Documente Academic

Documente Profesional

Documente Cultură

Lectura 1. - MÇtodo de Ciliberti

Încărcat de

Jose Quintero0 evaluări0% au considerat acest document util (0 voturi)

63 vizualizări4 paginiThe document summarizes Criticality-Based Maintenance (CBM), a 4-step process to identify and address risks. The steps include: 1) ranking equipment criticality, 2) developing follow-up action plans, 3) implementing approved plans, and 4) closing out completed plans. It then provides details on the first step of ranking equipment criticality, which involves assessing consequences, likelihoods, and risks to prioritize equipment. The document also outlines developing action plans to address higher risk equipment and managing the implementation and close-out of those plans.

Descriere originală:

Titlu original

Lectura 1.- MÇtodo de Ciliberti

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document summarizes Criticality-Based Maintenance (CBM), a 4-step process to identify and address risks. The steps include: 1) ranking equipment criticality, 2) developing follow-up action plans, 3) implementing approved plans, and 4) closing out completed plans. It then provides details on the first step of ranking equipment criticality, which involves assessing consequences, likelihoods, and risks to prioritize equipment. The document also outlines developing action plans to address higher risk equipment and managing the implementation and close-out of those plans.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

63 vizualizări4 paginiLectura 1. - MÇtodo de Ciliberti

Încărcat de

Jose QuinteroThe document summarizes Criticality-Based Maintenance (CBM), a 4-step process to identify and address risks. The steps include: 1) ranking equipment criticality, 2) developing follow-up action plans, 3) implementing approved plans, and 4) closing out completed plans. It then provides details on the first step of ranking equipment criticality, which involves assessing consequences, likelihoods, and risks to prioritize equipment. The document also outlines developing action plans to address higher risk equipment and managing the implementation and close-out of those plans.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

Page 1 of 4

January 14, 2001

Criticality-Based Maintenance

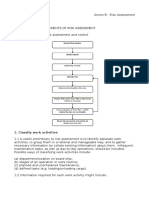

Criticality-Based Maintenance (CBM) is a four-step process of identifying and

addressing risk and exposure in a facility. These steps are:

1. Equipment Criticality Ranking (ECR)

2. Follow-up action plans

3. Implementation of approved action plans

4. Close-out of completed action plans

CBM is consistent with the following industry standards:

API RP 580: Risk-Based Inspection

NFPA 704: Standard System for the Identification of the Hazards of Materials for

Emergency Response

OSHA 29 CFR 1910.119: Process Safety Management

Equipment Criticality Ranking

Equipment criticality ranking is a qualitative assessment of potential consequences

associated with specific equipment items and the likelihood that those consequences will

occur. Potential consequences are evaluated for each equipment item using a cause-

event-consequence process. Each failure scenario is a combination of a cause and event,

and may have one or more potential consequences. Consequences considered for each

scenario are assessed and given values for consequence severity level and likelihood of

occurrence (Table 1, Table 2, and Table 3). Likelihood is based on a generic equipment

case, i.e. what is typical for the specific type of equipment. The consequence and

likelihood values for each consequence are entered into a risk-rating matrix to give a risk

rating value (Figure 1). The risk rating for a given equipment item is the worst case

rating for all consequences considered. Risk ratings are generated separately for hazard

and process consequences and the respective process and hazard rating values are entered

into a risk-ranking matrix to give equipment criticality rankings (Figure 2).

Risk ratings are also used to assess an order-of-magnitude level of exposure in monetary

terms (Table 4). Exposure is only present at the equipment items where the

consequences occur and must be assessed in that manner. For example, a pressure vessel

protected by a relief valve has a given level of exposure. The relief valve may cause an

overpressure situation in the vessel if it fails to function, but itself does not have

associated exposure.

Figure 1. Risk Rating Matrix Figure 2. Risk Ranking Matrix

VH

3 4 5 6 7

4-7

A A A A A

H

2 3 4 5 6

4

A A A A A

M

1 2 3 4 5

3

B B B A A

L

0 1 2 4

2

C C B A A

C

o

n

s

e

q

u

e

n

c

e

N

0 0 1 2 3

P

C

R

0,1

D C B A A

N L M H VH

0,1 2 3 4 4-7

Frequency

HCR

Page 2 of 4

January 14, 2001

Table 1. Safety and Environmental Consequence Categories

Category Select highest category for which one criterion is satisfied

Very High Multiple fatalities of company or associated personnel.

Severe injury, illness, or fatalities of one or more members of the community.

Catastrophic environmental impact requiring a full-scale response by outside

agencies.

High Death of one company or associated person.

Severe injury or illness of multiple plant personnel.

Major reportable environmental incident requiring significant company resource

commitment as defined by EH&S guidelines. Notification of regulatory agencies,

negative press coverage. Any hydrocarbon, produced water, or drilling fluid spill

greater than 12 bbl within the facility boundaries or any spill outside the facility

boundaries. Any spill of acid, caustic, or hazardous chemicals > 0.2 cubic meters

regardless of location

Medium Medical treatment required for personnel.

Minor reportable environmental incident as defined by EH&S guidelines. Any

hydrocarbon, produced water, or drilling fluid spill greater than 12 bbl within the facility

boundaries or any spill outside the facility boundaries. Any spill of acid, caustic, or

hazardous chemicals > 0.2 cubic meters regardless of location.

Low Minor medical treatment or first aid required for plant personnel.

Non-reportable environmental incident.

Negligible No safety or environmental consequences.

Table 2. Process Consequence Categories

Category Select highest category for which one criterion is satisfied

Very High Major production loss.

Financial impact at a corporate level.

400,000 4,000,000+

BBL

$10

7

- $10

8

+ USD

High Significant loss of production capacity (50-100%) for short

term (<48 hours).

Loss of production capacity (<10-50%) for long term (>48

hours).

Financial impact at a facility level.

40,000 400,000

BBL

$10

6

- $10

7

USD

Medium Loss of production capacity (10-50%) for short term (<48

hours).

Minor loss of production capacity (<10%) for long term

(>48 hours).

Financial impact at a unit level.

4,000 40,000 BBL

$10

5

- $10

6

USD

Low Minor loss of production capacity (<10%) for short term

(<48 hours).

400 4,000 BBL

$10

4

- $10

5

USD

Negligible Process capability not impacted. < 400 BBL

< $10

4

USD

Table 3. Likelihood Categories

Category Likelihood of Consequence

Very High One or more occurrences are credible annually

High Several occurrences are credible in the facility lifetime

Medium One occurrence is credible in the facility lifetime

Low Not expected to occur in the facility lifetime but not outside the realm of possibility

Negligible Practically impossible

Page 3 of 4

January 14, 2001

Table 4. Exposure Matrix (Consequence x Likelihood)

VH

1.00E+08 $1,000 $10,000 $100,000 $1,000,000 $10,000,000

H

1.00E+07 $100 $1,000 $10,000 $100,000 $1,000,000

M

1.00E+06 $10 $100 $1,000 $10,000 $100,000

L

1.00E+05 $1 $10 $100 $1,000 $10,000

C

o

n

s

e

q

u

e

n

c

e

N

1.00E+04 $0 $1 $10 $100 $1,000

1.00E-05 1.00E-04 1.00E-03 1.00E-02 1.00E-01

N L M H VH

Frequency/Probability

Total Exposure = (Hazard & Process Risk Amounts)

Furthermore, due to the qualitative nature of the ECR assessment, careful consideration

must be given as to whether the sum of the exposure of subsets of systems equals the

total exposure for the system. For example, the Mainline Pipeline has been evaluated by

piping segments between valve stations. The maximum consequence level associated

with each segment leak was very high. The likelihood of such a consequence was

considered as Medium: one occurrence is credible in the facility lifetime, based on that

fact that such failures are known to occur in industry. It would be inaccurate to state that

the level of exposure of the Mainline Pipeline is the sum of the exposure level determined

for each segment. Exposure level for this item would instead be the maximum exposure

level of its components.

Follow-up Action Plans

Follow-up is a process of reviewing high-risk equipment items and preparing and

implementing action plans for risk reduction. Figures 1 and 2 identify Red, Gray,

and White zones associated with criticality ratings for each equipment item. Action

plans should be brought forward for items in the red and gray zones; no action is required

for white-zone items as they are at acceptable risk levels. In general, all red zone items

should be reduced to a minimum of gray zone. Gray zone items should all be evaluated

for risk reduction, but in some cases risk cannot be feasibly reduced.

Preparation of Action Plans

Action plans are used to identify a course of action for reducing risk; they do not include

a design package for recommended changes, but rather bring forward a plan for risk

reduction for approval by management. The action plan is prepared as a document that

identifies the current situation and level of risk, proposed action, and residual risk once

the action has been implemented.

Actions plans should be prepared with the low-cost solution in mind. The first step is to

do more detailed analyses of equipment items in question to see if action is warranted.

Some review questions might be:

Were assumptions too conservative?

What is the specific versus generic case likelihood of the consequence?

Is the design basis adequate where it was assumed inadequate in the ECR study?

Are spare parts inventory levels adequate?

Page 4 of 4

January 14, 2001

If analyses show that action is warranted, low cost solutions should be reviewed first.

These might include:

Implementation of procedures

Implementation or improvement of predictive or preventive maintenance.

Adjustment of spare parts inventory levels

Exhausting these possibilities, facilities changes should be evaluated.

Approval of Action Plans

Action plans are presented to a management forum for approval in a sign-off meeting.

Typical attendees at a sign-off meeting include engineering, production, and maintenance

managers.

As a rule-of-thumb, a minimum of 100 actions plans should be presented at each meeting.

These should be grouped for expeditious presentation, typically by type of action. Sign-

offs are generally done by groups of action types once management is comfortable with

the basis and rationale for the respective types.

As part of the approval process, action plans should be assigned to specific people and

given completion dates.

Implementation of Action Plans

Once action plans are assigned to the appropriate people, implementation becomes the

responsibility of the assignee. However, the CBM Lead Engineer has responsibility for

monitoring the status of all action plans.

When risk for a given equipment item is reduced by implementing new procedures,

inspections, by taking credit for protective equipment, etc., the following considerations

must be taken:

1. Effectiveness of risk reduction measure. Use as a guideline the procedures

outlined in API Recommended Practice 580, Risk-Based Inspection.

2. Risk reduction via procedure or inspection requires that the procedure or

inspection assume the criticality of the risk that it reduced prior to implementation

of that procedure or inspection.

Management of Change procedures must accompany any facilities changes.

Close-Out of Completed Action Plans

After disposition of approved action plans, process safety information (PSI) must be

finalized and confirmed. Confirmation is documented by attaching appropriate copies of

process safety information to an Action Plan Resolution Form. The Action Plan

Resolution Form gives a statement of the initial condition, the action taken, and a

summary of before and after risk. The CBM Lead Engineer signs off the Action Plan

Resolution Form when the action has been satisfactorily implemented and applicable PSI

updated.

S-ar putea să vă placă și

- Risk Assessment DeliverablesDocument7 paginiRisk Assessment DeliverablesHani AhmedÎncă nu există evaluări

- Risk Assessment ProceduresDocument20 paginiRisk Assessment ProceduresAntony JebarajÎncă nu există evaluări

- Sample ALARP WorksheetDocument7 paginiSample ALARP WorksheetP100% (1)

- Plant Safety ChecklistDocument19 paginiPlant Safety ChecklistAbhishek PalÎncă nu există evaluări

- Risk MatrixDocument3 paginiRisk MatrixGhanta Ranjith KumarÎncă nu există evaluări

- RBI of ASTDocument10 paginiRBI of ASTangelo.petteÎncă nu există evaluări

- Topic Five: Risk Assessment & ManagementDocument35 paginiTopic Five: Risk Assessment & ManagementvikramÎncă nu există evaluări

- KAHLIDr Yehia45 PDFDocument36 paginiKAHLIDr Yehia45 PDFLuiz Rubens Souza CantelliÎncă nu există evaluări

- Determinacion de SIS and SILDocument10 paginiDeterminacion de SIS and SILAlejandro GorostietaÎncă nu există evaluări

- Risk Impact AssessmentsDocument6 paginiRisk Impact AssessmentsAjas AjuÎncă nu există evaluări

- RBIDocument19 paginiRBIseth_007Încă nu există evaluări

- Section 1-Scope: 1.1 GeneralDocument10 paginiSection 1-Scope: 1.1 GeneralangeljosechuquiureÎncă nu există evaluări

- Procedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresDocument10 paginiProcedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresradhouaneÎncă nu există evaluări

- QuestionDocument6 paginiQuestionAnosha AslamÎncă nu există evaluări

- Fmeca ProcedureDocument11 paginiFmeca Procedurewarigiyatno100% (1)

- Case For Safety - Bowtie AnalysisDocument23 paginiCase For Safety - Bowtie Analysistrau-nuocÎncă nu există evaluări

- 4428 Industrial Hygiene BPDocument4 pagini4428 Industrial Hygiene BPmohitÎncă nu există evaluări

- FINAL WEEK 4 - Personnel ManagementDocument23 paginiFINAL WEEK 4 - Personnel ManagementKenneth SibonghanoyÎncă nu există evaluări

- P5-Procedure For Identification and Evaluation of Environmental Aspects.Document4 paginiP5-Procedure For Identification and Evaluation of Environmental Aspects.Samsu Sams100% (1)

- Bow Tie BasicDocument6 paginiBow Tie BasicAnonymous WsaaJcd6Încă nu există evaluări

- Topic Five: Risk Assessment & ManagementDocument54 paginiTopic Five: Risk Assessment & ManagementsrkamÎncă nu există evaluări

- Safety in Design Paper A Live Picture of Organisational Risk by Linking Risk Management and Control AssuranceDocument12 paginiSafety in Design Paper A Live Picture of Organisational Risk by Linking Risk Management and Control Assurancemeercat_alexÎncă nu există evaluări

- Risk and OpportunityDocument5 paginiRisk and OpportunityQualityproÎncă nu există evaluări

- Hazards and Effects Management ProcessDocument12 paginiHazards and Effects Management ProcessrwerwerwÎncă nu există evaluări

- Equipment Criticality TutorialDocument7 paginiEquipment Criticality TutorialmailboxofmurliÎncă nu există evaluări

- Guidance On Process Safety Performance IndicatorsDocument12 paginiGuidance On Process Safety Performance IndicatorsJuan CarlosÎncă nu există evaluări

- Risk Analysis For The Inland Waterways Hygiene Code Food and FeedDocument16 paginiRisk Analysis For The Inland Waterways Hygiene Code Food and FeedEEder118Încă nu există evaluări

- Safety Ram2Document1 paginăSafety Ram2bilalak1990Încă nu există evaluări

- Health and Safety Forms Risk Assessment Matrix PDFDocument3 paginiHealth and Safety Forms Risk Assessment Matrix PDFTuan MetuanÎncă nu există evaluări

- Risk MatrixDocument3 paginiRisk MatrixNuzulul Iman100% (1)

- Road Safety Risk Assessment ToolkitDocument4 paginiRoad Safety Risk Assessment ToolkitTony RandersonÎncă nu există evaluări

- HSE Procedure For Environmental Aspects, Hazards, Evaluation of Impacts, Risks & Determination of Control MeasuresDocument19 paginiHSE Procedure For Environmental Aspects, Hazards, Evaluation of Impacts, Risks & Determination of Control MeasuresSafety IezzproÎncă nu există evaluări

- Risk Management PlanDocument5 paginiRisk Management PlanAni WuÎncă nu există evaluări

- Case Study RMWG-05 - Packaging Line OptimizationDocument4 paginiCase Study RMWG-05 - Packaging Line Optimizationtito1628Încă nu există evaluări

- PCP & FmeaDocument4 paginiPCP & FmeaDaniela AscolaniÎncă nu există evaluări

- UNIT IG2: Risk Assessment: Global Professional Training CentreDocument3 paginiUNIT IG2: Risk Assessment: Global Professional Training Centrevivek vÎncă nu există evaluări

- Guide To Risk Assessment in Ship OperationsDocument7 paginiGuide To Risk Assessment in Ship OperationsearthanskyfriendsÎncă nu există evaluări

- Risk Based MaintenanceDocument27 paginiRisk Based MaintenanceJoseÎncă nu există evaluări

- Laboratory Risk Assessment FormDocument8 paginiLaboratory Risk Assessment FormReni Swara Mahardika50% (2)

- Oil Gas Offshore Safety Case (Risk Assessment) : Pbt750@mun - CaDocument43 paginiOil Gas Offshore Safety Case (Risk Assessment) : Pbt750@mun - CaUlviyye ElesgerovaÎncă nu există evaluări

- Oil Gas Offshore Safety Case (Risk Assessment) : Pbt750@mun - CaDocument43 paginiOil Gas Offshore Safety Case (Risk Assessment) : Pbt750@mun - CaUlviyye ElesgerovaÎncă nu există evaluări

- Classify Work ActivitiesDocument9 paginiClassify Work Activitiesc rkÎncă nu există evaluări

- Hazard Identification at A Major Hazard Facility: Guidance NoteDocument25 paginiHazard Identification at A Major Hazard Facility: Guidance NotetemterÎncă nu există evaluări

- Module III Lec3Document10 paginiModule III Lec3Surajit SahaÎncă nu există evaluări

- Critical Control Risk RegistersDocument11 paginiCritical Control Risk Registersmowglitown100% (1)

- CombinepdfDocument105 paginiCombinepdfKenneth SibonghanoyÎncă nu există evaluări

- Risk Management PlanDocument5 paginiRisk Management PlanDr.Sivakumar SelvarajÎncă nu există evaluări

- 1.0 Introduction On Reliability: Figure 1.0 Bathtub Curve, Failure Rate vs. TimeDocument9 pagini1.0 Introduction On Reliability: Figure 1.0 Bathtub Curve, Failure Rate vs. TimeShukri ShabriÎncă nu există evaluări

- AB700 Ass 4-2-1Document4 paginiAB700 Ass 4-2-1Inam UllahÎncă nu există evaluări

- Iso13485 QOP4101 RiskMng PDFDocument4 paginiIso13485 QOP4101 RiskMng PDFQuality and Safety Consultants Co.Încă nu există evaluări

- Risk Assessment Document For LAFDocument10 paginiRisk Assessment Document For LAFLaraib BhattiÎncă nu există evaluări

- CCPS Metric Pres CustomizableDocument24 paginiCCPS Metric Pres CustomizableVikas NigamÎncă nu există evaluări

- How To Write A Risk AssessmentDocument8 paginiHow To Write A Risk AssessmentbranikÎncă nu există evaluări

- Troubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingDe la EverandTroubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingEvaluare: 4.5 din 5 stele4.5/5 (3)

- Cost-Contained Regulatory Compliance: For the Pharmaceutical, Biologics, and Medical Device IndustriesDe la EverandCost-Contained Regulatory Compliance: For the Pharmaceutical, Biologics, and Medical Device IndustriesÎncă nu există evaluări

- Recognizing Catastrophic Incident Warning Signs in the Process IndustriesDe la EverandRecognizing Catastrophic Incident Warning Signs in the Process IndustriesÎncă nu există evaluări

- CISA Exam-Testing Concept-Knowledge of Risk AssessmentDe la EverandCISA Exam-Testing Concept-Knowledge of Risk AssessmentEvaluare: 2.5 din 5 stele2.5/5 (4)

- Guidelines for Process Safety in Bioprocess Manufacturing FacilitiesDe la EverandGuidelines for Process Safety in Bioprocess Manufacturing FacilitiesÎncă nu există evaluări

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisDe la EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisÎncă nu există evaluări

- A Critical Review Evaluating Organizational Factors in Human Reliability AnalysisDocument17 paginiA Critical Review Evaluating Organizational Factors in Human Reliability AnalysisJose QuinteroÎncă nu există evaluări

- OGP 373-18-1 Guidelines For Offshore Drilling SurveysDocument38 paginiOGP 373-18-1 Guidelines For Offshore Drilling SurveysJose Quintero0% (1)

- Installation Pipelaying OffshoreDocument71 paginiInstallation Pipelaying OffshoreJose QuinteroÎncă nu există evaluări

- OGP 434-7 Consequence ModellingDocument40 paginiOGP 434-7 Consequence ModellingJose QuinteroÎncă nu există evaluări

- OGP 434-5 Human Factors in QRADocument66 paginiOGP 434-5 Human Factors in QRAJose Quintero0% (1)

- OGP Ignition Probabilities 434-6Document30 paginiOGP Ignition Probabilities 434-6jms1952100% (2)

- Technical Guidance For Hazards AnalysisDocument193 paginiTechnical Guidance For Hazards AnalysisJose QuinteroÎncă nu există evaluări

- Piping Engineer BookDocument107 paginiPiping Engineer BookMiguel Angel GrimaldoÎncă nu există evaluări

- Madeeha Shah ThesisDocument132 paginiMadeeha Shah ThesisAnum SafderÎncă nu există evaluări

- TO-HQ-02-071 Rev 00 Philosophy For HSE Management - OnshoreDocument39 paginiTO-HQ-02-071 Rev 00 Philosophy For HSE Management - OnshoreAHMED AMIRAÎncă nu există evaluări

- Summary CH 6 (Audit Evidence)Document10 paginiSummary CH 6 (Audit Evidence)bernadetteÎncă nu există evaluări

- BCP (Business Continuity Plan)Document34 paginiBCP (Business Continuity Plan)arbyjamesÎncă nu există evaluări

- Project Report ON: Portfolio Management in Sharekhan LTDDocument9 paginiProject Report ON: Portfolio Management in Sharekhan LTD26amitÎncă nu există evaluări

- CS205 Slides PDFDocument1.442 paginiCS205 Slides PDFAbiaz ZahraÎncă nu există evaluări

- Political Risk AssessmentDocument19 paginiPolitical Risk AssessmentMuhammad Sajid SaeedÎncă nu există evaluări

- Energy InsuranceDocument8 paginiEnergy Insurancezoltan zavoczkyÎncă nu există evaluări

- Cost of Capital 2010Document105 paginiCost of Capital 2010Amit PandeyÎncă nu există evaluări

- Concrete Takeoff.Document19 paginiConcrete Takeoff.Sarthak MohapatraÎncă nu există evaluări

- Business Analysis Practice ExamDocument4 paginiBusiness Analysis Practice ExamSean Dickerson100% (1)

- DENTISTASSUICIDASDocument8 paginiDENTISTASSUICIDASJESUS FRANCISCO SANCHEZ PATRICIOÎncă nu există evaluări

- Binder1 PDFDocument136 paginiBinder1 PDFkashmira100% (1)

- BoholPDRRMPlan v4Document97 paginiBoholPDRRMPlan v4marvinÎncă nu există evaluări

- Iso 14001 Quality ManualDocument9 paginiIso 14001 Quality ManualSyafarul MohammadÎncă nu există evaluări

- Business Continuity and Disaster Recovery: About The CourseDocument1 paginăBusiness Continuity and Disaster Recovery: About The CoursedandisdandisÎncă nu există evaluări

- Engineering EthicsDocument39 paginiEngineering EthicsSaranya S100% (2)

- Methodology For Calculation The Traffic Accidents Costs: September 2015Document7 paginiMethodology For Calculation The Traffic Accidents Costs: September 2015Sandy SandeepÎncă nu există evaluări

- Lightning Climatology in South AfricaDocument4 paginiLightning Climatology in South AfricareviloÎncă nu există evaluări

- Gym Risk AssessmentDocument4 paginiGym Risk Assessmentapi-443558457100% (1)

- 205 IsmDocument13 pagini205 IsmMihir Kumar swainÎncă nu există evaluări

- Tseng - Behavioral Finance, Bounded Rationality, Traditional FinanceDocument12 paginiTseng - Behavioral Finance, Bounded Rationality, Traditional FinanceMohsin YounisÎncă nu există evaluări

- ProposalDocument12 paginiProposalJon Rexor GomezÎncă nu există evaluări

- SITXWHS002 Identify Hazards, Assess and Control Safety Risks Learner Assessment Pack V2.2 - 06 - 2019Document46 paginiSITXWHS002 Identify Hazards, Assess and Control Safety Risks Learner Assessment Pack V2.2 - 06 - 2019Jyoti VermaÎncă nu există evaluări

- Fire Risk Analysis of The Airport TerminalsDocument5 paginiFire Risk Analysis of The Airport TerminalsKristaps Puļķis0% (1)

- J. Mourinho Presentation 31.05.2016 - PDF PDFDocument16 paginiJ. Mourinho Presentation 31.05.2016 - PDF PDFКирилл НестеренкоÎncă nu există evaluări

- Bakker2013 - Neoliberal Versus Postneoliberal Water PDFDocument9 paginiBakker2013 - Neoliberal Versus Postneoliberal Water PDFaimeeÎncă nu există evaluări

- Sd16 Hybrid p4 QDocument12 paginiSd16 Hybrid p4 QQasim AliÎncă nu există evaluări

- Load Capacitance Access Time AnDocument10 paginiLoad Capacitance Access Time AnSung Woo JangÎncă nu există evaluări

- Bangladesh National Plan For Disaster Management (2016-2020)Document77 paginiBangladesh National Plan For Disaster Management (2016-2020)sh4dow.strid3r9581Încă nu există evaluări