Documente Academic

Documente Profesional

Documente Cultură

Teca Peek Med

Încărcat de

Oscar CruzDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Teca Peek Med

Încărcat de

Oscar CruzDrepturi de autor:

Formate disponibile

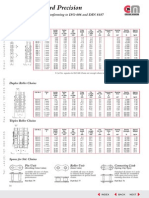

MATERIAL AVAILABILITY

Rods: Diameters: 3/16 to 4-3/4 diameter, 10 Length

5 and greater diameter, 5 Length

Primary Specification (Resin) (Typical)

Plates: 1/4 to 4 thickness inclusive are 2 x 4

Shapes Specification (Typical)

ASTM-D-6262 S-PAEK0111

ASTM-D-6262 S-PAEK0122

TYPICAL PROPERTY VALUES

Density

Specific Gravity

Water Absorption, @24 hours, 73F

@Saturation, 73F

D792

D792

D570

D570

lbs/in

3

gm/cm

3

%

%

0.0477

1.3

0.1

0.5

0.052

1.41

0.06

-

0.0499

1.38

0.1

0.5

0.0596

1.65

-

-

0.0517

1.43

0.052

-

-

-

-

-

Tensile Strength @ yield, 73F

Tensile Modulus 1% Sec 73F

Elongation, Yield 73F

Elongation Break 73F

Flexural Strength 73F

Flexural Modulus 73F

Compressive Strength 73F

Shear Strength Ultimate 73F

Izod Impact, Notched 73F

Rockwell Hardness 73F

Limiting PV 2 68F 1200 in/min

Coefficient of Friction @ 68F

1200 in/min, 155 lbs load

Heat Deflection Temperature @ 264psi

Maximum Continuous use Temperature

Melting Point

Coefficient of Linear Thermal Expansion

Thermal Conductivity

Flammability

Volume Resistivity

Surface Resistivity

Dielectric Strength

P

H

Y

S

I

C

A

L

M

E

C

H

A

N

I

C

A

L

T

H

E

R

M

A

L

E

L

E

C

T

R

I

C

A

L

PROPERTIES

ASTM

Test

Method

Units

TECAPEEK

XP98 XRO

This information is only to assist and advise you on current technical knowledge and is given without obligation or liability.

All trade and patent rights should be observed. All rights reserved. Data obtained from extruded shapes material.

TECAPEEK- Ensinger Industries Inc.

PEEK - Victrex

CLASSIX - Invibio

T

E

C

A

P

E

E

K

M

e

d

i

c

a

l

M

a

t

e

r

i

a

l

s

TECAPEEK

Medical Materials

TECAPEEK

high

performance polymer

has successfully

replaced glass, stainless

steel and titanium in a

growing range of

medical applications.

The materials

exceptional combination

of properties allow

engineers and

designers the ability

to create cost-effective,

innovative parts that

exhibit outstanding

wear, heat, electrical

and chemical

resistance.

The TECAPEEK

family

of materials for medical

applications are:

The TECAPEEK

family of high performance plastics are highly effective in the

creation and manufacture of high quality medical instruments. Five separate

grades, each with qualities to meet a wide range of requirements for the

engineer and product designer.

DISTRIBUTED BY

HEADQUARTERS

365 Meadowlands Boulevard

Washington, Pennsylvania 15301

Telephone: 800-243-3221 Sales

800-869-4029 Technical

Fax: 724-746-9209

e-mail: sales@ensinger-ind.com

Division of Ensinger, Inc.

MED805-0109

IS

O

9001:2000 CERTIFIED

E

N

SINGER WASHINGTON

PA

TECAPEEK MT, unfilled pigmented

medical grade PEEK.

TECAPEEK XP98, compression molded 30%

carbon fiber filled PEEK (isotropic properties).

TECAPEEK MT CF30, extruded 30%carbon

fiber filled PEEK.

TECAPEEK Classix, ISO10993 certification

by resin and extrusion lot for 30 days contact.

TECAPEEK Classix XRO-20 radio opaque

grade with 20% BaSO

4

added.

TECAPEEK

XP98

TECAPEEK

CLASSIX

XRO

TECAPEEK

MT CF 30

TECAPEEK

MT

TECAPEEK

TECAPEEK

CLASSIX

D638

D638

D638

D638

D790

D790

D695

D3846

D256

D785

-

-

-

D648

-

-

D696

C177

UL94

D149

D257

D257

ohm-cm

ohm/square

V/mil

4.9x10

16

1x10

16

190

10

16

10

16

200

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

psi

psi

%

%

psi

psi

psi

psi

ft-lbs/in

-

psi fpm

-

-

F

F

in/in/F

Btu-in/hr-ft-F

-

14,000

522,100

4.9

50

27700

530,000

17,100

7,600

1.55

M99

170,000

-

0.18

320

500

644

2.6x10

-5

1.7

V-O

320

500

644

2.6x10

-5

-

V-O

320

500

644

2.6x10

-5

-

-

-

500

644

-

-

-

600

500

644

0.8x10

-5

6.37

V-O

600

500

644

0.8x10

-5

-

-

-

500

644

-

-

-

0.0477

1.3

0.1

0.5

13,775

435,000

-

25

27,000

595,000

16,900

7,500

1.2

M99

-

-

-

27,000

1,885,400

-

1.1

46,100

1,850,000

34,800

14,100

0.9

M107

385,000

-

0.22

13,775

430,000

-

25

27,000

609,000

16,900

7,500

1.2

M99

-

-

-

11,600

725,000

-

2

-

580,000

-

-

-

-

-

-

-

21,960

1,280,000

-

1.5

32,610

1,500,000

25,694

13,000

0.69

M97

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

TECAPEEK grades are characterized by high strength, extreme resistance to hydrolysis and resistance to

ionizing radiation. All conventional sterilization methods are compatible. The above medical grades are

supported with biocompatibility testing to the ISO10993 matrix to support their use in contact with blood and

tissue for 24 hours or less. Additionally, Ensinger is an authorized converter for Invibios PEEKClassix

resin. PEEK Classix is tested by resin lot to support contact with the patient for up to 30 days.

TECAPEEK MT

Offered in colors and in natural for the purposes of

instrument identification, or for use in setting up the

equipment in preparation for machining Invibio

PEEK Optima implants. The machining properties

are the same, but the colored rod will eliminate the

possibility of mixing the set-up parts with the actual

implant parts.

Application showing the use of TECAPEEK in an

endoscopic surgical device.

TECAPEEK XP98 and MT CF30

Both grades are reinforced with 30% carbon fiber and differentiated by their processing methods.

Plastics as well as carbon fiber are radiolucent which make these materials ideal for the higher

modulus requirement of target devices for internal fixation bone trauma nails and plates. Both

materials are offered in standard shapes with TECAPEEK XP98 also available as a neat net shape

and TECAPEEK MT CF30 as an injection molded part by Ensinger Putnam Precision Molding.

TECAPEEK Classix and Classix XRO-20 Radio Opaque

These materials are offered for extended time contact with the patient and are tested by resin lot

with an additional cytotoxicity test by extrusion lot. A typical extended contact application would be

temporary dental implants. Since plastics are typically transparent to X-rays, the XRO formulation

allows oral surgeons to see the orientation of the temporary abutment by reflecting the X-rays, thus

making the part visible.

MRI Imaging and Artifact Concerns

Ensinger has tested various filled TECAPEEK

grades to determine issue of image artifacts

when used as components within and just

outside MRI coils. A data base of image testing

results are available for discussion for these

grades as well as other Ensinger TECA-grades.

Processing

Ensinger Inc. is unique in offering extrusion,

compression molding and injection molding

processes for our proprietary line of

TECAPEEK and other medical grade

materials. TECAPEEK shapes are extruded

at our facilities in Nufringen, Germany as

well as Washington, Pennsylvania. Ensinger

Special Polymers compression molds basic

and custom near net shapes in Houston,

Texas. Ensinger Putnam Precision Molding

offers molding services for high end

thermoplastic resins, and has been an end

point for process conversion of higher

volume application requirements that

evolved from lower volume machined

clinical trials and initial product launches.

TECAPEEK grades are available in

standard, custom near net shapes and

finished molded parts. One material for

many processes provides more flexibility

for scale up without a formal material

change.

TECAPEEKClassixXRO

Radio Opaque materials are

clearly visible on X-rays.

TECAPEEK

Medical Materials

TECAPEEK MT

TECAPEEK

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- IBR Design Calculations - FinalDocument6 paginiIBR Design Calculations - Finalshazan100% (1)

- Manual FM200 PDFDocument44 paginiManual FM200 PDFDIOGO FRANCO PUREZAÎncă nu există evaluări

- LASCOSCH80CPVCDocument14 paginiLASCOSCH80CPVCRoger Broca AriasÎncă nu există evaluări

- Usha Martin Wirerope HandbookDocument72 paginiUsha Martin Wirerope Handbookhaydarburedah100% (2)

- Deva - BM ENDocument24 paginiDeva - BM ENOscar CruzÎncă nu există evaluări

- Spherical Bearings enDocument32 paginiSpherical Bearings enOscar CruzÎncă nu există evaluări

- Deva - BM ENDocument24 paginiDeva - BM ENOscar CruzÎncă nu există evaluări

- 02 Wire Rope StrandDocument39 pagini02 Wire Rope Strandmanuelperezz2567% (3)

- Chiller CarrierDocument40 paginiChiller CarrierNicolas MatiasÎncă nu există evaluări

- LPD BrochureDocument8 paginiLPD BrochureOscar CruzÎncă nu există evaluări

- Installation Operating Instructions Couplings TSCHAN S SDD-5 SDDL-5 enDocument23 paginiInstallation Operating Instructions Couplings TSCHAN S SDD-5 SDDL-5 enOscar CruzÎncă nu există evaluări

- Pipesupport MDocument199 paginiPipesupport MOscar CruzÎncă nu există evaluări

- Miller 09Document5 paginiMiller 09Muhammad RaHadian WiranataÎncă nu există evaluări

- Qa Manual - Current EditionDocument51 paginiQa Manual - Current EditionAnonymous qhVGVpÎncă nu există evaluări

- THG Hooks Forged Hooks Catalogue SheetDocument5 paginiTHG Hooks Forged Hooks Catalogue SheetAnderson SantosÎncă nu există evaluări

- BPL Equiv ChartDocument1 paginăBPL Equiv ChartOscar CruzÎncă nu există evaluări

- G06Document6 paginiG06Oscar CruzÎncă nu există evaluări

- Energrease LS-EP SeriesDocument2 paginiEnergrease LS-EP SeriesOscar CruzÎncă nu există evaluări

- Industrial Grease Lubricant Application GuideDocument2 paginiIndustrial Grease Lubricant Application GuideOscar Cruz100% (2)

- CadenasDocument77 paginiCadenasRicardo SGÎncă nu există evaluări

- German Schematic DiagramDocument28 paginiGerman Schematic DiagramMajida HannanÎncă nu există evaluări

- Asme Specifications SA36 ToSA423Document4 paginiAsme Specifications SA36 ToSA423nadhabindhu0% (1)

- Roller Chain Bs-AnsienDocument3 paginiRoller Chain Bs-AnsienOscar CruzÎncă nu există evaluări

- DIN 8187-1 - Corrente SimplesDocument10 paginiDIN 8187-1 - Corrente Simplesmarcoszurc0% (1)

- LMX GreaseDocument2 paginiLMX GreaseOscar CruzÎncă nu există evaluări

- KettenHandbuch E Iwis ChainDocument86 paginiKettenHandbuch E Iwis ChainKiran Kumar K TÎncă nu există evaluări

- F1554 Anchor Rod Straight SubmittalDocument1 paginăF1554 Anchor Rod Straight SubmittalOscar CruzÎncă nu există evaluări

- Re17047 2003-11Document8 paginiRe17047 2003-11Oscar CruzÎncă nu există evaluări

- Threads&Threaded Joints 2007-08Document24 paginiThreads&Threaded Joints 2007-08Vikram Puttenahalli Nagesh GowdaÎncă nu există evaluări

- Cata - Flange ANSI - pdf1299758077 PDFDocument48 paginiCata - Flange ANSI - pdf1299758077 PDFNikhil PanchalÎncă nu există evaluări

- Equivalents of Carbon Steel QualitiesDocument11 paginiEquivalents of Carbon Steel QualitiesOscar CruzÎncă nu există evaluări

- Proses Manufaktur - Fundamental of Metal FormingDocument35 paginiProses Manufaktur - Fundamental of Metal FormingAnatolium IrgrandeÎncă nu există evaluări

- NFL BathindaDocument26 paginiNFL BathindaSukhman ChahalÎncă nu există evaluări

- Schneider - Chillers Range PDFDocument27 paginiSchneider - Chillers Range PDFerreagaaÎncă nu există evaluări

- Chapter-2 - IS MATTER AROUND US PUREDocument25 paginiChapter-2 - IS MATTER AROUND US PURESATYAM RATHOURÎncă nu există evaluări

- Basics in Process Design - 2006 PDFDocument30 paginiBasics in Process Design - 2006 PDFSamuel OnyewuenyiÎncă nu există evaluări

- Heat Transfer Operations Lab Report: Engr. M. Akmal RanaDocument4 paginiHeat Transfer Operations Lab Report: Engr. M. Akmal RanaUmair farooqÎncă nu există evaluări

- 2.3 Atterberg Limits - Testing and Interpretation of ResultsDocument27 pagini2.3 Atterberg Limits - Testing and Interpretation of Resultslu yinÎncă nu există evaluări

- Gafti AP Apeo SopDocument8 paginiGafti AP Apeo SopManoj ChaudhariÎncă nu există evaluări

- Urea & Melamine Formaldehyde ResinsDocument33 paginiUrea & Melamine Formaldehyde ResinsAkash Yadav50% (2)

- Hexamoll DINCH TDSDocument3 paginiHexamoll DINCH TDScmuthuprakashÎncă nu există evaluări

- Nanodrop PDFDocument2 paginiNanodrop PDFVinay TejaÎncă nu există evaluări

- TSB339Document6 paginiTSB339Anderson Alejandro Benites ZelayaÎncă nu există evaluări

- Centrifugal Pump Piping Design LayoutDocument19 paginiCentrifugal Pump Piping Design Layoutvijayakumar2015Încă nu există evaluări

- Centrifugal Compressors SRLDocument20 paginiCentrifugal Compressors SRLsammar_10Încă nu există evaluări

- Zangar C Water Percolation 5 Water OcrDocument86 paginiZangar C Water Percolation 5 Water Ocrreem.ranoom.moonÎncă nu există evaluări

- Science FairDocument9 paginiScience Fairapi-254632210Încă nu există evaluări

- b3 Quantum Atomic and Molecular PhysicsDocument67 paginib3 Quantum Atomic and Molecular PhysicsAndrew OrrÎncă nu există evaluări

- C1130Document4 paginiC1130dinhtung2210Încă nu există evaluări

- Absorption and StrippingDocument52 paginiAbsorption and StrippingTomasz KobaÎncă nu există evaluări

- Biochemistry of Connective Tissue DentistrykopptxDocument97 paginiBiochemistry of Connective Tissue DentistrykopptxAbdullah Khalid VirkÎncă nu există evaluări

- Aluminium Etching MicroChemicals PDFDocument3 paginiAluminium Etching MicroChemicals PDFDaniela Silva MolinaÎncă nu există evaluări

- Constitutive ModelsDocument8 paginiConstitutive ModelsAnonymous D5s00DdUÎncă nu există evaluări

- Hand Written NotesDocument12 paginiHand Written NotesOne phase 23Încă nu există evaluări

- Tecnica PC Rapido PDFDocument6 paginiTecnica PC Rapido PDFEnrique Castrillon AriasÎncă nu există evaluări

- 2 SonicScope SchlumbergerDocument19 pagini2 SonicScope SchlumbergersudiptodattaÎncă nu există evaluări

- Repair Manual: Series 45 K and L Frame Open Circuit Axial Piston PumpsDocument28 paginiRepair Manual: Series 45 K and L Frame Open Circuit Axial Piston PumpsJose Manuel Barroso PantojaÎncă nu există evaluări

- AMLTM.00.092-00-Iss1 Tape Adhesion Test For Paints and CoatingsDocument6 paginiAMLTM.00.092-00-Iss1 Tape Adhesion Test For Paints and CoatingsalbertoÎncă nu există evaluări

- General Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsDocument12 paginiGeneral Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsHazel EncarnacionÎncă nu există evaluări