Documente Academic

Documente Profesional

Documente Cultură

2014-4-107 - P Fitting Evaluation of Pattern Making Systems According To Female Body Shapes P

Încărcat de

Robert Thompson100%(1)100% au considerat acest document util (1 vot)

72 vizualizări5 paginiIn order to provide clothing ft, it is necessary to associate garment patterns with body shapes. Basic skirt patterns were created using the CAD system according to Contec, Metric, Muller, and basic blocks pattern making systems. These patterns are dressed up on virtual mannequins which have been created in the three-dimensional (3D) virtual sewing and try-on system.

Descriere originală:

Titlu original

2014-4-107- p Fitting Evaluation of Pattern Making Systems According to Female Body Shapes p

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentIn order to provide clothing ft, it is necessary to associate garment patterns with body shapes. Basic skirt patterns were created using the CAD system according to Contec, Metric, Muller, and basic blocks pattern making systems. These patterns are dressed up on virtual mannequins which have been created in the three-dimensional (3D) virtual sewing and try-on system.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

72 vizualizări5 pagini2014-4-107 - P Fitting Evaluation of Pattern Making Systems According To Female Body Shapes P

Încărcat de

Robert ThompsonIn order to provide clothing ft, it is necessary to associate garment patterns with body shapes. Basic skirt patterns were created using the CAD system according to Contec, Metric, Muller, and basic blocks pattern making systems. These patterns are dressed up on virtual mannequins which have been created in the three-dimensional (3D) virtual sewing and try-on system.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 5

107 Tama D, ndoan Z. Fitting Evaluation of Pattern Making Systems According to Female Body Shapes.

FIBRES & TEXTILES in Eastern Europe 2014; 22, 4(106): 107-111.

Fitting Evaluation of Pattern Making Systems

According to Female Body Shapes

Derya Tama,

Ziynet ndoan

Ege University,

Textile Engineering Department,

35100 Bornova-zmir, Turkey,

derya.tama@ege.edu.tr,

ziynet.ondogan@ege.edu.tr

Abstract

In order to provide clothing ft, it is necessary to associate garment patterns with body

shapes. In this study, basic skirt patterns werecreated using the Computer Aided De-

sign (CAD) system according to Contec, Metric, Mller, and Basic Blocks Pattern Mak-

ing Systems in order to evaluate ft. These patterns are dressed up on virtual mannequins

which have been created in the three-dimensional (3D) virtual sewing and try-on system.

The mannequins sizes (38) and body dimensions are specifed according to international

size charts. Besides this the body shapes are selected as hourglass, triangle, or rectangle.

The ft is evaluated according to pressure and tension maps, which are the tools of the 3D

virtual sewing and try-on system. Although the mannequins are in same the size, different

results are obtained for each body shape. Also different results are acquired for each pat-

tern making system. Consequently it can be said that the pattern making systems are not

suitable for each body shape.

Key words: body shapes, garment pattern, 3D virtual sewing and try-on system, pattern

making systems, ft and satisfaction.

plications and hand drawing. British re-

searcher Winifred Aldrich developed the

Metric Pattern Making System, in which

garment patterns can be easily prepared

using very few assistant lines. There are

some additional measurements and they

are added to the body measurements dur-

ing pattern making. In the Muller Pattern

Making System, which was developed by

Michael Muller for Germans, the basic

measurements are taken from the body

directly. Other measurements are calcu-

lated during pattern drawing using these

measurements. The Basic Blocks Pattern

Making System was developed in Amer-

ica by Handford in 1984. In this system,

patterns are drawn by the combination of

simple blocks [5].

Scientists have been greatly interested in

human body shape classifcation. Based

on long-time studies, human body shapes

have been classifed according to inherent

body characteristics and somatoshapes

have been determined [6]. Somatotyp-

ing is the most recent development in the

twenty-fve century history of morpho-

logical taxonomy and constitutional in-

vestigation [7]. Somatotyping refects the

overall outlook of the body and conveys

a meaning of the totality of morphologi-

cal features of the human body [6].

When descriptions of different body or

fgure shapes are being discussed, the

somatoshape terms are not usually the

most common. Instead of these terms ap-

parel manufacturers have developed new

body shapes [8]. Some apparel manufac-

turers have used alphabets (H, O, A, X,

R, I, S), geometric shapes (Rectangular,

Oval, Triangle), names of fruits (Apple,

external infuences, body cathexis and

physical dimensions of the garment as

important factors infuencing ft [3].

Although each persons defnition of

that may be subjective, satisfaction with

clothing ft will be higher if the body

shape of the wearer can be considered

when the clothing is designed and manu-

factured. Body shape is the major factor

that has an infuence on ft and satisfac-

tion with clothing [2]. Ideal body shapes

have always been used by the apparel

industry, from which technicians take di-

mensions for pattern making and ftting

and designers create their new designs. It

is also used by manufacturers for show-

ing their garments, as models for hire ,

and is needed by consumers for their rep-

resentation [4].

Making garment patterns accurately is

also important. It is necessary to associ-

ate garment patterns with body shapes

in order to provide ft and satisfaction.

Many different pattern making systems

are used in the apparel industry, devel-

oped according to the nations anatomy

and changes in the pattern preparation

steps with respect to different systems.

These systems are also widely used in

countries which lack their own pattern

making systems. Therefore it is neces-

sary to investigate these systems and

their ft. In this context the pattern mak-

ing systems are evaluated using interna-

tional standard size charts.

In this study, four common pattern mak-

ing systems are evaluated. The Contec

Pattern Making System, developed in

Germany, is suitable for computer ap-

n Introduction

Dressing is one of the fundamental needs

of the human being, serving various and

diverse purposes [1].

Most people want

clothing that fts well [2]. Fit in womens

wear is a complex issue with many facts.

The earliest conceptual framework on

consumers satisfaction with the ft of

ready-to-wear identifed personal and

FIBRES & TEXTILES in Eastern Europe 2014, Vol. 22, 4(106)

108

Pear) and other distinctly shaped things

(Hourglass, Bean, Heart) to classify body

shapes [4].

They refer to more or less

the same fgures with different codes of

identifcation and are based on the pro-

portions of the bodys silhouette mostly

from the front view [9].

Since a desired ft is becoming more im-

portant for consumers, research on body

shape classifcation has increased world-

wide. Karla Simmons from North Caro-

lina State University studied this subject

in 2002 [8]. Simmons created computer

software for body shape classifcation.

In her study, Simmons used bust, waist,

hip and high hip circumference measure-

ments and the relationship between them

in order to identify the body shapes. Ac-

cording to this research Simmons clas-

sifed female body shapes under nine

groups (Table 1).

Methods of examining ft, live ft mod-

els and dress forms have been commonly

used together. Although ft models can

vary in their measurements and may not

be perfectly symmetrical, they can com-

ment on misft areas based on judgments

of both the feel and look of the garment.

Although ft sessions are mainly conduct-

ed with live models, patternmakers or de-

signers also use dress forms during prod-

uct development because they have con-

sistent measurements and are convenient

to use. However, apparel professionals

consider dress forms as supplementary

because they do not accurately represent

the shape of a live model [11].

New technology that includes digital vir-

tual human and digital virtual garments

has had a signifcant impact on the cur-

rent apparel industry. Virtual simulation

technology enables the visualisation of a

3D virtual garment on a virtual avatar so

that consumers can try on garments with

their virtual mannequins before purchas-

ing [12].

n Material and methods

The pattern making systems used are de-

veloped according to the nations anato-

my where the researches are carried out.

In the apparel industry, frst the basic

patterns must be prepared and after this

step model patterns can be acquired by

using these basic patterns, which must

be prepared accurately in order to ob-

tain a full ft. Therefore the accuracy of

basic pattern making systems should be

researched. In this study, Contec, Metric,

Mller, and Basic Blocks pattern mak-

ing systems, which are commanly used

arround the world, are evaluated. Basic

skirt patterns are created in the Gerber

AccuMark V8 CAD System according to

these four pattern making systems. These

skirt patterns are dressed up on virtual

mannequins, which have different body

shapes in the same size and are created

using the 3D virtual sewing and try-on

(V-Stitcher) systems. Afterwards the ft

is evaluated.

Body measurements of the virtual man-

nequins are obtained from international

standard size charts [13]. The table of

normal sizes is used and bust, waist and

hip circumference measurements for size

38 are taken from this table. Size 38 is

selected due to it is prevalence. These

measurements are 88 cm for the bust

circumference, 72 cm for the waist cir-

cumference and 97 cm for the hip cir-

Table 1. Female body shape classifcation [7, 9].

Body Shape Defnitions Shape

Hourglass

A very small difference between bust and hip circumferences

The ratios of bust-to-waist and hips-to-waist are about equal and

signifcant

Top

hourglass

A larger bust circumference than hip circumference

The ratios of bust-to-waist and hips-to-waist measurements are signifcant

enough to produce a defnite waistline

Bottom

hourglass

A larger hip circumference than the bust circumference

The ratios of bust-to-waist and hips-to waist are signifcant enough to

produce a defnite waistline

Spoon

A larger circumferential difference in hips and bust

The bust-to-waist ratio is lower than the hourglass shape

The hip-to-waist ratio is high

Triangle

A larger hip circumference than that of the bust

The ratio of hip-to-waist was small

Larger in the hips than in the bust without having a defned waistline

Rectangle

Bust and hip measurement fairly equal

Bust-to-waist and hip-to-waist ratios are low

There is not a clearly discernible waistline

Oval

The average of the stomach, waist and abdomen measurements is less

than the bust measurement

Diamond

The average of the stomach, waist, and abdomen measurements is more

than the bust measurement

Inverted

Triangle

A larger bust circumference than that of the hips

A small bust-to-waist ratio

Table 2. Bust, waist and hip measurements according to body shapes.

Bust circumfr. Waist circumfr. Hip circumfr. Final result of formula Body shape

88 70

96

26.2 > 25.6 cm Hourglass

86

74

22.2 < 23.0 cm Triangle

88 97

14.1 < 23.0 cm and

23.2 < 25.6 cm

Rectangle

Table 3. Colours according to assessment

range.

Assessment range Colors

Very tight Red

Tight Red - Orange

Well Yellow - Green

Large Light blue - Yellow

Very large White

109

FIBRES & TEXTILES in Eastern Europe 2014, Vol. 22, 4(106)

cumference. The skirt patterns are pre-

pared according to these measurements.

Measurement ranges are determined for

the bust circumference as 86 - 90 cm, for

the waist circumference - 70 - 74 cm, and

for the hip circumference - 95 - 99 cm

according to EN 13402-3: Measurements

and Intervals Standard.

The three most common female body

shapes are selected as hourglass, rec-

tangle, and triangle in order to evaluate

the desired ft. The body measurements

of these body shapes are calculated with

the help of the study performed by Lee et

al [2]. In their study, they developed sev-

eral formulas, which include bust, waist

and hip circumference measurements, to

defne body shapes. With respect to the

measurement ranges discussed above,

the mannequins body measurements are

calculated with the help of these formu-

las. During the calculation process, opti-

mum body measurements are chosen ac-

cording to the EN 13402-3 standard.

n The mathematical formula defned for

the hourglass category is:

If (bust-hips) < = 2.56 cm then

If (hips-bust) < 9.22 cm then

If (bust-waist) > = 23.04 cm or (hips-

waist)> = 25.6 cm then shape = Hour-

glass

n The mathematical formula defned for

the triangle category is:

If (hips-bust) >= 9.22 cm then

If (hips-waist) < 23.04 cm then shape =

Triangle

n The mathematical formula defned for

the rectangle category is:

If (hips-bust) < 9.22 cm and (bust-hips) <

9,216 cm then

If (bust-waist) < 23.04 and (hips-waist) <

25.6 cm then shape = Rectangle

Virtual mannequins are created in a sys-

tem according to the measurements and

body shapes which are shown in Table 2.

The skirt patterns are also created virtu-

ally according to the four pattern making

systems by using 50% Cotton - 50% PES,

252 g/m

2

and twill fabric. The virtual try-

on is generated and fnally the skirt visu-

als are procured.

Pressure and tension maps, which are

the tools of V-Stitcher, are used to evalu-

ate the ft. The tension map represents

the tension level of the stretched fabric

based on its physical properties, pattern

size and the visual mannequins size. The

Table 4. Visuals of skirts according to contec, metric, mller and basic blocks systems for

the hourglass body type.

Pattern making

system

General appearance Visual of skirts tension

Visual of skirts

pressure

Contec system

Metric system

Mller system

Basic blocks

system

Table 5. Visuals of skirts according to Contec, Metric, Mller and Basic blocks systems for

triangle body type.

Pattern making

system

Visual of skirt Visual of skirts tension

Visual of skirts

pressure

Contec system

Metric system

Mller system

Basic blocks

system

FIBRES & TEXTILES in Eastern Europe 2014, Vol. 22, 4(106)

110

tension maps colours range from white

through light blue, green, yellow and

orange to red. The tension colour codes

represent numeric values in g/cm from

0 (White) to 1000 (Red). The pressure

map represents the pressure level exerted

by the stretched garment on the body,

which depends on the fabrics physical

properties, the pattern size and the visual

mannequins size. As on the tension map,

the pressure maps colors range from

white, through light blue, green, yellow

and orange to red. The body pressure

colour codes represent numeric values in

g/cm

2

from 0 (White) to 100 (Red) [14].

Unfortunately the numeric values of pres-

sure and tension for each color cannot be

calculated from the virtual garments due

to the disadvantage of V-Stitcher. Altera-

tion in pressure and tension values of the

garment is represented only by colours.

In order to evaluate the pressure and ten-

sion maps, the fve-point likert is used.

The assessment range was determined

as very tight, tight, well, large and very

large. The colours according to the as-

sessment range are shown in Table 3.

Findings

The general appearance, tension and

pressure visuals of the skirts are obtained

for each pattern making system accord-

ing to hourglass (Table 4), rectangle (Ta-

ble 5) and triangle (Table 6) body types.

n Conclusions and suggestions

Skirt patterns are generally evaluated for

each body shape with respect to the waist

and hip lines using V-Stithcer (Table 7),

the evaluation of which is carried out ac-

cording to the fve-point likert. The as-

sessment ranges are determined as very

tight, tight, well, large and very large.

The views of the virtual mannequins are

analysed for three body shapes using

pressure and tension maps. When visu-

als are evaluated for each pattern mak-

ing system, different results are obtained

for each body shape, although the man-

nequins in three body shapes are of the

same size.

According to the general evaluations

of body shapes, it is seen that Contec,

Metric, Mller and Basic Blocks Pattern

Making Systems can be used for rectan-

gle and hourglass body shapes. Further-

more it is observed that all skirts, which

are prepared in four pattern making sys-

tems, have ft problems for triangle body

shapes. It is possible to say that when the

difference between hip and waist circum-

ferences is high, it causes ft problems.

As a result of this study, it can be said

that the pattern making systems are

not suitable for each body shape. For

this reason the pattern making systems

should be revised with respect to differ-

ent body shapes. For instance, the num-

ber, location and width of the darts can

be calculated according to the difference

between hip and waist circumferences in

the pattern making systems, which have

constant dart widths. Developing alterna-

tives for garment patterns, modeling ap-

plications and pattern grading according

to different body shapes allows manufac-

turers to provide ft and satisfaction.

It is very important to fnd the character-

istics of each body shape among races

and countries. Body shape comparisons

between countries give the opportunity

to discover ways of improving the siz-

ing systems of each, as well as impact

the development of international sizing

standards that could have a signifcant

impact on brands producing products for

a variety of international consumers with

different sizes and shapes [2]. It can be

seen that it is necessary to analyse the tar-

get groups body shapes to determine the

most appropriate pattern making system.

Table 7. General evaluation of hourglass, triangle and rectangle body shapes according to

pattern making systems.

Body shape

Evaluation

criteria

Contec Metric Mller Basic blocks

Hourglass

Waist line Large

Well

Very large Tight

Hips line Well Large

Well

Triangle

Waist line

Large

Large Very large

Hips line

Well

Large

Rectangle

Waist line

Well

Large

Hips line Tight

Table 6. Visuals of skirts according to Contec, Metric, Mller and Basic blocks systems for

rectangle body type.

Pattern making

system

Visual of skirt Visual of skirts tension

Visual of skirts

pressure

Contec system

Metric system

Mller system

Basic blocks

system

111

FIBRES & TEXTILES in Eastern Europe 2014, Vol. 22, 4(106)

References

1. Utkun E, Ondogan Z, Tama D. Research

on the body sizes of female university

students: Turkey Aegean region case

study. In: 11

th

World Textile Conference

AUTEX 2011, France.

2. Lee JY, Istook CL, NamYJ, et al.

Comparison of body shape between

USA and Korean women. In: Int. J. of

Cloth Science and Tech. 2007; 19, 5:

374-391.

3. Pisut G, Connell LJ. Fit preferences

of female consumers in the USA. J. of

Fashion Markt. and Manage. 2007; 11,

3: 366-379.

4. Devarajan P. Validation of Female

fgure identifcation technique (FFIT)

for apparel methodology. Department

of Textile and Apparel, Technology and

Management, North Carolina State

University, Raleigh, 2003.

5. Klc A. Development of a new pattern

preparation method for skirt and ladies

trousers by utilizing anthropometric

measurement system. Department of

Textile Engineering, Ege University,

zmir, Turkey, 2011.

6. Singh SP. Somatoshape and disease.

A review, anthropology today: trends,

scope and applications. Anthropologist

Special Volume 2007; 3: 251-261.

7. Carter JEL, Heath BH. Somatotyping

development and applications.

Cambridge University Press, 1990,

Transferred to digital printing 2003. http://

assets.cambridge.org/97805213/51171/

sample/9780521351171ws.pdf.

8. Simmons KP. Body shape analysis

using 3D body scanning technology.

PhD Thesis, Textile Technology and

Management, North Carolina State

University, Raleigh, 2003.

9. Vuruskan A, Bulgun E. Identifcation of

female body shapes based on numerical

evaluations. Int. J. of Cloth Science and

Tech. 2010; 23, 1: 46-60.

10. Devarajan P, Istook CL. Validation of

Female fgure identifcation technique

(FFIT) for apparel software part 1:

describing female shapes. J. of Text.

and Apparel Tech. and Manag. 2004; 4,

1: 1-23.

11. Song HK, Ashdown SP. An exploratory

study of the validity of visual ft

assessment from three-dimensional

scans. Clothing & Tex. Res. J. 2011; 28,

4: 263-278.

12. Lim HS and Istook CL. Comparison of

virtual avatars by using automatic and

manual method. J. of the Korean Society

of Cloth. and Tex. 2010; 34: 1968-1979.

13. Istanbul Textile and Apparel Exporter

Associations (ITKIB), 2002, Technical

Manual Series: Dimensions in Apparel

Industry, stanbul, pp. 24.

14. Browzwear, V-Stitcher product catalog.

Received 08.08.2012 Reviewed 22.11.2013

,

Instytut Biopolimerw i Wkien Chemicznych

Institute of Biopolymers and Chemical Fibres

Multiflament Chitosan Yarn

The Institute of Bioploymers and Chemical Fibres is in

possession of the know- how and equipment to start the

production of continuous chitosan fbres on an extended

lab scale. The Institute is highly experienced in the wet

spinning of polysaccharides, especially chitosan.

The Fibres from Natural Polymers department, run

by Dr Dariusz Wawro, has elaborated a proprietary

environmently-friendly method of producing continuous

chitosan fbres with bobbins wound on in a form suitable

for textile processing and medical application.

We are ready, in cooperation with our customers, to

conduct investigations aimed at the preparation of

staple and continuous chitosan fbres tailored to specifc

needs in preparing non-woven and knit fabrics.

We presently offer a number of chitosan yarns with

a variety of mechanical properties, and with single

flaments in the range of 3.0 to 6.0 dtex.

The fbres offer new potential uses in medical products

like dressing, implants and cell growth media.

For more information please contact: Dariusz Wawro Ph.D., Eng

Instytut Biopolimerw i Wkien Chemicznych

ul. Skodowskiej-Curie 19/27; 90-570 d, Poland;

Phone: (48-42) 638-03-68, Fax: (48-42) 637-65-01

E-mail: dariusz.wawro@ibwch.lodz.pl http://www.ibwch.lodz.pl

Multiflament chitosan yarn

S-ar putea să vă placă și

- Basic Garment Pattern Design ConsizpdfDocument11 paginiBasic Garment Pattern Design ConsizpdfAhmad El TahanÎncă nu există evaluări

- Teach Yourself Stitch Craft and Dressmaking Volume IV: Pattern Drafting for Men and Practice Drafts - Trying your hand at drafting shirtsDe la EverandTeach Yourself Stitch Craft and Dressmaking Volume IV: Pattern Drafting for Men and Practice Drafts - Trying your hand at drafting shirtsÎncă nu există evaluări

- Details For A Trouser Manufacturing Unit: BY: Manisha Uttam Shweta Yadav Sonakshi Kochhar Piyush PushkarDocument16 paginiDetails For A Trouser Manufacturing Unit: BY: Manisha Uttam Shweta Yadav Sonakshi Kochhar Piyush PushkarSweetu NancyÎncă nu există evaluări

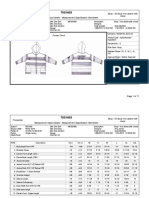

- Specification Sheet LayoutDocument9 paginiSpecification Sheet LayoutSharvari ShankarÎncă nu există evaluări

- Carr and Latham's Technology of Clothing ManufactureDe la EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerEvaluare: 4 din 5 stele4/5 (1)

- Cigarrette Pants: Tutorial and Pattern Created by Sandy at The Cloud Factory © 2015Document6 paginiCigarrette Pants: Tutorial and Pattern Created by Sandy at The Cloud Factory © 2015Zahida MariyamÎncă nu există evaluări

- How To Measure BottomsDocument42 paginiHow To Measure BottomsMayÎncă nu există evaluări

- Capacity - 2000 Shirts Per DayDocument4 paginiCapacity - 2000 Shirts Per DayAyush GautamÎncă nu există evaluări

- Tech PackDocument9 paginiTech Packapi-283157444Încă nu există evaluări

- Different Types of Knitted FabricsDocument11 paginiDifferent Types of Knitted FabricsDevashish BakshiÎncă nu există evaluări

- 38 Techpack PDFDocument9 pagini38 Techpack PDFAditya DevÎncă nu există evaluări

- Collared and Cuffed Shirt Sewing Tutorial: by Jhulian GDocument12 paginiCollared and Cuffed Shirt Sewing Tutorial: by Jhulian GK.SASIKUMAR MmilÎncă nu există evaluări

- Chapter One PDFDocument24 paginiChapter One PDFKibromGereÎncă nu există evaluări

- Specification Sheet SampleDocument11 paginiSpecification Sheet SampleNishu Jalotia0% (1)

- 4.2BHow To Measure Guide ApparelsDocument37 pagini4.2BHow To Measure Guide ApparelsAlokKumarÎncă nu există evaluări

- Different Grading System Used in Apparel IndustryDocument5 paginiDifferent Grading System Used in Apparel Industryzain bajwaÎncă nu există evaluări

- Polo Shirts & T-Shirts Terms & DefinitionsDocument13 paginiPolo Shirts & T-Shirts Terms & DefinitionsTafsir HaqueÎncă nu există evaluări

- Understanding of TrouserDocument36 paginiUnderstanding of TrouserVishwanath KrÎncă nu există evaluări

- Sweaters and Costing of A SweaterDocument14 paginiSweaters and Costing of A SweaterViveek Rules67% (3)

- ONLY:: Sample Consumption Follow-Up Sheet: Supplier: Style Name Brand NameDocument4 paginiONLY:: Sample Consumption Follow-Up Sheet: Supplier: Style Name Brand NameRejaalÎncă nu există evaluări

- Menswear Size GuideDocument5 paginiMenswear Size GuideS Melvyn SylvesterÎncă nu există evaluări

- Lectra Fashion Brochure - pdf898Document8 paginiLectra Fashion Brochure - pdf898Kanti ModhwadiaÎncă nu există evaluări

- Jute ProcessingDocument7 paginiJute Processingtulika_ajwaniÎncă nu există evaluări

- Apperal ProductionDocument48 paginiApperal ProductionAnonymous 51N3PEzjÎncă nu există evaluări

- Stitches and Seams: Essential Sewing Skills for the Beginner Sewist, Tailor, and DIY CrafterDe la EverandStitches and Seams: Essential Sewing Skills for the Beginner Sewist, Tailor, and DIY CrafterÎncă nu există evaluări

- Thread Consumption TemplateDocument7 paginiThread Consumption TemplateEmdad ApmÎncă nu există evaluări

- Breathable GarmentsDocument7 paginiBreathable Garmentsmarikaki12Încă nu există evaluări

- SeamsDocument17 paginiSeamsNidhi Shah0% (1)

- Garment Spec Sheet - ShirtDocument21 paginiGarment Spec Sheet - ShirtAneesha PandaÎncă nu există evaluări

- Garment Costing: Variable FunctionDocument16 paginiGarment Costing: Variable Functionarif UrmiÎncă nu există evaluări

- GSD CostDocument1 paginăGSD CostSomya SinhaÎncă nu există evaluări

- Basic Garment ConstructionDocument9 paginiBasic Garment ConstructionImran100% (1)

- Fabric and Garment FinishingDocument33 paginiFabric and Garment FinishingSurya Bakshi100% (4)

- Fabric Weight For KnitDocument36 paginiFabric Weight For KnitMohammad Zahirul IslamÎncă nu există evaluări

- Qualifications Pack - Fashion Designer - Level 5Document30 paginiQualifications Pack - Fashion Designer - Level 5Sudi ForFrndzÎncă nu există evaluări

- VM Section 6 Technical Design Sample & Fit RequirementsDocument46 paginiVM Section 6 Technical Design Sample & Fit RequirementssuditiÎncă nu există evaluări

- Men - Shirt - Measureguide Processo de Producao de Camisa Alfaiataria HomemDocument17 paginiMen - Shirt - Measureguide Processo de Producao de Camisa Alfaiataria Homemarouz_m2078Încă nu există evaluări

- Sample Section:It Is The First Section Of: Garment Manufacturing ProcessDocument6 paginiSample Section:It Is The First Section Of: Garment Manufacturing ProcesssantumysoreÎncă nu există evaluări

- 1.fabric Defects and IdentificationDocument16 pagini1.fabric Defects and IdentificationRuhi gnextÎncă nu există evaluări

- Men's Different Clothing Categories and BrandsDocument74 paginiMen's Different Clothing Categories and BrandsArtist Vandana Sharma100% (1)

- Sewn Products Machinery and EquipmentDocument14 paginiSewn Products Machinery and EquipmentBhaswati PandaÎncă nu există evaluări

- International British Garments Skill Matrix Analysis: Operation Process Rating % Result Remarks Target AchievedDocument8 paginiInternational British Garments Skill Matrix Analysis: Operation Process Rating % Result Remarks Target AchieveddpnairÎncă nu există evaluări

- Unit 3 - Design Development, Techpack & SamplesDocument8 paginiUnit 3 - Design Development, Techpack & Samplesmaya_muthÎncă nu există evaluări

- Unit - 3 Button Sewing Machine/button Attaching MachineDocument10 paginiUnit - 3 Button Sewing Machine/button Attaching MachineAshu GrewalÎncă nu există evaluări

- Fabric Defects & InspectionDocument23 paginiFabric Defects & InspectionYogesh SharmaÎncă nu există evaluări

- JeansDocument8 paginiJeansTarun Mehrotra100% (1)

- Make A LeotardDocument5 paginiMake A Leotardsherry singhÎncă nu există evaluări

- Adjustble Mannequins New How To Order 170217Document16 paginiAdjustble Mannequins New How To Order 170217KeneÎncă nu există evaluări

- Stitch LengthDocument4 paginiStitch LengthAjeet KumarÎncă nu există evaluări

- Basics Denims - Style Spec: Wash CommentDocument9 paginiBasics Denims - Style Spec: Wash CommentAnonymous kTEAR8k2YÎncă nu există evaluări

- In-Plant Training Report PresentationDocument60 paginiIn-Plant Training Report Presentationrajhossie9335100% (3)

- Product Analysis and Developement: Presented by Parul Vashist Divya Rani DFT Sem ViiDocument29 paginiProduct Analysis and Developement: Presented by Parul Vashist Divya Rani DFT Sem Viimaduvats100% (1)

- Af Specs Us Astm Men v4.1 17aug2015Document4 paginiAf Specs Us Astm Men v4.1 17aug2015Hargovind NainaniÎncă nu există evaluări

- Garment CostingDocument17 paginiGarment CostingEmranul Islam ShovonÎncă nu există evaluări

- T-Shirt - Poloshirt Cad DrawingDocument22 paginiT-Shirt - Poloshirt Cad Drawingopu100% (1)

- Jeans DRFTDocument6 paginiJeans DRFTTanmay JagetiaÎncă nu există evaluări

- Quality Aspects of Garment - A ReviewDocument4 paginiQuality Aspects of Garment - A ReviewSazid RahmanÎncă nu există evaluări

- Fashion Forecasting in 2020 in Clothtech and SportechDocument19 paginiFashion Forecasting in 2020 in Clothtech and Sportechᗩᒸᓿᗋ ᗱᕠᓮᘘᕦÎncă nu există evaluări

- Decoding The PatternDocument3 paginiDecoding The PatternCherry Escolano0% (1)

- Rate of Inflation Myanmar (2014 To 2018)Document12 paginiRate of Inflation Myanmar (2014 To 2018)Robert ThompsonÎncă nu există evaluări

- C 33 - 03 QZMZ PDFDocument11 paginiC 33 - 03 QZMZ PDFwafikmh4Încă nu există evaluări

- MNBC Myanmar 2016 - Part 1 & 2 PDFDocument210 paginiMNBC Myanmar 2016 - Part 1 & 2 PDFAdrianSebastianDarmansyah100% (2)

- C 331 - 04 - QZMZMQ - PDFDocument4 paginiC 331 - 04 - QZMZMQ - PDFRobert ThompsonÎncă nu există evaluări

- 95 102829 DC PDFDocument12 pagini95 102829 DC PDFRobert ThompsonÎncă nu există evaluări

- An Observation On Potential Alkali Silica Reactivity of Natural Aggregate in MyanmarDocument7 paginiAn Observation On Potential Alkali Silica Reactivity of Natural Aggregate in MyanmarRobert ThompsonÎncă nu există evaluări

- A Study On Durability of High-Performance ConcreteDocument6 paginiA Study On Durability of High-Performance ConcreteRobert ThompsonÎncă nu există evaluări

- Standard System 98Document79 paginiStandard System 98Ishmael JonathanÎncă nu există evaluări

- Standard System 98Document79 paginiStandard System 98Ishmael JonathanÎncă nu există evaluări

- Standard System 98Document79 paginiStandard System 98Ishmael JonathanÎncă nu există evaluări

- Industrial Internet of Things: Presented To-Presented byDocument18 paginiIndustrial Internet of Things: Presented To-Presented byGaurav RaturiÎncă nu există evaluări

- FAJASDocument891 paginiFAJASCecilia GilÎncă nu există evaluări

- Paranoia XP - Gamemaster Screen Booklet - Mandatory Fun Enforcement PackDocument24 paginiParanoia XP - Gamemaster Screen Booklet - Mandatory Fun Enforcement PackStBash100% (3)

- BTK Implant Guide SurgeryDocument48 paginiBTK Implant Guide SurgeryMaria VolvinaÎncă nu există evaluări

- LPPDocument4 paginiLPPMargarida ReisÎncă nu există evaluări

- Microbiology Part 3Document74 paginiMicrobiology Part 3Authentic IdiotÎncă nu există evaluări

- BS746 2014Document22 paginiBS746 2014marco SimonelliÎncă nu există evaluări

- PAG7.1 Student The Effects of Antibiotics On Microbial Growth - v0.3Document3 paginiPAG7.1 Student The Effects of Antibiotics On Microbial Growth - v0.3Habib UddinÎncă nu există evaluări

- Properties of Matter ReviewDocument8 paginiProperties of Matter Reviewapi-290100812Încă nu există evaluări

- Spectroscopy (L-26 To 29)Document81 paginiSpectroscopy (L-26 To 29)Vashistha GargÎncă nu există evaluări

- Exp6.Single Phase Bridge Inverter Using PWMDocument6 paginiExp6.Single Phase Bridge Inverter Using PWMAbdullah MohammedÎncă nu există evaluări

- 40 RT-flex Control-System Rev01Document68 pagini40 RT-flex Control-System Rev01Mayvon Botelho100% (2)

- Reloved - October 2015Document116 paginiReloved - October 2015Barron Fields67% (3)

- UC Lennox Serie 13 Acx Merit R-410aDocument52 paginiUC Lennox Serie 13 Acx Merit R-410ajmurcia80Încă nu există evaluări

- Dell W2306C LCD Monitor Service ManualDocument104 paginiDell W2306C LCD Monitor Service ManualIsrael B ChavezÎncă nu există evaluări

- QuantAssay Software Manual 11-Mar-2019Document51 paginiQuantAssay Software Manual 11-Mar-2019LykasÎncă nu există evaluări

- IPC's 2 Edition of Guidance Manual For Herbs and Herbal Products Monographs ReleasedDocument1 paginăIPC's 2 Edition of Guidance Manual For Herbs and Herbal Products Monographs ReleasedRakshaÎncă nu există evaluări

- Hazard Assessment For PPE - XX-DRAFTDocument4 paginiHazard Assessment For PPE - XX-DRAFTWayne VanderhoofÎncă nu există evaluări

- Sketchup-Rhino Cheat SheetDocument1 paginăSketchup-Rhino Cheat Sheetxanext7Încă nu există evaluări

- Dialog Bahasa InggirsDocument2 paginiDialog Bahasa InggirsKeRtha NeghaRaÎncă nu există evaluări

- Clinical Case StudyDocument20 paginiClinical Case Studyapi-252004748Încă nu există evaluări

- Calibration of Force ReductionDocument36 paginiCalibration of Force Reductionvincenzo_12613735Încă nu există evaluări

- Illuminati TruthsDocument27 paginiIlluminati TruthsDonnaveo ShermanÎncă nu există evaluări

- LighthouseDocument4 paginiLighthousejaneborn5345Încă nu există evaluări

- Of The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestDocument4 paginiOf The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestBaydaa QaidyÎncă nu există evaluări

- Report - IvatanDocument28 paginiReport - IvatanJohara Winel PerezÎncă nu există evaluări

- Datasheet Ark XH Battery System EngDocument2 paginiDatasheet Ark XH Battery System EngLisa CowenÎncă nu există evaluări

- Electrical Design Project (Three Bedroom House)Document13 paginiElectrical Design Project (Three Bedroom House)Sufi Shah Hamid Jalali100% (2)

- Comparative Performance of Some Cattle Breeds Under Barani Conditions of PakistanDocument4 paginiComparative Performance of Some Cattle Breeds Under Barani Conditions of PakistanMasood HassanÎncă nu există evaluări

- Sheet Metal Manufacturing Companies NoidaDocument9 paginiSheet Metal Manufacturing Companies NoidaAmanda HoldenÎncă nu există evaluări