Documente Academic

Documente Profesional

Documente Cultură

Mech 012

Încărcat de

hasan_6764896160 evaluări0% au considerat acest document util (0 voturi)

16 vizualizări2 paginiRESPONSIBILITY Before commencement of any installation activity, the following procedures are reuired to be carried out. CHEC$ that FCUs are in compliance with approved submittal.!.% Chec$ for any physical damages upon receipt of the same at site. %.% Select the correct si-e. Model FCU and install the unit in the location as configured in the shop drawing.

Descriere originală:

Titlu original

Mech-012

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentRESPONSIBILITY Before commencement of any installation activity, the following procedures are reuired to be carried out. CHEC$ that FCUs are in compliance with approved submittal.!.% Chec$ for any physical damages upon receipt of the same at site. %.% Select the correct si-e. Model FCU and install the unit in the location as configured in the shop drawing.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

16 vizualizări2 paginiMech 012

Încărcat de

hasan_676489616RESPONSIBILITY Before commencement of any installation activity, the following procedures are reuired to be carried out. CHEC$ that FCUs are in compliance with approved submittal.!.% Chec$ for any physical damages upon receipt of the same at site. %.% Select the correct si-e. Model FCU and install the unit in the location as configured in the shop drawing.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

METHOD STATEMENT FOR INSTALLATION OF FAN COIL UNIT

1.0 SCOPE OF WORK

The Method Statement is applicable to installation of Fan Coil Units at all designated levels.

2.0 RESPONSIBILITY

Before commencement of any installation activity, the following procedures are reuired to be carried out.

!." #ll materials used must have an approved material submittal.

!.! Chec$ that FCUs are in compliance with approved submittal.

!.% Chec$ for any physical damages upon receipt of the same at site.

!.& Before

!.' installations ensure that the location of FCU is as per the approved shop drawing.

!.( Chec$ Base Frame and #nti )ibration mounts are in place as per approved submittal.

!.* +etain the shipping crates and protection covers until the unit is at its final location.

3.0 DESCRIPTION OF WORK

Installat!n P"!#$%&"$

%." ,rovide supervision and labor to assist in the rigging operation.

%.! Maneuver the euipment from loading points to the proper locations as shown in approved drawing in a

reasonably timely manner.

%.% Select the correct si-e . model FCU and install the unit in the location as configured in the shop drawing.

%.& /rill 0 fi1 the hanging brac$ets 0 lift and hang the FCU2s.

%.' #fter completing the installation remove the shipping spacers between the fan.motor base frame and the

unit. 3Manufacturer to secure the fan assembly during shipment normally uses shipping spacers.4

%.( Connect drainpipe through a 5U5 trap to open drain. The trap shall have minimum water seal euivalent to

negative suction pressure at the fan plus "6mm.

%.* Connection of supply and return chilled water to be done as per with supply at the bottom and return at the

top and ensure counter flow connection.

%.7 Complete electrical connection to the unit recommended by the manufacturer. Motor up to &89 with

/.:.;. Starter and above star<delta starter.

%.= >nstallation to be as per approved shop drawing.

%."6 Ta$e the reuired action to protect the interior of the FCU during construction.

%."" Complete electrical connection to the unit recommended by the manufacturer.

'.0 LABOUR( PLANT ) MATERIAL RE*UIREMENTS

&." The material shall be of approved Manufacturer as per the material submittal.

&.! S$illed technicians, in sufficient numbers, shall carry out the installation.

&.% The wor$manship shall be maintained at all times.

+.0 SUPER,ISION ARRAN-EMENTS

'." # constant supervision by the foreman and supervisor shall be carried out in order to control the wor$ and

the wor$manship.

'.! ?1perienced supervisors shall be appointed to carry out the wor$ smoothly and to have the full control of

the labour.

..0 R$/$"$n#$ D!#&0$nts

(." /rawings

(.! Specification@ "'7%6

1.0 E2&30$nt R$2&"$%

*." #ll necessary rigging euipment i.e. slings, chains, deshac$les, spreader bars etc.

*.! Chain bloc$s, e1tra chains.slings, rollers etc for maneuvering within plant rooms.

4.0 EN,IRONMENTAL RE*UIREMENTS

7." # Safety officer shall ensure that the labor has a good wor$ing environment, a ha-ard free environment.

5.0 TEMPORARY WORKS TO BE DESI-NATED AND INSTALLED

A.#

10.0 HEALTH ) SAFETY RE*UIREMENTS

"6." ?nsure wor$ area is clean and tidy.

"6.! ?nsure the wor$ #rea is well ventilated.

"6.% #ll employees shall adopt safe wor$ing practices.

"6.& Safety euipment 3e1ample Bard Bats, Safety Shoes, Coveralls, Cloves, Coggles when necessary etc.4 to

be worn at all times.

P"$3a"$% 678 K. Ln9anna R$:$;$% 678 Can$" T!na< A33"!:$% 678 Can$" T!na<

S9nat&"$8 S9nat&"$8 S9nat&"$8

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- 2014 68 Eu PDFDocument96 pagini2014 68 Eu PDFAlienshow100% (1)

- LNG Tank Dismantling MS RevCDocument14 paginiLNG Tank Dismantling MS RevChasan_676489616100% (1)

- Delayed PWHTDocument4 paginiDelayed PWHThasan_676489616Încă nu există evaluări

- Duty CycleDocument1 paginăDuty Cyclehasan_676489616Încă nu există evaluări

- Acid PipingDocument1 paginăAcid Pipinghasan_676489616Încă nu există evaluări

- API 5L - 43rd and 44th Ed - Comparison r1Document68 paginiAPI 5L - 43rd and 44th Ed - Comparison r1gopidhan100% (1)

- Celex:02014l0068 20140717:en:txtDocument118 paginiCelex:02014l0068 20140717:en:txtedwinÎncă nu există evaluări

- Method of Statement Piping Fab. ErectionDocument22 paginiMethod of Statement Piping Fab. Erectionhasan_676489616Încă nu există evaluări

- ITP For Piping WorksDocument91 paginiITP For Piping Workshasan_676489616100% (1)

- Cross Cut TestDocument1 paginăCross Cut Testhasan_676489616Încă nu există evaluări

- Paul K. Feyerabend - Philosophical Papers, Volume 4 - Physics and Philosophy-Cambridge University Press (2015) PDFDocument438 paginiPaul K. Feyerabend - Philosophical Papers, Volume 4 - Physics and Philosophy-Cambridge University Press (2015) PDFDavor Katunarić100% (1)

- PNFJ8000Document71 paginiPNFJ8000seenu189100% (1)

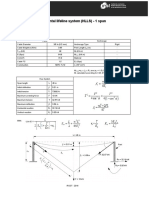

- Horizontal Life Line CalculationDocument1 paginăHorizontal Life Line Calculationhasan_676489616100% (1)

- ITP For Piping WorksDocument91 paginiITP For Piping Workshasan_676489616100% (1)

- Solar Power Plant ReportDocument1 paginăSolar Power Plant Reporthasan_676489616Încă nu există evaluări

- OSHA - 29CFR - Construction StandardsDocument22 paginiOSHA - 29CFR - Construction Standardshasan_676489616100% (1)

- Steel Grades ComparisonDocument14 paginiSteel Grades Comparisonhasan_676489616Încă nu există evaluări

- Fall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public ConsultDocument40 paginiFall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public Consultlwin_oo2435100% (4)

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDocument24 paginiPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishÎncă nu există evaluări

- Construction ProcedureDocument36 paginiConstruction ProcedureJagdish Busa100% (2)

- E SN854Document2 paginiE SN854hasan_676489616Încă nu există evaluări

- 1926.501 - Duty To Have Fall ProtectionDocument4 pagini1926.501 - Duty To Have Fall Protectionhasan_676489616Încă nu există evaluări

- Stainless Steels For H2SO4Document4 paginiStainless Steels For H2SO4Marshel LeninÎncă nu există evaluări

- E SN882Document2 paginiE SN882hasan_676489616Încă nu există evaluări

- ASME B16.47 Series B FlangeDocument4 paginiASME B16.47 Series B Flange41h189Încă nu există evaluări

- E SN834Document3 paginiE SN834hasan_676489616Încă nu există evaluări

- FITTINGS ButtweldDocument5 paginiFITTINGS ButtweldThamaraikani ManiÎncă nu există evaluări

- E SN883Document2 paginiE SN883hasan_676489616100% (1)

- Din 2461-66Document7 paginiDin 2461-66hasan_676489616Încă nu există evaluări

- Din 2614Document11 paginiDin 2614hasan_676489616Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Aspire Es1-432 - Quanta ZQF - Da0zqfmb6f0Document32 paginiAspire Es1-432 - Quanta ZQF - Da0zqfmb6f0Nico Saibort JuniorÎncă nu există evaluări

- Indian Standard Basic Requirements For Hospital Planning: 0. ForewordDocument2 paginiIndian Standard Basic Requirements For Hospital Planning: 0. ForewordAr Aditya SagarÎncă nu există evaluări

- ElectriCalc Pro ManualDocument71 paginiElectriCalc Pro ManualJuanDavinci100% (1)

- SoalDocument3 paginiSoaldekyÎncă nu există evaluări

- User Manual: - Installation - OperationDocument61 paginiUser Manual: - Installation - OperationKasun WeerasingheÎncă nu există evaluări

- LSBU MSC Cisco VlanDmvpn ProjectDocument91 paginiLSBU MSC Cisco VlanDmvpn Projectcool_nedianÎncă nu există evaluări

- Quick Start Guide: Plugs Into The Diagnostic Connector Already 1996 or Newer Cars and Light Trucks. Built Into AllDocument8 paginiQuick Start Guide: Plugs Into The Diagnostic Connector Already 1996 or Newer Cars and Light Trucks. Built Into Allfrank mutaleÎncă nu există evaluări

- CSS Interview Questions and Answers For Freshers PDFDocument14 paginiCSS Interview Questions and Answers For Freshers PDFramanranaÎncă nu există evaluări

- Nfpa 14, 2013 - Redundance in Pressure RegulatingDocument1 paginăNfpa 14, 2013 - Redundance in Pressure RegulatingDiego PovedaÎncă nu există evaluări

- Infoblox CLI Guide: NIOS 6.1 For Infoblox Network Core Services AppliancesDocument118 paginiInfoblox CLI Guide: NIOS 6.1 For Infoblox Network Core Services AppliancesPriyanto UkiÎncă nu există evaluări

- WCDMA Accessiblity KPIsDocument29 paginiWCDMA Accessiblity KPIsAbdoulayeAboubacar0% (1)

- HCLSIG$$Drug Safety and Efficacy$CDISCs SDTM BasicsDocument21 paginiHCLSIG$$Drug Safety and Efficacy$CDISCs SDTM BasicsprasannaÎncă nu există evaluări

- White Paper ISO 14001 2015 1 PDFDocument6 paginiWhite Paper ISO 14001 2015 1 PDFwaleedÎncă nu există evaluări

- Polaris 1996 SLT780 Owner's Manual 02Document90 paginiPolaris 1996 SLT780 Owner's Manual 02Scott Spectra BriteÎncă nu există evaluări

- Ceragon GlossaryDocument5 paginiCeragon GlossarypsnashÎncă nu există evaluări

- 8-6 Fits and AllowancesDocument15 pagini8-6 Fits and AllowancesshivendrakumarÎncă nu există evaluări

- Site Selection ProcessDocument11 paginiSite Selection ProcessAgnes Cheverloo CastilloÎncă nu există evaluări

- Rethink Fa 2018N 141 GreeceDocument1 paginăRethink Fa 2018N 141 GreeceΠέτρος ΜαρκόπουλοςÎncă nu există evaluări

- A Industral Visit ReportDocument12 paginiA Industral Visit ReportAnkit SharmaÎncă nu există evaluări

- Huawei Agile POL Hotel Solution PDFDocument31 paginiHuawei Agile POL Hotel Solution PDFMoises TemplinskiÎncă nu există evaluări

- BS 476-1 1953Document27 paginiBS 476-1 1953iask5275Încă nu există evaluări

- Process Understanding Related To Pharmaceutical Manufacture and ControlDocument7 paginiProcess Understanding Related To Pharmaceutical Manufacture and ControlDanielle monteiro uchoa alves100% (1)

- Engineering LetteringDocument3 paginiEngineering LetteringZeejnAÎncă nu există evaluări

- SMU MBA101 - Management Process and Organizational Behaviour Free Solved AssignmentDocument9 paginiSMU MBA101 - Management Process and Organizational Behaviour Free Solved Assignmentrahulverma2512100% (1)

- CCNA+3+Module+7+Version+4 0+answersDocument6 paginiCCNA+3+Module+7+Version+4 0+answersMinoli_Silva_7409Încă nu există evaluări

- Komatsu PC350LC-8 ManualDocument8 paginiKomatsu PC350LC-8 Manualgraig27Încă nu există evaluări

- MOOE Officers Roles and Responsibilities-2019Document9 paginiMOOE Officers Roles and Responsibilities-2019Jacquiline TanÎncă nu există evaluări

- Concentric-Lay-Stranded Aluminum 1350 Conductors: Standard Specification ForDocument11 paginiConcentric-Lay-Stranded Aluminum 1350 Conductors: Standard Specification ForAlexis AguillonÎncă nu există evaluări

- LEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedDocument189 paginiLEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedRana DanishÎncă nu există evaluări

- Q1 Requirements For MPL EndorsementDocument11 paginiQ1 Requirements For MPL Endorsementvahoh94266Încă nu există evaluări