Documente Academic

Documente Profesional

Documente Cultură

Basic Differences (KA C90ABGT and KA 200 - B200 - B200GT) Handout - R0.0

Încărcat de

Guilherme MarquesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Basic Differences (KA C90ABGT and KA 200 - B200 - B200GT) Handout - R0.0

Încărcat de

Guilherme MarquesDrepturi de autor:

Formate disponibile

Copyright 2011 FlightSafety International FOR TRAINING PURPOSES ONLY

Revision 0.0

BASIC DIFFERENCES

King Air C90A/B/GT Series

and

King Air 200/B200/B200GT Series

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-2

Revision 0.0

FOR TRAINING PURPOSES ONLY

AIRCRAFT GENERAL

Aircraft Dimensions

Weight and Balance Limitations (LBS)

Aircraft Speed Limitations (KIAS)

LANDING GEAR WINGTIP TURNING

SERIES

TYPE

LENGTH WIDTH TAIL HEIGHT

RADIUS

Standard 15 0

200

HI Floatation

43 9 54 6

14 6

39 10

Standard 43 10 14 10

B200/B200GT

Hi Floatation 43 9

54 6

14 6

39 10

C90A/B/GT N/A 35 6 50 3 14 3 35 6

MAXIMUM BAGGAGE ZERO

SERIES

CONDITIONS

LBS

FUEL

RAMP TAKEOFF

LANDING

200/B200 w/o Fold-Up Seats 410

(Prior to BB-1091) w/Fold-Up Seats 370

10,400 12,590 12,500 12,500

B200/B200GT w/o Fold-Up Seats 550

(BB-1091 & After) w/Fold-Up Seats 510

11,000 12,590 12,500 12,500

Nose Avionics Bay 350

C90A Light

Baggage Compartment 350

No Limit 9,710 9,650 9,600

Nose Avionics Bay 350

C90A/B/GT

Baggage Compartment 350

No Limit 10,160 10,100 9,168

V

FE

V

LO

V

LO

V

FE

SERIES VMC

DN RETRACT

*TAP VA

EXTEND

VLE

APP

VMO MMO

200 86 146 163 170 181 181 181 200 259 .52 M

B200/B200GT 86 157 163 170 181 181 181 200 259 .52 M

C90A Light 90 148 163 161 153 182 182 184 226 .46 M

C90A/B/GT 80 148 163 161 169 182 182 184 226 .46 M

*TAP = Turbulent Air Penetration Speed

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

Revision 0.0

FOR TRAINING PURPOSES ONLY

1-3

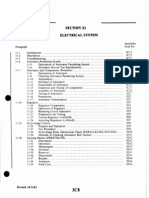

ELECTRICAL SYSTEM

200/B200/B200GT Series

Sustained Generator Loads

Ground Operations 85%

Sea level to 31,000 feet altitude (FL310) 100%

Above 31,000 feet altitude (FL310) 88%

External Power

A caution light on the caution advisory annunciator panel labeled EXT PWR is provided to alert the

operator when a ground power plug is connected to the airplane.

General System Design

The King Air 200/B200 electrical system is designed with four dual fed buses that are tied to both

generator buses. The dual fed buses are protected from over current conditions by two devices: a

50 amp circuit breaker and a 60 amp current limiter. A 70 amp diode on either side of each dual fed

bus protects the system from reverse current from the dual fed bus back to the generator buses.

The system is tied together by an isolation bus that is protected by two 325 amp current limiters.

The King Air B200 Proline 21 and the King Air B200GT electrical system is almost identical to the

King Air B200 electrical system. In the Proline 21 and B200GT application the system does not

contain the inverters for avionics (as shown above). The only inverter in the system is for the galley,

electrical outlets in the cabin, and electric fushing toilet. The system has three avionics buses (as

shown above) and two sub-panel buses (not shown).

Figure 1. King Air B200 Electrical System

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-4

Revision 0.0

FOR TRAINING PURPOSES ONLY

ELECTRICAL SYSTEM (Cont)

C90A/B/GT Series

Sustained Generator Loads

In-Flight limits with minimum 85% N

1

100%

Ground Operations at 70% N

1

85%

External Power

Whenever an external power plug is connected to the receptacle and the BAT switch is ON the yel-

low EXT PWR annunciator will illuminate, whether or not the external power unit is ON. If the EXT

PWR annunciator is fashing and the external power unit is connected then one of three conditions

exists: EXT PWR switch is OFF, EXT PWR voltage is below 24 Volts, or EXT PWR voltage is above

31 .5 Volts.

General System Design

The King Air C90A/B/GT electrical system is designed as a triple-fed system with one bus fed by

both generator buses and the battery. Additionally, it is protected by three 60 amp current limiters

and three reverse current diodes. The system is tied together by a system of bus ties which can

isolate a particular bus in the event of an over current scenario. The generator buses are also pro-

tected by two 250 amp current limiters for additional protection. During engine cross start, a cross

start relay limits the amount of current that is routed through the current limiter and the bus tie to

allow for the other generator bus to have additional protection.

Figure 2. King Air C90A/B/GT Electrical System

GEN TIES

MAN CLOSE

NORM

OPEN

BUS SENSE

RESET

TEST

HOT BATTERY BUS

275

H

E

D

TRIPLE-FED / BATTERY BUS

CENTER BUS LEFT GEN BUS RIGHT GEN BUS

H

E

D

275

250 250

2

7

5

H E D

BATTERY

BATT. BUS

TIE

LEFT GEN

BUS TIE

RIGHT GEN

BUS TIE

RCS LCS

RSR LSR

GEN

SW.

GPU

60

60

60

L GEN

CONTACTOR

GCU

GEN

SW.

R GEN

CONTACTOR

GCU

BATTERY CHARGE

L DC GEN

MAN TIES CLOSE

L GEN TIE OPEN R GEN TIE OPEN R DC GEN BAT TIE OPEN

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

K

I

N

G

A

I

R

C

9

0

/

2

0

0

D

I

F

F

E

R

E

N

C

E

S

H

A

N

D

O

U

T

R

e

v

i

s

i

o

n

0

.

0

F

O

R

T

R

A

I

N

I

N

G

P

U

R

P

O

S

E

S

O

N

L

Y

1

-

5

MASTER WARNING SYSTEM (200/B200/B200GT Series)

*Indicates Optional Equi9pment

KING AIR B200 (BB-1444 THRU BB-1842) KING AIR B200 (BB-854 THRU BB-870; BB-874 THRU BB-1443)

B200/B200GT AIRCRAFT (BB-1843 & AFTER; BY-1 & AFTER)

KING AIR 200 (BB-2 THRU BB-453) KING AIR 200 (BB-453 THRU BB-853; BB-871 THRU BB-873)

WARNING ANNUNCIATORS

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-6

Revision 0.0

FOR TRAINING PURPOSES ONLY

L ENG FIRE

R ENG FIRE

RED Fire in the indicated engine compartment.

FIRE L ENG

FIRE R ENG

L FUEL PRESS

R FUEL PRESS

RED Fuel Pressure Failure on the indicated engine.

L OIL PRESS

R OIL PRESS

RED Low oil pressure on the indicated engine.

L CHIP DETECT

R CHIP DETECT

RED Contamination is detected in the indicated engine oil.

INST INV

INVERTER

RED The selected inverter is inoperative.

L GEN OVHT

R GEN OVHT

RED The temperature of the indicated generator is too high.

L BL AIR FAIL

R BL AIR FAIL

RED Melted or failed plastic in the bleed air failure warning line on the indicated side.

DOOR UNLOCKED

CABIN DOOR

RED Cabin/Cargo Door open or not secure.

AP TRIM FAIL

A/P TRIM FAIL

RED Improper trim or no trim from autopilot trim command.

AP DISC

A/P DISC RED Autopilot is disconnected.

A/P FAIL

ALT WARN RED Cabin altitude exceeds 12,500 feet.

MASTER WARNING SYSTEM (200/B200/B200GT Series) (Cont)

WARNING ANNUNCIATORS

NOMENCLATURE COLOR CAUSE FOR ILLUMINATION

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

K

I

N

G

A

I

R

C

9

0

/

2

0

0

D

I

F

F

E

R

E

N

C

E

S

H

A

N

D

O

U

T

R

e

v

i

s

i

o

n

0

.

0

F

O

R

T

R

A

I

N

I

N

G

P

U

R

P

O

S

E

S

O

N

L

Y

1

-

7

MASTER WARNING SYSTEM (200/B200/B200GT Series) (Cont)

*Indicates Optional Equipment

B200 (BB-1444 THRU BB-1842)

B200/B200GT (BB-1988 & AFTER; BY-1 & AFTER) B200 (BB-1843 THRU BB-1987)

B200 (BB-854 THRU BB-870; BB-874 THRU BB-1443)

200 (BB-2 THRU BB-453) 200 (BB-453 THRU BB-853; BB-871 THRU BB-873)

CAUTION/ADVISORY ANNUNCIATORS

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-8

Revision 0.0

FOR TRAINING PURPOSES ONLY

CAUTION/ADVISORY ANNUNCIATORS

NOMENCLATURE COLOR CAUSE FOR ILLUMINATION

L DC GEN/R DC GEN AMBER The indicated generator is offine.

L CHIP DETECT/R CHIP DETECT AMBER Contamination is detected in the indicated engine oil.

L ICE VANE/R ICE VANE

The indicated Engine Anti-Ice (Ice Vane) has malfunctioned due

L ENG ICE FAIL/R ENG ICE FAIL

AMBER

to not attaining proper position.

CABIN DOOR AMBER Cabin Door open or not secure.

L PITOT HEAT/R PITOT HEAT AMBER The pitot mast heat has failed or the switch is in the OFF position.

HYD FLUID LOW AMBER The hydraulic fuid level in the landing gear reservoir is low.

ELEC HEAT ON AMBER Electric Heat is ON (Keith Environmental System Only)

PROP SYNC ON AMBER

The prop synchrophaser is on with the landing gear extended

(Type I Only)

BATTERY CHARGE (CHG) AMBER Excessive charge rate on the battery.

RVS NOT READY AMBER

Propellers are not in the High RPM position with the landing gear

extended.

DUCT OVERTEMP AMBER Duct air is too hot.

EXT PWR AMBER External power plug is connected.

L AUTOFEATHER/R AUTOFEATHER GREEN

The Autofeather system is armed with the power levers advanced

above the 90% N

1

position.

L ENG ANTI-ICE/R ENG ANTI-ICE

L ICE VANE EXT/R ICE VANE EXT

GREEN The indicated Engine Anti-Ice (Ice Vane) is extended.

The indicated starter/ignition switch is in the engine/ignition

L IGNITION ON/R IGNITION ON GREEN or the indicated auto-ignition system is armed and the engine

torque is below 400 ft-lbs.

BRAKE DEICE ON GREEN The Brake Deice has been selected to ON.

L BL AIR OFF/R BL AIR OFF GREEN The indicated Bleed Air valve is closed.

ELEC TRIM OFF GREEN

The Electric Trim is de-energized by a trim disconnect switch on

the control yoke with the system power switch turned on.

LDG/TAXI LIGHT

LANDING LIGHT

GREEN Landing Lights on with the Landing Gear up.

AIR COND N

1

LOW GREEN The Right Engine N

1

is too low for air-conditioning.

PASS OXY ON

PASS OXYGEN ON

GREEN Oxygen is available to the passengers.

FUEL CROSSFEED GREEN Crossfeed has been selected.

CAUT LGND OFF GREEN The caution annunciator is turned OFF.

MASTER WARNING SYSTEM (200/B200/B200GT Series) (Cont)

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

Revision 0.0

FOR TRAINING PURPOSES ONLY

1-9

MASTER WARNING SYSTEM (King Air C90A/B/GT Series)

*Indicates Optional Equipment

KING AIR C90B/GT SERIES ANNUNCIATOR PANEL (LJ-1353 & AFTER)

KING AIR C90A/B SERIES ANNUNCIATOR PANEL (LJ-1063 THRU LJ-1352)

WARNING ANNUNCIATORS

NOMENCLATURE COLOR CAUSE FOR ILLUMINATION

L GEN OUT

R GEN OUT

RED The indicated generator is offine.

L FUEL PRESS

R FUEL PRESS

RED Fuel Pressure Failure on the indicated engine; Check Boost Pump & Crossfeed.

L CHIP DETECT

R CHIP DETECT

RED Metal contamination in the indicated engine oil, probable engine shutdown.

L OIL PRESS

R OIL PRESS

RED Low oil pressure on the indicated engine.

L ENG FIRE

R ENG FIRE

RED Fire in the indicated engine compartment.

INVERTER RED The selected inverter is inoperative or both inverters are off.

A/P FAIL RED Autopilot is disconnected by switching other than the pilots disconnect button.

A/P TRIM FAIL

A/P TRIM

RED Improper trim or no trim from autopilot trim command.

Cabin altitude exceeds pre-set pressure altitude.

CABIN ALT HI RED LJ-1063 thru LJ-1352: 10,000 feet

LJ-1353 & After: 12,500 feet

CABIN DOOR RED Cabin Door open or not secure.

BAGGAGE DOOR RED **Prior to LJ-1531: Nose Baggage door is not secure.

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-10

Revision 0.0

FOR TRAINING PURPOSES ONLY

MASTER WARNING SYSTEM (King Air C90A/B/GT SERIES) (Cont)

*Indicates Optional Equipment

CAUTION/ADVISORY ANNUNCIATORS

NOMENCLATURE COLOR CAUSE FOR ILLUMINATION

L DC GEN

R DC GEN

AMBER The indicated generator is offine.

L NO FUEL XFR

R NO FUEL XFR

AMBER The indicated wing tank is empty or the transfer pump has failed.

RVS NOT READY AMBER

The propeller levers are not in the High RPM position with the landing gear

extended.

L CHIP DETECT

R CHIP DETECT

AMBER Metal contamination in the indicated engine oil, probable engine shutdown.

L ENG ANTI-ICE FAIL

R ENG ANTI-ICE FAIL

AMBER The indicated engine anti-ice (ice vanes) is inoperative.

L PITOT HEAT

R PITOT HEAT

AMBER The pitot heat switches are in the OFF position or the pitot mast heat has failed.

L GEN TIE OPEN

R GEN TIE OPEN

AMBER The indicated generator bus is isolated from the center bus.

BAT TIE OPEN AMBER The battery is isolated from the generator busses and the center bus.

PITCH TRIM OFF AMBER

The Electric Trim is de-energized by a trim disconnect switch on the control yoke

with the system power switch turned on.

FUEL CROSSFEED AMBER The crossfeed valve is receiving power.

HYD FLUID LO AMBER The hydraulic fuid level in the reservoir is low.

EXT POWER AMBER An external power plug is connected to the aircraft.

BATTERY CHARGE AMBER

*Prior to LJ-1534: The charge rate on the battery exceeds 7 amps for

6 seconds.

L BL AIR OFF **LJ-1688, LJ-1689, LJ-1691 & After: The bleed air switches are in the OFF

R BL AIR OFF

AMBER

position.

L IGNITION ON The Ignition and Engine Start switch is in the ON position on the indicated

R IGNITION ON GREEN side or the Auto-Ignition system is armed and the indicated engine is below

400 ft-lbs.

L AUTOFEATHER The autofeather system is armed with the power levers advanced above the

R AUTOFEATHER GREEN 90% N

1

position or the switch is in the test position with more than 400 ft-lbs

of torque.

L ENG ANTI-ICE

R ENG ANTI-ICE

GREEN The indicated Engine Anti-Ice is extended.

MAN TIES CLOSED GREEN The generator bus ties have been manually closed.

LDG/TAXI LIGHT GREEN Landing Lights on with the Landing Gear UP.

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

Revision 0.0

FOR TRAINING PURPOSES ONLY

1-11

FUEL SYSTEM

200/B200/B200GT Series

System Confguration and Capacities

Main tank holds 193 U.S. Gallons each (includes 57 Gallons in the nacelle tank) or a total of 386

U.S. Gallons for both sides. Auxiliary tank, located in the center wing, holds 79 U.S. Gallons each

or a total of 158 U.S. Gallons for both sides.

System Design and How Fuel is Used

Fuel in the auxiliary tank must be used frst before using fuel in the main tank. This happens auto-

matically without any action from the pilot when the system is working properly. If there is fuel in the

auxiliary tank and it is not being used frst, a yellow light on the fuel panel illuminates and the pilot

must put the AUX TRANSFER switch into the OVERRIDE position. The yellow light will extinguish if

the motive fow valve opens and the fuel is being used.

Fuel Limitations

Maximum Fuel Imbalance: 1,000 LBS

Crossfeed: Only when one engine is inoperative.

Figure 3. King Air 200/B200 Fuel System Schematic

LEGEND

FUEL

FUEL AT STRAINER OR FILTER

FUEL UNDER LOW PUMP PRESSURE

HIGH-PRESSURE FUEL

FUEL CROSSFEED

FUEL RETURN

GRAVITY FEED

FUEL VENT

FILLER

PROBES

SUCTION RELIEF VALVE

CHECK VALVE

FUEL FLOW TRANSMITTER

FUEL PRESSURE ANNUNCIATOR

F

L

L

F

AUXILIARY

WING LEADING EDGE

WING LEADING EDGE

INTEGRAL (WET WING) BOX

SECTION

BOX

SECTION

DRAIN

VALVE

VENT FLOAT VALVE

AIR INLET

DRAIN

RECESSED VENT

HEATED RAM VENT

FLAME ARRESTER

DRAIN

TRANSFER JET PUMP

STRAIN ER, DRAIN,

AND FUEL SWITCH

F

FUEL CONTROL UNIT

ENGINE FUEL MANIFOLD

PRESSURE TANK

FIREWALL FUEL FILTER

ENGINE-DRIVEN BOOST PUMP (LP)

DRAIN VALVE (FIREWALL)

FIREWALL SHUTOFF VALVE

STANDBY BOOST PUMP (30 PSI)

NACELLE TANK

VENT FLOAT VALVE

CROSSFEED VALVE (NC)

P3 BLEED AIR LINE

ENGINE FUEL PUMP (HP)

FUEL HEATER

AIR FILTER

TO ENGINE

FUEL FLOW TRANSMITTER AND INDICATOR

LEFT FUEL PRESSURE ANNUNCIATOR PRESSURE SWITCH

FUEL CONTROL PURGE VALVE

GRAVITY FLOW CHECK VALVE

STRAINER AND DEFUELING DRAIN VALVE

TRANSFER CONTROL MOTIVE FLOW VALVE (NC)

PRESSURE SWITCH FOR LEFT NO FUEL

TRANSFER LIGHT ON FUEL PANEL (6 PSI)

*BB 1401 & SUBSEQUENT LOCATED DOWNSTREAM OF FUEL CONTROL UNIT

**BB 1193 & SUBSEQUENT DRAIN RELOCATED TO OUTBOARD SIDE OF NACELLE

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-12

Revision 0.0

FOR TRAINING PURPOSES ONLY

FUEL SYSTEM (Cont)

C90A/B/GT Series

System Confguration and Capacities

Main tank holds 193 U.S. Gallons each (includes 61 gallons in the nacelle tank) or a total of 386 U.S.

Gallons for both sides. There are no auxiliary tanks only a center wing tank on each side which is

part of the main tank system.

System Design and How Fuel is Used

Fuel in the main tank is transferred automatically to the nacelle tank by a transfer pump when the

TRANS PUMP switch is placed in the AUTO position. If the fuel is not being transferred because

the transfer pump failed, a yellow NO FUEL XFER light will illuminate on the respective side of the

annunciator panel or if the main fuel tank is empty the light will illuminate. If the switch (49 Gal) in

the nacelle fails to turn the transfer pump on, the fuel in the nacelle will go well below 300 lbs. and

the TRANS PUMP switch must be placed in the OVERRIDE position. If the transfer pump has failed,

188 lbs. or 28 U.S. Gallons of fuel will be unusable.

Fuel Limitations

Maximum Fuel Imbalance: 200 LBS

Crossfeed: Only when one engine is inoperative or electric boost pump failure.

Figure 4. King Air C90A/B/GT Fuel System Schematic

L

ENGINE DRIVEN

FUEL PUMP

FUEL PRESSURE

SWITCH

0

QUANTITY

LBS X 100

QUANTITY

INDICATOR

FUEL PRESSURE

ANNUNCIATOR

SUBMERGED BOOST

PUMP & DRAIN

TO ENGINE FUEL

OUTLET

NOZZLES

FUEL MANIFOLD

DUMP-VALVE

ENGINE FUEL

CONTROL UNIT

FUEL HEATER

FUEL FLOW

INDICATOR

FIREWALL

FUEL

FILTER

& DRAIN

FUEL CONTROL

UNIT PURGE

FILLER CAP

TO RIGHT

ENGINE

CROSSFEED VALVE

DRAIN

VALVE

FUEL TRANSFER

PUMP RESTRICTOR

TRANSFER

PUMP AND

DRAIN

TRANSFER WARNING

LIGHT SWITCH

WHEEL

WELL

HEATED VENT

RAM SCOOP VENT

UNDER BOOST PRESS

FUEL SUPPLY

FUEL RETURN

VENT

CROSSFEED

CHECK VALVE

FUEL TRANSFER

FUEL QUANTITY

TRANSMITTER

THERMAL RELIEF

BYPASS

FILLER CAP

SIPHON

BREAK LINE

FIREWALL

SHUTOFF VALVE

4

6 8

10

12

14

2

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

Revision 0.0

FOR TRAINING PURPOSES ONLY

1-13

POWERPLANT

Engine Designations and General Limitations

Compressor Bleed Valve Operations

200/B200 Series Two compressor bleed valves

The low pressure valve closes and opens at approximately 65% N

1

The high pressure valve closes and opens at approximately 90% N

1

B200GT Series One compressor bleed valve

The compressor bleed valve closes and opens at approximately 85% N

1

C90A/B/GT Series One compressor bleed valve

The compressor bleed valve closes and opens at approximately 80% N

1

PROPELLERS

Normal Operating RPM

FIRE PROTECTION

200/B200/B200GT Series

On aircraft prior to BB-1439, BB-1444, the system consists of three photoconductive-cell fame detec-

tors for each engine. These are sensitive to infrared radiation and consequently can be activated by

sunlight in certain conditions. After BB-1444, the system consists of a temperature-sensing cable for

each engine which is flled with a gas that expands with heat in the nacelle. When the gas expands

enough to close a switch, the fre indication is displayed.

C90A/B/GT Series

The system consists of three photoconductive-cell fame detectors for each engine. These are sensitive

to infrared radiation and consequently can be activated by sunlight in certain conditions.

START MAX. CRUISE CLIMB MAX. CRUISE MAXIMUM CONTINUOUS

SERIES ENGINE SHP

ITT (C) TORQUE ITT (C) ITT (C) OIL PRESS. (psi) OIL TEMP. (C)

200 PT6A-41 850 1000 2230 725 750 105135 1099

B200 PT6A-42 850 1000 2230 770 800 100135 099

B200GT PT6A-52 850 1000 2230 800 820 90135 1099

C90A/B PT6A-21 550 1090 1315 695 695 80100 1099

C90GT PT6A-135A 550 1090 1520 805 805 85105 1099

SERIES ENGINE/PROPELLER MIN. IDLE TAKEOFF CLIMB CRUISE

200 PT6A-41 2000 1900 1900/1700

PT6A-42

3 Blade Propellers

2000 1900 1800/1700

PT6A-42

B200 4 Blade Propellers (McCauley)

1100 2000 1900 1800/1700

PT6A-42

4 Blade Propellers (Hartzell)

1180 2000 1900 1800/1700

B200GT PT6A-52 1180 2000 1800 1800/1700

C90A/B PT6A-21 1100 2200 2000 1900

C90GT PT6A-135A 1100 1900 1900 1900

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-14

Revision 0.0

FOR TRAINING PURPOSES ONLY

PNEUMATIC SYSTEM

200/B200/B200GT Series

Bleed Air Valve Switches have three positions (see picture at right).

Pneumatic air on each engine can be turned off when the bleed air

switch on that engine is placed in the INSTR & ENVIR OFF position.

For the B200 Proline 21 (BB-1834, BB-1843 & After) and the B200GT,

(BY-1 & After) this position is called the PNEU & ENVIR OFF position

as no pneumatic air is utilized for the fight instruments.

There is a bleed-air warning system to alert the pilot when a pressurization line or pneumatic line rup-

tures, exhausting hot engine bleed air into the airframe. When the line ruptures and the temperature

reaches approximately 204F (95C), a plastic tube melts which results in the illumination of one or both

BL AIR FAIL warning lights. The bleed air switch on that engine must be placed in the INST & ENVIR

OFF (PNEU & ENVIR OFF) position.

Figure 5. King Air 200/B200/B200GT Bleed Air Warning System

UNREGULATED PNEUMATIC BLEED AIR

BLEED AIR WARNING LINE

LEGEND

ENVIRONMENTAL BLEED AIR

ENGINE P

3

BLEED-AIR

CONNECTOR

ENGINE P

3

BLEED-AIR

CONNECTOR

AMBIENT

AIR

AMBIENT

AIR

FIREWALL

FIREWALL

PLUGS

PLUGS

PLUG

MANIFOLD

(18 PSI REGULATOR)

BLEED-AIR

WARNING

SWITCHES

RH N.O. PNEUMATIC

AIR VALVE

ENVIRONMENTAL

MIXING PLENUM

FLOW CONTROL

VALVE

AIR-TO-AIR

HEAT EXHCHANGER

BLEED-AIR

BYPASS VALVE

BLEED-AIR

BYPASS VALVE

AIR INLET AIR INLET

REAR SPAR

LH N.O. PNEUMATIC

AIR VALVE

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

Revision 0.0

FOR TRAINING PURPOSES ONLY

1-15

PNEUMATIC SYSTEM (Cont)

200/B200/B200GT Series (Cont)

LEGEND

HIGH PRESSURE BLEED AIR

REGULATED BLEED AIR

VACUUM

TO

DEICE

BOOTS

EXHAUST

OVERBOARD

EJECTOR

VACUUM

REGULATOR

RIGHT BLEED-AIR WARNING SYSTEM

* PRIOR TO BB-1842 ONLY

RIGHT

P AIR

LEFT BLEED-AIR WARNING SYSTEM

LEFT

P AIR

AIRSTAIR

DOOR SEAL

LINE

LANDING GEAR

RESERVOIR

(HYDRAULIC

GEAR ONLY)

PNEUMATIC PRESSURE

GAGE

(IN COCKPIT)

PRESSURE

SWITCH

RIGHT

SQUAT

SWITCH

LEFT

SQUAT

SWITCH

CLOSED ON

GROUND

(NO)

CHECK VALVE CHECK VALVE

PNEUMATIC

AIR VALVE

(NO)

PNEUMATIC

AIR VALVE

(NO)

LEFT BRAKE

DEICE

VALVE

(NC)

RIGHT BRAKE

DEICE

VALVE

(NC)

18 PSI

PRESSURE

REGULATOR

DEICE

DISTRIBUTOR

VALVE

PRESSURIZATION

CONTROLLER,

OUTFLOW AND

SAFETY VALVES

* GYRO

INSTRUMENTS

* GYRO

SUCTION

(IN COCKPIT)

HOURS

FLIGHT

1/10

60 PSID

P SWITCH

RUDDER

BOOST

SYSTEM

VALVE

L SERVO

R SERVO

RUDDER BOOST

RUDDER BOOST

LEFT

NC

RIGHT

NC

15 PSI

REGULATOR

4 PSI

REGULATOR

Figure 6. King Air 200/B200/B200GT Pneumatic and Vacuum Systems Diagram

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-16

Revision 0.0

FOR TRAINING PURPOSES ONLY

PNEUMATIC SYSTEM (Cont)

C90A/B/GT Series

Bleed Air Valve switches have two positions (see fgure at right). The

pneumatic air can not be turned off; therefore, no switch has to be

turned on to have pneumatic pressure. As long as an engine is run-

ning, there is pneumatic pressure.

Figure 7. King Air C90A/B/GT Pneumatic and Vacuum Systems Diagram

PRESSURE

SWITCH

PNEUMATIC PRESSURE

GAUGE (IN COCKPIT)

RIGHT

SQUAT

SWITCH

OPEN IN

FLIGHT

(N.C.)

TO DEICE

BOOTS

EJECTOR

LEFT SQUAT

SWITCH

LANDING GEAR

HYDRAULIC FILL CAN

CLOSED ON

GROUND (N.O.)

L SERVO

R SERVO

VALVE

L N.C.

R N.C.

CHECK VALVE CHECK VALVE

AIRSTAIR

DOOR SEAL

LINE

EMERGENCY

EXIT SEAL

LINE

50 PSID

P SWITCH

VACUUM

REGULATOR

GYRO SUCTION

(IN COCKPIT)

GYRO

INSTRUMENTS

PRESSURIZATION

CONTROLLER,

OUTFLOW & SAFETY

VALVES

HIGH PRESSURE BLEED AIR

REGULATED BLEED AIR

VACUUM

4 PSI

PRESSURE

REGULATOR

18 PSI

PRESSURE

REGULATOR

RUDDER BOOST

SYSTEM

13 PSI

REGULATOR

GYRO

SUCTION

INCHESOFMERCURY

3 6

5 4

30K

15K

PNEUMATIC

PRESSURE

PSI

0

10

20

DEICE

DISTRIBUTER

VALVE FLIGHT

HOURS 1/00

0 0 0 0 0

LEGEND

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

Revision 0.0

FOR TRAINING PURPOSES ONLY

1-17

ICE AND RAIN PROTECTION

200/B200/B200GT Series

BRAKE DEICE

Aircraft with pneumatic brake deice systems have a BRAKE DEICE switch located in the far bottom

left ICE PROTECTION group. When selected ON, this system will continuously operate when the

landing gear is extended or for a maximum of 10 minutes when the landing gear is retracted.

ENGINE ANTI-ICE (ICE VANES)

Prior to BB-1444, the engine anti-ice (ice vanes) are normally controlled by ON/OFF switches lo-

cated on the pilots left subpanel which control electric actuators. Mechanical backup T-handles are

located below the pilots control yoke.

After BB-1444, the engine anti-ice (ice vanes) are normally controlled by an electric main actuator

as well as a electric standby actuator with ON/OFF switches as well as MAIN/STANDBY actuator

switches located on the pilots left subpanel.

PROPELLER DEICE

Systems applicable to serial numbers prior to BB-825, which was equipped with inner and outer

deice boots for each propeller blade. This system incorporated two switches: AUTO/OFF and IN-

NER/OUTER. The AUTO function performed a cycle of 30 seconds on the outer segment of the

right propeller, and then 30 seconds for the inner segment of the right propeller. This was followed

by the same sequence for the left propeller.

18 PSI

PRESSURE

REGULATOR

18 PSI

PNEUMATIC

PRESSURE

PNEU

RIGHT

P

3

AIR

PNEU

LEFT

P

3

AIR

LEFT

BRAKE

DEICE

MANIFOLD

RIGHT

BRAKE

DEICE

MANIFOLD

VDC

BRAKE

DEICE C/B

N.C. N.C.

BRAKE DEICE

N.C. VALVES

GEAR

UPLOCK

10

MIN

BRAKE DEICE

TIMER PCB

BRAKE

DEICE

DUAL FED

BUS NO.1

Figure 8. Brake Deice System

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-18

Revision 0.0

FOR TRAINING PURPOSES ONLY

ICE AND RAIN PROTECTION (Cont)

200/B200/B200GT Series (Cont)

PROPELLER DEICE (Cont)

The system applicable to serial number BB-826 and after was equipped with single segment deice

boots. This system incorporated two switches: AUTO/OFF and MANUAL/OFF. The AUTO/OFF

switch, when in the AUTO position, initiates a timer which sequences the boots in 90 second inter-

vals from one propeller to the other and the amps are shown on the prop ammeter. If the timer fails,

the manual switch can be held in the MANUAL position to bypass the timer and ammeter.

STALL WARNING

The stall warning switch, when in the ON position, applies heat to both the mounting plate and the

vane. To prevent overheating, the current available to the stall warning vane is reduced when the

aircraft is on the ground.

C90A/B/GT Series

BRAKE DEICE

This system was not available on the C90A/B/GT Series.

ENGINE ANTI-ICE (ICE VANES)

Engine anti-ice (ice vanes) are normally controlled by an electric main actuator and an electric

standby actuator with ON/OFF switches. MAIN/STANDBY actuator switches are located on the

pilots left subpanel.

PROPELLER DEICE

The propeller ice protection only has an AUTO/OFF switch. This allows the deice boots to cycle in

90 second intervals between one propeller to the other.

STALL WARNING

The stall warning switch, in the ON position, applies heat to the mounting plate only. The battery

switch applies heat to the vane through the triple-fed bus. To prevent overheating, the current avail-

able to the stall warning vane is reduced when the aircraft is on the ground.

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

Revision 0.0

FOR TRAINING PURPOSES ONLY

1-19

AIR CONDITIONING

200/B200/B200GT Series

AIR CONDITIONING

The air conditioning compressor is belt driven and mounted on the right engine. An N

1

speed switch

will prevent the compressor from operating if N

1

is below 62%. A green AIR COND N

1

LOW an-

nunciator light illuminates if air conditioning is requested and N

1

is below 62%. The air conditioning

system has an evaporator in the nose compartment with an optional aft evaporator.

BLEED AIR HEATING

When heating, a DUCT OVERTEMP annunciator will illuminate if the duct, which directs air to the

cabin foor outlets, reaches a temperature of 300F (149C). If this occurs the CABIN/COCKPIT AIR

knob can be pushed in to allow more air fow to the cabin and the light should extinguish.

SUPPLEMENTAL HEAT

Prior to BB-1444: Radiant heat was used for supplemental heating of the cabin which can be oper-

ated on the ground or in the air. The radiant heating system should be used with the manual tem-

perature control mode only. When on the ground it is highly recommended to use auxiliary power.

BB-1444 and After: Electric heat was used for supplemental heating of the cabin before engine

start when used concurrently with an auxiliary power unit. The electric heat system will draw ap-

proximately 300 amps and is used for ground operation only. For aircraft serial numbers BB-1988

and after, BY-1 and after, the electric heat system will draw approximately 160 amps and is limited

to ground operations only.

C90A/B/GT Series

AIR CONDITIONING

The compressor for the air conditioning is mounted in the nose compartment and is belt driven by

an electric motor. Only one evaporator is installed in the nose compartment.

BLEED AIR HEATING

These aircraft do not have a DUCT OVERTEMP annunciator.

SUPPLEMENTAL HEAT

Electric heat can be used to warm the cabin before engine start concurrently with an auxiliary power

unit or with both generators operating. The electric heat system will draw approximately 284 amps

and has eight elements which are divided into two sets with four elements in each set. The ELEC

HEAT switch has three positions: GND MAXNORMOFF. If GND MAX is selected, while on the

ground, the switch is solenoid-held in position and automatically drops to the NORM position when

the landing gear safety switch is opened at liftoff. In the NORM position, only one set of the four

elements are used but will be locked out to prevent an overload during operation of the propeller

deice system or windshield heat.

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

1-20

Revision 0.0

FOR TRAINING PURPOSES ONLY

PRESSURIZATION SYSTEM

200/B200/B200GT Series

On serial numbers prior to BB-854, the pressurization system is designed to provide a working pressure

differential of 6.0 0.1 psi which provides a cabin altitude of 11,700 feet at 35,000 feet (FL350).

From BB-854 and after, the pressurization system is designed to provide a working pressure differential

of 6.5 .1 psi which provides a cabin altitude of 10,400 feet at 35,000 feet (FL350).

C90A/B/GT Series

On this series of aircraft, the pressurization system is designed to provide a working pressure differential

of 5.0 .1 psi which provides a cabin altitude of 12,000 feet at 30,000 feet (FL300).

LANDING GEAR AND BRAKES

200/B200/B200GT Series

On aircraft with serial numbers prior to BB-1193 (except BB-1158 and BB-1167) had electric landing

gear not incorporating Beech Kit P/N 101-8018-1. The landing gear is held in the UP position by friction

in the jackscrew assembly. The main gear is held in the DOWN position by a notched hook and plate

attachment on the drag brace and the nose wheel by an over-center condition on the drag brace. The

maximum airspeed for manual extension is 130 KTS.

On aircraft with serial numbers of BB-1158, BB-1167, and BB-1193 and after had hydraulic landing

gear. The landing gear is held in the UP position by hydraulic pressure in the system. The main landing

gear is held in the DOWN position by mechanical down-lock mechanisms in the drag brace and the

nose wheel is held DOWN by a mechanical lock within the nose gear actuator.

C90A/B/GT Series

All aircraft serials had hydraulic landing gear. The landing gear is held in the UP position by hydraulic

pressure in the system. The main landing gear is held in the DOWN position by mechanical down-lock

mechanisms in the drag brace and the nose wheel is held DOWN by a mechanical lock within the nose

gear actuator.

FLIGHT CONTROLS

200/B200/B200GT Series

For aircraft serial numbers prior to BB-1444, these aircraft do not have follow up faps which do not

allow easy selection of the approach (40%) condition upon retracting faps. To retract the faps to the

APPROACH (40%) position from the DN (100%) position, the fap handle must be placed in the UP

position until the faps reach the desired position, then return the fap handle to APPROACH (40%)

position.

Aircraft serial numbers BB-1444 and after, have follow-up faps; therefore, only the UP, APPROACH (or

Take-Off), and DN positions are selectable. The approach selection is available on when extending or

retracting the faps.

All the 200/B200/B200GT serial number ranges have split fap protection between the inner and outer

panels of the faps on the same side.

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

KING AIR C90/200 DIFFERENCES HANDOUT

Revision 0.0

FOR TRAINING PURPOSES ONLY

1-21

FLIGHT CONTROLS (Cont)

C90A/B/GT Serials

The C90A aircraft do not have follow-up faps; therefore, the faps can be stopped anywhere between

the APPROACH and DOWN position. To retract the faps to the approach position from the full down

position, the fap handle must be placed in the full UP condition until the faps reach the desired posi-

tion, then return the fap handle to APPROACH position.

The C90B/GT aircraft have follow-up faps; therefore only the UP, APPROACH, and DN positions are

selectable. The approach selection is available when extending or retracting the faps.

OXYGEN SYSTEM

200/B200/B200GT Series

For aircraft serial numbers BB-2 through BB-54, the aircraft is equipped with a plug-in system for pas-

senger oxygen masks. This system is designed to supply adequate oxygen pressure up to an altitude

of 31,000 feet (FL310). For oxygen computations, each passenger mask is counted as one and each

crew mask is counted as two masks.

For aircraft serial numbers BB-55 and after, the aircraft is equipped with an automatic deployment

system for passenger oxygen masks. This system is designed to supply adequate oxygen pressure

up to an altitude of 31,000 feet (FL310) for the 200 serials and 35,000 feet (FL350) for B200 serials.

For oxygen computations, each passenger mask is counted as one and each crew mask is counted

as two.

C90A/B/GT Serials

For these aircraft, the oxygen system has a manual plug-in system, except for the crew which have

quick-donning masks connected to the oxygen supply lines, at all times. The oxygen system provides

an adequate fow up to an altitude of 30,000 feet (FL300). For oxygen computations, each passenger

mask is counted as one and each crew mask is counted as two masks.

Criptografia: Fred Mesquita

Criptografia: Fred Mesquita

S-ar putea să vă placă și

- PDM Challenger 605/604Document58 paginiPDM Challenger 605/604tayo_bÎncă nu există evaluări

- H8-8XP CRHDocument560 paginiH8-8XP CRHJaime Arroyo100% (1)

- King Air C90ABGT Pilot Training ManualDocument409 paginiKing Air C90ABGT Pilot Training ManualFabio100% (8)

- An Aviator's Field Guide to Middle-Altitude Flying: Practical skills and tips for flying between 10,000 and 25,000 feet MSLDe la EverandAn Aviator's Field Guide to Middle-Altitude Flying: Practical skills and tips for flying between 10,000 and 25,000 feet MSLEvaluare: 4.5 din 5 stele4.5/5 (2)

- 500 Series Technical Review October 2012Document41 pagini500 Series Technical Review October 2012Melinda Hudson100% (1)

- Flying the Light Retractables: A guided tour through the most popular complex single-engine airplanesDe la EverandFlying the Light Retractables: A guided tour through the most popular complex single-engine airplanesÎncă nu există evaluări

- Falcon 50 Checklist PDFDocument402 paginiFalcon 50 Checklist PDFJosé A. Montiel Quirós100% (2)

- Pilot Check List - PCL - BE40Document174 paginiPilot Check List - PCL - BE40Gustavo Souza100% (1)

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsDe la EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsEvaluare: 5 din 5 stele5/5 (1)

- PA31Document9 paginiPA31dagger21100% (3)

- BE20 Cockpit Reference PDFDocument438 paginiBE20 Cockpit Reference PDFmalsr100% (1)

- Beech King Air B200 Tech QuizDocument20 paginiBeech King Air B200 Tech QuizSaisvam Chandrasekaran80% (10)

- Beechcraft King Air B100-King Air B100 Reference Manual - Rev 0pdf PDFDocument299 paginiBeechcraft King Air B100-King Air B100 Reference Manual - Rev 0pdf PDFricardo perez100% (4)

- Piper Progressive Inspection 100 Hour Cycle: CheyenneDocument66 paginiPiper Progressive Inspection 100 Hour Cycle: CheyenneJavier JaureguiÎncă nu există evaluări

- King Air C90 A-BDocument342 paginiKing Air C90 A-BBruno Graziano Almeida Migliavacca94% (18)

- Turbo Commander MELDocument53 paginiTurbo Commander MELAndre Peli100% (5)

- Beechcraft Baron 58Document24 paginiBeechcraft Baron 58tayo_b100% (1)

- King Air 350 Limitations, Specs, and Study Guide N Compressor N PropellerDocument4 paginiKing Air 350 Limitations, Specs, and Study Guide N Compressor N PropellerMikeÎncă nu există evaluări

- Metro NormDocument12 paginiMetro NormFrancisco Martinez Barreira67% (3)

- Hawker 800xp SpecsDocument5 paginiHawker 800xp SpecsCooper L100% (2)

- Commander Package 2013Document20 paginiCommander Package 2013Carlos Marquez100% (1)

- C90GTi Pilot Check List Flight Safety PDFDocument107 paginiC90GTi Pilot Check List Flight Safety PDFRaoul Penent d'Izarn100% (1)

- Project Management Tools and TechniquesDocument32 paginiProject Management Tools and TechniquesReena Sanehi100% (2)

- King Air 300: Operating HandbookDocument92 paginiKing Air 300: Operating HandbookMoises Sanchez100% (2)

- KA 300 Memory Flash CardsDocument110 paginiKA 300 Memory Flash CardsRafaelMolina100% (1)

- Car RentalDocument30 paginiCar RentalKarthik Arumugham100% (5)

- 12 Ice RainDocument10 pagini12 Ice RainBlueSkyMaster100% (2)

- Aid Smith Bell 206 ChecklistDocument1 paginăAid Smith Bell 206 Checklistchris josephsÎncă nu există evaluări

- Cheyenne - APDocument14 paginiCheyenne - APtumb100% (1)

- Wheels Up 2017 King Air 350i SN FL 1099 N868up Vref DirectDocument10 paginiWheels Up 2017 King Air 350i SN FL 1099 N868up Vref Directnormand67Încă nu există evaluări

- Beechcraft 350iDocument18 paginiBeechcraft 350iBhaskerNegi100% (2)

- 757-767 Study GuideDocument117 pagini757-767 Study Guideviegas123100% (1)

- King Air GVBCD Operations ManualDocument50 paginiKing Air GVBCD Operations ManualBrendanRatchford100% (2)

- Checklist c90 Rev 1Document2 paginiChecklist c90 Rev 1Gilberto FonsecaÎncă nu există evaluări

- 1super King Air Series MTM V1Document590 pagini1super King Air Series MTM V1C. CONTRERAS100% (1)

- KING AIR 300 Study QuestionsDocument6 paginiKING AIR 300 Study QuestionsMike100% (1)

- Cheyenne - Pressurization SystemDocument3 paginiCheyenne - Pressurization Systemtumb100% (1)

- Cessna 340 340ADocument8 paginiCessna 340 340Ajoserufoperezarias100% (2)

- Beechcraft King Air C90 PTM PDFDocument374 paginiBeechcraft King Air C90 PTM PDFwolmert100% (7)

- Manual de Mantenimieno Del PapyerDocument1.561 paginiManual de Mantenimieno Del PapyerBRAYAN DAVID CHAMBO GONZALEZÎncă nu există evaluări

- Pa31t OmDocument91 paginiPa31t OmPercy HornickelÎncă nu există evaluări

- Operational Suitability Data (OSD) Flight CrewDocument40 paginiOperational Suitability Data (OSD) Flight CrewVincent Lefeuvre100% (1)

- 350ER Pilot Checklist P - N 130-590031-273Document142 pagini350ER Pilot Checklist P - N 130-590031-273Hassan Ali Cheema100% (1)

- Title Page - King Air F90Document1 paginăTitle Page - King Air F90sergio0% (1)

- Raytheon Beech King Air C90A Pilot's Technical Examination: CandidateDocument20 paginiRaytheon Beech King Air C90A Pilot's Technical Examination: CandidateEduardo Almeida Silva100% (1)

- Snap728 enDocument8 paginiSnap728 enRajÎncă nu există evaluări

- Ska M300 Check ListDocument110 paginiSka M300 Check ListJose Francisco Colina100% (2)

- Flight1 441 Conquest TutorialDocument10 paginiFlight1 441 Conquest TutorialJosé A. Montiel QuirósÎncă nu există evaluări

- Handbook PDFDocument71 paginiHandbook PDFCarlos Navarro PalominoÎncă nu există evaluări

- Training Checklist - King Air F90Document52 paginiTraining Checklist - King Air F90Bruno Martins Machado100% (1)

- Pilot Operating Handbook For Rockwell Turbo Commander 690BDocument18 paginiPilot Operating Handbook For Rockwell Turbo Commander 690BGuillermo Hernández100% (1)

- King 300Document304 paginiKing 300Diego Bran100% (1)

- Introduction To Production and Operations ManagementDocument17 paginiIntroduction To Production and Operations ManagementSyed M. Fakharullah KazmiÎncă nu există evaluări

- C90GT Pre-Course Study GuideDocument32 paginiC90GT Pre-Course Study GuideRaoul Penent d'Izarn100% (1)

- Metro 3 Operating Tips PDFDocument18 paginiMetro 3 Operating Tips PDFFatih Iscan100% (1)

- King C90Document322 paginiKing C90Marcelo Lorenzon50% (2)

- Bonanza A36 PohDocument250 paginiBonanza A36 Pohalvarone100% (1)

- Public TransportDocument8 paginiPublic TransportAkhmal HaziqÎncă nu există evaluări

- Faa-Approved Pilot'S Operating Handbook and Airplane Flight Manual Supplement For TheDocument161 paginiFaa-Approved Pilot'S Operating Handbook and Airplane Flight Manual Supplement For TheErdem ArıkanÎncă nu există evaluări

- Pipper Navajo Electric SystemDocument163 paginiPipper Navajo Electric SystemHerri Sutrisna100% (1)

- C90B Performance TablesDocument8 paginiC90B Performance TablesCarlos MarquezÎncă nu există evaluări

- Cessna 182 Pilots Operating Handbook (1966)Document31 paginiCessna 182 Pilots Operating Handbook (1966)Gustavo Adolfo Términe100% (1)

- Beon For Suppliers: It-& Process-Qualifications Audi AgDocument4 paginiBeon For Suppliers: It-& Process-Qualifications Audi AgJavier Alejandro Roman MoncadaÎncă nu există evaluări

- Glotut 01 AnsDocument2 paginiGlotut 01 AnsJean LawÎncă nu există evaluări

- Intelligent BPM The Next Wave For Customer Centric Business Applications - Khoshafian PDFDocument212 paginiIntelligent BPM The Next Wave For Customer Centric Business Applications - Khoshafian PDFVintila AlexandraÎncă nu există evaluări

- MICHIGAN MOTORZ - New Engine Warranty InformationDocument2 paginiMICHIGAN MOTORZ - New Engine Warranty InformationDaddyos Marine EnginesÎncă nu există evaluări

- Draft Determination To Resolve A Dispute Between Stour Marine and O2 About Termination RatesDocument75 paginiDraft Determination To Resolve A Dispute Between Stour Marine and O2 About Termination RatesalifatehitqmÎncă nu există evaluări

- Selecting ERPs PDFDocument17 paginiSelecting ERPs PDFlucky414Încă nu există evaluări

- A Project Report On Analysis of Financial Statement at Kirloskar Project Report Mba FinanceDocument86 paginiA Project Report On Analysis of Financial Statement at Kirloskar Project Report Mba FinanceAmar Singh KushwahÎncă nu există evaluări

- JasperReports Server CP Install GuideDocument68 paginiJasperReports Server CP Install GuideDavid LoaisigaÎncă nu există evaluări

- Higueras Castillo2020Document16 paginiHigueras Castillo2020Duryodhan vithal PendamÎncă nu există evaluări

- Thesis Chapter IDocument8 paginiThesis Chapter Ijessie julongbayanÎncă nu există evaluări

- No.56 Vignarajan Nagar IAF Post, Avadi Chennai-600055.: N.BalasubramanianDocument1 paginăNo.56 Vignarajan Nagar IAF Post, Avadi Chennai-600055.: N.BalasubramanianbalakarnÎncă nu există evaluări

- Asme B18.5.2.1M 1996Document8 paginiAsme B18.5.2.1M 1996Jesse ChenÎncă nu există evaluări

- StickerDocument1 paginăStickerCiv HerreraÎncă nu există evaluări

- LOPAS SA Company Profile - ENDocument63 paginiLOPAS SA Company Profile - ENCyril Jean-BaptisteÎncă nu există evaluări

- Metro de Madrid PresentationDocument39 paginiMetro de Madrid PresentationMarton CavaniÎncă nu există evaluări

- Activity Based CostingDocument20 paginiActivity Based CostingPrashanth DarÎncă nu există evaluări

- GlobalSample Pakistan ExportDocument6 paginiGlobalSample Pakistan ExportFarhan WahidÎncă nu există evaluări

- Cardan Case Study1Document2 paginiCardan Case Study1JJÎncă nu există evaluări

- World Audio Level Reference PDFDocument1 paginăWorld Audio Level Reference PDFHector Herrera ChavezÎncă nu există evaluări

- Animesh Roy Pune 8.00 YrsDocument7 paginiAnimesh Roy Pune 8.00 Yrskingkong2011Încă nu există evaluări

- Product Quality in Part Banbury: The Application of Kaizen in Improving Efficiency and PT Bridgestone Tire IndonesiaDocument18 paginiProduct Quality in Part Banbury: The Application of Kaizen in Improving Efficiency and PT Bridgestone Tire IndonesiawilliamÎncă nu există evaluări

- Quest SQL Optimizer For Oracle 7.5.3Document47 paginiQuest SQL Optimizer For Oracle 7.5.3awda0Încă nu există evaluări

- Astm-B601 Temper TerminologyDocument5 paginiAstm-B601 Temper TerminologyAloke BhaduriÎncă nu există evaluări

- Project ProposalDocument4 paginiProject ProposalSele KondoÎncă nu există evaluări