Documente Academic

Documente Profesional

Documente Cultură

RFQ Dor Ga

Încărcat de

Ha NguyenDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RFQ Dor Ga

Încărcat de

Ha NguyenDrepturi de autor:

Formate disponibile

Request for Quotation

1 GENERAL

1.1 Description of the project

- Name of the project: NSRP Complex Project

- Boiler Spec : 295 T/H x 127.4 bar x 520 x 4 Units, Fuel: Oil

- Name of the Client : Nghi Son Refinery and Petrochemical Limited Liability Company

- Project Location: Nghi Son, Thanh Hoa Province, Vietnam

1.2 Quotation sheet must be submitted until 9. Sap. 2013

1.3 The bid validity shall be 90 days.

1.4 In the event that you require clarification on anything in connection with the enquiry package,

Please contact the follow:

- Soo-Geun, Park

- Tel. : +82-02-2189-5721

- Fax. : +82-02-572-7071

- E-mail : pass3877@hansol.com

Add. : 25F Trust Tower 275-7 Yangjae-dong, Seocho-gu, Seoul, Korea (137-739)

<Attachment>

Attachment 1. Division of Responsibility.pdf.. 4Sheets

Attachment 2. General Arrangement Drawing.pdf.. 4Sheets

Attachment 3. Bill of Quotation.xlsx... 5Sheets

page1

Client

Site

Project Name

Project No.

Nghi Son Refinery and Petrochemical Limited Liability Company

Nghi Son, Thanh Hoa Province, Vietnam

NSRP Complex Project

Page

Document No.

Revision No.

Issued Date

1/4

Division of Responsibility

REV DATE DESCRIPTION PREPARED CHECKED

APPROV

ED

APPROVED

This document is confidential, and shall be legally privileged. So it can not reproduced without approval of Contractor EME

NSRP RROJECT

Division Of Responsibility

Doc. NO.

Revision : 0

Date. : 28. Aug. 2013

Sheet : 2 of 4

page2

1. Description of the project

1.1 Name of the project: NSRP Complex Project

1.2 Boiler Spec : 295 T/H x 127.4 bar x 520 x 4 Units, Fuel: Oil

1.3 Name of the Client : Nghi Son Refinery and Petrochemical Limited Liability Company

1.4 Name of the EPC : SK E&C

1.3 Project Location: Nghi Son, Thanh Hoa Province, Vietnam

2. Sub contractors work scope

2.1 Refer to attached Division of Responsibility and Bill of Quotation (DOR & BOQ)

3.Sub Contractors Scope

3.1. All required utility Supply

3.2. QC / QA Control

3.3. PQR and WPS provide

3.4. All welding Rod and consumable material supply

3.5. Heavy equipment mobilization and demobilization

3.6. Man-Power mobilization and demobilization

3.7. All required tools

3.8. All required safety control including first aid facility

3.9. All required site management

3.10. All Document provide for site construction

3.11. All field test as for specification including NDE

3.12. All required insurance for site construction

3.13. Preparation of material and lay down and storage area

3.14. In door storage / ware house

3.15. All material control at site

3.16. House transportation at construction site

3.17. All required Temporary Facilities and equipment at site such as site office

and all accommodation Etc.

3.18. Site cleaning and house keeping

3.19. Work permission and authorization for construction

3.20. Rubbish & hazardous material control and disposal

3.21. Traffic and environment control

3.22. Site security & guard

3.23. Relevant licenses permit and approval

NSRP RROJECT

Division Of Responsibility

Doc. NO.

Revision : 0

Date. : 28. Aug. 2013

Sheet : 3 of 4

page3

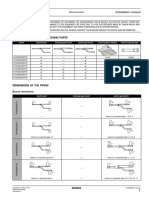

DESCRIPTION

Supply Fabrication Installation

HanSol Sub-Con HanSol Sub-Con HanSol Sub-Con

1.PRESSURE PART

1)DRUM

-Steam Drum (Internal Assembly Inclusion)

-Attachment

2)PANEL

- Furnace front wall tube panel

- Furnace rear wall tube panel

- Furnace side wall tube panel

- HRA. side wall tube panel

- HRA. Rear wall tube (Down-Comer)

- Attachment

3)HEADER

- Furnace front lower HDR

- Furnace rear lower HDR

- Furnace front wall upper HDR

- Furnace side wall lower HDR

- Furnace side wall upper HDR

- HRA side wall lower HDR

- HRA side wall upper HDR

- Primary S/H Inlet/Outlet HDR

- Final S/H Inlet/Outlet HDR

- Internal economizer Inlet/Outlet HDR

- Attachment

- Nozzle

4) LOOP

- ECONOMIZER

- PRIMARY S/H

- FINAL S/H

- ATTACHMENT & BAFFLE

NSRP RROJECT

Division Of Responsibility

Doc. NO.

Revision : 0

Date. : 28. Aug. 2013

Sheet : 4 of 4

page4

DESCRIPTION

Supply Fabrication Installation

HanSol Sub-Con HanSol Sub-Con HanSol Sub-Con

2.NON-PRESSURE PART

1) Hanger

2) Buck stay

3) Roof Inner Casing

4) Header Box Inner Casing

5) Bottom Inner Casing

6) Eco Inner Casing

7) Wind box

8) OAP

9) Outer Casing

10) Outer Casing Support

11) Accessory

12) INSULATION & REFRACTORY

13) Gas & Air Duct

3. STEEL STRUCTURE

1) Column (Built-up& Roll Beam)

2) Girder (Built-up& Roll Beam)

3) Beam (Built-up& Roll Beam)

4) Brace

5) High Tension T.C B/N

6) Stairway

7) Handrail

8) Ladder

9) Anchor & Anchor Frame

10) Grating

11) Chequered Plate

12) Steel structure for others

4. Auxiliary Equipment

1) Burner

2) Soot Blower

3) Level Gauge

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

1 DRUM 62,902 62,902

DRUM SHELL PLATE SA516-70 1525 111 14,833 1 33,214 33,214

DRUM TUBE PLATE SA516-70 1471 165 495 1 1,648 1,648

DRUM HEAD PLATE SA516-70 1525 111 HEMI 2 9,330 9,330

INTERNAL SA106-B 4,419 4,419

STEAM DRUM INTERNAL(SEPARATOR) SA36 1 91 1,329 1,329

STEAM DRUM INTERNAL(CHEVRON DRYER) SA36 1 45 1,472 1,472

NOZZLE SA105 4,861 4,861

ATTACHMENT(U-BAND) SA36 6,629 6,629

2 PANEL 172,804 175,945

FURNACE FRONT WALL TUBE SA192 63.5 6 31,080 170 48,101 49,063

FURNACE FRONT WALL TUBE MEMBRANE SA36 6 19.6 30,980 167 4,776 4,872

FURNACE REAR WALL TUBE SA192 63.5 6 21,965 131 26,195 26,719

FURNACE REAR WALL TUBE MEMBRANE SA36 6 19.6 21,865 129 2,604 2,656

FURNACE SIDE WALL TUBE SA192 63.5 6 13,668 221 27,499 28,049

FURNACE SIDE WALL TUBE MEMBRANE SA36 6 19.6 13,568 217 2,718 2,772

HRA SIDE WALL TUBE SA192 63.5 6 13,000 69 8,166 8,329

HRA SIDE WALL TUBE MEMBRANE SA36 6 47.1 12,900 65 1,860 1,897

HRA. REAR WALL TUBE(DOWN COMER) SA210-A1 114.3 8.56 19,495 69 32,128 32,771

HRA. REAR WALL TUBE(DOWN COMER) MEMBRANE SA36 6 51.3 19,395 65 3,046 3,107

ATTACHMENT SA36 0 0 - 0 15,709 15,709

3 HEADER 50,783 51,659

FURNACE FRONT & REAR WALL LOWER HEADER SA106-C 406.4 68 13,966 1 7,926 8,084

FURNACE FRONT WALL UPPER HEADER SA106-C 273 47 3,750 4 3,929 4,008

FURNACE SIDE WALL LOWER HEADER SA106-C 273 47 3,135 6 4,927 5,025

FURNACE SIDE WALL UPPER HEADER SA106-B 273 47 3,135 6 4,927 5,025

HRA SIDE WALL LOWER HEADER SA106-C 273 35 3,767 2 1,548 1,579

HRA SIDE WALL UPPER HEADER SA106-C 273 35 3,767 2 1,548 1,579

NOZZLE SA105 0 0 - 0 1,488 1,488

ATTACHMENT SA36 0 0 - 0 2,480 2,480

PRIMARY S/H INLET HEADER SA335-P11 273 25.58 11,558 1 1,804 1,840

PRIMARY S/H OUTLET HEADER SA335-P22 273 34 6,278 2 2,516 2,567

FINAL S/H INLET HEADER SA335-P11 273 28.58 7,448 2 2,566 2,618

FINAL S/H OUTLET HEADER SA335-P22 273 45 7,726 2 3,910 3,988

NOZZLE SA182-22 0 0 - 0 648 648

ATTACHMENT SA387-22 0 0 - 0 1,080 1,080

SPRAY PIPE SA335-P22 273 28.58 12,000 2 4,135 4,217

NOZZLE SA182-F11 0 0 - 0 248 248

SPRAY NOZZLE SA182-F304 0 0 - 0 414 414

INTERNAL ECONOMIZER INLET HEADER SA106-C 273 28.58 12,025 1 2,072 2,113

INTERNAL ECONOMIZER OUTLET HEADER SA106-C 273 28.58 11,453 1 1,973 2,012

ATTACHMENT SA36 0 0 - 0 405 405

NOZZLE SA105 0 0 - 0 243 243

4 LOOP 346,363 350,884

INTERNAL ECONOMIZER TUBE SA192 50.8 4.8 56,400 67 22,017 22,457

ECO. TUBE (FIN TYPE) FIN A1008 0 0 - 0 17,760 17,760

ECONOMIZER PROTECTOR PLATE SUS304 51 0 - 179 949 949

ATTACHMENT SA36 0 0 - 0 4,403 4,403

EXTERNAL ECONOMIZER TUBE fin tube SA192 50.8 4.8 168,643 63 61,903 63,141

ECO. TUBE (FIN TYPE) FIN A1008 0 0 6,100 0 53,700 53,700

EXTERNAL ECONOMIZER TUBE Bare Tube SA192 50.8 4.8 101,611 63 37,298 38,044

ECONOMIZER PROTECTOR PLATE SUS304 51 0 - 171 906 906

ATTACHMENT SA36 0 0 - 0 23,071 23,071

PRIMARY S/H TUBE (INLET) SA213-T11 45 3.8 36,400 262 39,399 40,187

PRIMARY S/H TUBE (MIDDLE) SA213-T11 45 4.1 16,800 262 19,477 19,867

PRIMARY S/H TUBE (OUTLET)-1 SA213-T11 45 4.3 7,600 262 9,196 9,380

PRIMARY S/H TUBE (OUTLET)-2 SA213-T22 45 5.4 7,600 262 11,236 11,461

FORGING(STUB) SA182-F91 0 0 - 281 28 28

SUPPORT LUG A297-HH 0 0 - 1561 937 937

PRIMARY S/H OVAL LUG (LOWER) A213-T11 0 0 - 2098 2,308 2,308

Thickness

(mm)

L/pcs

(mm)

Q'ty

NET

Weight

NO DESCRIPTION MAT

ID or OD (t)

(mm)

GROSS

WEIGHT

(kg)

Materials Assembly Expenses/Charge Total

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Thickness

(mm)

L/pcs

(mm)

Q'ty

NET

Weight

NO DESCRIPTION MAT

ID or OD (t)

(mm)

GROSS

WEIGHT

(kg)

Materials Assembly Expenses/Charge Total

PRIMARY S/H OVAL LUG (UPPER) A213-T22 0 0 - 1586 1,745 1,745

PRIMARY S/H PROTECTOR PLATE SUS304 51 0 - 435 2,306 2,306

ATTACHMENT & BAFFLE SA387-22 0 0 - 0 6,807 6,807

FINAL S/H TUBE(INLET) SA213-T22 38.1 3 4,200 253 2,953 3,012

FINAL S/H TUBE(VERTICAL) SA213-T22 38.1 4.3 7,800 253 7,568 7,720

FINAL S/H TUBE(OUTLET) SA213-T22 38.1 4.3 7,800 253 7,568 7,720

FINAL S/H TUBE(OUTLET) SA213-T22 38.1 4.8 4,200 253 4,482 4,572

FINAL S/H TUBE(OUTLET) SA213-T91 38.1 3 4,200 253 2,953 3,012

FORGING(STUB) SA182-F91 0 0 - 281 28 28

SUPPORT LUG A297-HH 0 0 - 263 158 158

TIE LUG A297-HH 0 0 - 164 33 33

FINAL S/H OVAL LUG (LOWER) A213-T22 0 0 - 1786 1,965 1,965

FINAL S/H SLIDE SPACE SCH11 0 0 - 298 27 27

FINAL S/H PROTECTOR PLATE SUS310S 51 0 - 175 928 928

ATTACHMENT & BAFFLE SA387-22 0 0 - 0 2,257 2,257

5 PIPE 53,369 54,277

SATURATED STEAM PIPE SA106-B 273 28.58 23,700 2 8,166 8,329

90^ ELBOW SA234WPB 10" SCH 160 - 2 206 206

NOZZLE SA105 0 0 - 0 817 817

SUPPORT & ATTACHMENT SA36 0 0 - 0 1,225 1,225

PRIMARY S/H OUTLET PIPE SA335-P22 273 28.58 3,000 3 1,551 1,582

FINAL S/H INLET PIPE SA335-P11 273 28.58 3,000 3 1,551 1,582

90^ ELBOW SA234WP22 10" SCH NO - 4 417 417

90^ ELBOW SA234WP11 10" SCH NO - 4 417 417

NOZZLE SA182-F11 0 0 - 0 248 248

SUPPORT & ATTACHMENT SA387-11 0 0 - 0 465 465

ECONOMIZER OUTLET FEED PIPE SA106-B 273 28.58 15,694 1 2,704 2,758

SUPPORT & ATTACHMENT SA36 0 0 - 0 406 406

ECONOMIZER OUTLET FEED PIPE SA106-B 273 28.58 6,000 6 6,202 6,326

SUPPORT & ATTACHMENT SA36 0 0 - 0 930 930

HRA SIDE WALL DOWNCOMER SA106-B 141.3 15.88 20,000 2 1,965 2,004

90^ ELBOW SA234WPB 5" SCH 160 - 8 117 117

SUPPORT & ATTACHMENT SA36 0 0 - 0 295 295

FURNACE SIDE WALL FEEDER PIPE SA106-B 141.3 15.88 9,000 8 3,537 3,607

90^ ELBOW SA234WPB 5" SCH 160 - 4 59 59

SUPPORT & ATTACHMENT SA36 0 0 - 0 539 539

FURNACE FRONT WALL RISER PIPE SA106-B 141.3 15.88 9,000 9 3,979 4,058

90^ ELBOW SA234WPB 5" SCH 160 - 4 59 59

FURNACE SIDE WALL RISER PIPE SA106-B 141.3 15.88 9,000 19 8,399 8,567

HRA SIDE WALL RISER PIPE SA106-B 141.3 15.88 9,000 3 1,326 1,353

SUPPORT & ATTACHMENT SA36 0 0 - 0 597 597

SPRING HANGER - 0 0 - 4 4 4

EXPANSION BELLOW - 4 4 4

TRANSPORTATION JIG SS400 H200x200 8x12 90,000 4,410 4,410

PRESSURE PARTS SUB TOTAL 683,444 692,770

Note : Quantities of Spare Part and special tool are not included in this list

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

1 NON-PRESSURE PART 131,000 131,000

1-1 Hanger HANGER ROD A105 Round Bar 9,000 9,000

1-2 Buckstay BUCK STAY A36 Plate /H-beam 40,000 40,000

1-3 Roof Inner Casing INNER CASING A36 Plate /H-beam 18,000 18,000

1-4 Header Box Inner Casing INNER CASING A36 Plate 10,000 10,000

1-5 Bottom Inner Casing INNER CASING A36 Plate / Angle 4,000 4,000

1-6 Eco Inner Casing INNER CASING A36 Plate / Angle 10,500 10,500

1-7 Windbox WIND BOX A36 Plate 13,500 13,500

1-8 OAP INNER CASING A36, A240-304 Plate 5,000 5,000

1-9 Outer Casing OUTER CASING(AL-SHEET) ALUMINUM (1t) Keystone Plate 10,000 10,000

1-10 Outer Casing Support OUTER CASING A36 Plate / Angle 8,000 8,000

1-11 Accessory ACCESSORY A36, A312-304 (M/H,P/H,NOZZLE) 3,000 3,000

2 INSULATION & REFRACTORY 74,000 74,000

2-1 INSULATION FOR BOILER PROPER 38,000 38,000

INSULATION MINERAL WOOL/PERLITE 35,000 35,000

LAGGING FOR BOILER AL 3,000 3,000

ATTACHMENT A240-TP304 -

2-2 REFRACTORY FOR BOILER PROPER 36,000 36,000

REFRACTORY CASTABLE(MAX.1600) 36,000 36,000

REFRACTORY ATTACHMENT & Y-ANCHOR A240-TP304 -

NON PRESSURE PARTS SUB TOTAL 205,000 205,000

NO MATERIAL DESCRIPTION

Materials Assembly Expenses/Charge Total

Q'ty

NET

WEIGHT

GROSS

WEIGHT

(kg)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

1 STEEL STRUCTURE 303,595 303,595

Column (Built-up) STRUCTURAL STEEL SM490A 57,715 57,715

Column (Roll Beam) STRUCTURAL STEEL SS400 41,225 41,225

Girder (Built-up) STRUCTURAL STEEL SM490A 41,225 41,225

Girder (Roll Beam) STRUCTURAL STEEL SS400 32,980 32,980

Beam (Built-up) STRUCTURAL STEEL SM490A 24,735 24,735

Beam (Roll Beam) STRUCTURAL STEEL SS400 24,735 24,735

Brace STRUCTURAL STEEL SS400,SM490A 24,735 24,735

High Tension T.C B/N HIGH STRENGTH BOLT F10T,Dacrotized 8,245 8,245

Stairway STRUCTURAL STEEL SS400

Handrail HANDRAIL 32A,SGP

Ladder CAGED LADDER SS400

Anchor & Anchor Frame ANCHOR BOLTS SS400

Grating GRATING I-32x5x3,SS400

Chequered Plate CHECKERED PLATE 6t,SS400

STEEL STURCTURE FOR OTHERS

Pipe rack S/S STRUCTURAL STEEL SS400 Piperack -

TAH, SCR support STRUCTURAL STEEL SS400 SCR ~ TAH -

Yard Duct support STRUCTURAL STEEL SS400 TAH ~ Stack -

Base Frame for Transportation STRUCTURAL STEEL 48,000 48,000

NO MATERIAL DESCRIPTION

Materials Assembly Expenses/Charge Total

SIZE

(mm)

TH'K

(mm)

LENGTH

(mm)

Q'ty

NET

WEIGHT

GROSS

WEIGHT

(kg)

Bill of Quotation.xlsx/Steel Structure PAGE 1 / &N 2013-08-29

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

Unit Price

(USD)

Amount

(USD)

1 Burner Low NOx Burner 6 Set

Total

Q'ty Unit NO

Materials Assembly

DESCRIPTION

Expenses/Charge

S-ar putea să vă placă și

- API 570 Quiz - Recertification 2016 NovDocument6 paginiAPI 570 Quiz - Recertification 2016 Novadma1100% (5)

- Manual IND-XDocument152 paginiManual IND-XHumberto Veliz100% (2)

- TS498 PDFDocument659 paginiTS498 PDFgallantprakashÎncă nu există evaluări

- Opgc Owners Engineer - CPPDocument18 paginiOpgc Owners Engineer - CPPwas00266Încă nu există evaluări

- HRSG Tender8228 PDFDocument222 paginiHRSG Tender8228 PDFnefoussiÎncă nu există evaluări

- Technical Bid No 1Document235 paginiTechnical Bid No 1kaushalÎncă nu există evaluări

- CMI Energy Reference ListDocument23 paginiCMI Energy Reference ListMochamad BhadawiÎncă nu există evaluări

- Part - I - 220 - KV - LUNAWADA - EPCDocument115 paginiPart - I - 220 - KV - LUNAWADA - EPCKishore KrishnaÎncă nu există evaluări

- 4646396Document28 pagini4646396Samuel OnyewuenyiÎncă nu există evaluări

- Itb Part I - Instruction To BiddersDocument16 paginiItb Part I - Instruction To BiddersilsaÎncă nu există evaluări

- Power Evacuation Main Single Line Diagram Grid Interconnection and Switchyard LayoutDocument24 paginiPower Evacuation Main Single Line Diagram Grid Interconnection and Switchyard Layoutkanav.davesarÎncă nu există evaluări

- 19 - Part III - Section 4.0 - Scope of WorkDocument100 pagini19 - Part III - Section 4.0 - Scope of Workابومحمد الكنانيÎncă nu există evaluări

- DS Datasheet ERHARD Needle Valves enDocument8 paginiDS Datasheet ERHARD Needle Valves enEnrike GutierrezÎncă nu există evaluări

- 000 SP Pi02 0221Document10 pagini000 SP Pi02 0221Samuel ValbuenaÎncă nu există evaluări

- P158-PR-RFQ-ITB-001-02 Clarification 2 - PLNDocument2 paginiP158-PR-RFQ-ITB-001-02 Clarification 2 - PLNhasan shahriarÎncă nu există evaluări

- Tender Package Electrical SystemsDocument221 paginiTender Package Electrical SystemsMohan BabuÎncă nu există evaluări

- RFQ for 100kW Gas GeneratorDocument2 paginiRFQ for 100kW Gas GeneratorHarish GundaÎncă nu există evaluări

- 220 3PS JQ07 00001Document41 pagini220 3PS JQ07 00001Augusto Francisco Diaz LaraÎncă nu există evaluări

- Fresh Engineers: Regd - Office: Engineers India Bhavan, 1, Bhikaiji Cama Place, New Delhi-110 066Document18 paginiFresh Engineers: Regd - Office: Engineers India Bhavan, 1, Bhikaiji Cama Place, New Delhi-110 066Nrt PorÎncă nu există evaluări

- 1 ITB For Scour Protection at SLTS PROJECTDocument13 pagini1 ITB For Scour Protection at SLTS PROJECTEng Muhammad Afzal AlmaniÎncă nu există evaluări

- CS Pipe Wall Thickness CalculationDocument16 paginiCS Pipe Wall Thickness CalculationunnicyriacÎncă nu există evaluări

- Bypass Control Valve: Special Features and ControlsDocument13 paginiBypass Control Valve: Special Features and ControlsBrain J PérezÎncă nu există evaluări

- Fichtner ElectricalDocument51 paginiFichtner ElectricalMathivanan AnbazhaganÎncă nu există evaluări

- DBNPP MDM1 ASYYY 07 342001 0001 - Rev03Document31 paginiDBNPP MDM1 ASYYY 07 342001 0001 - Rev03Krishnan KrishÎncă nu există evaluări

- Topsides 1 - Equipment ListDocument22 paginiTopsides 1 - Equipment ListMathias OnosemuodeÎncă nu există evaluări

- Technical Spesification of Distribution Transformer 33/0.416 KVDocument14 paginiTechnical Spesification of Distribution Transformer 33/0.416 KVAhmed Ja100% (1)

- Technical FF PRT C 20181016 171523 PDFDocument851 paginiTechnical FF PRT C 20181016 171523 PDFAayeshaÎncă nu există evaluări

- Request for quotation for diesel pumps and filtersDocument29 paginiRequest for quotation for diesel pumps and filtersgustavo aguilarÎncă nu există evaluări

- Airboard - Spec and InfoDocument11 paginiAirboard - Spec and InfoSiwat KiokaewÎncă nu există evaluări

- RTRP Piping Systems - DohaDocument7 paginiRTRP Piping Systems - DohaRaziKhanÎncă nu există evaluări

- Gantry Structure Calculation - T Type Rev - 1Document2 paginiGantry Structure Calculation - T Type Rev - 1Pritom AhmedÎncă nu există evaluări

- Determining Class LocationDocument57 paginiDetermining Class LocationJorgeSCZÎncă nu există evaluări

- Application For SBC Caste Certificate v0.1Document4 paginiApplication For SBC Caste Certificate v0.1Kunal SonwaneÎncă nu există evaluări

- TUV-Technical Due Diligence Report On Huawei Inverters Operation and Performance Technical Indexs in 220MW PV Plant EN 0Document22 paginiTUV-Technical Due Diligence Report On Huawei Inverters Operation and Performance Technical Indexs in 220MW PV Plant EN 0Hernan Arrigone100% (1)

- Steel Insight 4Document7 paginiSteel Insight 4sharjahsharjahÎncă nu există evaluări

- Saes B 001Document2 paginiSaes B 001Ahmed Nasralla HefnawyÎncă nu există evaluări

- QPDT1 9 Mar A 0055Document168 paginiQPDT1 9 Mar A 0055Hamid KhanÎncă nu există evaluări

- LPG Blending Facilities Tender Documents ListDocument235 paginiLPG Blending Facilities Tender Documents ListManish MehtaÎncă nu există evaluări

- H274743002P00 PDFDocument24 paginiH274743002P00 PDFMohamed AmrÎncă nu există evaluări

- Hfo Supply Scheme: From Hfo Day Tank From Auxiliary Steam HeaderDocument7 paginiHfo Supply Scheme: From Hfo Day Tank From Auxiliary Steam HeaderSamÎncă nu există evaluări

- Deliverable List for Alindo Hydrogen Transfer Line ProjectDocument4 paginiDeliverable List for Alindo Hydrogen Transfer Line ProjectEdo FaiZal CandraWinataÎncă nu există evaluări

- Emergency Generator SpecificationDocument54 paginiEmergency Generator SpecificationHussainRazviÎncă nu există evaluări

- Electra Sample Drawing 1Document17 paginiElectra Sample Drawing 1stelios_yuhas4576Încă nu există evaluări

- Equipment List Including Long Lead ItemsDocument6 paginiEquipment List Including Long Lead Itemspapilolo2008Încă nu există evaluări

- Wind Turbine and Grid Connection Modelling With PSCADDocument1 paginăWind Turbine and Grid Connection Modelling With PSCADrselecÎncă nu există evaluări

- Inception Report Draft Rev.01Document23 paginiInception Report Draft Rev.01sa_oosman0% (1)

- 104 08655 000 Esp J 007 - 0 Ultrasonic and Radar Level TransmittersDocument8 pagini104 08655 000 Esp J 007 - 0 Ultrasonic and Radar Level TransmittersCristian RománÎncă nu există evaluări

- Vol - V of V - Gspl-DrawingsDocument102 paginiVol - V of V - Gspl-Drawingsapi-36989960% (1)

- 2 - A - Technical - Bid - Part - II - Supply - Erection - of - 220kV - Lines PDFDocument30 pagini2 - A - Technical - Bid - Part - II - Supply - Erection - of - 220kV - Lines PDFKassem Baalbaki100% (1)

- KKS Handbook Edition 07Document126 paginiKKS Handbook Edition 07Hüseyin ÖnözÎncă nu există evaluări

- ELECTRICAL SYSTEM FOR BARC DESALINATION FACILITYDocument63 paginiELECTRICAL SYSTEM FOR BARC DESALINATION FACILITY9044nksÎncă nu există evaluări

- Carbon Steel API 5l Smls PipesDocument2 paginiCarbon Steel API 5l Smls Pipesreliant pipesÎncă nu există evaluări

- LPG-1102-E-EL-ELS-001 - Electrical Load Schedule - Rev. ADocument11 paginiLPG-1102-E-EL-ELS-001 - Electrical Load Schedule - Rev. ARadhaÎncă nu există evaluări

- Sachal Feasibility Study 50 MW Utility Scale Wind PowerDocument191 paginiSachal Feasibility Study 50 MW Utility Scale Wind PowerArif Mateen AnsariÎncă nu există evaluări

- BOQ For GIS 7.02.2014Document106 paginiBOQ For GIS 7.02.2014matshonaÎncă nu există evaluări

- Appendix A - Bid FormDocument3 paginiAppendix A - Bid FormUmair AfrimaÎncă nu există evaluări

- Mayakan Phase III Scope of Work Oct 30 FINALDocument22 paginiMayakan Phase III Scope of Work Oct 30 FINALPedro MendezÎncă nu există evaluări

- GensizDocument27 paginiGensizinsan_soft6498Încă nu există evaluări

- B 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerDocument11 paginiB 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerpragatheeskÎncă nu există evaluări

- RT22-09-09 01Document2 paginiRT22-09-09 01cristhian.sebastian.12Încă nu există evaluări

- Reject RBC UpgradationDocument9 paginiReject RBC Upgradationirfan.ali0463Încă nu există evaluări

- Flange Details & DrawingsDocument338 paginiFlange Details & DrawingsshazanÎncă nu există evaluări

- Lessons from Lilama's International Business CooperationDocument2 paginiLessons from Lilama's International Business CooperationHa NguyenÎncă nu există evaluări

- For The StudentsDocument1 paginăFor The StudentsHa NguyenÎncă nu există evaluări

- Japanese Distribution:: Background, Issues, ExamplesDocument26 paginiJapanese Distribution:: Background, Issues, ExamplesHa NguyenÎncă nu există evaluări

- BEN AUTO ORG CHART & BUDGETDocument3 paginiBEN AUTO ORG CHART & BUDGETHa NguyenÎncă nu există evaluări

- How To Reset PasswordDocument8 paginiHow To Reset PasswordHa NguyenÎncă nu există evaluări

- Ch05 06Document49 paginiCh05 06Ha NguyenÎncă nu există evaluări

- Individual AssignmentDocument2 paginiIndividual AssignmentHa NguyenÎncă nu există evaluări

- Chapter 04Document52 paginiChapter 04Ha NguyenÎncă nu există evaluări

- HW 9.9 AnswesDocument5 paginiHW 9.9 AnswesHa NguyenÎncă nu există evaluări

- How To Reset PasswordDocument8 paginiHow To Reset PasswordHa NguyenÎncă nu există evaluări

- MBA530 Group2 Final Rev1Document10 paginiMBA530 Group2 Final Rev1Ha NguyenÎncă nu există evaluări

- HW 4 AnswersDocument3 paginiHW 4 AnswersHa NguyenÎncă nu există evaluări

- HW 2 & 3 AnswersDocument8 paginiHW 2 & 3 AnswersHa NguyenÎncă nu există evaluări

- Siphonic Roof Drainage Systems ExplainedDocument7 paginiSiphonic Roof Drainage Systems ExplainedRenzo Marquina AstoÎncă nu există evaluări

- Oil and Gas IndonesiaDocument87 paginiOil and Gas IndonesiaRavihasmi RusdiÎncă nu există evaluări

- Landside Fac BOQ-FinalDocument22 paginiLandside Fac BOQ-FinalIzo SeremÎncă nu există evaluări

- LSTK PMC Inspection Methodology For Assam Bio Refinery ProjectDocument33 paginiLSTK PMC Inspection Methodology For Assam Bio Refinery ProjectSreedhar PayyavulaÎncă nu există evaluări

- Brochure Gever 2020 ASTM B819Document2 paginiBrochure Gever 2020 ASTM B819sahriÎncă nu există evaluări

- Anna University CHENNAI - 600 025: B.Tech. Chemical Engineering (Full Time)Document113 paginiAnna University CHENNAI - 600 025: B.Tech. Chemical Engineering (Full Time)Abner kolinÎncă nu există evaluări

- 02 e PDocument34 pagini02 e PAmro HassanÎncă nu există evaluări

- Pressure Vessel Fabrication & Inspection: Poyyara ConsultantsDocument82 paginiPressure Vessel Fabrication & Inspection: Poyyara ConsultantsRajeeb MohammedÎncă nu există evaluări

- En 1555 1Document15 paginiEn 1555 1Mohammad Rashad BarakatÎncă nu există evaluări

- Gic-Tg Gas FilledDocument4 paginiGic-Tg Gas FilledAnonymous edvYngÎncă nu există evaluări

- Innocent Oke's CV (Project Engineer)Document8 paginiInnocent Oke's CV (Project Engineer)richardykeÎncă nu există evaluări

- Basic Data RatesDocument300 paginiBasic Data RatesGurram Lakshmi NavakanthÎncă nu există evaluări

- Piping MaterialsDocument3 paginiPiping MaterialsMurtadda MohammedÎncă nu există evaluări

- Cameron-MBS-Multi-Bowl Wellhead System - CedipDocument6 paginiCameron-MBS-Multi-Bowl Wellhead System - CedipiswantmachooÎncă nu există evaluări

- Danh Mục Quy Chuẩn, Tiêu Chuẩn Áp DụngDocument15 paginiDanh Mục Quy Chuẩn, Tiêu Chuẩn Áp DụngSơn VũÎncă nu există evaluări

- Workshop Practice Guide for Manufacturing FundamentalsDocument32 paginiWorkshop Practice Guide for Manufacturing Fundamentalsmanipsg100% (2)

- Air Lift Design Pumps PDFDocument5 paginiAir Lift Design Pumps PDFinggerman100% (1)

- HIS KIT Includes THE Following Parts: Installation ManualDocument4 paginiHIS KIT Includes THE Following Parts: Installation ManualOPER123Încă nu există evaluări

- Sulphuric Acid Handbook (1918) - Thomas Joseph SullivanDocument264 paginiSulphuric Acid Handbook (1918) - Thomas Joseph SullivanTerence Crawford0% (1)

- A Series Single 01Document20 paginiA Series Single 01Cahyo DiyantoÎncă nu există evaluări

- Installation Manual: Air Conditioner (Multi Type)Document68 paginiInstallation Manual: Air Conditioner (Multi Type)Tín Nguyễn ThànhÎncă nu există evaluări

- Civil Work SpecificationDocument143 paginiCivil Work Specificationgea alifa amorynaÎncă nu există evaluări

- Conflex RisersDocument3 paginiConflex RisersAdam KnottÎncă nu există evaluări

- Near Miss Incident Report OCLDocument3 paginiNear Miss Incident Report OCLThusithaÎncă nu există evaluări

- Donaldson Filter ServiceDocument2 paginiDonaldson Filter ServiceJulissa Villarreal ChavezÎncă nu există evaluări

- Core Sampling of The Filter Bed: Appendix 11Document3 paginiCore Sampling of The Filter Bed: Appendix 11Ahmed ShawkyÎncă nu există evaluări

- ZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NODocument52 paginiZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NORiaz Ali Khan BangashÎncă nu există evaluări

- MacEwans Dinflow Instructions 2019Document10 paginiMacEwans Dinflow Instructions 2019Akash ChandraÎncă nu există evaluări