Documente Academic

Documente Profesional

Documente Cultură

Acknowledgement

Încărcat de

Shamsul ArefinTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Acknowledgement

Încărcat de

Shamsul ArefinDrepturi de autor:

Formate disponibile

Acknowledgement

We want to give our heartiest gratitude to our

honorable teacher and thesis supervisor DR.

CHOWDHURY MD. FEROZ, Professor,

Department of Mechanical Engineering, BUET,

for his continuous guidance, suggestions and

inspiration throughout this work This thesis

would not have been possible without his

supervision We also like to thank our honorable

teacher DR. MD. MAHBUBUR RAZZAQUE,

!ssociate Professor, Department of Mechanical

Engineering, BUET, for his active help during this

thesis work

We are also greatful to Engr. Syed M.A. Qdd!

for his valuable advise during the thesis work

During this thesis we visited Bangladesh Bank

Training "entre for which we are thankful to

A""#! Udd$n S$dd$%e& for his co#operation

during our visit

A"!tr#ct

$imited research has been under taken in the fire

fighting in our countr% The perceived rate of

in&uries and damages is high and it being

increased from few %ears 'o, fire and safet% deals

with a great importance toda%(s

This paper mainl% concerns design of standpipe

s%stem for buildings whose occupanc% is

Educational )n developing fire safet% plan,

evaluation of all individual floor la%out should be

taken into consideration )n our design we have

concentrated in designing a fire fighting s%stem of

EME building, since we don(t have an% facilit%

regarding fire protection The s%stem we choose is

a manual standpipe s%stem We have designed and

suggested all the necessar% e*uipments ie Pump,

+eservoir, ,osepipe etcetera, re*uired for this

design

1

CHA'(ER O)E

*)(RODUC(*O)

+.+ *ntrodct$on

The generating of e-cessive and unwanted heat is

the basic problem of the fire ,eat is actuall% a

form of energ% in transmit )n as much as nature

strives to maintain e*uilibrium, heat is constantl%

moving from warmer bodies to cooler ones There

is no such thing as cold "old is merel% a relative

term to denote a lower than normal degree of heat

The common scales for measurement are

.ahrenheit, "elsius and /elvin

,eat and temperature are not identical The total

heat energ% of a bod% is the sum of kinetic and

potential energies of all its molecules 0/E 123

mv

4

5 and is determined b% the total number of

molecules and their average velocit% Temperature

is a measure of the average molecular velocit%

onl% Thus it is the degree or intensit% of the heat

,eat is the sum total of all the molecular energ%

of a bod% )t is measured in "alories or British

Thermal Unit 0BTU5

+., W-#t $! .$re

'ince heat is a form of energ% in transmit an% kind

of energ%# electrical, mechanical, chemical and

nuclear, can be converted to heat and thus start a

fire The fire once started, is a form of

carbonaceous material, such decomposition

having been initiated b% heat caused b% one of the

above forms of energ%

6ases are composed of small particles

0molecules5 which are separated b% relativel%

large spaces 6as molecules move in a random

manner with the average moving in one direction

e*ual to the average moving in an% other

direction !s a gas is heated, the molecular motion

increases )f the gas is contained, the impact of

pressure )f the gas is uncontained, the increase in

molecular motion will cause it to rise

+./ F$re 'rogre!!

! fire starts when energ% ie electrical,

mechanical or chemical energ% evolves sufficient

heat to ignite a combustible substance The

progress is governed b% five ma&or factors are as

follows#

) The amount of e-posed combustible surface

0fuel source5

)) The arrangement of the combustible surfaces

))) The nature of the combustible surfaces

)7 The ratio of combustible surface to room

volume

7 The amount of ventilation

The total amount of combustible material is onl%

of interest in determining how long the fire will

burn if unchecked )t is the amount of surface

which is the fuel source that will determine the

si8e and intensit% of the fire 9nl% the portion of

the combustible material near the surface is

sufficientl% heated to provide fuel gases

+.0 Fl#!-o1er ($me

!ssuming an ade*uate air suppl%, the ratio of

combustible surface to room volume is the

primar% factor determining time to flashover !

high amount of combustible surfaces will beget an

earl% flashover :et in a small enclosure such as a

closet, fire reached flashover much more *uickl%

The rate of sustained combustion is largel%

determined of air flow The amount of ventilation,

therefore, can affect the progress of a fire either

positivel% or negativel% !n increased suppl% of

9-%gen can increase the speed of combustion 9n

the other hand, ventilation permits the escape of

heat of convection

+.2 F$re (r$#ngle

The fire triangle shows three prere*uisites for a

fire#

; !n o-idi8ing agent 0Usuall% 9-%gen5

; ! reducing agent 0! fuel5

; ! minimum temperature level 0.or self <

substance5

2

.ig==3 .ire Triangle

)f one leg of the triangle can be removed, the fire

will be e-tinguished

The famed fire triangle is an e-cellent basis for

establishing an understanding of fire, but not trul%

complete There is a fourth element which should

be considered to gain an understanding of all

processed b% which fire can be e-tinguished and

that is the chain reaction

.ig =4> .ire Tetrahedron

+.4 An#tomy o. .$re

The combustion reaction occurs b% a transfer of

electrons )n this process, an o-idi8ing agent,

usuall% o-%gen adopts electrons and thereb%

becomes reduced The reducing agent which is

called a fuel surrenders electrons and thereb%

becomes o-idi8ed The end products conse*uentl%

are neutral and more stable The reaction

manifests itself b% emitting energ% The process is

elevated temperature to a self# sustaining level

.ires have two general forms#

; .laming#Three dimensional and ver% rapid

; ?on#flaming

The latter is represented b% the slow surface glow

combustion which takes place when charcoal

burns This t%pe of combustion uses a direct union

of o-%gen and fuel source without the formation

of intermediate gases .laming combustion has a

fourth prere*uisite ! number of intermediate

combustion products are both formed and

consumed and are comprised of fire ions,

molecular fragments termed free radicals,

electrons etc The interpla% of these active species

is a necessar% part of the combustion process

,ence there is the fourth pre#re*uisite, free chain

reaction

CHA'(ER (WO

F*RE E5(*)C(*O)

3

,.+ F$re E6t$nct$on

We have now determined the nature and course of

the fire, and wish to evaluate the capacit% of

e-tinguishment re*uired to bring it under control

)t should be emphasi8ed that the relations

described are simplified and that the estimations

should be regarded as e-emplifications of a

comple- s%stem

,., W#!te E6t$ng$!-$ng Med$#

When used to fight a fire at a chemical

warehouse, the e-tinguishing water will almost

certainl% be polluted b% chemicals !s man% of

the stored products are designed especiall% to

interfere with the ecological s%stem, the% have the

potential to cause substantial damage should the%

be released or dissolved in runoff water

Therefore, all water from the fire scene should be

collected and prevented from reaching water

courses or drainage s%stems Different methods

can be applied

The building itself can be designed to contain the

water b% having a floor lower than the

surrounding area and interior doors with high sills

tank !n e-terior basin can be used # either as a

sealed pit in the ground or as a portable spill

basins could be used to collect the water )f the

amount of li*uid is limited, absorbents can be

used The choice of method of spill water

collection varies with the on#site conditions

)t is an the area available, possibilities of &oint use

of the s%stem with other companies etc Whatever

the methods used, the s%stem must be designed to

contain advantage if the s%stem is designed with

an inherent robustness, ie if the water is

automaticall% led to a tank and there is no need to

collect the water using pumps This is an

advantage for s%stems where the container is

located below the floor level of the building

There are e-amples where holes for containers

have been drilled into the ground ! sealed pit in

the ground is used at the small warehouse There

are also e-amples where the building itself is used

to contain the water, as is the case at the large

warehouse The s%stem must be designed to

operate under different conditions During the

winter, for e-ample, a valve in a drainage s%stem

ma% free8e and it ma% not be possible to open or

close it Portable spill basins commonl% have a

volume of about =2 m@ ! s%stem of portable spill

basins is, as the name indicates, ver% fle-ible )t

does not re*uire e-pensive fi-ed installations and

it can be used in a variet% of operations There

ma%, however, be some practical problems during

large operations, as at fires in chemical

warehouses, which are studied here

!t fires in chemical warehouses these practical

problems ma% be such that the aim of collecting

all the e-tinguishing water is not achieved )f

there is a stationar% tank which can be brought

into use &ust b% turning a valve or preferabl% b%

doing nothing at all, valuable resources are

released to fight the fire

Portable spill basins are presumabl% best suited

for spills of chemicals without fire ha8ards The

re*uired volume is then onl% the volume of the

released chemical !t small fires, ie when a fire

involving chemicals is put out within a few

minutes b% a sprinkler s%stem the basins ma% also

be valuable to urge on the overhaul work When

foam is used as the e-tinguishing medium, the

same dimensioning rules can be used as with pure

water with the addition of water to break down the

foam 9ne must bear in mind that water

containing foam has a decreased surface tension

which ma% increase the infiltration rate in soil )t

should also be noted that a substantial foam la%er

ma% be created when water mi-ed with foam is

pumped, and that this foam la%er ma% overflow

the spill basins

When using dr% powder, the onl% volume that

should be collected at the fire is the spill of an%

li*uid chemicals ,owever, dr% powder is rarel%

used solel% at the fire brigades, so the basins must

be dimensioned for the other e-tinguishing agents,

commonl% water or foam

,./ W#ter& (-eoret$c#l A"!or7t$on C#7#c$ty

!t most fires, water is used as the e-tinguishing

medium The e-tinguishing effect comes from the

4

heat absorbed b% the water as it is heated and

vapori8ed The water is usuall% applied in one of

three different wa%s>

= The water is applied in small droplets, with a

diameter less than about =2 mm, into the flames,

in the gas phase of the fire The heat absorption

cools the flame down and when the adiabatic

flame temperature falls below about =A22 / at

stoichiometric conditions, the flame goes out The

ratio of the lower limit of flammabilit% for the fuel

to stoichiometric concentration is 32 to A2B for

man% pre#mi-ed flames The diluents are

therefore responsible for absorbing about C3B of

the energ% released to e-tinguish the flame .or

diffusion flames, the removal of D2 to D3B of the

released energ% is sufficient This is because a

diffusion flame looses more energ% due to

radiation than a pre#mi-ed flame, and that

combustion does not onl% occur at stoichiometric

conditions This indicates that for diffusion

flames, the theoretical absorption capacit% should

be multiplied b% a factor of D to obtain the

e-tinction capacit% ! good e-ample of this t%pe

of e-tinction is when a B! team overcomes a

flashover fire b% simpl% aiming the fog no88le

into the burning smoke la%er !nother e-ample is

the fog nail which is inserted into a burning

compartment through the roof or the wall, giving

a fine water spra% right in the smoke

4 The burning fuel surface is cooled b% the water,

leading to a reduction in the p%rol%sis rate, and

the flame goes out due to lack of fuel This is the

case when a B! team has knocked down the

flashover and is to e-tinguish the fire itself

!nother e-ample is when e-ternal e-tinguishing

is applied ,ere the water droplet often becomes

so large, more than 42 to D2 mm in diameter E4FG

that the% pass through the flames ?earl%

unaffected

D The surface of a not %et burning fuel is cooled

b% water, and the p%rol%sis rate does not increase

enough for the fuel to ignite This is the case at a

defensive operation where a wall is protected

from ignition b% wetting

Both points 4 and D are focused on the fuel with

the difference that in point 4, the surface is

burning, and in point D, it is not The difference is

vital when discussing firefighting tactics and the

difference between an offensive and a defensive

operation The heat absorption capacit% of water

can easil% be calculated>

0T # =225 H 22242= EMIJkgG, where T EK"G is the

actual steam temperature

This means that to transform = kg of water at

=2K" to steam at A22K", an energ% input of2DL M

44A M 0=222#=225 H 22242= 1 DA MI is needed

The heat absorption capacit% is DA MI per kg of

water used to its ma-imum at A22K"

Water that is not vapori8ed, which can be seen

flowing along the ground at man% fire scenes, has

a ma-imum absorption capacit% of onl% 2DL

MIJkg Theoreticall%, a hose delivering = kgJs

might absorb the energ% given in .igure 4=

Unfortunatel%, the water is rarel% applied in an

optimal wa%, which means that an efficienc%

factor must be included

.igure 4= ,ow the ma-imum theoretical

absorption capacit% of water at =2K" varied with

the team temperature

5

,.0 Dry 'owder

Dr% powder is commonl% used in two different

wa%s b%N either in small 0A to =4 kg5 fire

e-tinguishers or in larger powder units 0=22 to

D22 kg5 )t is the latter t%pe that is considered

here .ire brigades at airports have used dr%

powder for a long time in combination with foam

+oom fire tests have also been carried out in

which powder has been used in a fast initial

attack )n spite of this, and in spite of being an

e-tinguishing medium with a ver% high

e-tinguishing capacit%, there seems to be a lack of

e-perience in using dr% powder at real fires in

storage buildings

! large number of different dr% powders are

available 'ome of the most common ones are

mi-tures of ?,C,4P9C 0M!P5, /"l, /9,,

/,"9D, ?a9, and ?a,"9D

,.2 8#!eo! E6t$nct$on Med$#

There are a large number of different gaseous

e-tinguishing media> nitrogen, carbon dio-ide,

halons 0which are to be replaced for

environmental reasons5 and different halon#related

compounds E-cept for ver% special operations,

gaseous e-tinguishing media are rarel% used b%

the fire brigade 9ne e-ception is a fire in a silo,

where the smouldering fire is easier to put out

with a gaseous e-tinguishing agent than with

water or foam )n this t%pe of deep seated fire,

gaseous agents are valuable .or use at fires in

chemical warehouses, there has not %et proved to

be an% gaseous e-tinguishing medium of practical

use 0e-cept perhaps for halon5 This means that

gaseous e-tinction media can, for the present, be

e-cluded from this specification

CHA'(ER (HREE

(HE S(A)D'*'E SYS(EM

/.+ H$!tory #nd De1elo7ment o.

!t#nd7$7e Sy!tem!

The basic philosoph% and concept of

standpipe s%stems have not changed

e-tensivel% since =F=3 when the original

?+P! standard was adopted although the

specific re*uirements have been modified

continuall% The original standard on

standpipes developed and adopted b% the

?ational .ire Protection !ssociation, was

entitled +egulations for the )nstallation of

)nterior 'tandpipe E*uipments 0Wet Pipe

'%stems5 What follows is a comparison of a

standpipe s%stem in the =F=3 edition of the

standard with the =FLA edition of the

standard# ?.P! =C 'tandard for the

)nstallation of 'tandpipe and ,ose '%stems

+9+2

Primaril% a standpipe s%stem should afford a

read% means for the control of incipient fires

b% the occupants of buildings during working

hours and b% watchmen and those present

during the nighttime and holida%s )t should

also be capable of furnishing the high power

streams re*uired b% fire departments during

the more advanced stages of fire on the inside

of building and the heav% caliber streams

necessar% for e-terior protection and for

fighting fire in one building from another

+9:4

'tandpipe s%stem !n arrangement of piping,

valves, hose connections, and allied

e*uipment installed in a building or structure

with the hose connections located in such a

manner that water can be discharged in

streams or spra% patterns through attached

hose and no88les, for the purpose of

e-tinguishing a fire and so protecting a

building or structure and its contents in

addition to protecting the occupants This is

accomplished b% connections to water suppl%

s%stems or b% pumps, tanks and other

e*uipment necessar% to provide an ade*uate

suppl% or water to the hose connections

These basic si8es are listed in the =FLA

standard as the minimum si8es for standpipe

for "lass ) and "lass ))) service not

e-ceeding =22ft in length, and "lass ))

service not e-ceeding 32 ft in length The

original standard also specified a minimum of

two steamer 0fire department5 connections on

different sides of the building

The amendments to the =F=O standard, which

was then entitled> +egulations for the

)nstallation of 'tandpipe and ,ose '%stems,

defined a standard standpipe and hose s%stem

as a s%stem with water pressure maintained at

all times, or arranged to admit water

automaticall% to the s%stem This standard

stated specificall% that s%stems into which the

water had to be admitted manuall% were not

standard s%stems This standard also

established the three classes of standpipe

service, which are still utili8ed in the current

standard in the following manner

"lass ) .or use b% fire departments and those

trained in handling heav% fire

streams

"lass )) .or use b% the occupants of the

buildings as first and fire protection

"lass ))) .or both of these classes of service

/., Cl#!!$.$c#t$on o. St#nd$ng Sy!tem

The ?ational .ire Protection !ssociations

?.P! =C contains a classification of

standpipes based on the purpose or intended

usage of the s%stem

The class = s%stem is designed for use b% fire

department personal or other persons 0such as

industrial fire brigade or securit% personnel5

who are trained in fire fighting procedures

involving 4

=

J4 inch hose streams at high

pressures

The class )) s%stem is designed for use

primaril% b% building occupants who,

presumabl%, have no speciali8ed training

"lass )) s%stems are usuall% limited to hose

si8es of =

=

J4 inches and smaller 'ome fire

protection personnel prefer to restrict the

installation of "lass )) s%stems to industrial or

militar% occupancies where personnel

s%stematicall% receive fire suppression

training The provision of standpipe hose and

no88les for occupancies with limited numbers

of personnel, or for occupancies populated

e-tensivel% b% the general public 0including

office buildings5, would appear to create a

risk of personnel in&ur% from operation of the

hose lines Therefore, the assumed benefits of

fire control or suppression from the operation

of hose on a "lass )) standpipe s%stem are

neither assured nor dependable )t would

seem that the provision of a standpipe s%stem

with =

=

J4 inch hose for occupant use is usuall%

favored b% individuals who do not have 0=5

an understanding of or appreciation for, the

ha8ards of manual fire fighting procedures

and 045 an awareness of the ha8ards to

untrained personnel who do not have

ade*uate personnel protective e*uipment,

including breathing apparatus

The "lass ))) s%stem is designed for use b%

either the fire department of the building

occupants Therefore, a "lass ))) s%stem will

have both 4

=

J4 inch and =

=

J4 inch reducer

s%stem can be converted to a "lass ))) s%stem

b% attaching a 4

=

J4 inch to =

=

J4 inch reducer

and =

=

J4 inch hose and no88le, provided the

reducer and hose can be disconnected readil%

Table == presents a summar% of the hose

pipe si8e, and minimum water suppl%

re*uirements for the three classes of

standpipe and hose s%stems, as classified b%

?.P! =C

The combined standpipe and sprinkler s%stem

is defined b% the ?.P! as a s%stem where the

water piping supplies Thus, with the

combined s%stem, the standpipe# sprinkler

s%stem rises can be si8ed b% h%draulic

calculations based on the flow and pressure

re*uired for the standpipe s%stem when the

building is completel% sprinklered .or full%

sprinklered buildings with class ) or "lass )))

standpipe s%stems, with combined s%stems,

the sprinkler demand does not have to be

added to the standpipe pressure and flow

re*uirements as shown in Table == ,owever

where the sprinkler s%stem demand,

including the inside hose station allowance of

32 gpm for a single station and =22gpm for

multiple stations, e-ceeds the standpipe

s%stem demand, the sprinkler s%stem demand

shall be included

)t should be noted that the ma-imum demand

of 4322 gpm for a "lass ) standpipe s%stem

0as indicated in Table ==5 is reduced for

completel% sprinkle red buildings to =322

gpm for a light ,a8ard 9ccupanc%, and 4222

gpm for an 9rdinar% ,a8ard 9ccupanc% in

addition, for a completel% sprinklered

building with a combined s%stem, the "lass ))

t%pe of standpipe or the "lass )) provision of

=

=

J4 inch hose for occupant use on a "lass )))

s%stem can be omitted with the approval of

the authorit% having &urisdiction

With a combined standpipe and sprinkler

s%stem in a building e*uipped with a partial

sprinkler s%stem, the standpipe s%stem water

suppl% re*uirements must be increased b% the

h%draulicall% calculated sprinkler s%stem

demand or b% =32 gpm for $ight ,a8ard

9ccupancies or 322 gpm for 9rdinar% ,a8ard

9ccupancies whichever is the greatest

demand

/./ (y7e! o. St#nd7$7e Sy!tem

'tandpipe s%stems are also classified b% t%pe

according to the design of the relative to the

water suppl% features of the s%stem ?.P! =C

defines the various t%pes of standpipe

s%stems as follows

= Wet standpipe s%stem having suppl%

value open and water pressure

maintained at all times

4 Dr% standpipe s%stem so arranged

through the use of approved devices

as to admit water to the s%stem

automaticall% b% opening a hose

valve

D Dr% standpipe s%stem arranged to

admit water to the s%stem through

manual operation of approved remote

control devices located at each hose

station

C Dr% standpipe having no permanent

water suppl%

! filled standpipe having a small water

suppl% connection to keep the piping full

re*uiring water to be pumped into the s%stem

shall be considered a dr% standpipe of this

t%pe

)n addition to the preceding t%pes of s%stems,

s%stems that are similar that are wet standpipe

s%stems can be found in some areas however

in such s%stems the water suppl% valve that

keeps the s%stem full at water involves a

limited launch or connection These s%stems

are sometimes called primed s%stems and

operating pressure for their use with

/.0 WA(ER SU'';*ES FOR S(A)D'*'E

The water suppl% to a standpipe will ver%

with the design of the particular standpipe

s%stem and according to the location of the

structure that contains the standpipe

!cceptable water suppl% sources include

connections to public or private water mains,

pressure tanks gravit% tanks and fire pumps

'ome standpipe s%stems are designed so that

when a discharge valve at a hose station is

openedN water from public or private water

mains is automaticall% admitted into the

s%stem 'uch s%stems might utili8e a

principle of operation similar to that of dr%#

pipe sprinkler s%stems Thus the standpipe

normall% contains air pressure, the opening of

the discharge valve causes a pressure drop

which in turn allows water to flow into the

standpipe s%stem

The s%stems that are designed to operate with

remote#control devices often utili8e a

principle of operation similar to the deluge

valve, with a remote manual release that is

located ad&acent to each standpipe discharge

valve or hose station The remora#control

devices can be electrical pneumatic or

h%draulic in design and operation These

stand pipe s%stems Which allow water to

flow into the s%stem when the discharge

valve is opened, are usuall% found in free8ing

climates in occupancies where heat is not

provided 0including warehouses, piers and

similar structure5

The t%pical sources of water for standpipe

s%stems are similar to the water sources for

sprinkler s%stems The most prevalent source

of water is a direct connection to a public or

water mains of high#rise building, the

pressure of the water could be inade*uate if

the height of a building e-ceeds =2 stories

0CDC spire re*uired to overcome the pressure

loss in =22 ft of height5 Thus the use of fire

pumps is often re*uired on standpipe

s%stems )n high#rise buildings series of fire

pumps are usuall% arranged to suppl% vertical

8ones of the building

?.P! =C recommends that the ma-imum

height per 8one be 4O3ftN this involves

appro-imatel% =42 psi head pressure loss on

the s%stem ,owever, 8one heights up to C22

ft are permitted when the s%stem is rated for

the ma-imum pressure and the outlet pressure

is controlled to a ma-imum of =32 psi also,

?.P! =C re*uires a water suppl% capabilit% at

the topmost outlet of the standpipe s%stem to

provide 322 gpm at A3 psi for class = and

"lass ))) s%stems and =22 gpm at A3 psi for

class )) s%stems !t least one water suppl%

source must be automatic and must be

capable of suppl%ing the initial hose streams

on class )) and "lass ))) s%stems until the

au-iliar% or secondar% sources of suppl% can

be utili8ed man% standpipe s%stems utili8e the

standees fire depart sources of suppl% can be

utili8ed Man% standpipe s%stems utili8e the

'iamese fire department connection as the

au-iliar% or secondar% source of water

suppl% ?ote to taken that, with a dr%

standpipe s%stem the fire department

connection is the onl% source of water

/.2 F$re 'm7!

)n order to suppl% the pressure needed to

ensure an ade*uate volume of water at an

efficient pressure a stationar% pump with an

automatic stating controller can be connected

to the standpipe With a wet standpipe

normall% hilled with water from the

connection to the public water main The auto

man fire pump usuall% is arranged with the

controller on a pressure drop or water flow in

the standpipe thus, while a minor pressure

drop or flow will not start the fire pump, a

pressure drop that indicates that a standpipe

hose line valve is being opened will stat the

fire pump

Manuall% controlled fire pumps can be used

to suppl% standpipe s%stems The manuall%

controlled pumps can be arranged on

standpipe s%stem in combination with a

pressure tank or a gravit% tank the pressure

tank The pressure tank is often arranged to

operate on the pressure drop in the standpipe

s%stem caused b% the operation of a s%stem

discharge valve The pressure tank operation

then provide visual and audible signals on the

fire alarm s%stem which in turn, alert the

responsible personnel to manuall% start the

fire pump This t%pe of fire pump operation

often is found in industrial and manufacturing

occupancies where the fire pump is located in

a power plant, boiler house, or other locations

having personnel in 4C hour attendance

The manual fire pump operation often is

found where the industr% utili8es a stream

operated turbine or reciprocating fire pump

because pumps often are located at the source

of steam, such as a power plant or boiler

station 'team fire pumps usuall% will be

found in occupancies where steam is re*uired

in the operation of the industr% The% are also

usuall% found in e-isting conditions rather

than new installations .igure =A shows a

hori8ontal diesel#engine#driven centrifugal

pump

'tandpipe risers and branch lines can be

e*uipped with water flow alarm devices of

the same t%pe used in the wet#pipe automatic

sprinkler s%stem 'uch devices are useful in

large s%stems to indicate the area of the

building or the comple- in which the

standpipe hori8ontal electric#motor#driven

centrifugal fire pump, which arranged for

automatic start with a water pressure drop

from the opening of a standpipe control

valve .igure =L is a diagrammatic view of a

hori8ontal split#case fire pump ?ot that

pumps are usuall% made of single#stage

construction ! vertical submersible turbine

pump is preferred when the water source is

well or reservoir that re*uires a static suction

lifts

.ire pumps also are utili8ed to suppl%

standpipes from above ground reservoirs or

suction tanks, as well as from public or

private or private mains .ire pumps alwa%s

have discharge headers or series of outlets

located ad&acent to them often on the outside

of a building 'ome of these connections

could be identified as wall h%drants .ire

department personnel should be familiar with

the locations of fire pumps because these wall

h%drants or header outlets might valuable in

fire situation involving ad&acent buildings or

an e-posure to the fire pump locations

.igure ==2 shows an e-terior wall h%drant

located ad&acent to an interior fire pump

location

Pressure# maintenance pumps, sometimes

referred to as &ocke% or makeup pumps 9ften

are found on sprinkler s%stems and standpipe

s%stems These pumps are mostl% of the

centrifugal t%pe, although vane and positive

displacement #t%pe pumps might be found on

some s%stems Usuall% provided with electric

motor drive and having limited gpm capacit%,

these pumps operate on the initial pressure

drop from the s%stem and prevent the fire

pump from c%cling on and off due to pressure

losses from surges on the s%stem or leakage

through

The &ocke% assures maintenance pump first

operates with the initial pressure dropN once

the flow of water from the standpipe s%stem

or the sprinklers e-ceeds the capacit% of the

&ocke% pumpN the continued drop in pressure

activates the fire pump

'tationar% fire pumps installed in building to

ensure ade*uate water pressure and volume

to the standpipe s%stems are an effective and

valuable assistance factor to the fire

department especiall% in high rise buildings

/.4 8r#1$ty (#nk!

6ravit% tanks are installed on the roofs of

some buildings and supported on towers in

man% industrial manufacturing and

warehouse areas The prime advantage of the

gravit% tank is its head#pressure capabilit%

Because of this capabilit%, the gravit% tank is

able to provide a constant source of pressure

to the standpipe or sprinkler s%stem .or

ever% foot the water is elevated above a

gravit% tankPs discharge outlet, the pressure is

increased b% 2CDC pounds ,owever, gravit%

tanks re*uire e-tensive and continuing

maintenanceN in man% geographical areas,

the% also re*uire protection against free8ing

'eparate tanks or discharge pipes are

recommended to prevent the gravit% tank

from being emptied of water when the tank

supplies both operational and fire protection

s%stems 6ravit% tanks have collapsed from

ice loads created b% overflows when being

filled, and from lack of maintenance 6ravit%

tanks are of various si8es and are

manufactured from both wood and steel, with

steel being the prevalent material utili8ed in

modern tank construction

/.< 're!!re (#nk!

Pressure tanks are enclosed water tanks of

limited si8e, with air pressure maintained

within the tank to provide the velocit% energ%

for the discharge of the water from the tank

ThereforeN pressure tanks operate on a

principle similar to that of pressuri8ed air#

water e-tinguishers )t is preferable to locate

a pressure tank on a buildingPs upper floor

when building construction is sufficientl%

advanced to support the structural load of a

tank filled with water ,owever, with

facilities involving light such as health care

facilities or nursing homes where public

water mains are not available, the tanks

should be located in basements or outside the

structure Pressure tanks provide a means of

ensuring immediate water discharge from

standpipes in tall structuresN therefore, the%

are sometimes used in combination with fire

pumps or gravit% tanks

?ormall%, pressure tanks are kept

appro-imatel% two#thirds full of water and

charged with a minimum air pressured of O3

psi When gravit% tanks are connected to a

suppl% riser for sprinklers or standpipes with

a pressure tank, the connection should be

made C2 ft or more below the bottom of the

gravit% tank with the check valve for the

gravit% tank at the connection in order to

avoid air lock

!ir lock occurs when the gravit% tank and the

pressure tank are connected to a common

riser, and the gravit% water#pressure from the

gravit% tank is less than the remaining air and

water pressure in the riser at the gravit% tank

check valve Therefore, for new s%stems

being installed air lock can be avoided b%

providing sufficient gravit% pressure at the

gravit% tank check valveN this can be

accomplished b% making the connections a

possible solution to air lock is to reduce the

air pressure maintained on the pressure tank

to a safe minimum to allow discharge of the

water and also to increase the water level in

the pressure tank to about L2B ! reduction

in air pressure to appro-imatel% A2 psi with

increased water should provide a minimum

residual air pressure after the pressure tank

has been discharged completel%

/.: F$re De7#rtment Connect$on

The fire department connection is mandator%

on all standpipe s%stems and most sprinkler

s%stems according to the ?.P! standards

The fire department connection provides the

onl% means of suppl%ing water to a dr%

standpipe s%stem The onl% valve allowed in

the connecting pipe between the standpipe

riser and the fire department connection is a

check valve, which is installed to allow water

to flow into the s%stem from the fire

departments 'iamese connection Because no

t%pe of control valve is allowed on the pipe,

the fire department connection should alwa%s

be available to suppl% water to the standpipe

s%stem

The fire department connection should

alwa%s be inspected b% fire companies when

conducting in#service inspections, especiall%

when such connections are missing the plugs

or caps and before attaching hose lines These

connections often become depositories for all

t%pes of trash and obstructions including

empt% bottles The 6len Echo .ire

Department in Mar%land has an effective

inspection program whereb% members of the

department locate and inspect all fire

department connections to both standpipes

and sprinkler s%stems in their response area

With the cooperation and permission of

propert% owners, shrubs that obstruct

connections are removed and reflective

marketing are painted around the connections

to make them more visible from a distance,

especiall% at night

CHA'(ER FOUR

MECHA)*CA; EQU*'ME)(S USED *)

F*REF*8H(*)8

0.+ WA(ER SU'';Y CO)(RO; =A;=ES

.ire service personnel often need rapid access to

valves )f a valve is closed during an incident, it

ma% need to be opened to permit flow of water )f

a sprinkler valve is open, it ma% need to be closed

to assist in manual suppression efforts

The wording Qcontrol valveR b% itself does not tell

a user the specific use of the valve or what portion

of the s%stem is downstream of a particular valve

Using more descriptive labels such as Q=4th floorR

or Qpump b%passR will avoid confusion 0.igure

C=5

.ig C= 'prinkler 8one diagram

)f a valve identification is not obvious, an

additional diagram should be provided .or

instance, if a floor has multiple 8ones, each

control valve sign should identif% the

corresponding 8one, such as Q=4th floor eastR or

Q8one O#4R ! diagram of 8ones and the

boundaries between them should be mounted

ad&acent to each valve 0.igure C45 This will

enable firefighters to *uickl% determine which

valve controls each specific area

7alves are to be accessible for operation )f valves

are located in stairs, the% will be protected and

easil% accessible during a fire event

When a water suppl% control valve must be

.ig C4> Pressure controlling 7alve

located in a room or in a concealed space, a sign

outside the door or access panel helps firefighters

to *uickl% locate it )f the concealed space is

above a suspended ceiling, the appropriate place

for the sign is on the fi-ed ceiling grid, rather than

on a removable ceiling tile )n addition, some

&urisdictions re*uire e-terior signs that indicate

the locations of interior valves

7alve handles are often located high enough to be

out of vandals( eas% reach ,owever, such

placement re*uires a ladder to reach them when

necessar% !lthough some &urisdictions ma%

re*uire that valves be low enough to reach

without a ladder, all minimum height

re*uirements for obstructions must be followed

7alves for testing and draining purposes should

also be labeled This will prevent an% potential

confusion E-terior valves should be placed in

locations accessible even during a fire incident

Wall#mounted valves should be positioned no

higher than 3 feet above grade 0ground level5 and

located at least C2 feet from openings such as

windows, doors, or vents

.ig CD> E-terior sign showing valve location 0in

this case for a standpipe s%stem5

Designers should re*uire proper notification when

their designs re*uire s%stems, or portions of

s%stems, to be temporaril% shut off This would

t%picall% occur during s%stem alterations, or

phased installations )n these instances, the design

documents should re*uire notification of an%

s%stem impairments to the responsible fire service

organi8ation and coordination with the fire service

about an% re*uirements that these impairments

ma% entail

0.ig CC5 Wall control valve ne-t to window .ire

issuing from this window could prevent access to

the valve

0.ig> C35 Wall control valve

0., Con!$der#t$on

; $evel all valves for specific area covered

; Provide diagrams to show boundaries between

8ones

; $ocate interior valves in enclosed stairs where

possible

; Provide signage for valve that is outside stairs or

in concealed spaces

0./ F*RE 'UM'S

.ire pumps are used to boost the water pressure in

sprinkler and standpipe s%stems and to deliver the

re*uired amount of water This is necessar% when

the s%stem is fed b% a non#pressuri8ed water tank,

or when the water suppl% feeding the s%stem has

inade*uate pressure ! fire pump ma% be driven

b% an electric motor, diesel engine, or steam

turbine

0.ig CA5 .ire pump

'tandard for the )nstallation of 'tationar% Pumps

for .ire Protection, contains design and

installation details for fire pump installations

Electrical monitoring of pump controllers are also

re*uired for pump running, power failure, or

controller trouble These remote alarm signals are

often incorporated into fire alarm enunciators, so

that fire departments ma% identif% the status of a

given fire pump

! fire pump controller is the enclosure that

contains controls and status indicators for a fire

pump These devices are re*uired to be within

sight of the fire pump motor or engine The

automatic transfer switch, which is often in a

separate enclosure, transfers power to a secondar%

power source 0when provided5 .ire service

personnel ma% need access to this e*uipment

during the course of a fire

The power suppl% to an electricall% driven fire

pump must be reliable .or e-ample, power

suppl% lines must be protected and the circuit

must be independent of a building(s electric

service The latter feature allows the fire service

to shut down building power while the fire pump

continues to run The most desirable location for a

fire pump is in a separate building This affords

the most protection from fire, and gives

firefighters eas% access to the pump and its

controllers )f locating the pump in a separate

building is not possible, a fire#rated room with an

outside entrance is the ne-t best option The pump

rooms should be separated from the rest of the

building b% 4#hour fire#rated construction in

buildings without full sprinkler protection, and =#

hour construction in full% sprinklered buildings

)nside and outside entrances to fire pump rooms

should be labeled with signage Minimum

lettering si8e should be si- inches high with a

=

J4

inch stroke 0thickness of lines in each letter5

0.0 F*RE HOSE CO))EC(*O)S

,ose connections in "lass ) s%stems are t%picall%

4

=

J4 inch threaded outlets !s discussed in the .ire

,%drant section, it is essential that hose

connection t%pe and si8e match that used b% the

fire department in the &urisdiction where the

building is located

The primar% location for hose connections is

within enclosed, fire#resistance rated stairs

.irefighters set up and begin their attack from

within the protected stair enclosure Then the

attack ma% proceed towards the fire location )f a

*uick evacuation becomes necessar%, the hose

then functions as a lifeline, leading the firefighters

back to the protection of the stairs

The current preferred location for stairwa% hose

connections is at the intermediate stair landings

between floors This is because firefighters

usuall% stretch hose from below the fire floor for

their protection )f the connections are at

intermediate landings, the hose line reaches

farther than it would if the connection were at the

main landing, a full stor% below the fire floor

)f hose valves are located on main landings,

consider the position of hose connections in

relation to the door The connections should not

be behind the door when it is open Designers

should position the outlet to permit the hose line

to run out the door without kinking and without

obstructing travel on the stair

.ire attack using hose lines from stairwa% hose

connections re*uires stair doors to be propped

open This prevents the hose from becoming

kinked and restricting water flowN however, it can

also allow smoke and heat to enter the stairwa%

!t this point, occupants should either have e-ited

the building, be below the level of the fire, use

another stairwa%, or be sheltered in place until

after the incident But, there is now some concern

within the fire protection communit% that

occupants ma% be e-posed to fire or smoke

conditions during these firefighting operations

'ome reasons for this include> conflicting

evacuation instructions, occupants not following

evacuation instructions, the need for the fire

department to operate from all stairwa%s, or the

need for total building evacuation

0.ig CO5 ,ose connection on the corridor side of

such vestibules re*uire a little more stair door

0.ig CL5 'tripe on column to identif% hose

connection location in a parking garage

0.2 'RESSURE RE8U;A(*)8 DE=*CES

Pressure +egulating Devices 0P+Ds5 restrict

s%stem pressures, usuall% below =O3 psi for "lass

) s%stems 0.igure C=25 This is considered the

ma-imum safe operating pressure as well as the

ma-imum working pressure limit of most fire

protection components Proper design of P+Ds is

imperative so that firefighters have ade*uate

pressure for hose streams

!s a stark e-ample, failure to coordinate settings

on these devices with fire department tactics

emerged as a ke% issue in the =FF= Meridian Pla8a

high#rise fire in Philadelphia, which resulted in

the death of three firefighters

P+Ds fall into three categories> pressure reducing

valves 0P+7s5, pressure control valves, and

pressure restricting devices Pressure restricting

devices do not limit pressure during static 0non#

flowing5 conditions, nor do the% maintain a

constant discharge pressure These devices

incorporate orifice plates, mechanical pressure

restrictors, or valve limiting stops Pressure

restricting devices are not used for new "lass )

standpipe s%stems ,owever, designers ma%

encounter these when redesigning e-isting

s%stems, which would provide the opportunit% to

implement some or all of the considerations

below

0.ig CF5 ,ose connection e*uipped with a

pressure regulating device

P+7s and pressure control valves limit both static

and residual 0flowing5 pressures ,owever, man%

of these valves are factor% preset to attain specific

outlet pressures with specific inlet pressures )t is

important for designers to specif% the inlet

pressure range for valves as well as the desired

outlet pressure, so that the% ma% be designed

properl% and then installed on the correct floors

"areful attention during design, installation,

acceptance testing, and maintenance ensures that

s%stems with P+Ds will function properl%

P+7s and pressure control valves have other

disadvantages Their failure rate has been high

'econdl%, man% cannot be ad&usted b% firefighters

during a fire, or the% re*uire special tools and

knowledge .inall%, hose connections with these

devices cannot be used as backup fire department

inlet connections, since water can onl% flow

through a P+D in one direction

The most reliable means of limiting pressures in

standpipe s%stems is to design them to preclude

the need for pressure regulating devices )n

shorter buildings, careful attention to the design of

pumps and the ma-imum pressure supplied b%

incoming water mains can accomplish this )n

taller buildings, the same concept can be applied

to each separate vertical standpipe 8one Pressure

fluctuations in the water suppl% as well as the full

range of fire pump capacit% are essential

considerations in an% building

)f the use of P+Ds cannot be avoided, certain

design features will balance their disadvantages

The easier the valves are to ad&ust in the field, the

faster the fire service can overcome an%

unforeseen situation Designers should select

valves which can be easil% ad&usted and specif%

that identification signs and ad&ustment

instructions be posted at each valve The tools

re*uired to perform field ad&ustments should be

kept in a secure %et accessible location such as the

fire command center or a locked cabinet near the

fire alarm enunciator .inall%, a supplemental

s%stem inlet should be provided at the level of fire

department entr% This can be simpl% an e-tra

hose connection without a P+D on a riser

+ecommended a supplemental inlet, and it is

especiall% important for s%stems with a single fire

department connection

0.4 S(A)D'*'E *SO;A(*O) =A;=ES

The considerations in the section, Water 'uppl%

"ontrol 7alves, appl% to standpipe s%stems as

well This section gives additional guidance on

valves specific to standpipe s%stems The vertical

pipes that feed hose connections are called

standpipes or risers )f there are multiple risers, it

re*uires interconnections with suppl% piping to

form a single s%stem, with valves at the point

where each riser is fed b% the main bulk piping

coming from the water suppl% point Designers

should also put valves on the feed lines to remote

or supplemental hose connections

These valves are all called Qstandpipe isolation

valvesR The ones on vertical risers are called

Qriser isolation valvesR The% allow the fire

department to shut off or isolate an% given riser or

feed that breaks or otherwise fails .irefighters

ma% then use the remaining standpipes

+iser isolation valves separatel% control the feed

to each standpipe 'e*uential valves are not

acceptable where a single valve in the bulk main

can shut off more than one downstream riser .or

risers in stairwa%s, the riser isolation valves

should be within the fire#rated stair enclosure to

protect firefighters who ma% need to operate

them Previous editions re*uired designers to

place

.igC=2> )solation valve between the feed main

0entering from the lower left5 and the vertical riser

0on the right5 )t is located within the stair

enclosure for protection The valve at the top of

the photo is a sprinkler 8one control valve

the riser isolation valves at the bottom of the

risers to make them *uickl% accessible to

firefighters .ire departments ma% still prefer that

these valves be located on the level that the% use

for their primar% entr% )f the bulk feed main is

located on a different level it could be piped up or

down to the fire department entr% level, where the

isolation valve would be placed for that particular

riser 0.igure C==5

.ig C==> The feed for this standpipe was on a

level above the fire department entr% The suppl%

pipe was fed down 0on the left5 to the entr% level,

where the isolation valve was located Then, the

pipe was routed back upwards 0on the right5 to

feed the standpipe riser

0.< O(HER DES*8) *SSUES

'tandpipes should be installed as the construction

of building progresses These can be temporar% or

permanent 'tandard for 'afeguarding

"onstruction, !lteration, and Demolition

9perations, contains re*uirements for standpipes

during construction Design documents should

indicate the applicable re*uirements ! marked,

accessible fire department connection can suffice

as a water suppl% until building construction

progresses to the point at which the water suppl%

s%stem and fire department pampers can no longer

provide ade*uate pressure to the s%stem !t this

point, a temporar% or permanent fire pump also

becomes necessar%

)n climates sub&ect to free8ing temperatures, it is

vital that standpipes in unheated areas be dr% t%pe

s%stems ,eat tracing and insulation are

ineffective protection for dr% fire protection

s%stems because water is not normall% flowing

through the piping

$arge dr% s%stems deserve special considerations

!s the si8e of a dr% s%stem increases, the time

re*uired to deliver water to the remote hose

connection increases This is due to the increased

pipe volume that must be filled This can be

mitigated b% subdividing the s%stem into smaller

independent s%stems, or 8ones The disadvantage

is that fire department inlet connections to dr%

s%stems cannot be interconnected 0.igure C=45

.ig C=4> .D"s for separate manual dr% standpipe

s%stems in a large parking garage

Beside this some other e*uipments are used in fire

fighting and fire prevention, such as#

.ig C=D> ! *uick#connect t%pe of .D"

.ig C=C> This .D" is mounted too close to a

wall 9ther obstructions could be fences, pipes,

downspouts, vegetation, etc

.ig C=3> )nitiating device 0smoke detector5

.ig C=A> .irefighter emergenc% power receptacle

ne-t to a standpipe fire hose connection inside of

a stair enclosure

CHA'(ER F*=E

F*RE F*8H(*)8 SYS(EM OF EME

BU*;D*)8

"!$"U$!T)9? .9+ .+)"T)9? $9'', .$9W

!?D ,E!D 9. PUMP 9. .)+E .)6,T)?6

':'TEM

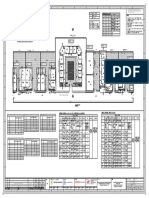

.ig 3=> T%pical diagram for a stand pipe and

hose s%stem connected directl% to the water main

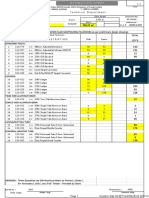

2.+ M#>or ;o!! $n St#nd7$7e

!ccording to the B?B" =FFD, Table CC=, we

find the fire protection flow re*uirements

.low rate for stand#pipe and hose s%stem,

S 1 =F22 $Jmin

!gain from continuit% e*uation we know,

S 1 ! T 7

A

Q

V =

4

5 = 2 0

C

2D=AO 2

= V

s m V J AO4 2 =

We have taken diameter of the pipe to be =2 mm

0C in5

"alculation of +e%nolds number

d

= +e

D

=2 OFL 2

= 2 AO4 2 O FF3

=

D

=2 L3 LD = 0U 42225

'o flow is turbulent

We consider the pipe material to be "ommercial

'teel ?ow, from chart we find the relative

roughness of the pipe

eJD 1 2222CD

?ow from Mood% Diagram, we get the Q.riction

.actor , fR

f 1 22D3

g

V

D

L

f h

4

4

=

L= F 4

AO4 2

= 2

DC 4L

2D3 2

4

=

m 4D 2 =

ft O3 2

2., M$nor ;o!! $n =#r$o! com7onent!

.rom Table DD=2 of VMark(s handbook for

Mechanical Engineering(

23 2 = K

Therefore,

m

g

V

K h

D

4

4

=2 =3 =

L= F 4

AO4 2

23 2

4

=

=

Therefore, total head,

m

h

D

D

=2 F A

=2 =3 = A

=

=

2./ M$nor ;o!! $n )o??le

!ccording to the specification of B?B" =FFD,

each standpipe must observe a flow of =F22

$Jmin, for a floor area of =222

4

m !s the

building is si- 0A5 storied, we have si- outlets

from each standpipe 'o each branch must suppl%

a flow of one si-th of the standpipe flow 'o the

flow in one no88le is,

A

F =

= Q

min J D=AO 2

D

m =

.rom continuit% e*uation,

A

Q

V =

s mJ A3 C

2DL 2

C

=2 4O 3

4

D

=

We have taken the diameter of the no88le is DLmm

0=3 in5

.rom Table DD=2 of VMark(s handbook for

Mechanical Engineering(

23 2 = K

m

g

V

K h

233 2

L= F 4

A3 C

23 2

4

4

4

=

=

=

2.0 Fr$ct$on ;o!! $n Ho!e '$7e

!ccording to the specification of B?B" =FFD,

ma-imum length of a hose pipe is D2 meter We

assumed our hose to be D2 meter

We also assumed the hose diameter to be DL cm

0=3 in5

m

g

V

D

L

f h

s m V

in mm D

f

m L

A= 4

L= F 4

A3 C

2DL

D2

22D 2

4

J A3 C

5 3 = 0 DL

22D 2

D2

4

4

=

=

=

=

=

=

=

2.2 (ot#l He#d

+esidual pressure at the no88le tip should be

=22psi for professional fire fighters !s the s%stem

will be operated b% non efficient people, we ma%

not keep the pressure at such elevation !ccording

to the B?B" =FFD, for non#professionals the

pressure should be A2WA3 psi We, in our

calculation, have assumed,

+esidual pressure A3 psi at top out of +iser E*uals

CA m 0=32 ft5

7ertical 'traight Pipe E*uals

4L3 m 0FD ft5

Total Ma&or $oss 024D m M 242 m5

2CD m 0=C= ft5

Total Minor $oss 0

D

=2 F A

m M 2233 m5

22A=F m 024 ft5

Total ,ead 0,5 1 OCFF m 04CCA= ft5

O3 m 04C3 ft5 Eappro-G

Therefore the re*uired head of pump,

, 1 O3 m

2.4 Re%$red Flow R#te o. t-e M#$n 'm7

!ccording to B?B" =FFD, each stand pipe should

cover =222 m4 floor area !nd for this it should

have a flow of =F22 $Jmin !lso the ma-imum

hosepipe length is D2 m "onsidering all the above

re*uirements, we have chosen four standpipes at

four suitable different places in EME building

)n the above calculation we have calculated the

re*uired head for one stand pipe 'ince we have

chosen four standpipes for our design, re*uired

flow is four 0C5 times the flow for one standpipe

'o the flow rate is,

s m

m

m Q

J =4AO 2

min J A O

min J F = C

D

D

D

=

=

=

2.< 'm7 C#7#c$ty

'ince flow rate, S is 2=4AO

D

m Js and head of the

pump including all ma&or and minor losses is O3

m, the pump capacit% is,

hp

hp

kW

QH p

=43

F3 =4C

44 FD

O3 =4AO 2 L= F

=

=

=

=

?ote

= Main fire pump capacit% has been

considered as per clause no C4D4 of

Bangladesh ?ational Building "ode

0B?B"5 for four standpipes

4 The si8e of standpipes 0=22 mm5 has been

taken as per table CC4 of B?B"

D "apacit% of &ocke% pump has been

considered as =L2 $Jmin and head F3 ft

slightl% higher then the main pump as

&ocke% pump operates with initial pressure

drop When the flow of main pump

e-ceeds the capacit% of the &ocke% pump,

main pump activates

2.: Re!er1o$r De!$gn

!ccording to B?B" =FFD, each stand pipe should

cover =222

4

m floor area !nd for this it should

have a flow of =F22 $Jmin !s we have four

standpipes in our design, the reservoir should

posses four times the flow rate of a single

standpipe That is,

Total reserve is 1 C T =F22$Jmin T 32 min

1 DL2222 $

1DL2

D

m

This amount of water is kept in the reservoir for

fire fighting The water should be changed at

ever% si- months !lso we have to prevent it from

contamination +estriction should be applied so

that this water ma% not be used in domestic

purpose

CO)C;US*O)

'ince we do not have an% fire fighting facilities in

our EME building, we got interested in designing

a fire fighting s%stem in our EME building .or

ever% sort of design information we have gone

through the B?B" =FFD The information

collected from the B?B" proves to be of great

value in designing fire fighting s%stem of

educational and all sort of buildings

We have provided fire department connection at

the west side of the EME building as the place is

ver% eas% to reach The nearest fire service station

is located at $albagh )t will take a few minutes to

reach BUET at an% unwanted situation But as the

B?B" =FFD has suggested at least 32 minutes

back#up, we have gone through the rule We have

not suggested fire e-tinguishers here

We have designed the s%stem basing on water But

at all the places it ma% not be helpful !s we know

damages made b% water is no less than fire But in

ever% sense we have to save lives There should

have other dr% s%stems to control fire of electrical

e*uipment There are also some laboratories

where water ma% create more disaster )n those

cases we have to go through gas s%stem or other

options

9ur s%stem is a manual one, where presence of

personal is needed for 4C hours Besides it is a

standpipe s%stem, which needs individuals to

operate .or development it can be replaced b% an

automatic s%stem )t would also be ver% good if

the total s%stem is replaced b% sprinklers 'uitable

amount of fire e-tinguishers are also needs to be

provided

Re.erence!

= Marks hand book for Mechanical

Engineers

4 Bangladesh ?ational Building "ode

0=FFD5

D !ndersson, Berit, To-icological,

"hemical and Ph%sical Properties of

'elected Pesticides, Department of .ire

'afet% Engineering, $und Universit%

C .ire 'afet% in Tall Buildings, "ouncil on

Tall Buildings and Urban ,abitat,

Mc6raw#,ill =FF4

3 Uni*ue .og Iets and a ?ew Wa% of

.ighting .ires, Product "atalogue,

Waterfog

S-ar putea să vă placă și

- Introduction to Transfer Phenomena in PEM Fuel CellsDe la EverandIntroduction to Transfer Phenomena in PEM Fuel CellsÎncă nu există evaluări

- Parametric Analysis of Combined Cycle Power Plant Using Steam Jet Inlet CoolingDocument7 paginiParametric Analysis of Combined Cycle Power Plant Using Steam Jet Inlet CoolingmontymilkyÎncă nu există evaluări

- Chapter 14 and 15Document7 paginiChapter 14 and 15api-236697820Încă nu există evaluări

- Iceland Geothermal PlantsDocument10 paginiIceland Geothermal Plantslov3lyjoannaÎncă nu există evaluări

- Determination of Mass Transfer CoefficientDocument5 paginiDetermination of Mass Transfer CoefficientgalojlÎncă nu există evaluări

- High Temp BrochureDocument2 paginiHigh Temp BrochureDenver Castro GuzmanÎncă nu există evaluări

- The Basics of Steam Generation and UseDocument12 paginiThe Basics of Steam Generation and UseKamugasha KagonyeraÎncă nu există evaluări

- Homogineous Charged Compression Ignition EngineDocument10 paginiHomogineous Charged Compression Ignition EnginePushkar FegadeÎncă nu există evaluări

- Maharana Pratap College of Technology, Gwalior: Seminar File ON Fire ProtectionDocument29 paginiMaharana Pratap College of Technology, Gwalior: Seminar File ON Fire ProtectionVijendra SolankiÎncă nu există evaluări

- AFF Manual CompleteDocument132 paginiAFF Manual Completeabhi1234uÎncă nu există evaluări

- Nordica RocketDocument14 paginiNordica RocketradianÎncă nu există evaluări

- Chapter Six: SterilizationDocument28 paginiChapter Six: SterilizationNOBLEMANÎncă nu există evaluări

- Heat Transfer CoefficientDocument3 paginiHeat Transfer CoefficientFrank DempsyÎncă nu există evaluări

- Polymerase Chain ReactionDocument29 paginiPolymerase Chain ReactionsrgÎncă nu există evaluări

- Dynamic Fuel Cell Gas Humidification SystemDocument8 paginiDynamic Fuel Cell Gas Humidification SystemDimitrios TsiplakidesÎncă nu există evaluări

- Cod Removal of Slaughter Wastewater by Expanded Granular Sludge Bed (Egsb) With Polyvinyl Alcohol (Pva) As A Biomass CarrierDocument6 paginiCod Removal of Slaughter Wastewater by Expanded Granular Sludge Bed (Egsb) With Polyvinyl Alcohol (Pva) As A Biomass CarrierChinh Nguyen DangÎncă nu există evaluări

- Chp4 SteriliDocument34 paginiChp4 Steriliyordanos gulilatÎncă nu există evaluări

- HPHT Well DesignDocument17 paginiHPHT Well Designvanthodc100% (1)

- 48 JCLP2827 Tsarouhis Libre PDFDocument10 pagini48 JCLP2827 Tsarouhis Libre PDFEmmanuel JaenÎncă nu există evaluări

- Study of Combined Rice Husk Gasifier Thermoelectric GeneratorDocument8 paginiStudy of Combined Rice Husk Gasifier Thermoelectric GeneratorAstitva MishraÎncă nu există evaluări

- Storage-Tank Heat TransferDocument57 paginiStorage-Tank Heat Transfervitcon87100% (12)

- Fuel Cell Experiment Fall 2010Document11 paginiFuel Cell Experiment Fall 2010Burcu Gözde BilolÎncă nu există evaluări

- Lab 2 Full Reprt HEx DoaaDocument22 paginiLab 2 Full Reprt HEx DoaaDoaa BadarnehÎncă nu există evaluări

- Biomass Gasification For Hydrogen ProductionDocument9 paginiBiomass Gasification For Hydrogen ProductionCris CrisÎncă nu există evaluări

- Lab 5 Heat ExchangerDocument4 paginiLab 5 Heat ExchangerJoson ChaiÎncă nu există evaluări

- Quiz7 SetAKeyDocument4 paginiQuiz7 SetAKeyLEXTER SOLISÎncă nu există evaluări

- 2.1 Manufacturing Processes and Selection:: 2.1.1 Oxidation ProcessDocument4 pagini2.1 Manufacturing Processes and Selection:: 2.1.1 Oxidation ProcessLucky9922100% (1)

- 8-17nov JeggelsDocument15 pagini8-17nov JeggelsQuynh NguyenÎncă nu există evaluări

- Prashant Seminar ReportDocument18 paginiPrashant Seminar ReportPrashant RajoleÎncă nu există evaluări

- Lab ManualDocument17 paginiLab ManualDaniel WigginsÎncă nu există evaluări

- Equations and Theory of The Simple Correlation Model of FierasystemDocument29 paginiEquations and Theory of The Simple Correlation Model of FierasystemJustice Mbam ChineduÎncă nu există evaluări

- Coal HandlingDocument32 paginiCoal Handlingkowsar0221Încă nu există evaluări

- 2.alternative Source of Energy (Fuel Cells)Document12 pagini2.alternative Source of Energy (Fuel Cells)Shrishant PatilÎncă nu există evaluări

- AQA GCSE Physics Specification (New GCSE)Document18 paginiAQA GCSE Physics Specification (New GCSE)siezchÎncă nu există evaluări

- FY BTech Lab Manaul 2021/01/01Document46 paginiFY BTech Lab Manaul 2021/01/01harshÎncă nu există evaluări

- Tri Sec AphDocument36 paginiTri Sec AphKrishnan Santhanaraj100% (1)

- Heat Pipe As A Cooling Mechanism in An Aeroponic SystemDocument10 paginiHeat Pipe As A Cooling Mechanism in An Aeroponic SystemArley Salazar HincapieÎncă nu există evaluări

- Solar Energy, & Its Advantages & DisadvantagesDocument3 paginiSolar Energy, & Its Advantages & DisadvantagesGishan Kelum PereraÎncă nu există evaluări

- Hydrogène Internal Combustion Engine: MR - Yusuf Mulani Ms. Tejashri Khochare Collège of Engineering, PandharpurDocument11 paginiHydrogène Internal Combustion Engine: MR - Yusuf Mulani Ms. Tejashri Khochare Collège of Engineering, PandharpurPushkar FegadeÎncă nu există evaluări

- Ar001Document33 paginiAr001josebaianetoÎncă nu există evaluări

- Petroleum Refinary 3Document14 paginiPetroleum Refinary 38wmswyzy8tÎncă nu există evaluări

- Model For Calculating Steam Ejector PerformanceDocument15 paginiModel For Calculating Steam Ejector PerformanceMuhammad KhurramÎncă nu există evaluări

- Gas SamplingDocument1 paginăGas SamplinganjanÎncă nu există evaluări

- Article 65831Document9 paginiArticle 65831Vaibhav Kawale patil.Încă nu există evaluări

- (Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Document11 pagini(Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Siraj AL sharifÎncă nu există evaluări

- Reyes 2014Document8 paginiReyes 2014fabio1199Încă nu există evaluări

- Analysis of Non-Isothermal Effects On Polymer Electrolyte Fuel Cell Electrode Assemblies - Madhur - EA PaperDocument16 paginiAnalysis of Non-Isothermal Effects On Polymer Electrolyte Fuel Cell Electrode Assemblies - Madhur - EA PaperMadhur BhaiyaÎncă nu există evaluări

- Monitoring of Sag & Temperature in The Electrical Power Transmission LinesDocument3 paginiMonitoring of Sag & Temperature in The Electrical Power Transmission Linesdasilva6391Încă nu există evaluări

- A Transient Study of Double-Jacketed Membrane Reactor Via Methanol Steam ReformingDocument9 paginiA Transient Study of Double-Jacketed Membrane Reactor Via Methanol Steam Reformingmerialeng34Încă nu există evaluări

- Heat and Mass Transfer Through A Thick Bed of Cocoa Beans During DryingDocument9 paginiHeat and Mass Transfer Through A Thick Bed of Cocoa Beans During DryingFadli Ryan ArikundoÎncă nu există evaluări

- ANW, Samenvatting, Hoofdstuk 9-12Document4 paginiANW, Samenvatting, Hoofdstuk 9-12Mathijs de ZoetenÎncă nu există evaluări

- Evaporation of Excess Alcohol in Biodiesel in A Microchannel Heat Exchanger With PeltierDocument9 paginiEvaporation of Excess Alcohol in Biodiesel in A Microchannel Heat Exchanger With PeltierAnonymous vqOhvhaoH2Încă nu există evaluări

- Desalination 1Document13 paginiDesalination 1weda allamÎncă nu există evaluări

- Aiaa 2010 6680Document15 paginiAiaa 2010 6680Talayeh MshÎncă nu există evaluări

- Plant Adaptations To The Environment Ii: Thermal, Moisture, and Nutrient EnvironmentsDocument12 paginiPlant Adaptations To The Environment Ii: Thermal, Moisture, and Nutrient EnvironmentshomamunfatÎncă nu există evaluări

- Unit 1&2Document42 paginiUnit 1&2Pavankumar PavankumarpvÎncă nu există evaluări

- Rankine - Regenerative Cycle - GoodDocument4 paginiRankine - Regenerative Cycle - GoodSafaa Hameed Al NaseryÎncă nu există evaluări

- Development of A Simulation Model For The Hybrid Solar Dryers As Alternative Sustainable Drying System For Herbal and Medicinal PlantsDocument21 paginiDevelopment of A Simulation Model For The Hybrid Solar Dryers As Alternative Sustainable Drying System For Herbal and Medicinal PlantsAdel BahnasawyÎncă nu există evaluări

- Heat Transfer Processes and Equipment in The Detergent IndustryDocument17 paginiHeat Transfer Processes and Equipment in The Detergent Industryعبدالمحسن علي EÎncă nu există evaluări

- Natural Gas Based Hydrogen Production WiDocument16 paginiNatural Gas Based Hydrogen Production WiManuel PavanÎncă nu există evaluări

- Traffic Area Resident Parking Scheme Permit Application 2014Document3 paginiTraffic Area Resident Parking Scheme Permit Application 2014Shamsul ArefinÎncă nu există evaluări

- PrefaceDocument3 paginiPrefaceShamsul ArefinÎncă nu există evaluări

- List of Halal and Haram Food Ingredients: 1. An Alphabetical Definition GuideDocument1 paginăList of Halal and Haram Food Ingredients: 1. An Alphabetical Definition GuideShamsul ArefinÎncă nu există evaluări

- Al Albani Unveiled - With Important Fatwas and Disclaimers AttachedDocument33 paginiAl Albani Unveiled - With Important Fatwas and Disclaimers AttachedRaana Khan100% (1)

- Local IcddrbDocument14 paginiLocal IcddrbShamsul ArefinÎncă nu există evaluări

- Grammar, Punctualization and CapitalizationDocument108 paginiGrammar, Punctualization and CapitalizationFernando Ornelas100% (1)

- Maintaining Family TiesDocument63 paginiMaintaining Family TiesShamsul ArefinÎncă nu există evaluări

- Sydney Opera House: Subject-Advanced Structural SystemsDocument15 paginiSydney Opera House: Subject-Advanced Structural Systemspriyanka100% (2)

- Belt Conveyor - Pull Rope Switch HEN PDFDocument4 paginiBelt Conveyor - Pull Rope Switch HEN PDFOussema ElloumiÎncă nu există evaluări

- SkyAir Standard R32 FBFCDocument2 paginiSkyAir Standard R32 FBFCTi Ti100% (1)

- Contents-WPS Office1Document17 paginiContents-WPS Office1junaidi 9Încă nu există evaluări

- Social Media Content Plan For LokalLivingDocument98 paginiSocial Media Content Plan For LokalLivingipo throwdownÎncă nu există evaluări

- Shrinkage and Temperature ReinforcementDocument5 paginiShrinkage and Temperature ReinforcementMustafaÎncă nu există evaluări

- Altar Estimate 2Document2 paginiAltar Estimate 2Kris PalÎncă nu există evaluări

- Apton Standard Price - 020219Document11 paginiApton Standard Price - 020219venspalÎncă nu există evaluări

- 3 Vetonit BOND2 PDFDocument2 pagini3 Vetonit BOND2 PDFengrrahman3135Încă nu există evaluări

- Irrigation Slab SCAFFOLDING BOQ (CRCC)Document1 paginăIrrigation Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelÎncă nu există evaluări

- Plant and Equipment MaintenanceDocument2 paginiPlant and Equipment MaintenanceBongbong GalloÎncă nu există evaluări

- Front View Elevation Rear View Elevation: Scale: 1:200 M Scale: 1:200 MDocument1 paginăFront View Elevation Rear View Elevation: Scale: 1:200 M Scale: 1:200 MHilary Grace Sumbi GargarÎncă nu există evaluări

- Building NumberingDocument1 paginăBuilding Numberingsamwail siddiquiÎncă nu există evaluări

- DLP 4 Types and Sizes of Linens With Produre of Bed MakingDocument2 paginiDLP 4 Types and Sizes of Linens With Produre of Bed MakingMyles GonatoÎncă nu există evaluări

- How To Avoid Cracking in AAC Block Wall: Mukund JoshiDocument18 paginiHow To Avoid Cracking in AAC Block Wall: Mukund JoshiSyed Ali0% (1)

- Fire DampersDocument6 paginiFire DampersTecnalcoÎncă nu există evaluări

- Koralaima Sales Kit SmallDocument19 paginiKoralaima Sales Kit SmallK.S.Sahan Jeewantha Kumara JayasuriyaÎncă nu există evaluări

- Hotel Scheme With Plans CDocument4 paginiHotel Scheme With Plans CRobert Oconer AguilarÎncă nu există evaluări

- Cálculo de Carga Térmica Tienda de SouvenirDocument8 paginiCálculo de Carga Térmica Tienda de SouvenirIvan HernándezÎncă nu există evaluări

- Seminar PresentationDocument14 paginiSeminar PresentationkollolÎncă nu există evaluări

- S0104 ENG Double Portal Frame Hanger Open FarmDocument23 paginiS0104 ENG Double Portal Frame Hanger Open Farmrimshabatoool72Încă nu există evaluări

- D112 ENGLISH VersionDocument2 paginiD112 ENGLISH VersionRinor Rushiti100% (1)

- Plant Visits and Seminars For Ce Assignment 5.1Document7 paginiPlant Visits and Seminars For Ce Assignment 5.1CYREL VINCE CASUGBOÎncă nu există evaluări

- List Buyer Handicraft & Furniture IIDocument91 paginiList Buyer Handicraft & Furniture IIKharisma Rizky NugrahaÎncă nu există evaluări

- FullStack AssignmentDocument5 paginiFullStack AssignmentVidisha singhalÎncă nu există evaluări

- Types of Hardscape MaterialsDocument3 paginiTypes of Hardscape MaterialsMichaela Santos100% (1)

- GTU Academic Calender 15 16Document2 paginiGTU Academic Calender 15 16Ram BhagwanÎncă nu există evaluări

- Antoni Gaudi: Artist & Architect 1852-1926Document11 paginiAntoni Gaudi: Artist & Architect 1852-1926aarti sahuÎncă nu există evaluări

- Chapter - 3 - Advanced STP TuningDocument40 paginiChapter - 3 - Advanced STP TuningNgoc Hai TranÎncă nu există evaluări

- HIROSE (Singapore) Pte LTD: Product CatalogueDocument8 paginiHIROSE (Singapore) Pte LTD: Product CatalogueHien nguyen thi dieuÎncă nu există evaluări