Documente Academic

Documente Profesional

Documente Cultură

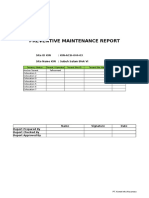

Raw Mill Patroller Checklist Route 1

Încărcat de

AbasiemekaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Raw Mill Patroller Checklist Route 1

Încărcat de

AbasiemekaDrepturi de autor:

Formate disponibile

Yes No Comment

Work Request

No.

Are motion detector and tail drum guards

in good condition? If NO Specify and give

reason.

Are drift switches, tail drum lagging and

plough deflector in good condition without

material accumulation, If NO Specify and

give reason.

Is the belt joint in good condition? Indicate

if there are openings on the belt joint.

Are the rope switches OK, accessible and

having good tension? If NO, Specify and

give reason.

Are the motion detector, head and tail

drum lagging of 133 BC 490 in good

condition? Specify bad ones and state the

observed problem.

Is the housekeeping & illumination along

the belt (133 BC 490) and walkway good?

Is the drive motor and gearbox running in

good condition with guard and oil level OK

(133 BC 490)

Check Fire extinguisher, how many are in

good condition?

Are the drift switches working properly

and in good position?, If NO specify

Is there any part of the belt (133 BC 490)

not secured with safety guard

Is the belt joint in good condition (133 BC

490)? Indicate if their is opening on the

belt joint

Is the belt running at the center or drifted

to one side?, if YES give reason

Is dedusting Bag filter (133BF440) working

properly and in correct mode? Indicate

whether P or TIMER Mode

Safety :- Wear at all time the PPEs : Hard hat, Safety glasses, Hand gloves, Respirator. Ear defenders, Safety shoes and any other related PPE

Note: Equipment inspections are carried out by: feeling,touching,smelling, hearing and seeing. If something is not clear on this, it is advisable to

leave the space and call Shift Leader or Area Owner for assistance. It is a punishable offence to fill what you don't know.

133 BC 400 FEED BELT TO 133 BC 500

INSPECTION CHECKLIST FOR ROUTE 1 (RAW MIX AND ADDITIVE TRANSPORT)

NB: Kindly fill

and submit to

Shift Leader 4

hrs after shift

start.

SAFETY, HEALTH AND ENVIRONMENT

Note :-The Attendant/Patroller and the Shift Leader are concerned with this list. If they observe any problem they should record in the log book and inform the Area

Owner to report to the PM Department.

Patroller Name: Sign:

Shift Leader Name: Sign:

Shift duty: Date:

Indicate the pressure value on the Bag

Filter (133BF440)

Is the bearing temperature on Bag Filter

(133BF440) is unsually high?

Is the counterweight structural frame,sling

wire, fall back arrestors and its auxillaries

okay?

Are the trough & return roller okay

(running)? If NO specify the number of

faulty ones

Are their spillages under return idlers?

Is the bend pulley at the counter-weight

secured with guards?

Are the snub pulley lagging in good

condition?

Are there broken/ missing bolts, damage,

cracks on handrails,stair way?

Are primary and secondary scrappers OK

and in correct position for good scrapping

effect?, If NO give reason

Are there unusual noise, vibration, high

temperature and oil leakage on the drive &

gearbox? (133 BC 400)

Is there any materal build up at the

discharge chute and walkway? If YES state

reason.

Are the scrappers and side skirts in good

condition?

Yes No Comment

Work Request

No.

Is the belt joint in good condition? Indicate

if their is opening on the belt joint

Is the belt joint in good condition? Indicate

if their is opening on the belt joint

Is the belt joint in good condition? Indicate

if their is opening on the belt joint

Is the belt joint in good condition? Indicate

if their is opening on the belt joint

Is the belt joint in good condition? Indicate

if their is opening on the belt joint

Are drift switches, tail drum lagging and

plough deflector in good condition without

material accumulation, If NO Specify and

give reason

133 BC 500 FEED BELT TO 133 BC 520

Are the rope switches OK and having good

tension?, If NO Specify and give reason

Is the belt running at the center or drifted

to one side?, if YES give reason

Is the bend pulley at the counter-weight

secured with guards?

Is the counterweight structural frame,sling

wire, fall back arrestors and its auxillaries

okay?

Are there unusual noise, vibration, high

temperature and oil leakage on the drive &

gearbox?

Are the trough & return rollers okay

(running)? If NO specify.

Are there broken/ missing bolts, damage,

cracks on handrails,stair way?

Are primary and secondary scrappers OK

and in correct position for good scrapping

effect?, If NO give reason

Are there unusual noise, vibration, high

temperature and oil leakage on the drive &

gearbox?

Is dedusting Bag filter (133 BF 510)

working properly and in correct mode?

Indicate whether P or TIMER Mode

Indicate the pressure value on the Bag

Filter (133BF510)

Is the bearing temperature on Bag Filter

(133BF510) is unsually high?

Are the scrappers and side skirts in good

condition?

Yes No Comment

Work Request

No.

Are all side guards & coupling guard

secured?

Are motion detectors at drive drums MO1

& MO2 and guards in good condition/, If

NO Specify and give reason

Are there unusual noise, vibration, high

temperature and oil leakage on the drive &

gearbox?

Is dedusting Bag filter (131 BF 450)

working properly and in correct mode?

Indicate whether P or TIMER Mode

Indicate the pressure value on the Bag

Filter (131BF450)

131 BC 400 FEED BELT TO MIX BIN

Is the bearing temperature on Bag Filter

(131BF450) is unsually high?

Is the belt running at the center or drifted

to one side?, if YES give reason

Are the trough & return rollers okay

(running)?, If NO specify faulty ones

Is the submerge pump at the tunnel

working properly with no water

accumulation?

Are the pull ropes and drift switches at the

centre in good condition?, If NO specify

faulty one

Are there broken/ missing bolts, damage,

cracks on handrails,stair way?

Is the counterweight structural frame,sling

wire, fall back arrestors and its auxillaries

okay?

Is the belt joint in good condition? Indicate

if their is opening on the belt joint

Is the housekeeping and illumination at

the tunnel O.K, How many lights are not

ON?

Are their leakages from intake hopper

chute as a result of wear?

Are the air blasters at the intake chute

blasting properly without air leakage?, If

NO specify and give reason

Indicate the pressure reading on the air

blaster

Are the scrappers and side skirts in good

condition?

Is there any materal build up at the intake

and discharge chutes? If YES state

reason.

Are motion detector and tail drum guards

in good condition/, If NO Specify and give

reason

Are drift switches, tail drum lagging and

plough deflector in good condition without

material accumulation, If NO Specify and

give reason

Yes No Comment

Work Request

No.

Is the housekeeping around the stacker

boom good?

Are there big stones/metal piece from

stacker or at the area being Re-claimed?, If

YES specify the size in mm

Is there any missing bolt and nut on the

reclaimer conveyor sprocket?, If YES

specify no.

Is there any build up of material inside 131

BC 400 intake hopper

Is the chain bucket well lubricated?,if no

state reason(s)

Any abnormal sound from reclaimer buggy

wheel?

Is there any missing reclaimer rake/arrow?

Is there any missing bolt and nut on the

reclaimer chain link?

Is there any unwanted material along

reclaimer rail line?

Are the fire extinguishers in good

condition?

Are the panel doors closed properly and

the Air condition working properly.

Is there any unusual alarm at the reclaimer

cabin?, if yes state the alarm.

Any other notes/comments not captured above?

131 RE 300 CBS RECLAIMER

S-ar putea să vă placă și

- Method Statement UnitizedDocument22 paginiMethod Statement Unitizedifeanyi EmmanuelÎncă nu există evaluări

- Metco 16C 10-040Document8 paginiMetco 16C 10-040JSH100Încă nu există evaluări

- Carpentry: Exploratory CourseDocument25 paginiCarpentry: Exploratory CourseJohn Nelson Picones100% (3)

- Mold Design ChecklistDocument10 paginiMold Design ChecklistRamesh RaoÎncă nu există evaluări

- CF 500cc Service Manual PDFDocument254 paginiCF 500cc Service Manual PDFJonathan RojasÎncă nu există evaluări

- WH 2place ManualDocument5 paginiWH 2place ManualJessie O.BechaydaÎncă nu există evaluări

- Risk Assessment - Cleaning of Bucket Elevator BoothDocument2 paginiRisk Assessment - Cleaning of Bucket Elevator BoothAbasiemekaÎncă nu există evaluări

- Gmail - IELTS Test ConfirmationDocument2 paginiGmail - IELTS Test ConfirmationAbasiemekaÎncă nu există evaluări

- Wood Magazine Issue #189Document96 paginiWood Magazine Issue #189bangbang63100% (1)

- Oil Gas Custody Data Sheet 2Document52 paginiOil Gas Custody Data Sheet 2Mathias OnosemuodeÎncă nu există evaluări

- Form PM KIN Rev1Document155 paginiForm PM KIN Rev1sichaoeloemÎncă nu există evaluări

- GR00003400 34Document26 paginiGR00003400 34Art Del R SalongaÎncă nu există evaluări

- Maintenance Schedules For BG Coaches of Icf DesignDocument6 paginiMaintenance Schedules For BG Coaches of Icf DesignParthaprotim NathÎncă nu există evaluări

- 4T40 Cuerpo ValvulasDocument15 pagini4T40 Cuerpo ValvulasJorge Arturo100% (1)

- 50 Series Mechanical Handouts.Document66 pagini50 Series Mechanical Handouts.Ruben Ruiz Rebolledo50% (2)

- Preventive Maintenance Checklist Drafted Q34 Q44 1Document152 paginiPreventive Maintenance Checklist Drafted Q34 Q44 1shani5573100% (1)

- 01 QC Preventive Maintenance Checklist Drafted Q34 Q44 1Document153 pagini01 QC Preventive Maintenance Checklist Drafted Q34 Q44 1shani5573Încă nu există evaluări

- Epl 2Document0 paginiEpl 2Luis Alberto OrtegaÎncă nu există evaluări

- May Cap Da Voi Nhiet DienDocument14 paginiMay Cap Da Voi Nhiet Dienlinhcdt3Încă nu există evaluări

- QC Preventive Maintenance Checklist Drafted Q QDocument370 paginiQC Preventive Maintenance Checklist Drafted Q QjoetylorÎncă nu există evaluări

- REVO ChecklistsDocument4 paginiREVO ChecklistsAllison NolanÎncă nu există evaluări

- 50 Question Related To ValvesDocument24 pagini50 Question Related To ValvesNjat HakimÎncă nu există evaluări

- No Parameter Yes No RemarkDocument4 paginiNo Parameter Yes No Remarkardiansyahsave23Încă nu există evaluări

- FB All QuestionDocument169 paginiFB All QuestionAshish B PandeyÎncă nu există evaluări

- Man I Have A Question On A 928g Loader I Have Been Doing Some Test On The Transmission I Need A Little Bit of Direction.Document17 paginiMan I Have A Question On A 928g Loader I Have Been Doing Some Test On The Transmission I Need A Little Bit of Direction.ikperha jomafuvweÎncă nu există evaluări

- Royal Enfield Thunderbird 500 - Pdi Checklist Troubleshooting GuideDocument45 paginiRoyal Enfield Thunderbird 500 - Pdi Checklist Troubleshooting GuideAnonymous zjSL6JLlÎncă nu există evaluări

- Boom Truck Instructors NotesDocument76 paginiBoom Truck Instructors NotesWill RodriguezÎncă nu există evaluări

- 01 Purifier 03 Defect & Maint - TAKDocument49 pagini01 Purifier 03 Defect & Maint - TAKzinminpaing9892Încă nu există evaluări

- Tensioner Training PresentationDocument29 paginiTensioner Training Presentationaravindan476Încă nu există evaluări

- Gear Failure AnalysisDocument22 paginiGear Failure AnalysisKarthick Kumar100% (1)

- 2000H Service Wheel Loader 993KDocument4 pagini2000H Service Wheel Loader 993KmhmdtrainingÎncă nu există evaluări

- Carmudi Inspection Form: Autolabs Trading - Henry Dizon/Kris YulipDocument10 paginiCarmudi Inspection Form: Autolabs Trading - Henry Dizon/Kris YulipDizon HenryÎncă nu există evaluări

- ASK 21 Preflight ManualDocument12 paginiASK 21 Preflight Manualstephen390Încă nu există evaluări

- 204-00 General InfoDocument6 pagini204-00 General InfoMiguel AngelÎncă nu există evaluări

- Manual de Reparacion Motor Jac 4da1 Parte 5 PDFDocument117 paginiManual de Reparacion Motor Jac 4da1 Parte 5 PDFFerran Alfonso100% (2)

- 9N 2N 8N New Holland Service ManualDocument156 pagini9N 2N 8N New Holland Service Manualmardukzek100% (9)

- BM Governer Kit (2021 - 01 - 27 20 - 16 - 46 UTC)Document3 paginiBM Governer Kit (2021 - 01 - 27 20 - 16 - 46 UTC)wade.hynesoutlook.comÎncă nu există evaluări

- 5r55n How-To-Fix-ItDocument87 pagini5r55n How-To-Fix-ItDavid Chalker100% (14)

- Belt Tensioner AdujustmentDocument1 paginăBelt Tensioner AdujustmentRAMANÎncă nu există evaluări

- 5 6057415857582114918Document15 pagini5 6057415857582114918sujaraghupsÎncă nu există evaluări

- TDD - YER.1.00000 Updated (TDS-11)Document5 paginiTDD - YER.1.00000 Updated (TDS-11)Mohamed AnwarÎncă nu există evaluări

- Checklist Pms TB Tytyan Karimata 02Document3 paginiChecklist Pms TB Tytyan Karimata 02alsitorÎncă nu există evaluări

- Driveline System - General Information: Principle of OperationDocument15 paginiDriveline System - General Information: Principle of OperationSergeyÎncă nu există evaluări

- SSR Instruction ManualDocument12 paginiSSR Instruction Manualgrandmas developerÎncă nu există evaluări

- Renault Technical Note 3419A Turbocharger DiagnosisDocument15 paginiRenault Technical Note 3419A Turbocharger DiagnosisClaudiu CondreaÎncă nu există evaluări

- Check List For Synchromesh Transmission-ZFDocument3 paginiCheck List For Synchromesh Transmission-ZFSandeep Varma'sÎncă nu există evaluări

- Group 33ADocument22 paginiGroup 33AArt Del R SalongaÎncă nu există evaluări

- Orals Electrical For MMDDocument44 paginiOrals Electrical For MMDStrongest AvengerÎncă nu există evaluări

- Crank Case Inspection ProcedureDocument6 paginiCrank Case Inspection ProcedureSid ACHARYAÎncă nu există evaluări

- Failure Analysis of Ball ValvesDocument12 paginiFailure Analysis of Ball ValvesGhiyat FarisÎncă nu există evaluări

- 3 - Warning Signs & Shut inDocument110 pagini3 - Warning Signs & Shut inMohamed TefaÎncă nu există evaluări

- Failure Analysis of Ball Valves WorcesterDocument12 paginiFailure Analysis of Ball Valves Worcestercvishwas1159Încă nu există evaluări

- Checklist Pms ObDocument3 paginiChecklist Pms ObalsitorÎncă nu există evaluări

- Checklist Pms ObDocument3 paginiChecklist Pms ObalsitorÎncă nu există evaluări

- Inspection ChecklistDocument6 paginiInspection Checklistmechman5Încă nu există evaluări

- Tesco Corporation: Unit #: Date: Operating DaysDocument1 paginăTesco Corporation: Unit #: Date: Operating Daysboy tryadiÎncă nu există evaluări

- SI433 ADocument21 paginiSI433 ASubhojit Samonta100% (7)

- Pioneer SCE Safety Inspection - Halliburton BSS - SafetyCultureDocument9 paginiPioneer SCE Safety Inspection - Halliburton BSS - SafetyCultureBilal KhanÎncă nu există evaluări

- Marine Engineering PracticeDocument19 paginiMarine Engineering PracticeAnoop Vijayakumar100% (1)

- TransmissionDocument2 paginiTransmissionlee washingtonÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Inspection Route ScheduleDocument10 paginiInspection Route ScheduleAbasiemekaÎncă nu există evaluări

- Re: Blue Rose WaterDocument1 paginăRe: Blue Rose WaterAbasiemekaÎncă nu există evaluări

- Dear Colleagues,: 1. 331CV303 Missing Bolt Replaced by MechanicalDocument1 paginăDear Colleagues,: 1. 331CV303 Missing Bolt Replaced by MechanicalAbasiemekaÎncă nu există evaluări

- Monthly Production Meeting MinutesDocument4 paginiMonthly Production Meeting MinutesAbasiemekaÎncă nu există evaluări

- Kiln Log Sheet Sched 20140520 A Day DailyDocument47 paginiKiln Log Sheet Sched 20140520 A Day DailyAbasiemekaÎncă nu există evaluări

- Kiln Area Learning ReportDocument24 paginiKiln Area Learning ReportAbasiemekaÎncă nu există evaluări

- Sensor Location Measuring Range/ideal ValueDocument1 paginăSensor Location Measuring Range/ideal ValueAbasiemekaÎncă nu există evaluări

- Unicem Cement Factory Access Control Policy/Procedure Rev.01Document5 paginiUnicem Cement Factory Access Control Policy/Procedure Rev.01AbasiemekaÎncă nu există evaluări

- Internal and External - Store AttendantDocument2 paginiInternal and External - Store AttendantAbasiemekaÎncă nu există evaluări

- Internal and External - Store KeeperDocument2 paginiInternal and External - Store KeeperAbasiemekaÎncă nu există evaluări

- VACANCY - Operations AnalystDocument2 paginiVACANCY - Operations AnalystAbasiemekaÎncă nu există evaluări

- Risk Assessment - Loading of CBS Hopper Using Pay-LoaderDocument2 paginiRisk Assessment - Loading of CBS Hopper Using Pay-LoaderAbasiemekaÎncă nu există evaluări

- Subject: Unicem Computer Auctioning Exercise: Assets Disposal CommitteeDocument1 paginăSubject: Unicem Computer Auctioning Exercise: Assets Disposal CommitteeAbasiemekaÎncă nu există evaluări

- Problem 468 - Project EulerDocument1 paginăProblem 468 - Project EulerAbasiemekaÎncă nu există evaluări

- The TCP/IP Protocol Suite: TutorialDocument74 paginiThe TCP/IP Protocol Suite: TutorialRiyaz AhmedÎncă nu există evaluări

- Manual de Instruções John Deere D170 (56 Páginas)Document2 paginiManual de Instruções John Deere D170 (56 Páginas)Antonio CostaÎncă nu există evaluări

- Master Thesis: Tasuku KanedaDocument77 paginiMaster Thesis: Tasuku Kanedamkali345Încă nu există evaluări

- Exception Handling Notes For Vtu StudentsDocument42 paginiException Handling Notes For Vtu StudentshelloÎncă nu există evaluări

- Introduccion To PhysicsDocument475 paginiIntroduccion To PhysicsLyvsÎncă nu există evaluări

- Manual PSW 2600Document18 paginiManual PSW 2600Jc C. GomezÎncă nu există evaluări

- 91 194 DCDocument57 pagini91 194 DCGusdeluxeÎncă nu există evaluări

- Project Management Quick Reference GuideDocument5 paginiProject Management Quick Reference GuidejcpolicarpiÎncă nu există evaluări

- RIL AGM Presentation SlidesDocument44 paginiRIL AGM Presentation SlidesDeshGujaratÎncă nu există evaluări

- SY-5SSM V1.1 SY-5SSM/5 V1.1 Super 7 Motherboard: User's Guide & Technical ReferenceDocument88 paginiSY-5SSM V1.1 SY-5SSM/5 V1.1 Super 7 Motherboard: User's Guide & Technical Referencealopezcuervo82190% (1)

- Caustic CrackingDocument17 paginiCaustic CrackingDurga PrasadÎncă nu există evaluări

- ABB LMU 574 - mcd80Document12 paginiABB LMU 574 - mcd80gadware2011bplÎncă nu există evaluări

- 048Document6 pagini048kokykarkarÎncă nu există evaluări

- AÇO - DIN17100 St52-3Document1 paginăAÇO - DIN17100 St52-3Paulo Henrique NascimentoÎncă nu există evaluări

- TSA Surface Preparation and ApplicationDocument7 paginiTSA Surface Preparation and ApplicationMythri Metallizing Pvt Ltd Projects100% (1)

- Pakistani Radio MarketDocument72 paginiPakistani Radio MarketNajeeb Anwar100% (1)

- Retrofit of Water Mist Catcher: WMC For L23/30 (H) and L28/32 (H) GensetsDocument2 paginiRetrofit of Water Mist Catcher: WMC For L23/30 (H) and L28/32 (H) GensetsMichael GorobaoÎncă nu există evaluări

- Assignment 1Document4 paginiAssignment 1MikeyÎncă nu există evaluări

- Maintenence SchedulingDocument4 paginiMaintenence SchedulingCarloVanZyl0% (1)

- HHW 35 m6 GBDocument6 paginiHHW 35 m6 GBSuper WhippedÎncă nu există evaluări

- Shaft Design Problem 10 - 12Document9 paginiShaft Design Problem 10 - 12BernalynMalinaoÎncă nu există evaluări

- Hela Bojuna - Comparative StatementDocument27 paginiHela Bojuna - Comparative StatementNadeeshani MunasingheÎncă nu există evaluări

- Bomba de Vácuo Sotorbilt 4mrDocument12 paginiBomba de Vácuo Sotorbilt 4mrWormInchÎncă nu există evaluări

- BX-74 / BX-78: Sliding Gate Operator BX SeriesDocument24 paginiBX-74 / BX-78: Sliding Gate Operator BX SeriesStefce PetrovÎncă nu există evaluări

- No35-Inclined Roof SystemDocument24 paginiNo35-Inclined Roof SystemKitanovic NenadÎncă nu există evaluări

- UntitledDocument34 paginiUntitledRayudu VVSÎncă nu există evaluări

- Know It BrochureDocument8 paginiKnow It BrochureSonali SinhaÎncă nu există evaluări