Documente Academic

Documente Profesional

Documente Cultură

3 Culvert Design

Încărcat de

Sandeep VaishnavDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

3 Culvert Design

Încărcat de

Sandeep VaishnavDrepturi de autor:

Formate disponibile

Learning Element: LE-2 Culverts for streams and small rivers

LARGE-SIZED CULVERTS

Remember that:

- when the natural soil is soft or unstable a foundation has to be provided to support the culvert. Such a foundation can be

flexible (floating timber in wet areas, a layer of gravel in dryer conditions) or rigid (lean concrete);

- box culverts need to be designed according to the required size, the type of soil in the area and the layer of soil covering

the culvert. Assemble the data mentioned in FIELD INSTRUCTIONS - STRUCTURES so that a wall-founded decision on the type

of structure can be taken;

- the minimum area of culvert space required is one-third of the area of the waterway at times of flood. If the cross-section

of the waterway at a time of flooding is 30 m

2

an opening of at least 10 m

2

should be provided;

- box culverts should be protected from scour by headwalls, wingwalls and aprons;

- aprons can be made of different materials (reinforced concrete, gabions, masonry) but a filter construction made of various

sizes of stone (the largest on top) is both cheap and effective;

- the gradient of the culvert should be between 3 and 5 per cent. If a gradient steeper than 5 per cent is necessary, aprons

are essential!;

- whenever possible the opening of the culvert should be in line with the water flow in the existing stream bed;

- you should ask for instruction booklets and appropriate tools when you are requested to assemble corrugated steel pipes.

DRIFTS

Remember that:

- drifts are best applied in streams which are usually dry or have a very small permanent water flow;

- drifts and causeways should not be located near or in a river bend;

- different designs are used for streams with stony/gravelly beds than for streams with beds of loose sand;

- it is best to construct the drift within the dry seasons and, as near as possible, towards the end of the dry season when the

water-table is lowest.

Construction

- Rechannel the water flow so that you obtain a dry working space.

- Set out the centre-line of the drift with survey pegs showing the future level of the drift surface.

- Set out reference pegs at the down-stream and the up-stream sides of the drift. These pegs should be placed at a fixed

distance (say two metres) from the edges of the future drift so that they will not be lost during construction. The drift

surface should preferably have a crossfall of approximately 3 per cent towards the down-stream side. This means that if your

reference pegs are 10 metres apart the one on the down-stream side should be 30 cm lower than the one on the up-stream

side. In case of doubt, always follow the gradient of the existing river bed. A string over the tops of the survey and reference

pegs shows the level of the drift surface.

- The longitudinal section should be horizontal with two sloping approaches joining the drift to the road. These approaches

should have a gradient of maximum 20 per cent (10 per cent is better) and should carry on well above the highest flood

level. The transitions from the horizontal section to the approaches should be gently curved so that a smooth-riding surface

is provided to the passing vehicles.

- Place multi-purpose pegs showing where the foundation trenches will be excavated. These trenches should be wide

enough to allow sufficient working space to the masons or carpenters.

- Dig these trenches as deep as possible, preferably until you have reached a solid layer (rock, hard soil). When you

encounter water very soon (high water-table) drain this water as well as possible (buckets, pump, mitre drain) and continue

digging until further progress is impossible. In such conditions, a gabion foundation wall is best. If gabions are not available,

fill the trench with rocks up to the water level and continue with masonry until you have reached the correct levels as shown

by the strings.

- After completing the foundation wall(s) excavate the area in between and place the hand-packed stone.

- Finish with a layer of concrete if specified in the design.

- Excavate as necessary for the apron on the down-stream side of the drift, going from one metre depth at the drift edge

sloping upwards to the river bed. The width of the apron should be minimum two metres but preferably more.

- First place small-sized stones, then larger-sized and put the largest at river bed level.

Note: Always study the design carefully. Depending on the design of the drift, sometimes a different work method will be

necessary.

- After the work on the drift itself has been completed, improve (especially in sandy soils) the transitions from the road

surface to the drift approaches.

- Dig trenches of one metre wide and one metre deep immediately next to the drift approaches, across the width of the

road.

- Place a layer of hand-packed stones at the bottom of the trench and backfill the trench with layers of gravel. Compact each

layer (maximum thickness 15 cm) thoroughly with hand-rammers.

LEARNING ELEMENT OBJECTIVES

After you have learned this element you should be able to:

- explain which factors have to be considered before a big culvert is designed;

- give a rule of thumb to determine the approximate size of a culvert;

- describe important points to be taken into account when a culvert is constructed;

- describe the advantages and disadvantages of corrugated-steel pipes.

Concrete pipe culverts are discussed in module M-10, LE-5 Drainage.

The culverts discussed here are larger structures designed to accommodate larger flows.

All culverts require a good foundation whether they have a large or a small diameter. A foundation can be provided in

different ways:

(1) by improving the existing subsoil (place gravel);

(2) by constructing a floating floor. This method is especially suitable in soft swampy areas and consists of placing several

layers of round timber (diameter 5-10 cm) on top of each other, so that a floating timber floor results;

(3) by pouring a concrete floor (usually only applied when major structures are concerned).

Fig 4

Box culvert

Arch culvert - Scaffolding for the arch e.g. removable armco pipes

Box culverts are generally made of reinforced concrete, although the walls can also be made of masonry. The thickness of

base, walls and roof and the reinforcement steel required depend on:

- the over-all dimensions of the culverts;

- the type of soil in the area where the culvert is constructed;

- the layer of soil covering the culvert.

Since these factors vary with the circumstances encountered, the design of these culverts should be done by qualified

engineers. There are, however, a number of points which are generally applicable to all culverts:

- the foundation for pipe culverts should always be shaped to fit the pipe;

- the maximum area of the waterway needs to be determined in order to calculate the size of the culvert required. As a rule

of thumb you can assume that the area of the culvert required is one-third of the area of waterway when the stream has

reached its highest flood level, i.e. for every three square metres of waterway one square metre of culvert should be placed;

- an apron (figure 5) should be made to protect the bed from erosion at the outlet side of the culvert. Aprons can be made of

different materials (reinforced concrete, gabions, masonry). A filter construction made of stones of various sizes, as shown in

figure 2, is cheap and very effective.

Fig 5

- head/wing walls should be made at the inlet and outlet side of the culvert. They protect the road embankment from the

river water and serve also to support the embankment, so that the soil does not slide into the river when a vehicle passes;

- it is very important to properly compact the soil around, between and on top of the culverts. This compaction should be

done in layers not exceeding 15 centimetres.

- the gradient of culverts should normally be the same as the gradient of the stream bed. However, to prevent silting the

gradient should not be less than 3 per cent. A gradient greater than 5 per cent is not recommended unless the

circumstances are exceptional. In this case take protective measures to prevent erosion!

- when a natural stream crosses the road at an angle, it is often better to construct a skew crossing or to realign the road, so

that a 90 crossing can be constructed. If an existing channel bed is altered, usually a lot of erosion problems can be

expected.

Fig 6

Corrugated steel culverts

This culvert type consists of sections of metal which can be bolted with simple tools (figure 7).

Fig 7

The assembly and installation of these culverts is not described here, as the instructions can be easily obtained from the

supplier. The advantages of these steel culverts are their strength, their flexibility and their easy assembly. However, steel is

a costly material and in many countries the pipes are not locally manufactured and readily available.

Always make a cost comparison between alternative solutions. You will find that for rural roads the manufacture of

structures with locally available materials and skills is often cheaper and preferable.

S-ar putea să vă placă și

- Chapter - 5 Culvert DesignDocument7 paginiChapter - 5 Culvert DesignammarnakhiÎncă nu există evaluări

- Structural Analysis 1: Statically Determinate StructuresDe la EverandStructural Analysis 1: Statically Determinate StructuresÎncă nu există evaluări

- A325 Tension Control Bolts PDFDocument1 paginăA325 Tension Control Bolts PDFBoris GalindoÎncă nu există evaluări

- Releasing Plate Elements From Attached Beams - RAM - STAAD Forum - RAM - STAAD - Bentley CommunitiesDocument2 paginiReleasing Plate Elements From Attached Beams - RAM - STAAD Forum - RAM - STAAD - Bentley CommunitiesvijaykumarzÎncă nu există evaluări

- Dynamic Loading and Testing of Bridges in Ontario PDFDocument11 paginiDynamic Loading and Testing of Bridges in Ontario PDFChathurika Supeshala GamageÎncă nu există evaluări

- Debris Flow Protection Systems For Mountain Torrents 2016Document281 paginiDebris Flow Protection Systems For Mountain Torrents 2016ceice2013Încă nu există evaluări

- Practices For Pier and Intermediate Diaphragms of Precast Concrete Girder BridgesDocument16 paginiPractices For Pier and Intermediate Diaphragms of Precast Concrete Girder BridgesbonsektesteraÎncă nu există evaluări

- Aeroport Pavement PDFDocument541 paginiAeroport Pavement PDFLaurentiu BalasaÎncă nu există evaluări

- Part 1 - Geometric Design of Rural RoadsDocument152 paginiPart 1 - Geometric Design of Rural Roadsmusiomi2005Încă nu există evaluări

- CG 1 Anchor Block DesignDocument37 paginiCG 1 Anchor Block DesignGEOMAHESHÎncă nu există evaluări

- A State-Of-The-Art Review of Parameters Influencing Measurement and Modeling of Skid Resistance of Asphalt PavementsDocument16 paginiA State-Of-The-Art Review of Parameters Influencing Measurement and Modeling of Skid Resistance of Asphalt PavementsRoss319303100% (1)

- Fully Book of Drawing May 16-2020 With Catch Water Drain PDFDocument17 paginiFully Book of Drawing May 16-2020 With Catch Water Drain PDFDaniel Pasy SelekaÎncă nu există evaluări

- Development of A Precast Bent Cap SystemDocument402 paginiDevelopment of A Precast Bent Cap SystemvÎncă nu există evaluări

- GT 1490the Observational Method Can Be Simple202Document4 paginiGT 1490the Observational Method Can Be Simple202h100% (1)

- Module-2: 3.1.1. Design Criteria of Earthen DamDocument9 paginiModule-2: 3.1.1. Design Criteria of Earthen DamsakshiÎncă nu există evaluări

- A Critical Analysis of Kylesku BridgeDocument10 paginiA Critical Analysis of Kylesku BridgeVeenoy DabeeÎncă nu există evaluări

- Cement StabilisationDocument12 paginiCement StabilisationFanuel MsangiÎncă nu există evaluări

- 751.24 LFD Retaining Walls Sept 2011 PDFDocument94 pagini751.24 LFD Retaining Walls Sept 2011 PDFIjaz ShahÎncă nu există evaluări

- Thornthwaite Mather 1957Document132 paginiThornthwaite Mather 1957david100% (2)

- HSFG Bolt PDFDocument6 paginiHSFG Bolt PDFSatish PawarÎncă nu există evaluări

- Design and Construction of Road Embankments in Swampy Area-A Case Study of Uganda in East AfricaDocument14 paginiDesign and Construction of Road Embankments in Swampy Area-A Case Study of Uganda in East AfricaNancy NiolaÎncă nu există evaluări

- Soil ArchingDocument10 paginiSoil ArchingAhmed Serag ZayedÎncă nu există evaluări

- Piled Embankments Decide & DesignDocument12 paginiPiled Embankments Decide & DesignJamie MooreÎncă nu există evaluări

- Economic Assembly of ReinforcementDocument9 paginiEconomic Assembly of ReinforcementAgarry EmmanuelÎncă nu există evaluări

- CSCWorld Tedds Calculations British Standards and Eurocodes 20140826Document3 paginiCSCWorld Tedds Calculations British Standards and Eurocodes 20140826shawnmckenzie840% (1)

- Bridge Maint and Repair HBDocument203 paginiBridge Maint and Repair HBHermann PankowÎncă nu există evaluări

- Tensartech Earth Retaining SystemsDocument16 paginiTensartech Earth Retaining SystemsLogan BrownÎncă nu există evaluări

- Bore and Jack CasingsDocument4 paginiBore and Jack CasingsranggaalviÎncă nu există evaluări

- Bridge Inspection Standards - A Review of International Practice To Benchmark Bridge Inspection Standards For KiwiRail Network's BridgesDocument10 paginiBridge Inspection Standards - A Review of International Practice To Benchmark Bridge Inspection Standards For KiwiRail Network's BridgesAndy AcousticÎncă nu există evaluări

- Elements of Soil Mechanics by G.N.SmithDocument509 paginiElements of Soil Mechanics by G.N.Smithvb_ajitÎncă nu există evaluări

- JRC Report - Tunnels Design and Eurocodes - 2022 - 11 - 02 (No Annex C)Document94 paginiJRC Report - Tunnels Design and Eurocodes - 2022 - 11 - 02 (No Annex C)Dataniel RosarioÎncă nu există evaluări

- Battens DesignDocument3 paginiBattens DesignPrakash Singh RawalÎncă nu există evaluări

- AASHTO - LRFD - Construction Specs-2nd Edition-2 PDFDocument664 paginiAASHTO - LRFD - Construction Specs-2nd Edition-2 PDFSharfaraz Hossain100% (1)

- Practical Shoring Systems PresentationDocument53 paginiPractical Shoring Systems PresentationMajdi AljarrahÎncă nu există evaluări

- NCHRP Syn 368Document126 paginiNCHRP Syn 368Cesar Garcia JrÎncă nu există evaluări

- Pile - Chapter 6Document16 paginiPile - Chapter 6SudharsananPRSÎncă nu există evaluări

- JFE SheetPile CatalogDocument24 paginiJFE SheetPile Cataloghutuguo100% (1)

- Rock Mass Classification in Rock Engineering - 1976 - BieniawskiDocument10 paginiRock Mass Classification in Rock Engineering - 1976 - BieniawskiFQ ElvisÎncă nu există evaluări

- Erosion Control Steep Slopes PDFDocument2 paginiErosion Control Steep Slopes PDFRashidÎncă nu există evaluări

- Geotechnical Engineering Circular No. 5Document386 paginiGeotechnical Engineering Circular No. 5Ay Ch100% (1)

- Foundation Foundation Foundation: Caisson What Is Caisson ?Document2 paginiFoundation Foundation Foundation: Caisson What Is Caisson ?nandhuÎncă nu există evaluări

- Field Performance of Full Depth Precast Concrete Panels in Bridge Deck ReconstructionDocument27 paginiField Performance of Full Depth Precast Concrete Panels in Bridge Deck Reconstructionunix0123Încă nu există evaluări

- Road Engineering & Geotechnical Branch, JKR Ir. Liew Shaw ShongDocument47 paginiRoad Engineering & Geotechnical Branch, JKR Ir. Liew Shaw ShonggabemzamanÎncă nu există evaluări

- Geosythetic Reinforced Unpaved RoadDocument10 paginiGeosythetic Reinforced Unpaved RoadPalak ShivhareÎncă nu există evaluări

- Concrete Thermal Strain PDFDocument34 paginiConcrete Thermal Strain PDFSushmit SharmaÎncă nu există evaluări

- Geotechnical Design For The Nakheel Tall TowerDocument5 paginiGeotechnical Design For The Nakheel Tall TowerLuca BrandiÎncă nu există evaluări

- Expansion Joint Fitting InstructionsDocument9 paginiExpansion Joint Fitting Instructionsxyztaa100% (1)

- Drilled ShaftsDocument16 paginiDrilled Shaftsmahajanniket0% (1)

- Irc 78 2000Document54 paginiIrc 78 2000Shiva Kumar M100% (2)

- Chapter 8Document10 paginiChapter 8bini1221Încă nu există evaluări

- LE 5 CulvertsDocument3 paginiLE 5 CulvertsSandeep VaishnavÎncă nu există evaluări

- Chapter IVDocument33 paginiChapter IVAbhishek JoshiÎncă nu există evaluări

- Lecture No.8 - Bridge FoundationsDocument40 paginiLecture No.8 - Bridge FoundationsGerald Maginga100% (1)

- Guide To Stream Crossing: Culverts, Bridges and FordsDocument13 paginiGuide To Stream Crossing: Culverts, Bridges and FordsMissoula Conservation DistrictÎncă nu există evaluări

- Foundation & Construction EngineeringDocument20 paginiFoundation & Construction Engineeringamitkap00rÎncă nu există evaluări

- GeologyDocument16 paginiGeologyRonan MalacatÎncă nu există evaluări

- Ash Dyke 2.1 (SEC 1)Document11 paginiAsh Dyke 2.1 (SEC 1)karthikraja21Încă nu există evaluări

- Culverts and Low Level CrossingsDocument3 paginiCulverts and Low Level CrossingsAbdykafy ShibruÎncă nu există evaluări

- University of KirkukDocument9 paginiUniversity of KirkukBashdar AzadÎncă nu există evaluări

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionDe la EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionÎncă nu există evaluări

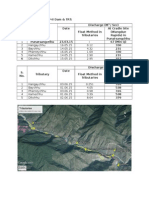

- Manning Equation For Discharge & Rating Puna-1Document30 paginiManning Equation For Discharge & Rating Puna-1Sandeep VaishnavÎncă nu există evaluări

- Height of Colimation MethodDocument4 paginiHeight of Colimation MethodSandeep VaishnavÎncă nu există evaluări

- WTP Design 3.12 MLDDocument21 paginiWTP Design 3.12 MLDSandeep VaishnavÎncă nu există evaluări

- Discharge KamechhuDocument1 paginăDischarge KamechhuSandeep VaishnavÎncă nu există evaluări

- Discharges of Punatsangchhu River Near Taksha Parameters Computed DischargesDocument2 paginiDischarges of Punatsangchhu River Near Taksha Parameters Computed DischargesSandeep VaishnavÎncă nu există evaluări

- Final EmoDocument21 paginiFinal EmoSandeep VaishnavÎncă nu există evaluări

- Routine Maintenance Activities For RoadDocument1 paginăRoutine Maintenance Activities For RoadSandeep VaishnavÎncă nu există evaluări

- Function and Composition of A Surface LayerDocument2 paginiFunction and Composition of A Surface LayerSandeep VaishnavÎncă nu există evaluări

- Nature, Definition and of Soil Mechanics PDFDocument1 paginăNature, Definition and of Soil Mechanics PDFSandeep VaishnavÎncă nu există evaluări

- LE-5 Placing, Compacting and Curing of Concrete - 2Document1 paginăLE-5 Placing, Compacting and Curing of Concrete - 2Sandeep VaishnavÎncă nu există evaluări

- LE-4 The Manufacture of Concrete (Part1)Document2 paginiLE-4 The Manufacture of Concrete (Part1)Sandeep VaishnavÎncă nu există evaluări

- AggregateDocument1 paginăAggregateSandeep VaishnavÎncă nu există evaluări

- LE-4 The Manufacture of Concrete (Part2)Document4 paginiLE-4 The Manufacture of Concrete (Part2)Sandeep VaishnavÎncă nu există evaluări

- LE-5 Placing, Compacting and Curing of Concrete - 1Document1 paginăLE-5 Placing, Compacting and Curing of Concrete - 1Sandeep VaishnavÎncă nu există evaluări

- Improvement of Soils by Mechanical MeansDocument3 paginiImprovement of Soils by Mechanical MeansSandeep VaishnavÎncă nu există evaluări

- Gravel, Sand and Fine Particles in A Soil SampleDocument3 paginiGravel, Sand and Fine Particles in A Soil SampleSandeep VaishnavÎncă nu există evaluări

- Simple Field Tests To Determine Soil PropertiesDocument2 paginiSimple Field Tests To Determine Soil PropertiesSandeep VaishnavÎncă nu există evaluări

- Catchwater Drains and Scour ChecksDocument3 paginiCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- Types of DrainageDocument2 paginiTypes of DrainageSandeep VaishnavÎncă nu există evaluări

- Types of DrainageDocument2 paginiTypes of DrainageSandeep VaishnavÎncă nu există evaluări

- Catchwater Drains and Scour ChecksDocument3 paginiCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- Catchwater Drains and Scour ChecksDocument3 paginiCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- Side Drains and Mitre DrainsDocument3 paginiSide Drains and Mitre DrainsSandeep VaishnavÎncă nu există evaluări

- Catchwater Drains and Scour ChecksDocument3 paginiCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- 2 - Cause Way DesignDocument7 pagini2 - Cause Way DesignSandeep VaishnavÎncă nu există evaluări

- Field Instruction For DrainageDocument4 paginiField Instruction For DrainageSandeep VaishnavÎncă nu există evaluări

- Water Table DrainageDocument2 paginiWater Table DrainageSandeep VaishnavÎncă nu există evaluări

- LE 5 CulvertsDocument3 paginiLE 5 CulvertsSandeep VaishnavÎncă nu există evaluări

- 4 Bridge DesignDocument7 pagini4 Bridge DesignSandeep VaishnavÎncă nu există evaluări

- People vs. Samson, September 2, 2015Document5 paginiPeople vs. Samson, September 2, 2015Alpha Grace JugalÎncă nu există evaluări

- Chraj 1Document6 paginiChraj 1The Independent GhanaÎncă nu există evaluări

- Krok 1 Stomatology: Test Items For Licensing ExaminationDocument28 paginiKrok 1 Stomatology: Test Items For Licensing ExaminationhelloÎncă nu există evaluări

- Social Media As An Effective Tool To Promote BusinessDocument5 paginiSocial Media As An Effective Tool To Promote BusinessHannah Gwyneth BalaÎncă nu există evaluări

- Former UM Soccer Coach Sues University For DefamationDocument12 paginiFormer UM Soccer Coach Sues University For DefamationNBC MontanaÎncă nu există evaluări

- Npcih IDocument2 paginiNpcih IRoYaL RaJpOoTÎncă nu există evaluări

- International Business of Pizza HutDocument13 paginiInternational Business of Pizza Hutpratikdotia9100% (2)

- Dauns Prime Module 1978Document26 paginiDauns Prime Module 1978Ivan AdrianÎncă nu există evaluări

- Contoh MOTIVATION LETTERDocument19 paginiContoh MOTIVATION LETTERDavin Tiska AbrianiÎncă nu există evaluări

- Suarez-Eden v. Dickson Et Al - Document No. 3Document9 paginiSuarez-Eden v. Dickson Et Al - Document No. 3Justia.comÎncă nu există evaluări

- Hechethorn - The Secret Societies of All Ages and Countries, Vol. I (1875) PDFDocument417 paginiHechethorn - The Secret Societies of All Ages and Countries, Vol. I (1875) PDFsongpoetÎncă nu există evaluări

- GDPR ReportDocument4 paginiGDPR ReportnasirdiariesÎncă nu există evaluări

- Chapter 4 The ProcessorDocument131 paginiChapter 4 The ProcessorAk GptÎncă nu există evaluări

- Rodriguez v. Adams PHCDocument40 paginiRodriguez v. Adams PHCNorthern District of California BlogÎncă nu există evaluări

- Lesson Plan 1 (Types of Industries)Document3 paginiLesson Plan 1 (Types of Industries)Chonie VillanuevaÎncă nu există evaluări

- Structural Elements For Typical BridgesDocument3 paginiStructural Elements For Typical BridgesJoe A. CagasÎncă nu există evaluări

- Chapter Three: The Topography of Ethiopia and The HornDocument4 paginiChapter Three: The Topography of Ethiopia and The Horneyob astatke100% (1)

- Fiber Optic Color ChartDocument1 paginăFiber Optic Color Charttohamy2009100% (2)

- Regional Trade Integration in SEE Benefits and ChallengesDocument178 paginiRegional Trade Integration in SEE Benefits and ChallengesRakip MaloskiÎncă nu există evaluări

- Time To Kill PagesDocument24 paginiTime To Kill PagesFrancisco FerreiraÎncă nu există evaluări

- Paper-CutoutDocument5 paginiPaper-CutoutmauricioÎncă nu există evaluări

- Orange PeelDocument2 paginiOrange PeelCharul Shukla100% (1)

- Gartner Magic Quadrant Report For SFA - Aug 2016Document31 paginiGartner Magic Quadrant Report For SFA - Aug 2016Francisco LSÎncă nu există evaluări

- Technology Theatres, Plays and PerformanceDocument48 paginiTechnology Theatres, Plays and PerformanceHannah Williams WaltonÎncă nu există evaluări

- Cesc Modules 8Document6 paginiCesc Modules 8kiethly juanitezÎncă nu există evaluări

- Very Important General Knowledge MCQs With DetailsDocument13 paginiVery Important General Knowledge MCQs With DetailsNiaz AsgharÎncă nu există evaluări

- APPELANTDocument30 paginiAPPELANTTAS MUNÎncă nu există evaluări

- Marathi Book ListDocument4 paginiMarathi Book ListGajanan PatilÎncă nu există evaluări

- Interim Order in The Matter of Sukhchain Hire Purchase LimitedDocument18 paginiInterim Order in The Matter of Sukhchain Hire Purchase LimitedShyam SunderÎncă nu există evaluări

- METCON 6 Quickstart Action PlanDocument9 paginiMETCON 6 Quickstart Action PlanVictorÎncă nu există evaluări