Basic Equipment Wiring AGY EngineDocument20 paginiBasic Equipment Wiring AGY EnginemasterbfishÎncă nu există evaluări

- STD C0003Document1 paginăSTD C0003Chris BradacÎncă nu există evaluări

- Do It Yourself DIY Dog Training by Sharda BakerDocument142 paginiDo It Yourself DIY Dog Training by Sharda BakerDiego Enrique Durán CaballeroÎncă nu există evaluări

- Workplace Health & Safety Act - Quick Start GuideDocument14 paginiWorkplace Health & Safety Act - Quick Start GuideStuart EdwardsÎncă nu există evaluări

- Commercial Vehicles Air Brake AdjustmentDocument14 paginiCommercial Vehicles Air Brake Adjustmentarstjunk100% (1)

- Slewing Gearboxes-Dinamic OilDocument12 paginiSlewing Gearboxes-Dinamic OiltonyÎncă nu există evaluări

- 10 Important Guide For SlingsDocument26 pagini10 Important Guide For SlingsAhmedÎncă nu există evaluări

- Tips and Tricks For GuysDocument31 paginiTips and Tricks For GuysAbhishek ShahÎncă nu există evaluări

- Model Military International M12 2-2017 PDFDocument68 paginiModel Military International M12 2-2017 PDFPrplkniteÎncă nu există evaluări

- CAH Small Frame Air Hoist Manual 11720901Document30 paginiCAH Small Frame Air Hoist Manual 11720901cj7man80Încă nu există evaluări

- Luces International InstalacionDocument157 paginiLuces International InstalaciondanflocaÎncă nu există evaluări

- Dynamic Cone Penetrometer (DCP)Document2 paginiDynamic Cone Penetrometer (DCP)Harcana AdriantaraÎncă nu există evaluări

- El - Electrical PDFDocument147 paginiEl - Electrical PDFMoaed Kanbar100% (6)

- 11.-Ttt Truck AnfoDocument2 pagini11.-Ttt Truck AnfoDarwin AjomadoÎncă nu există evaluări

- Mackay Flex Isolators CatalogueDocument142 paginiMackay Flex Isolators Cataloguemuss21Încă nu există evaluări

- The Cosmos Companion: Material Properties Used in CosmosworksDocument23 paginiThe Cosmos Companion: Material Properties Used in Cosmosworksjontylee87Încă nu există evaluări

- AS1418.8-2008 Rated Capacity For Earthmoving Machines: Plant AssessorDocument3 paginiAS1418.8-2008 Rated Capacity For Earthmoving Machines: Plant AssessorTAIYONG GUOÎncă nu există evaluări

- EES011 Technical Principles For Design of Electrical SystemsDocument17 paginiEES011 Technical Principles For Design of Electrical Systemsoadipphone7031Încă nu există evaluări

- Calibracion de Motores Cummins 1Document2 paginiCalibracion de Motores Cummins 1joseÎncă nu există evaluări

- STD - Iso 27956 Load Restraint System PDFDocument12 paginiSTD - Iso 27956 Load Restraint System PDFOscar Marino Campo BonellÎncă nu există evaluări

- CB MAX Parts PDFDocument179 paginiCB MAX Parts PDFJozze Morales100% (2)

- The Basic Bridge CircuitDocument8 paginiThe Basic Bridge CircuitMuhammad QasimÎncă nu există evaluări

- 2006 Dirt Jam Pro ManualDocument58 pagini2006 Dirt Jam Pro ManualJeff MittingÎncă nu există evaluări

- RF Steel Fatigue Members Manual en PDFDocument53 paginiRF Steel Fatigue Members Manual en PDFSakthivel VÎncă nu există evaluări

- TRN 2007 CG CNLDocument66 paginiTRN 2007 CG CNLRene D. ArrietaÎncă nu există evaluări

- Trakindo Lifting-Jacking-BlockingDocument80 paginiTrakindo Lifting-Jacking-BlockingEnan YayankÎncă nu există evaluări

- Clutch Release BearingDocument3 paginiClutch Release BearingSunil DeshpandeÎncă nu există evaluări

- Loadcells Quarter Half and Full BridgeDocument25 paginiLoadcells Quarter Half and Full BridgeCharles le MagneÎncă nu există evaluări

- Eaton DiffsDocument20 paginiEaton DiffsPatrick StivénÎncă nu există evaluări

- Privia PX-3 ManualDocument70 paginiPrivia PX-3 ManualBridget O'LearyÎncă nu există evaluări

- L4W - TLILIC2001A - Information Booklet - V4 PDFDocument54 paginiL4W - TLILIC2001A - Information Booklet - V4 PDFdulshanÎncă nu există evaluări

- First Responder Instruction Manual EnglishDocument28 paginiFirst Responder Instruction Manual Englishdonald_wilson4741Încă nu există evaluări

- Front End Loaders.Document8 paginiFront End Loaders.kartheek GÎncă nu există evaluări

- Electrical Strain Gauges: A Report OnDocument31 paginiElectrical Strain Gauges: A Report OnAnonymous GRY6OCJÎncă nu există evaluări

- Whole-Body Vibrations Exposure - Dr. Tammy Eger - CROSHDocument64 paginiWhole-Body Vibrations Exposure - Dr. Tammy Eger - CROSHNereu NunesÎncă nu există evaluări

- Time and Distance PDFDocument11 paginiTime and Distance PDFImtiaz AhmedÎncă nu există evaluări

- Hastings PDFDocument220 paginiHastings PDFEmily BullockÎncă nu există evaluări

- Safety Systems Catalog 2014Document284 paginiSafety Systems Catalog 2014groelzjÎncă nu există evaluări

- NPS 75 - 45-155 SERVICEPACK X - ARK 1250 - v04 PDFDocument4 paginiNPS 75 - 45-155 SERVICEPACK X - ARK 1250 - v04 PDFAal CassanovaÎncă nu există evaluări

- JOSAMDocument4 paginiJOSAMStefan CristeaÎncă nu există evaluări

- Export Vehicle Application Guide July 2014Document180 paginiExport Vehicle Application Guide July 2014jairofgfÎncă nu există evaluări

- Winching Operations in Forestry: Technical GuideDocument30 paginiWinching Operations in Forestry: Technical GuideAshrafELWardagyÎncă nu există evaluări

- Air Flex - ClutchDocument34 paginiAir Flex - ClutchJuan Gustavo GuillermoÎncă nu există evaluări

- Reedrill SKF: No. Unit: MU 108 Manufactured Year: 2006 Power UnitDocument1 paginăReedrill SKF: No. Unit: MU 108 Manufactured Year: 2006 Power Unitslamat widodoÎncă nu există evaluări

- C10338811 PDFDocument8 paginiC10338811 PDFCapacitaciones RutasÎncă nu există evaluări

- SAC Brake Training: Simplex Air Cam Drum Brake Exploded ViewDocument19 paginiSAC Brake Training: Simplex Air Cam Drum Brake Exploded ViewAnonymous gTerattFpQ100% (1)

- 8 Ball RulesDocument2 pagini8 Ball RulesMåřïä Ļà ĞŕëàthaÎncă nu există evaluări

- AUTO TRANSMISSION SYSTEMDocument35 paginiAUTO TRANSMISSION SYSTEMAalekh PrajapatiÎncă nu există evaluări

- Track and Wheel TorqueDocument64 paginiTrack and Wheel TorqueAnderson ertsÎncă nu există evaluări

- StrainDocument13 paginiStrainspanandk0% (1)

- Web+lashings+SI+23 0 PDFDocument2 paginiWeb+lashings+SI+23 0 PDFAekJayÎncă nu există evaluări

- The Official New Zealand: Truck Loading CodeDocument121 paginiThe Official New Zealand: Truck Loading CodeTawo MogbojuriÎncă nu există evaluări

- Ttma-100 - Trailer Tma General SpecificationsDocument5 paginiTtma-100 - Trailer Tma General SpecificationsKamalÎncă nu există evaluări

- Manitowoc Ringer Traveling InstructionsDocument1 paginăManitowoc Ringer Traveling InstructionsStuart EdwardsÎncă nu există evaluări

- Air Suspension - Stability ReportDocument49 paginiAir Suspension - Stability ReportStuart EdwardsÎncă nu există evaluări

- DH31 Load Capacity Charts PDFDocument38 paginiDH31 Load Capacity Charts PDFStuart EdwardsÎncă nu există evaluări

- Hillman Broch - Skates AP-10Document8 paginiHillman Broch - Skates AP-10Stuart EdwardsÎncă nu există evaluări

- Aker STD Lifting LugsDocument1 paginăAker STD Lifting LugsStuart EdwardsÎncă nu există evaluări

- Wind Guidance Note - RevADocument11 paginiWind Guidance Note - RevAStuart EdwardsÎncă nu există evaluări

- Information Bulletin - MAC 25 Allowable Wind SpeedDocument1 paginăInformation Bulletin - MAC 25 Allowable Wind SpeedStuart EdwardsÎncă nu există evaluări

- Transport Weighjts and DimensionsDocument9 paginiTransport Weighjts and DimensionsStuart EdwardsÎncă nu există evaluări

- Civil Specification PDFDocument684 paginiCivil Specification PDFRafael Echano AcederaÎncă nu există evaluări

- West Virginia Drivers Handbook - West Virgina Drivers ManualDocument88 paginiWest Virginia Drivers Handbook - West Virgina Drivers ManualpermittestÎncă nu există evaluări

- Reduce London Commute Times Through Public TransportDocument10 paginiReduce London Commute Times Through Public TransportLana BawanehÎncă nu există evaluări

- Barandas 4Document1 paginăBarandas 4Victor HigueraÎncă nu există evaluări

- Civil Construction Cost Estimate WorksheetDocument6 paginiCivil Construction Cost Estimate WorksheetXozanÎncă nu există evaluări

- Jvt01ivil024 17.02.2021Document1 paginăJvt01ivil024 17.02.2021MUQEET ahmedÎncă nu există evaluări

- Cycling in The City 2021Document24 paginiCycling in The City 2021Matt TroutmanÎncă nu există evaluări

- 2019 OTS Grantee Funding ListDocument12 pagini2019 OTS Grantee Funding ListTimothy WeisbergÎncă nu există evaluări

- The City of BhubaneswarDocument3 paginiThe City of BhubaneswarNikiÎncă nu există evaluări

- Speed Hump Request ProcedureDocument19 paginiSpeed Hump Request ProcedureEnis Eryılmaz100% (1)

- Our Complete Guide To Things To Do in Singapore With KidsDocument39 paginiOur Complete Guide To Things To Do in Singapore With KidsBeshoy GirgisÎncă nu există evaluări

- Ext Qv3sjrqfv5rytpivf81nDocument6 paginiExt Qv3sjrqfv5rytpivf81nNoelia GarcíaÎncă nu există evaluări

- StatementDocument3 paginiStatementalifÎncă nu există evaluări

- Food Truck GuideDocument1 paginăFood Truck GuideTimeOutChicagoWebÎncă nu există evaluări

- Serviced Apt 2010Document48 paginiServiced Apt 2010Nirun Sam YindeeamornchaiÎncă nu există evaluări

- THE Bridge: Binondo - IntramurosDocument3 paginiTHE Bridge: Binondo - IntramurosErika Faye CalzetaÎncă nu există evaluări

- Highway & Bridge Projects in IndiaDocument120 paginiHighway & Bridge Projects in Indialenkapradipta2011Încă nu există evaluări

- Dynamic Business Law 4th Edition Kubasek Solutions ManualDocument25 paginiDynamic Business Law 4th Edition Kubasek Solutions ManualCatherineMontesgsai100% (57)

- Sculfort Technical CatalogueDocument10 paginiSculfort Technical Catalogueapi-251352527Încă nu există evaluări

- LTO Circular Order - RA 4136 - JAO No. 2014-01 (Applicable Laws Consti Assignment)Document4 paginiLTO Circular Order - RA 4136 - JAO No. 2014-01 (Applicable Laws Consti Assignment)Adoniz Tabucal100% (2)

- Rubberised Bitumen ForDocument19 paginiRubberised Bitumen FornishankgopishettyÎncă nu există evaluări

- New UKPDocument2 paginiNew UKPfahmik11Încă nu există evaluări