Documente Academic

Documente Profesional

Documente Cultură

R-Values of SPF

Încărcat de

Jason MillerTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

R-Values of SPF

Încărcat de

Jason MillerDrepturi de autor:

Formate disponibile

Insulation R-value, What does it really mean?

Every designer knows that the R-value of a material is important in specifying insulation

products. Regulations abound that require minimum R-values for wall, ceiling and roof

assemblies in buildings. But are R-values reliable in predicting energy performance?

This article will address the test methods used to determine R-values and their relative

degree of accuracy.

What is an R-value?

As most of you already know, we dont really measure R-values, we measure the

K-factor of a material. The K factor is the thermal conductivity for a unit thickness of

material. The lower the K-factor the better the insulation.

R-value is the reciprocal of K factor and reports the resistance to heat transfer of a given

material. So once the researcher determines the K-factor, they divide the K-factor into 1

to obtain the R-value. Example: If the K-factor were 0.166, then the R-value would be

6.02.

The higher the R-value the better the insulation

Once you have an R-value of a material, it becomes much easier to determine the overall

thermal conductance of the building assembly (U factor). In order to obtain the U factor,

add the total R-values of the materials in an assembly then divide it into 1.

How do you measure for K-factor and R-value?

ASTM developed standards for the most commonly used insulation products including

fiberglass, cellulose, polyiso board, expanded polystyrene foam, extruded polystyrene

foam and spray polyurethane foam and code bodies and governmental agencies most

commonly require the test methods referenced in the material standards.

There are 3 basic test methods used most frequently to measure R-value;

ASTM C 177 Standard Test Method for Steady-State Heat Flux Measurements

and Thermal Transmission Properties by Means of the Guarded Hot-Plate

Apparatus;

ASTM C 518, Standard Test Method for Steady-State Heat Flux Measurements

and Thermal Transmission Properties by Means of the Heat Flow Meter

Apparatus;

ASTM C 976 Standard Test Method for Thermal Performance of Building

Assemblies by Means of a Calibrated Hot Box;

In addition to these tests, there is an ASTM Standard Test Method for estimating the long

term R-value of foam insulation, ASTM C-1303. While the other test methods are actual

measurements, ASTM C-1303 is an estimate that uses short-term measurements to

predict R-values of foam plastics over a longer period of time.

R-values reported from the tests can vary depending on how the samples were prepared,

the thickness of the sample and the type of test apparatus.

For example, when testing spray polyurethane foam (SPF) for its R-value according to

ASTM C-1029 (Standard Specification for Spray Applied Cellular Polyurethane

Insulation) both ASTM C-518 and ASTM C177 require a 12x 12 x 1 sample cut from

a sprayed board of foam. After aging the material 6 months in a controlled environment,

the foams R-value is measured. The 6-month aged R-values are the measurements

accepted by FTC and are used by a majority of the SPF industry. Typical aged SPF R-

values from ASTM C-518 and C-177 range from 5.6 to 6.2 per inch. However, another

test procedure, ASTM C-976 consists of measuring the R-value of SPF installed in an 8

x 8 wall at the installed thickness. These tests typically provide higher R-values than

ASTM C-518 or C-177 measurements for SPF thickness greater than 2 inches.

Why? R-values of some foam plastics such as extruded polystyrene, polyiso and SPF can

vary depending on the thickness of the foam and whether the foam is measured with or

without being adhered to a substrate. Factors affecting the R-value include: thickness of

application, (the thicker the foam the better the aged R-value) the substrate and covering

systems used, (the lower the perm rated covering and substrate, the higher the aged R-

value).

Robert Alumbaugh, a researcher with the Navy studied the aged R-values (between 5 to

10 years) of SPF on test panels at the Naval Station in Port Hueneme, CA. According to

Alumbaughs research SPF sprayed to a high perm rated substrate such as wood or

concrete ranged from 5.8 to 6.2 R-value per inch at a 1 to 3-inch thickness, but the same

SPF applied to metal decks ranged from 6.5 to 7.3 R-value per inch. Other researchers

such as Mark Bomberg with the National Research Center of Canada and Andre

Desjarlais with the Oak Ridge Laboratories, U.S. Department of Energy observed similar

results.

The type of blowing agent used can also affect the R-value, CFC, HCFC, HFC and

hydrocarbon blown SPF range within the R-values described above, while water blown

foams typically have much lower R-values. Blends of these blowing agents with water

can also affect the R-value.

Why dont we settle on one test method that works for everyone? The problem with this

solution is there is no one test that works best for all products. So we are left with the

process of determining the test methods, sample preparation and conditioning procedures

that are accurate, reproducible and relate to actual field performance of specific materials.

It is not too difficult to find test methods that are accurate and reproducible, but to have

one that relates to actual field performance is a challenge. Remember also that R-values

only measure conduction of heat not radiation or convection. It also does not take into

consideration R-value reductions caused by thermal bridging, humidity, temperature

changes, air infiltration and wind.

At present the typical approach to determine actual field performance is to start with the

R-value from small sample testing, and using other test procedures determine the

insulation efficiency reduction based on air infiltration, thermal bridging and other

considerations. The results from these tests can vary widely depending on assumptions

made. For example, in the 1980s to 1990s ASHRAE surveyed typical residential

construction for air leakage using a blower door test. The results of their survey was

published as a table in the ASHRAEs Fundamentals Handbook and determined that the

typical house had 1-1/2 air exchanges per hour. This would be the equivalent of having a

two-inch hole in each of your 8x 8 wall assemblies. In moderate climates such as

southern California or Hawaii, this might not be a significant factor, but in South Texas

or Minnesota the air leakage would reduce the energy efficiency of any building

considerably. However, Oakridge National Laboratories (ORNL) more recent survey

concluded that the total air exchanges in new houses is closer to 0.32 air exchanges per

hour which would be the equivalent of a 1/2" hole in the same 8x8 wall assembly.

(ORNL attributes the tighter housing to improved construction techniques and sealing

materials such as foam sealants and housewrap.)

ASHRAE also publishes a table referenced in the 2003 International Energy

Conservation Code that calculates the reduction of R-value based on thermal bridging. In

roofing applications, thermal bridging (brought on by gaps in insulation boards, fasteners,

etc. can reduce the R-value from 5% to 35% depending on the size of the gaps, type and

number of fasteners.

In conclusion, the tools to more accurately predict energy efficiency of building products

and assemblies are getting better every day. But it is up to the designer to take advantage

of these tools to ensure that the R-value required is being achieved in the design.

SIDE BAR

ASTM R-value Measurement Tests:

ASTM C-177: Standard Test Method for Steady-State Heat Flux

Measurements and Thermal Transmission Properties of the Guarded Hot Plate

Apparatus.

This test method measures the steady-state heat flux through homogeneous flat

specimens. Two test specimens (as identical as possible) are placed on both sides of a

guarded hot plate and in contact on the other side with a cold surface assembly.

Compliance with this test requires the establishment of steady-state conditions (same

temperature across the assembly) and the measurement of the heat flow in one direction.

The apparatus is called guarded because it is insulated on the edges to minimize or

prevent lateral heat flow, which would corrupt the results.

Cold Surface Assembly

Specimen

----Guard---- ---Hot Plate-- --Guard--

Specimen

Cold Surface Assembly

ASTM C-518: Standard Test Method for Steady-State Thermal Transmission

Properties by Means of the Heat Flow Meter Apparatus

This test method covers the measurement of steady-state thermal transmission through

flat slab specimens using a heat flow meter. One test specimen is placed between a cold

plate and a hot plate. One or more heat flux transducers can be used.

Example 1

Cold Plate

Specimen

Heat Flux Transducer

Hot Plate

Example 2

Hot Plate

Specimen

Heat Flux Transducer

Specimen

Cold Plate

Example 3

Cold Plate

Heat Flux Transducer

Specimen

Heat Flux Transducer

Hot Plate

ASTM C-976: Standard Test Method for Thermal Performance of Building

Assemblies by Means of a Calibrated Hot Box.

The test method provides for laboratory measurement of heat transfer through a specimen

under controlled air temperature, air velocity and radiation conditions established in a

metering chamber on one side and in a climatic chamber on the other side.

The calibrated hotbox method is specially suited for large non-homogeneous specimens

such as building structures and composite assemblies. It can also be used for

measurements of individual building elements such as windows and doors. The chamber

can be configured for wall assemblies or attics and floors.

ASTM C-1303: Standard Test Method for Estimating the Long-Term Change in the

Thermal Resistance of Unfaced Rigid Closed Cell Plastic Foams by Slicing and

Scaling Under Controlled Laboratory Conditions.

The test method covers a procedure for estimating long-term change in thermal resistance

of un-faced foam plastic, by reducing the thickness of the sample to accelerate aging

under controlled laboratory conditions.

Standard test procedures such as ASTM C-177 and ASTM C-518 are utilized to measure

the thermal resistance of thin sliced test specimens at short time intervals (up to 6

months). These measurements are then used to estimate the predicted aged R-value of

materials for longer time intervals (typically 2.5 to 40 years). It should be noted that this

test method is an estimate and not a true measurement. Some products such as polyiso

board with facers and SPF may not be appropriate for ASTM C-1303 estimates due to

their non-homogenic nature and adherence to facers or substrates.

References: (to follow)

S-ar putea să vă placă și

- Development of A New Hot Box Apparatus To Measure Building Enclosure Thermal PerformanceDocument19 paginiDevelopment of A New Hot Box Apparatus To Measure Building Enclosure Thermal PerformanceFrancisco José Moralejo100% (1)

- Geo S Ience TestingDocument4 paginiGeo S Ience TestingAzad RahmanÎncă nu există evaluări

- RR 0901 Thermal Metrics High Performance Walls Limitations R ValueDocument30 paginiRR 0901 Thermal Metrics High Performance Walls Limitations R ValueMohammed AliÎncă nu există evaluări

- Radiator Heat Transfer Augmentation by Changes To Wall Surface Roughness and EmissivityDocument16 paginiRadiator Heat Transfer Augmentation by Changes To Wall Surface Roughness and EmissivitywillalizadeÎncă nu există evaluări

- ASTM D 3012 - 00 Thermal-Oxidative Stability of Polypropylene Using A Specimen Rotator Within An OvenDocument6 paginiASTM D 3012 - 00 Thermal-Oxidative Stability of Polypropylene Using A Specimen Rotator Within An Ovenalin2005Încă nu există evaluări

- CMHC Vapor Barrier Study Phase II-SmallDocument25 paginiCMHC Vapor Barrier Study Phase II-SmallJohn StraubeÎncă nu există evaluări

- C653Document5 paginiC653dinhtung2210Încă nu există evaluări

- TR Value Testing PDFDocument11 paginiTR Value Testing PDFKingsley InbasinghÎncă nu există evaluări

- Thermal Contact Resistance in Insulated PipesDocument7 paginiThermal Contact Resistance in Insulated PipesAnkur JainÎncă nu există evaluări

- Prp-1018 Thermal & Moisture Transport Database For Common BLDG & Insulating MaterialsDocument229 paginiPrp-1018 Thermal & Moisture Transport Database For Common BLDG & Insulating Materialsjdietz4Încă nu există evaluări

- Design Concepts For A New Guarded Hot Plate Apparatus For Use Over An Extended Temperature RangeDocument37 paginiDesign Concepts For A New Guarded Hot Plate Apparatus For Use Over An Extended Temperature RangealpegambarliÎncă nu există evaluări

- Author's Accepted Manuscript: Case Studies in Thermal EngineeringDocument12 paginiAuthor's Accepted Manuscript: Case Studies in Thermal EngineeringEmilio SassineÎncă nu există evaluări

- U Value CalculationsDocument5 paginiU Value CalculationsSalley BukhariÎncă nu există evaluări

- ASTM D4541 Coating Adhesion Testing in Accordance With PDFDocument2 paginiASTM D4541 Coating Adhesion Testing in Accordance With PDFHaldirLeao100% (1)

- Nonlinear Thermal Analyses of A Liquid Hydrogen Tank WallDocument27 paginiNonlinear Thermal Analyses of A Liquid Hydrogen Tank WallSaad Al HelyÎncă nu există evaluări

- Article CFB Anslysis On Coal State Test of 300MW CFB BoilerDocument8 paginiArticle CFB Anslysis On Coal State Test of 300MW CFB Boilernguyenhuutan91Încă nu există evaluări

- D 5516 - 02 - Rdu1mtytukveDocument9 paginiD 5516 - 02 - Rdu1mtytukveEd Riveros FerilÎncă nu există evaluări

- Solidification Point Of: Test Method For - XyleneDocument3 paginiSolidification Point Of: Test Method For - XyleneCarlos SaldañaÎncă nu există evaluări

- D 2471Document26 paginiD 2471Luis Enrique Quispe Hancco0% (1)

- 47IJMPERDJUN201947Document14 pagini47IJMPERDJUN201947TJPRC PublicationsÎncă nu există evaluări

- D 6841 - 02 - Rdy4ndetukveDocument7 paginiD 6841 - 02 - Rdy4ndetukveM Mirza Abdillah PratamaÎncă nu există evaluări

- C 356 - 87 R97 - Qzm1ni1sruqDocument5 paginiC 356 - 87 R97 - Qzm1ni1sruqElvis Lionel FLORES ROCAÎncă nu există evaluări

- 14 Testing and Failure AnalysisDocument24 pagini14 Testing and Failure AnalysisEdith Chavez LindosÎncă nu există evaluări

- On Brick Construction: Technical NotesDocument13 paginiOn Brick Construction: Technical NotesamokhtaÎncă nu există evaluări

- tn-16 Rate Process Method Projecting Pe PipeDocument8 paginitn-16 Rate Process Method Projecting Pe Pipeyrdna nawaiteos100% (1)

- Comparison Between BS and UL-ASTM 2012 CDA-1Document3 paginiComparison Between BS and UL-ASTM 2012 CDA-1Samet CelıkÎncă nu există evaluări

- Tested R-Value For Straw Bale Walls and Performance Modeling For Straw Bale HomesDocument10 paginiTested R-Value For Straw Bale Walls and Performance Modeling For Straw Bale HomesElsa LaminÎncă nu există evaluări

- Thermal performance parameters for non-AC buildingsDocument19 paginiThermal performance parameters for non-AC buildingsNirbhay SinghÎncă nu există evaluări

- ASTM E 84 TestDocument36 paginiASTM E 84 TestseetharamannÎncă nu există evaluări

- Astm D5930.1207343-1 Condutividade Termica PDFDocument5 paginiAstm D5930.1207343-1 Condutividade Termica PDFtadeuafÎncă nu există evaluări

- RHO Related PDFDocument11 paginiRHO Related PDFelectrical_1012000Încă nu există evaluări

- D 3895 - 02 OitDocument8 paginiD 3895 - 02 Oitגבריאל קליןÎncă nu există evaluări

- A Method For The Temperature Calibration of Pushrod DilatometersDocument9 paginiA Method For The Temperature Calibration of Pushrod DilatometerszairaÎncă nu există evaluări

- Thermal BridgingDocument13 paginiThermal BridgingVinod VkÎncă nu există evaluări

- Heat Transfer Improvement in Radiator by Effect of Different Walls EmissivityDocument4 paginiHeat Transfer Improvement in Radiator by Effect of Different Walls EmissivityIJORATÎncă nu există evaluări

- D 5334 - 92 - Rduzmzqtukve PDFDocument8 paginiD 5334 - 92 - Rduzmzqtukve PDFchabibÎncă nu există evaluări

- Astm E84 2001Document19 paginiAstm E84 2001Nirav Desai100% (2)

- Determination of Resistance To Abrasion at Ambient Temperature in Order To Establish Better Comparability Between Laboratories, Existing Standards Have To Be RevisedDocument6 paginiDetermination of Resistance To Abrasion at Ambient Temperature in Order To Establish Better Comparability Between Laboratories, Existing Standards Have To Be RevisedpetemberÎncă nu există evaluări

- Oxidative-Induction Time of Polyolefins by Differential Scanning CalorimetryDocument7 paginiOxidative-Induction Time of Polyolefins by Differential Scanning CalorimetryScott RamirezÎncă nu există evaluări

- The Requirements of California Residential Code R302.10 (Based On ASTM E84 Testing)Document6 paginiThe Requirements of California Residential Code R302.10 (Based On ASTM E84 Testing)vytoÎncă nu există evaluări

- US Legally Binding Document Establishes Water Vapor Transmission Test MethodsDocument10 paginiUS Legally Binding Document Establishes Water Vapor Transmission Test MethodsKasra GolbanÎncă nu există evaluări

- Fire Test ComparisonDocument20 paginiFire Test ComparisonMasahiko HiganeÎncă nu există evaluări

- A Comparison of Techniques To Measure Commercial Building Infiltration RatesDocument8 paginiA Comparison of Techniques To Measure Commercial Building Infiltration RatesSathiaram RamÎncă nu există evaluări

- Air Leakage Tests For The Requirements of The LEED in Two High-Rise Residential BuildingsDocument8 paginiAir Leakage Tests For The Requirements of The LEED in Two High-Rise Residential BuildingsSathiaram RamÎncă nu există evaluări

- Guide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodsDocument24 paginiGuide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodszaheermechÎncă nu există evaluări

- Recommending Piping Materials for Corrosive EnvironmentsDocument13 paginiRecommending Piping Materials for Corrosive Environmentsquikmusic10Încă nu există evaluări

- Revising Abrasion Resistance Standards for Better ComparabilityDocument6 paginiRevising Abrasion Resistance Standards for Better ComparabilityLeenmackÎncă nu există evaluări

- The Significance of Bolts in The Thermal Performance of Curtain-Wall Frames For Glazed FacadesDocument16 paginiThe Significance of Bolts in The Thermal Performance of Curtain-Wall Frames For Glazed FacadesSaka NguyenÎncă nu există evaluări

- D 2164 Â " 83 R94 RDIXNJQTODNSOTRFMQDocument8 paginiD 2164 Â " 83 R94 RDIXNJQTODNSOTRFMQdorbarelÎncă nu există evaluări

- Air Leakage DissertationDocument4 paginiAir Leakage DissertationWriteMyPaperInApaFormatBuffalo100% (1)

- ASTM D 3895 2007 8pDocument8 paginiASTM D 3895 2007 8psandrasilvabr2124100% (1)

- Ul - Pal PirDocument5 paginiUl - Pal PirSatish ChakravarthyÎncă nu există evaluări

- Thermal Resistance Measurements of Two-And Three-D Thermal Bridges Using An ASTM C177-Based ApparatusDocument9 paginiThermal Resistance Measurements of Two-And Three-D Thermal Bridges Using An ASTM C177-Based ApparatusBan ZanganaÎncă nu există evaluări

- E 1529 - 93 Rte1mjktukveDocument19 paginiE 1529 - 93 Rte1mjktukveRufo CascoÎncă nu există evaluări

- Fast method predicts slow crack growth in HDPE pipeDocument7 paginiFast method predicts slow crack growth in HDPE pipeMehboob ulHaqÎncă nu există evaluări

- Jres NIST-122-023 - Validation Indirecte CharpyDocument11 paginiJres NIST-122-023 - Validation Indirecte CharpypresleÎncă nu există evaluări

- Whole Wall Performance Analysis of Autoclaved Aerated Concrete An Example of Collaboration Between Industry and A Research Lab On Development of Energy Efficient Building Envelope SystemsDocument12 paginiWhole Wall Performance Analysis of Autoclaved Aerated Concrete An Example of Collaboration Between Industry and A Research Lab On Development of Energy Efficient Building Envelope Systemsh2odavidÎncă nu există evaluări

- Astm e 648 Rev A 2006Document14 paginiAstm e 648 Rev A 2006Jorge ToribioÎncă nu există evaluări

- ASTM Testing ProcedureDocument7 paginiASTM Testing Procedurederecka100% (1)

- Advanced Temperature Measurement and Control, Second EditionDe la EverandAdvanced Temperature Measurement and Control, Second EditionÎncă nu există evaluări

- Fun With Tool PalettesDocument12 paginiFun With Tool PalettesJason MillerÎncă nu există evaluări

- Crosby Rigging EquipmentDocument20 paginiCrosby Rigging EquipmentJason MillerÎncă nu există evaluări

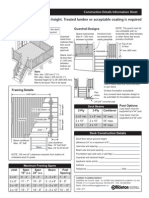

- Deck Under 6 Feet Construction Information HandoutDocument1 paginăDeck Under 6 Feet Construction Information HandoutJason MillerÎncă nu există evaluări

- Hvac SizingDocument3 paginiHvac SizingnubazÎncă nu există evaluări

- Style 997 Transition Coupling HDPE Plastic To Steel: Product DescriptionDocument2 paginiStyle 997 Transition Coupling HDPE Plastic To Steel: Product DescriptionJason MillerÎncă nu există evaluări

- Calculating Heat Loss From A RoomDocument4 paginiCalculating Heat Loss From A RoomJason MillerÎncă nu există evaluări

- Endseal Pipe Groove SpecificationsDocument4 paginiEndseal Pipe Groove SpecificationsJason MillerÎncă nu există evaluări

- Techsheet Cold TapDocument1 paginăTechsheet Cold TapJason MillerÎncă nu există evaluări

- Pad Eye Design Lifting Lug StandartDocument7 paginiPad Eye Design Lifting Lug Standartstalin_83Încă nu există evaluări

- Fossil Fuel and The Environment PPT Project FinalDocument14 paginiFossil Fuel and The Environment PPT Project Finalapi-298052133Încă nu există evaluări

- Traxonecue Catalogue 2011 Revise 2 Low Res Eng (4!5!2011)Document62 paginiTraxonecue Catalogue 2011 Revise 2 Low Res Eng (4!5!2011)Wilson ChimÎncă nu există evaluări

- BS 7941-1-2006Document20 paginiBS 7941-1-2006Willy AryansahÎncă nu există evaluări

- CalderaDocument56 paginiCalderaEsteban TapiaÎncă nu există evaluări

- Research Article (Lavandula Angustifolia) Essential Oil On: Effect of Lavender Acute Inflammatory ResponseDocument10 paginiResearch Article (Lavandula Angustifolia) Essential Oil On: Effect of Lavender Acute Inflammatory ResponseAndreeaÎncă nu există evaluări

- 32776Document6 pagini32776Muqtar KhanÎncă nu există evaluări

- Real Possibility of Future ConditionDocument3 paginiReal Possibility of Future ConditionHusÎncă nu există evaluări

- Cambridge International AS & A Level: Mathematics 9709/13Document20 paginiCambridge International AS & A Level: Mathematics 9709/13Justin OngÎncă nu există evaluări

- AWWA M28 Rehabilitation of Water Mains 3rd Ed 2014Document133 paginiAWWA M28 Rehabilitation of Water Mains 3rd Ed 2014millini67% (3)

- Fundamentals of SwimmingDocument7 paginiFundamentals of SwimmingSheila Mae Lira100% (1)

- Indo American Journal of Pharmaceutical Research (India)Document4 paginiIndo American Journal of Pharmaceutical Research (India)Pharmacy2011journalsÎncă nu există evaluări

- National Leprosy Control Program For CHNDocument18 paginiNational Leprosy Control Program For CHNNaomi Cyden YapÎncă nu există evaluări

- Cryptography 01092014Document19 paginiCryptography 01092014Anshu MittalÎncă nu există evaluări

- Mahavir Glass Proforma InvoiceDocument2 paginiMahavir Glass Proforma Invoicemahendra patelÎncă nu există evaluări

- 692pu 6 6Document1 pagină692pu 6 6Diego GodoyÎncă nu există evaluări

- The Ultimate Life GuideDocument12 paginiThe Ultimate Life GuideNLPCoachingÎncă nu există evaluări

- 2019 Torch and Consumables Catalog: For Mechanized Plasma SystemsDocument64 pagini2019 Torch and Consumables Catalog: For Mechanized Plasma SystemsRaj DomadiyaÎncă nu există evaluări

- Msds PentaneDocument6 paginiMsds PentaneMuhammad FikriansyahÎncă nu există evaluări

- Electrolyte Turns On The Solar Cell: 2009 Project SummaryDocument1 paginăElectrolyte Turns On The Solar Cell: 2009 Project SummaryAshu SarasÎncă nu există evaluări

- Higher-Order InteractionsDocument6 paginiHigher-Order Interactions山木Încă nu există evaluări

- Return SectionDocument1 paginăReturn SectionDaniel Pouso DiosÎncă nu există evaluări

- Spectrophotometric Determination of Triclosan Based On Diazotization Reaction: Response Surface Optimization Using Box - Behnken DesignDocument1 paginăSpectrophotometric Determination of Triclosan Based On Diazotization Reaction: Response Surface Optimization Using Box - Behnken DesignFitra NugrahaÎncă nu există evaluări

- Psychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)Document48 paginiPsychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)sfrtr100% (1)

- Ego7 Manual enDocument76 paginiEgo7 Manual ensullivanj69Încă nu există evaluări

- Psychoacoustics: Art Medium SoundDocument3 paginiPsychoacoustics: Art Medium SoundTheodora CristinaÎncă nu există evaluări

- BASIC IMMUNOLOGY TERMSDocument2 paginiBASIC IMMUNOLOGY TERMSAnnicoldjohn LariozaÎncă nu există evaluări

- Pancreatic NekrosisDocument8 paginiPancreatic Nekrosisrisyda_mkhÎncă nu există evaluări

- Kinematics Problem SetDocument1 paginăKinematics Problem SetMohammad JubranÎncă nu există evaluări

- Rizal's Allegorical Play 'El Consejo de Los DiosesDocument9 paginiRizal's Allegorical Play 'El Consejo de Los DiosesAlexiahree ChaiÎncă nu există evaluări

- Torn MeniscusDocument10 paginiTorn MeniscusKrystal Veverka100% (3)