Documente Academic

Documente Profesional

Documente Cultură

45604

Încărcat de

mariutza_luciaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

45604

Încărcat de

mariutza_luciaDrepturi de autor:

Formate disponibile

Quelle/Publication:

Ausgabe/Issue:

Seite/Page:

European Coatings Journal

12/2004

42

European bodies update coil coating

standards

CEN, the European Committee for Standardization, has

Europe-wide membership, work procedures and role. This

organization and its associated standards body, ECISS, the

European Committee for Iron and Steel Standardization, are

introduced, as is its growing cooperation with ISO, the

International Organization for Standardization. Over the past

months a three-part standard on coil coated steel products

has been published. A number of standardized test methods

for coil coated metals are also available.

Bernd Meuthen.

Against the background of recent activities, it seems

appropriate to refer to the relevant international

standardization institutions and committees, and summarize

their way of working. Standardization of coil coated products

and test methods are also among the key objectives of the

European Coil Coating Association (ECCA) of Brussels.

CEN - the European Committee for Standardization

CEN was founded in 1961 by the national standards bodies

in the European Economic Community and European Free

Trade Association (EFTA) countries as an independent legal

organization with its Central Secretariat in Brussels.

The principal issue is the European standard (EN) that

exists in three official languages (English, French and

German). CEN national members are bound to comply with

the CEN Internal Regulations. These stipulate the conditions

for giving a standard the status of a national standard

without any alteration or by endorsement within six months

and that any pre-existing national standard in conflict be

withdrawn. German versions are prefixed as in DIN EN,

corresponding to BS EN and NF EN. A version in any other

language made by translation under the responsibility of a

CEN member into its own language and notified to the

Management Centre (CMC) has the same status as the

three official versions.

New work items start with a working document prepared by

a Working Group. The working document becomes a draft

European Standard (prEN) and, following a customary

administrative route via the CEN Management Centre, in the

end a European Standard (EN). CEN members are granted

a six-month enquiry of the drafts and a two-month deadline

of cognisance of the final texts but without any technical

changes to them. This procedure is completed by the

ratification by CEN.

CEN membership and relations

National Members (Figure 1) are the national standards

bodies (NSB) of the enlarged European Union, EFTA and

some Central and Eastern European (CEE) countries. They

(1) make up the delegations to the technical committees by

finding expertise in each country; (2) vote for and implement

European standards as national standards; (3) provide the

secretariats of the committees; and (4) finance more than 50

% of the work. In turn they are largely financed by industry,

sales of standards and government grants.

CEN presently comprises in all 28 NSB (listed with their

acronyms) compared with only 18 in 1996. There are 25

from the EU: Austria (ON), Belgium (IBN/BIN), Czech

Republic (CSNI), Cyprus (CYS), Denmark (DS), Estonia

(EVS), Finland (SFS), France (AFNOR), Germany (DIN),

Greece (ELOT), Hungary (MSZT), Ireland (NSAI), Italy

(UNI), Latvia (LVS), Lithuania (LST), Luxembourg (SEE),

Malta (MSA), The Netherlands (NEN), Poland (PKN),

Portugal (IPQ), Slovakia (SUTN), Slovenia (SIST), Spain

(AENOR), Sweden (SIS), and the United Kingdom (BSI). In

addition, Iceland (IST), Norway (NSF) and Switzerland

(SNV) are members from EFTA.

Counsellors, affiliates and partners

Counsellors are the European Commission and the EFTA

Secretariat. Affiliates are other national standards bodies of

Central and Eastern Europe, which can in principle become

members of the Union or EFTA, and which therefore can

become full National Members of CEN by meeting certain

criteria.

Present affiliates are Albania (DPS), Bulgaria (SASM),

Croatia (DZNM), Romania (ASRO), the former Yugoslav

Republic of Macedonia (FYROM), and Turkey (TSE).

Partner Standardization Bodies (corresponding

organizations) are Egypt (EOS), Serbia and Montenegro

(SZS), South Africa (SABS), and Ukraine (DSSU).

ECISS - the European Committee for Iron and Steel

Standardization

Since 1986 ECISS has taken over the standardization

activities of COCOR, the Coordinating Committee on the

nomenclature of iron and steel products, a committee

originally set up under the ECSC (European Coal and Steel

Community). ECISS, a CEN Associated Standards Body.

(ASB), is administered by, but independent of, CEN. Internal

rules are in accordance with those of CEN. ECISS develops

draft standards for the definition, classification, testing,

chemical analysis and technical delivery requirements for

the products of the steel industry which are then submitted

to CEN for further launching.

The origins of ECISS and its precursor go back to the early

1950s and the foundation of ECSC as the very first of the

European communities. The process of European

integration began with coal and steel (Treaty of Paris,

ratified in 1952). The Euronorms issued since 1953 had

merely an optional status.

ECISS and CEN functions

Functions of the two standards bodies are performed by

Technical Committees (TC), which are responsible for the

programming and planning, monitoring and execution of the

technical work, and Subcommittees (SC), which are

responsible for a defined portion of the scope of the relevant

TC.

Working Groups (WG) are appointed by a TC or SC to deal

with a special and limited area of work. They are composed

of individual members (experts) from CEN/ECISS members

and organizations.

All the CEN national members are entitled to nominate

delegates to ensure a balance of all interested parties.

Strategies identified as achieving CEN- and ECISS-defined

objectives may include, among others:

- Use of available national, regional or international source

documents (such as ISO standards) on which to base

European Standards;

- Where appropriate, cooperation and liaisons with other

CEN committees and international committees;

- information that directly demonstrates the possible use and

acceptance of the standards by the affected business

community.

Vincentz Network +++ Schiffgraben 43 +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication:

Ausgabe/Issue:

Seite/Page:

European Coatings Journal

12/2004

42

The work programme

The ECISS work programme is dealt with by 21 Technical

Committees. Among others, these include:

- TC 13: Flat products for cold working - Qualities,

dimensions, tolerances and specific tests (uncoated hot or

cold-rolled steels and cold-rolled steel sections); chairman,

J. Dawance; secretariat held by D. Jacobs, IBN/BIN;

- TC 27: Surface coated flat products - Qualities,

dimensions, tolerances and specific tests; chairman, P.

Fnders; secretariat held by H.-F. Hach, FES im DIN; and

- TC 27/SC 1: Continuously organic coated (coil coated)

steel flat products; chairman, B. Meuthen.

European standardization and the role of CEN

CEN is contributing to the objectives of the European

Economic Area with technical standards which promote free

trade, the safety of workers and consumers, interoperability

of systems and technologies, environmental protection,

exploitation of research and development programmes, and

public procurement. The foremost aim is to facilitate the

exchange of goods and services through the elimination of

technical barriers to global trade, thus ensuring the

interoperability and interchangeability of safe and high

quality products and systems.

The use of standards by industry and the social and

economic partners is always voluntary; however, European

standards are sometimes related to European legislation

(Directives), and conformity to such standards may

constitute a presumption of conformity to the legal

requirements of the Directives which must be met by

manufacturers before certain products can be traded legally

within the Single Market. A European standard embodies

the essential principles of global openness and

transparency, consensus, technical coherence and national

commitment.

ISO - International Organization for Standardization

One cannot report on standardization without mentioning

ISO, the worldwide federation of national standards bodies,

constituted as far back as 1947, with its Central Secretariat

in Geneva, Switzerland. Its current membership comprises

national standards institutes from 148 countries, working in

partnership with international organizations, governments

and industry, business and consumer representatives.

Official languages are English and French. Final Draft

International Standards (FDIS) become Standards (ISO).

Implementation is, however, optional only.

A growing cooperation

ISO and CEN work closely together according to their

Vienna Agreement (1991): Technical cooperation under the

VA, where the work is done by CEN following a formal

notification of interest received by CEN from ISO (VA CEN

lead) or vice versa (VA ISO lead). Parallel synchronized

procedures are applied in either organization for the

approval processes.

The growing cooperation between CEN and ISO may be

characterized by CEN/TC 139 "Paint and varnishes"

(secretariat held by DIN) established in 1988 and its

counterpart ISO/TC 35 "Paint and varnishes" established in

1947. Over the past years, an increasing number of ISO

standards, particularly on terminology (SC 1) and test

methods (SC 9) have already been transposed into the CEN

network (as EN ISO). (EN) ISO standards are referred to,

whenever applicable.

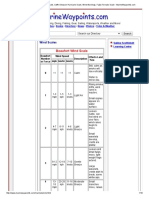

However, the specific work on test methods for coil coated

metals has since 1995 been the responsibility of CEN/TC

139/WG 9 "Coil coated metals - Test methods" (convenors,

F. Ferron / H. Hughes) in cooperation with and supported by

ECCA. 25 Parts have already been published (Table 1).

An update on coil coated steel standardization

The EN 10169 standard for coil coated steel consists of

three parts: EN 10169-1:2003, Continuously organic coated

(coil coated) steel flat products - Part 1: General information

(definitions, materials, tolerances, test methods),

superseding the 1996 issue; prEN 10169-2:2004, Part 2:

Products for building exterior application, replacing ENV

10169-2:1999; and EN 10169-3:2003, Part 3: Products for

building interior applications.

ECISS/TC 27/SC 1 began work in 1992 tasked with

updating the Euronorm EU 169-85 for continuously organic

coated steel flat products. This Euronorm was prepared by a

Working Group established in the late 70s and was the first

standard of its kind. It is common practice for existing

standards to be reviewed about every five years to

determine whether any need exists for some major editorial

or technical amendments. The transposition into EN (Part 1

since 1996) did not pose any problems.

Work was then started on compiling supplements Parts 2

and 3, governing building exterior and interior applications,

since these are the prime sales markets. WG 2 and WG 3

were founded for this purpose, with B. Creton and J.

Mnigault, BNS (Bureau de Normalisation de la Sidrurgie),

Paris, since renamed BN Acier, acting as convenors.

WG 2 (Exterior applications) applied considerable efforts

between 1992 and 2003 in developing, first of all, a

pre-standard (ENV 10169-2:1999). This was only recently

transposed into prEN 10169-2:2004. The final standard is

due to be published in 2005. In the period 1997 to 1999, WG

3 (Interior applications) succeeded in drafting the new EN

10169-3:2003. In their source English versions, the three

standards together have some 60 pages.

What's in the standards

The usual contents are: Foreword, Scope, Normative

references, Terms and definitions, Designation, Information

to be supplied by the purchaser, Substrates and organic

coatings, Requirements, Inspection and testing, Marking,

Packing and dispatch, Storage, Disputes, Annex, and

Bibliography.

Regarding "Scope" (Part 1): The standard is not applicable

to organic coated tin mill products, electrical steels and steel

strapping. Alongside the updated standards for the steel

substrates, all three parts now include many of the new

parts of the EN 13523 series, Coil coated metals - Test

methods (Table 1). "Terms and definitions" list altogether 45

definitions for the coil coating process, coating systems,

building applications etc.

Acknowledgements

The author would like to thank all ECISS experts, the SC 1

secretariat and BN Acier for their unfailing commitment to

these ECISS activities.

Reference

[1] F. Ferron, European Standards for Coil Coated Metals -

Test Methods (EN 13523), Proceedings, ECCA 38th

General Meeting, Salzburg, June 2004

Table 1: EN Standards on Coil Coated Metals - Test

Methods

EN 13523-0:2001

Coil coated metals -Test methods

Part 0: General introduction and list of test methods

EN 13523-1:2001

Part 1: Coating thickness

EN 13523-2:2001

Vincentz Network +++ Schiffgraben 43 +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication:

Ausgabe/Issue:

Seite/Page:

European Coatings Journal

12/2004

42

Part 2: Specular gloss

EN 13523-3:2001

Part 3: Colour difference - Instrumental comparison

EN 13523-4:2001

Part 4: Pencil hardness

EN 13523-5:2001

Part 5: Resistance to rapid deformation (impact test)

EN 13523-6:2002

Part 6: Adhesion after indentation (cupping test)

EN 13523-7:2001

Part 7: Resistance to cracking on bending (T-bend test)

EN 13523-8:2002

Part 8: Resistance to salt spray (fog)

EN 13523-9:2001

Part 9: Resistance to water immersion

EN 13523-10:2001

Part 10: Resistance to fluorescent UV light and water

condensation

prEN 13523-11:2003

Part 11: Resistance to solvents (rubbing test)

prEN 13523-12:2003

Part 12: Resistance to scratching

EN 13523-13:2001

Part 13: Resistance to accelerated ageing by the use of heat

EN 13523-14:2001

Part 14: Chalking (Helmen method)

EN 13523-15:2002

Part 15: Metamerism

prEN 13523-16:2003

Part 16: Resistance to abrasion

prEN 13523-17:2003

Part 17: Determination of adhesion of strippable films

EN 13523-18:2002

Part 18: Resistance to staining

prEN 13523-19:2003

Part 19: Panel design and method for atmospheric exposure

testing

prEN 13523-20:2003

Part 20: Foam adhesion

EN 13523-21:2003

Part 21: Evaluation of outdoor exposed panels

EN 13523-22:2003

Part 22: Colur difference - Visual comparison

EN 13523-23:2002

Part 23: Colour stability in humid atmospheres containing

sulphur dioxide

prEN 13523-24:2003

Part 24: Resistance to blocking and pressure marking

In preparation: Part 25: Resistance to humidity Part 26:

Resistance to condensation

The author:

-> Dr Bernd Meuthen studied Chemistry and obtained a ScD

degree at the University of Bonn/Germany. He worked at the

Hoesch Steel Group in Dortmund and Wuppertal in charge

of R&D pre-coated steel products (1959-1990). He is

chairman of ECISS/TC 27/SC 1 and ECCA German Group.

This paper was presented at the ECCA 38th General

Meeting, Salzburg/Austria, June 2004.

Vincentz Network +++ Schiffgraben 43 +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication:

Ausgabe/Issue:

Seite/Page:

European Coatings Journal

12/2004

42

Figure 1: Map of Europe with CEN membership countries (EU=brown, EFTA=green,

affiliates=yellow, partners=red, non-members=blue).

Vincentz Network +++ Schiffgraben 43 +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

S-ar putea să vă placă și

- ASME SEC IX - Welding Procedure and PerfDocument44 paginiASME SEC IX - Welding Procedure and Perfstefanie_1980100% (2)

- Wind Scales - Beaufort Wind Scale, Saffir-Simpson Hurricane Scale, Wind Warnings, Fujita Tornado Scale - MarineWaypointsDocument10 paginiWind Scales - Beaufort Wind Scale, Saffir-Simpson Hurricane Scale, Wind Warnings, Fujita Tornado Scale - MarineWaypointsmariutza_luciaÎncă nu există evaluări

- Commercial Threshold: Applies To The Following ThresholdsDocument1 paginăCommercial Threshold: Applies To The Following Thresholdsmariutza_luciaÎncă nu există evaluări

- SR EN 1993 4 2 - NA - 2011 - en PDFDocument8 paginiSR EN 1993 4 2 - NA - 2011 - en PDFmariutza_luciaÎncă nu există evaluări

- Wind Uplift-Wind SpeedDocument1 paginăWind Uplift-Wind Speedmariutza_luciaÎncă nu există evaluări

- AMCA 500 D 07 Damper TestingDocument74 paginiAMCA 500 D 07 Damper TestingMMMOH200100% (1)

- 0198 Ce Perm Conversion FactorsDocument1 pagină0198 Ce Perm Conversion Factorsmariutza_luciaÎncă nu există evaluări

- 814 Multi-Purpose MB Flashing CementDocument3 pagini814 Multi-Purpose MB Flashing Cementmariutza_luciaÎncă nu există evaluări

- 3M 3015 Division 07 25 SpecificationDocument8 pagini3M 3015 Division 07 25 Specificationmariutza_luciaÎncă nu există evaluări

- 171 171B - MSDSDocument2 pagini171 171B - MSDSmariutza_luciaÎncă nu există evaluări

- Pneumatic Tyred Rollers Power and PerformanceDocument8 paginiPneumatic Tyred Rollers Power and Performancemariutza_luciaÎncă nu există evaluări

- 27 J AdhesionDocument25 pagini27 J Adhesionmariutza_luciaÎncă nu există evaluări

- 27 J AdhesionDocument25 pagini27 J Adhesionmariutza_luciaÎncă nu există evaluări

- 27 J AdhesionDocument25 pagini27 J Adhesionmariutza_luciaÎncă nu există evaluări

- BF - 307 - 071 - Rapport 1Document59 paginiBF - 307 - 071 - Rapport 1mariutza_luciaÎncă nu există evaluări

- Usg Gypsum Board Arc Spec en 09260 092116Document27 paginiUsg Gypsum Board Arc Spec en 09260 092116mariutza_luciaÎncă nu există evaluări

- Tech-Spec:: Product Reference SheetDocument1 paginăTech-Spec:: Product Reference Sheetmariutza_luciaÎncă nu există evaluări

- Rugasol - 2-Liquid: Surface Retarder For Exposed Aggregate FinishDocument2 paginiRugasol - 2-Liquid: Surface Retarder For Exposed Aggregate Finishmariutza_luciaÎncă nu există evaluări

- RalDocument1 paginăRalmariutza_luciaÎncă nu există evaluări

- Equivalence and Harmonisation in Reaction-To-fire Performance - April 2012Document32 paginiEquivalence and Harmonisation in Reaction-To-fire Performance - April 2012Rúben Sobreiro100% (1)

- BP BandeauDocument7 paginiBP Bandeaumariutza_luciaÎncă nu există evaluări

- 160 Release Notes EnuDocument130 pagini160 Release Notes Enumorgan0001710Încă nu există evaluări

- Illmod600 TDS EX 7710 - Banda de EtansareDocument2 paginiIllmod600 TDS EX 7710 - Banda de Etansaremariutza_luciaÎncă nu există evaluări

- Technical Data Sheet: Tectane Zinc SprayDocument1 paginăTechnical Data Sheet: Tectane Zinc Spraymariutza_luciaÎncă nu există evaluări

- Certificat ConformitateDocument2 paginiCertificat Conformitatemariutza_luciaÎncă nu există evaluări

- Pneumatic Tyred Rollers Power and PerformanceDocument8 paginiPneumatic Tyred Rollers Power and Performancemariutza_luciaÎncă nu există evaluări

- Suede Skirt TemplateDocument15 paginiSuede Skirt TemplateNancy WebbÎncă nu există evaluări

- 814 Multi-Purpose MB Flashing CementDocument3 pagini814 Multi-Purpose MB Flashing Cementmariutza_luciaÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Matrices PDFDocument13 paginiMatrices PDFRJ Baluyot MontallaÎncă nu există evaluări

- Mass Communication: NtroductionDocument6 paginiMass Communication: NtroductionGul Hassan ChaudharyÎncă nu există evaluări

- Student Management System Project Report PDFDocument18 paginiStudent Management System Project Report PDFgopiga sriÎncă nu există evaluări

- Microsoft PowerPoint 2010 TutorialDocument10 paginiMicrosoft PowerPoint 2010 Tutorialchronos65340% (1)

- 10.3 The Nerve ImpulseDocument20 pagini10.3 The Nerve ImpulseazwelljohnsonÎncă nu există evaluări

- Costco Cover Letter ExamplesDocument6 paginiCostco Cover Letter Examplesxwxxoyvhf100% (1)

- ABE SEASON II Quiz Bee FinaleDocument8 paginiABE SEASON II Quiz Bee FinaleENFORCEMENT PENRO-APAYAOÎncă nu există evaluări

- Life Cycle of GISDocument12 paginiLife Cycle of GISNikin JayswalÎncă nu există evaluări

- Cost of FasdDocument12 paginiCost of FasdMary Harber-IlesÎncă nu există evaluări

- PSA Maintenace in SAP BIDocument11 paginiPSA Maintenace in SAP BImath_mallikarjun_sapÎncă nu există evaluări

- United States Foreign Policy and The Middle EastDocument19 paginiUnited States Foreign Policy and The Middle EastAinyÎncă nu există evaluări

- Sarmiento - 2011Document422 paginiSarmiento - 2011jmhinos4833Încă nu există evaluări

- School Action Plan in Science (S.Y. 2018-2019)Document2 paginiSchool Action Plan in Science (S.Y. 2018-2019)Jorie Cardaño Cacho75% (4)

- cs4l 2 0 en PDFDocument84 paginics4l 2 0 en PDFmishka123Încă nu există evaluări

- Physics - NCERTDocument154 paginiPhysics - NCERTPirated VirusÎncă nu există evaluări

- Tower Scientific CompanyDocument3 paginiTower Scientific Companymaloy0% (1)

- Souvenirs Messengers of MeaningDocument7 paginiSouvenirs Messengers of MeaningAna BrunetteÎncă nu există evaluări

- NCUK BrochureDocument8 paginiNCUK BrochureDulguun EnkhtaivanÎncă nu există evaluări

- 6405 23062 2 PB PDFDocument15 pagini6405 23062 2 PB PDFBaim Ar RayyanÎncă nu există evaluări

- How To Change The Cell Color of A Jquery Datepicker - Stack OverflowDocument2 paginiHow To Change The Cell Color of A Jquery Datepicker - Stack Overflowrithuik1598Încă nu există evaluări

- Koolhaas SpotCheckConversation 1999Document21 paginiKoolhaas SpotCheckConversation 1999Lijani GriesselÎncă nu există evaluări

- Open Channel Laboratory ExperimentDocument3 paginiOpen Channel Laboratory ExperimentJohn Ceasar PascoÎncă nu există evaluări

- Exchange 2013 High Availability and Site ResilienceDocument4 paginiExchange 2013 High Availability and Site ResilienceKhodor AkoumÎncă nu există evaluări

- Decision Making in A Crisis What Every Leader Needs To KnowDocument10 paginiDecision Making in A Crisis What Every Leader Needs To KnowFradegnis DiazÎncă nu există evaluări

- Week 1 2 EstimationDocument71 paginiWeek 1 2 EstimationGerad TeoÎncă nu există evaluări

- SOP SampleDocument2 paginiSOP SampleLikhit VermaÎncă nu există evaluări

- Electrohydrodynamic Atomization (EHDA)Document15 paginiElectrohydrodynamic Atomization (EHDA)Ananya SinghÎncă nu există evaluări

- Final Demo A Detailed Lesson Plan in Math 1Document8 paginiFinal Demo A Detailed Lesson Plan in Math 1Brenda PelicanoÎncă nu există evaluări

- Principles of Language AssessmentDocument13 paginiPrinciples of Language AssessmentTamara KristianiÎncă nu există evaluări

- SPACEPLACE: ART IN THE AGE OF ORBITIZATION - ZKM Germany 2005-8Document55 paginiSPACEPLACE: ART IN THE AGE OF ORBITIZATION - ZKM Germany 2005-8Philip Pocock100% (1)