Documente Academic

Documente Profesional

Documente Cultură

N Giungas Presentation P

Încărcat de

Gustavo FuentesDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

N Giungas Presentation P

Încărcat de

Gustavo FuentesDrepturi de autor:

Formate disponibile

huge SAVINGS of capitals:

MAINTENANCE FREE

LOW energetic costs

LIFETIME DURATION

less electric power needed

ELECTRIC current flow INTERRUPT

WITHOUT technical CHARACTERISTICS

ALTERATION

O-RINGS SEALING SYSTEM

RECTANGULAR SHAPED SEALING

SYSTEM

U SHAPE SEALING SYSTEM

Mechanical assembly needed to induce

the right deformation

2 or 4 O-Rings between metal and insulating

Deformation/compression required is reached

while compressing O-Rings against the rigid

INSULATING spacer

a surface load higher than

internal pressure

RESULT

TIGHT SEAL

ONE OF THE POSSIBLE SIDE EFFECTS

IN THE LONG TERM COULD BE

FLUID LEAKAGE

O-Ring-walls rubbing rubber overheating

O-Rings wearing and tearing

Surface load decreases - due to O-Rings shape

deformation- up to becoming less than the internal

pressure

LEAKAGE

ABRASION

Shaping

Dimensioning

Finishing operating pressures

Temperatures

cause

O-Rings tear off

The structure deforms material looses flexibility

Surface load P1 becomes less than pressure P,

FLUID LEAKAGE

EXTRUSION

Gas saturates the O-Ring at a certain pressure.

If pressure suddenly decreases, gas gets rapidly expelled.

That previously trapped in nano cavities expands violently

O-Rings causing swell-up and bubbles

Explosive

decompression could

generate blisters, or

tears

O-Ring shape is

deformed

Surface load becomes

less than pressure,

causing FLUIDS

LEAKAGE.

EXPLOSIVE

DECOMPRESSION

STRONG HOLDS

MICROSCOPIC PRECISION

STRICT TOLERANCES.

STRUCTURAL DEFORMATIONS

NOT WATERPROOFED

EXTRUSION

SHORTENING

WEAK POINTS:

LACERATIONS

CHEAP

NO PARTICULAR EQUIPMENTS

OF EASY PROVISION

SYMMETRIC SYSTEM

NO FAST PRESSURE CHANGES

One rectangular shaped gasket hardly compressed among

the metallic surfaces, the metal and the insulating spacer

CHEAP

EASY TO

ASSEMBLY.

NO SURFACE FINISHING

WATER PROOFED

NO EXPLOSIVE DECOMPRESSION

NO EXTRUSION

SHORTENING

PRESSURE APPLICATION CIRCLE

IS VERY HIGH

SPECIFIC EQUIPMENTS

AND MOULDS

NON-SYMMETRIC SEALING SYSTEM

STRONG HOLDS

WEAK POINTS:

Even widely used they experienced some

inconveniences

NOT RECOMMEND

for very

HIGH PRESSURES.

NUOVA GIUNGAS

In the 70s, started to invest in R&D

to design new more efficient solutions.

Time is ripe for the

U-shape sealing system

RGD

Rapid gas decompression

(Explosive Decompression)

17

Increasing the level of groove fill

( 90%)is one way to improve the

resistance of a sealing elastomer

compound to RGD effects

In classical O-RING system, higher

levels of fill may not be appropriate

for service !

O-ring must be fill max 2/3 of groove.

O-ring fill 2/3

of groove

DNV rules

say

20

O-RING SEALING SYSTEM

PRIOR AND AFTER ASSEMBLY

DNV RULES REQUIRE AED/RGD CERTIFICATION

FOR O-RINGS BECAUSE THE SYSTEM ARE

SUBJECT TO RGD/ED EFFECT

SYSTEM ARE ENCLOSED IN A

COMPLETELY CONFINED SPACE!

DNV RULES DO NOT REQUIRE AED/RGD CERTIFICATION

BECAUSE THE SYSTEM ARE

NOT SUBJECTED TO RGD/ED EFFECT.

NUOVA GIUNGAS SEALING SYSTEM

PRIOR AND AFTER ASSEMBLY

We have check if is true

With comparative test based on NORSOK M710:2001

The Tests was carried out at the same time and in the

same condition on O-RING sealing system and on

NuovaGiungas U-Shape system manufactured with

standard FKM Compound (NOT AED!)

Test condition, fluid media, pressure and cycles:

Test Gas Mixture: 10% CO2 in CH4

Test Temperature: 100C

Test Pressure: 150 bar

The initial exposure period at 150 Bar: 72 hrs

decompression rate: 20 - 40

Bar/min.

Holding at atmospheric pressure(each cycle): 1 h (approx)

Holding at 150 Bar (each cycle): 23 hrs (+/-

1hrs)

Decompression cycles: 10

U-shape sealing system

TEST APPARATUS

25

GAS

O-RING samples

U-SHAPE samples

O-RING

Equivalent to

NORSOK RATING#4

RGD results

U-SHAPE

Equivalent to

NORSOK

RATING #0

RGD results

Nuova Giungas has developed different rubber

compound

SUITABLE FOR:

GAS

OIL

STEAM

LOW TEMPERATURE

HIGH TEMPERATURE

AND OTHERS

and even if the system is not subject to the

explosive decompression phenomena, a compound

tested to Norsok M-710

NORSOK RGD

NGPR1201

NORSOK AGEING TESTS

Change in properties against time

and temperature for Arrhenius model

Arrhenius model

for life prediction

References

The NORSOK tests was carried out

according to NuovaGiungas procedure

N 11522143

Test report N 11511221

O-ring

low pressures

small

diameters

no bending, no

tensile, no torsion

and no

compression

Rectangular

Only medium pressure.

U-SHAPE

NO SERVICE LIMITATIONS

THE VERY HIGH INVESTMENT IN SEARCH OF

MATERIALS, EQUIPMENTS AND MOULDS

HAS BEEN SATISFYINGLY PAID BACK

A LESS EFFICIENT PRODUCT STRONGLY

UNDERMINE, ORIGINAL SAVINGS.

A WIDE RANGE OF PRODUCTS

ALWAYS AT STOCK

BUT THAT'S JUST THE BEGINNING

10 BAR

25 BAR

100 BAR

ALL YOUR WISHES

ARE OUR JOB

WE ARE ABLE TO MANUFACTURE

J OINTS SUITABLE FOR

ALL YOUR REQUESTS

WE HAVE ALWAYS

SATISFIED OUR CLIENTS

And we keep on doing it with our

KNOWLEDGE able TO MEET every

kind of REQUIREMENTS

NO LIMITS ON :

Pressures

Sizes

Fluids

128 WATER SERVICE

88 PN 100

BENI

HAROUN

PROJECT

(ALGERIA)

48 API 5L X100

SAI PEM TAP PROJ ECT

GORGON UPSTREAM

PROJ ECT - AUSTRAL I A

DUPLEX CARBON STEEL

WEST SACRAMENTO FORCE MAIN,

PROJECT NEW NATOMAS & SOUTH RIVER PUMPING STATION

WA FA - ME L L I TA H

BL UE STREAM PROJ ECT

KPO PROJECT

TECHI NT PERU - CAMI SEA PROJ ECT

BELAYIM EGYPT

SAIPEM - MENZEL

SAI PEM - MENZEL

ALL OUR PROCESSES ARE UNDER

STRICHT CONTROLS

ELECTRICAL TEST

DIELECTRICAL TEST

HYDRAULI C TEST

HYDRAULIC TEST

TENSILE TEST

TORSIONAL TEST

BENDING TEST

HOL I DAY T E S T

MAGNETIC TEST

MAGNETIC TEST

IMMERSION IN SALINE SOLUTION

AND MANY OTHERS

ACCORDING TO CLIENT REQUEST

R&D AND TECHNOLOGY

AT YOUR SERVICE!

NUOVA GIUNGAS srl

41043 Formigine Modena Italy

Via A. Moro 26,28

Tel: +39 059 578611

Fax: +39 059 570633

E-mail ng@nuovagiungas.com

URL : www.nuovagiungas.com

S-ar putea să vă placă și

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe la EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsEvaluare: 5 din 5 stele5/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe la EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesÎncă nu există evaluări

- Velan Forged Steel CatalogueDocument26 paginiVelan Forged Steel CatalogueJuan Carlos Ojeda RamirezÎncă nu există evaluări

- VAG Absperrklappen02-05Document27 paginiVAG Absperrklappen02-05Muhamad FajriÎncă nu există evaluări

- Rolon Dry Gas SealsDocument39 paginiRolon Dry Gas Sealsnarayan rajuÎncă nu există evaluări

- Change Gasket Brochure PDFDocument8 paginiChange Gasket Brochure PDFermusatÎncă nu există evaluări

- Klinger SealexDocument2 paginiKlinger Sealexdarsh2001patelÎncă nu există evaluări

- AVK Gas Brochure PDFDocument37 paginiAVK Gas Brochure PDFTudor ConstantinÎncă nu există evaluări

- Super Mechanical Seal PresentationDocument100 paginiSuper Mechanical Seal PresentationAshish TIwariÎncă nu există evaluări

- 12-006 NASC Mailing (29 JUNE 2012)Document5 pagini12-006 NASC Mailing (29 JUNE 2012)fiemsabyasachiÎncă nu există evaluări

- Safe ThermDocument6 paginiSafe ThermLoganBohannonÎncă nu există evaluări

- Updated GeneralDocument24 paginiUpdated GeneralMOHAMMED HANEEFÎncă nu există evaluări

- Plasma CuttingDocument42 paginiPlasma CuttingivanessgÎncă nu există evaluări

- Generator Fleet ExperienceDocument16 paginiGenerator Fleet Experiencevasilev_darkoÎncă nu există evaluări

- DGS - 2. JCDocument15 paginiDGS - 2. JCfjafarvand100% (1)

- 06-Sundyne Presentation Fs SealsDocument74 pagini06-Sundyne Presentation Fs Sealsjoseellargo88% (8)

- Catalogo Valvulas WandfluhDocument16 paginiCatalogo Valvulas WandfluhHéctor IbáñezÎncă nu există evaluări

- Rei Vol IiDocument142 paginiRei Vol IiDineshÎncă nu există evaluări

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Document3 paginiMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsÎncă nu există evaluări

- Double Block and Bleed ValveDocument16 paginiDouble Block and Bleed ValveBa Jun Thối100% (1)

- Swagelok Medium Pressure Fittings Alloy 625Document16 paginiSwagelok Medium Pressure Fittings Alloy 625totcsabÎncă nu există evaluări

- Trainee Name: Trainee Engineer Mechanical Maintenance DeptDocument50 paginiTrainee Name: Trainee Engineer Mechanical Maintenance DeptAdnan119Încă nu există evaluări

- Velan Valve KatalogDocument22 paginiVelan Valve KatalogAinurizal HilmiÎncă nu există evaluări

- AFA RubberJoint 99TU ScrewedDocument1 paginăAFA RubberJoint 99TU ScrewedSandi AslanÎncă nu există evaluări

- Siemens MV Gas Insulated Switch GearDocument14 paginiSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VÎncă nu există evaluări

- O Ring Troubleshoothing GuideDocument1 paginăO Ring Troubleshoothing GuideLylla Damasceno DamascenoÎncă nu există evaluări

- Raychem-Cata MV TerminationDocument16 paginiRaychem-Cata MV TerminationKeshab ShresthaÎncă nu există evaluări

- Catalogue EKOVAL VALVEDocument4 paginiCatalogue EKOVAL VALVERoxy AksesoriesÎncă nu există evaluări

- Series 825YD Specification SheetDocument2 paginiSeries 825YD Specification SheetFEBCOÎncă nu există evaluări

- Aux. Mach. 1: Nyk-Tdg Maritime AcademyDocument97 paginiAux. Mach. 1: Nyk-Tdg Maritime AcademyDennis IndayÎncă nu există evaluări

- Folleto Valvula EknDocument2 paginiFolleto Valvula EknosvaldoreneÎncă nu există evaluări

- Klamflex Product Training September 2022 MetitoDocument65 paginiKlamflex Product Training September 2022 MetitoAhmed NagiebÎncă nu există evaluări

- The Boss of Control Loop, Final Control Element: Reliance Industries Ltd. JamnagarDocument61 paginiThe Boss of Control Loop, Final Control Element: Reliance Industries Ltd. JamnagarRaju NaiduÎncă nu există evaluări

- Hyd Inc SwivelsDocument140 paginiHyd Inc SwivelsCentral HydraulicsÎncă nu există evaluări

- Cage Clamp - 51184677Document22 paginiCage Clamp - 51184677Leandro H. MartinezÎncă nu există evaluări

- CV For Pressure Up To 50bDocument4 paginiCV For Pressure Up To 50bmattuiffÎncă nu există evaluări

- Screw Less Cage ClampDocument23 paginiScrew Less Cage ClampApurbaÎncă nu există evaluări

- Dry Gas Seals 101 - PresentationDocument52 paginiDry Gas Seals 101 - Presentationrico.fortuna78% (9)

- Technological AdvancementsDocument52 paginiTechnological AdvancementsMeirinaDiahPuspitaIIÎncă nu există evaluări

- Valves: Types and Working PrinciplesDocument73 paginiValves: Types and Working PrinciplesEhab AbowardaÎncă nu există evaluări

- DHT-DHC OverviewDocument39 paginiDHT-DHC OverviewTaras ByloÎncă nu există evaluări

- Jcs2 Mech SealDocument6 paginiJcs2 Mech SealManojkumar ThilagamÎncă nu există evaluări

- Ke Masterhose: Metallic and Rubber Flexible HosesDocument40 paginiKe Masterhose: Metallic and Rubber Flexible HosesfcspekÎncă nu există evaluări

- Technip Drilling BrochureDocument12 paginiTechnip Drilling Brochurenedumaran.sÎncă nu există evaluări

- IN2065-07-01 MPreC enDocument6 paginiIN2065-07-01 MPreC enknsbÎncă nu există evaluări

- Swel Plug BrochureDocument4 paginiSwel Plug BrochureLuis MoranÎncă nu există evaluări

- #Omprehensiveß Solution Forß (Ydroß0Owerß3Tations: $uctileßironßpipe Forßrenewable EnergyDocument16 pagini#Omprehensiveß Solution Forß (Ydroß0Owerß3Tations: $uctileßironßpipe Forßrenewable EnergysebasfarsaÎncă nu există evaluări

- Pt. Magdatama - Brosur Wabo Jeene JointDocument4 paginiPt. Magdatama - Brosur Wabo Jeene JointRismansyah Rizqian SundawaÎncă nu există evaluări

- CAT DewranceDocument93 paginiCAT DewranceHorvatAladar100% (1)

- Valvulas KiezelMannDocument0 paginiValvulas KiezelMannManuel SaavedraÎncă nu există evaluări

- Service Manual - R410a - RS6200006R32Document131 paginiService Manual - R410a - RS6200006R32AireCom100% (1)

- O-Rings: By: Muhammad Shoaib FareedDocument68 paginiO-Rings: By: Muhammad Shoaib Fareedsaadpervaiz14Încă nu există evaluări

- Solenoid Operated Valves: Nuclear Power GenerationDocument12 paginiSolenoid Operated Valves: Nuclear Power GenerationVeerabhadra BujurkeÎncă nu există evaluări

- Rubber Seal - O Rings - IRIDocument35 paginiRubber Seal - O Rings - IRIGnaneshÎncă nu există evaluări

- HVAC Duct LeakageDocument68 paginiHVAC Duct LeakageuzairÎncă nu există evaluări

- Jordan Control Valves RegulatorsDocument16 paginiJordan Control Valves RegulatorsDucVikingÎncă nu există evaluări

- Butterfly Valve TorqueDocument8 paginiButterfly Valve TorqueShyam KrishnanÎncă nu există evaluări

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDocument2 paginiStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771Încă nu există evaluări

- Dry Gas Seals Theory Basic Design and Applications PDFDocument38 paginiDry Gas Seals Theory Basic Design and Applications PDFsaadpervaiz14100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe la EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- Bt-Ar: Mechanical Seals - Mechanical Seals For Pumps - Elastomer Bellows SealsDocument6 paginiBt-Ar: Mechanical Seals - Mechanical Seals For Pumps - Elastomer Bellows SealsimtiyazÎncă nu există evaluări

- Monitoring KatalogDocument92 paginiMonitoring KatalogChandra Agung WicaksanaÎncă nu există evaluări

- ERIKS SealingElements Technical Handbook Oring StandardsDocument1 paginăERIKS SealingElements Technical Handbook Oring Standardsyanuar_adhiÎncă nu există evaluări

- Qty. Description CR 4-30 A-A-A-BUBE: Company Name: Created By: Phone: DateDocument12 paginiQty. Description CR 4-30 A-A-A-BUBE: Company Name: Created By: Phone: Dateabhe prasetyaÎncă nu există evaluări

- Bomba de Lubricação Automatca de MarteloDocument53 paginiBomba de Lubricação Automatca de MarteloDaniel F BarrosÎncă nu există evaluări

- Parts List: RV-123/IRV403-90Document126 paginiParts List: RV-123/IRV403-90Ming Wey LimÎncă nu există evaluări

- 100F RCP 03CR2Document14 pagini100F RCP 03CR2Jorge Cortés RubianoÎncă nu există evaluări

- Section E - Hydraulics Pressure Reducing Solenoid Valve (To Serial No. 752462)Document34 paginiSection E - Hydraulics Pressure Reducing Solenoid Valve (To Serial No. 752462)Marcelo Elói De Amorim SilvaÎncă nu există evaluări

- Tcra and Atra, A Strategic Alliance: Ford 6F50N Rebuilding TechniquesDocument72 paginiTcra and Atra, A Strategic Alliance: Ford 6F50N Rebuilding TechniquesAlex Maceira GraterolÎncă nu există evaluări

- Siemens NEMA IEC Selection and Pricing Guide 2009 2010Document383 paginiSiemens NEMA IEC Selection and Pricing Guide 2009 2010lduong40% (1)

- Plan Prueba Stanadyne Db4629Document4 paginiPlan Prueba Stanadyne Db4629Mas Inyeccion Electronica100% (2)

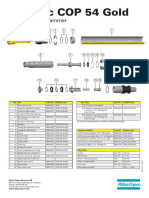

- Atlas Copco COP 54 GoldDocument1 paginăAtlas Copco COP 54 GoldAlparslanÎncă nu există evaluări

- TM Dis and AssyDocument160 paginiTM Dis and AssyJoseph Emmanuel ParedesÎncă nu există evaluări

- Shipping Mark 唛 头 Box qty 箱数 package 包装 PN&Description 型号 &描述 Amt qty 总数量 size/cm G.w/box (毛) 重 (m3) /box 单箱体积 Unit (pc/set) Quantity Lx长 Wx宽 Hx高Document2 paginiShipping Mark 唛 头 Box qty 箱数 package 包装 PN&Description 型号 &描述 Amt qty 总数量 size/cm G.w/box (毛) 重 (m3) /box 单箱体积 Unit (pc/set) Quantity Lx长 Wx宽 Hx高Ya ŞamÎncă nu există evaluări

- Pre-Inspection Safety Valve 2.81 FxeDocument3 paginiPre-Inspection Safety Valve 2.81 FxeNasrien Kadir100% (1)

- E 426 04Document35 paginiE 426 04shahganÎncă nu există evaluări

- MRM, TRM, Ad Note, Rii, Daily Event Plan 23 Oct 2023Document34 paginiMRM, TRM, Ad Note, Rii, Daily Event Plan 23 Oct 2023Rommy RamadlanÎncă nu există evaluări

- R902401949 - en - 13000 - 4404 - 20150918191058 Catalogo Bomba Hidraulica Kalmar DR450Document24 paginiR902401949 - en - 13000 - 4404 - 20150918191058 Catalogo Bomba Hidraulica Kalmar DR450Bolívar EspinozaÎncă nu există evaluări

- Submersible Pumps For High Temperature LiquidsDocument4 paginiSubmersible Pumps For High Temperature LiquidsIpenu Sujarwo100% (1)

- QDP:24 Mechanical Seals Product RangeDocument16 paginiQDP:24 Mechanical Seals Product Rangeyogeshjain38Încă nu există evaluări

- Duo Cone SealDocument15 paginiDuo Cone SealM Ferry AnwarÎncă nu există evaluări

- Oil ValveDocument4 paginiOil ValveGolbert GolbiÎncă nu există evaluări

- 2401 DP Instrument Level v0.0Document162 pagini2401 DP Instrument Level v0.0GioquququqÎncă nu există evaluări

- Rubber Seal - O Rings - IRIDocument35 paginiRubber Seal - O Rings - IRIGnaneshÎncă nu există evaluări

- 170-00 - HTHP Filter Press, 175 ML, Single-Capped, CO2Document32 pagini170-00 - HTHP Filter Press, 175 ML, Single-Capped, CO2latnrythmzÎncă nu există evaluări

- Product Group Codes: Pump SealsDocument15 paginiProduct Group Codes: Pump SealsJesus PicaluaÎncă nu există evaluări

- Geith - Acople Ec460bDocument25 paginiGeith - Acople Ec460bjrincon26Încă nu există evaluări

- Parker - PTFE Lip SealsDocument170 paginiParker - PTFE Lip Sealspughreader1100% (1)

- Compresor MYCOMDocument8 paginiCompresor MYCOMPEDROÎncă nu există evaluări

- O-Ring Design - Best PracticeDocument7 paginiO-Ring Design - Best PracticeJnanesh K SÎncă nu există evaluări