Documente Academic

Documente Profesional

Documente Cultură

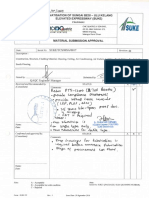

Comprehensive Service and Maintenance Schedule For Mech System Updated 14-1-13

Încărcat de

Zulkarnain Dahalan0 evaluări0% au considerat acest document util (0 voturi)

99 vizualizări40 paginiengineering

Titlu original

Comprehensive Service and Maintenance Schedule for Mech System Updated 14-1-13

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentengineering

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

99 vizualizări40 paginiComprehensive Service and Maintenance Schedule For Mech System Updated 14-1-13

Încărcat de

Zulkarnain Dahalanengineering

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 40

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 1

Cawangan Kejuruteraan Mekanikal - Rev.1

COMPREHENSIVE SERVICE AND MAINTENANCE SCHEDULE FOR MECHANICAL SYSTEM

1.0 AIR CONDITIONING AND MECHANICAL VENTILATION SYSTEM

1.1 WATER COOLED CHILLER SYSTEM

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

1 REFRIGERANT COMPRESSOR & SYSTEM

a Take and record the reading of motor

amperage and voltage, refrigerant pressures

and temperatures, compressor oil pressure,

condenser water entering-leaving

temperatures, chilled water entering-leaving

temperatures, chiller load, etc. Compare with

the design technical specifications. If

abnormal, trace faults and rectify as

necessary.

X

b Check crankcase heater operation. If

abnormal, rectify as necessary.

X

c Check the purge unit operation. If abnormal,

rectify as necessary.

X

d Check all seals, gaskets and pipelines for

leaks and rectify as necessary.

X

e Check all refrigerant and oil levels, and

charge the refrigerant and oil into the

refrigerant system as necessary.

X

f Check the operation of all refrigerant controls.

Clean, adjusts, repair, replace and lubricate

as necessary.

X

g Check the operation of all safety devices.

Clean, adjust, repair, replace and lubricate as

necessary.

X

h Check the suction and discharge pressures of

all refrigerant compressors. If abnormal trace

the faults and rectify as necessary.

X

i Check all bolts and nuts for tightness and

tighten as necessary.

X

j Service the chiller including changing of

compressor oil, filter and topping up

refrigerant and carry out leak test.

X

2 WATER PUMPS

a Check all pump mechanical seals for leaks

(for pump gland leakage rate is a maximum of

10 drops per min if not specified by the

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 2

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

manufacturer). Adjust, re-pack and replace

pump glands or mechanical seals as

necessary.

b Check all pump bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

c Take reading and record the noise and

vibration levels for all pumps and compare

with the design technical

specifications/standards. If abnormal, trace

the faults and rectify as necessary.

X

d Check the alignment and condition of all

rubber couplings between pumps and drive

motors, and rectify as necessary.

X

e Check each pump mountings. Tighten all bolts

and nuts as necessary.

X

3 EVAPORATOR / AIR HANDLING UNIT

a Check all filters. Clean and renew as

necessary.

X

b Check all water coils, seals and pipelines for

leaks and rectify as necessary.

X

c Clean cooling coil with biodegradable, non-

toxic, non-corrosive and hospital grade

multiple enzymes (pH 7) cleaning agent.

X

d Purge air from all water coils.

X

e Check all fan and motor bearings for

excessive noise, vibration and wear. Lubricate

with oil or grease or replace if necessary.

X

f Check the tension of all belt drives. Adjust or

replace as necessary.

X

g Check the operation of ultraviolet air purifier

system. Repair or replace as necessary. (if

applicable)

X

h Check the operation of all automatic water

regulating valves. Clean, adjusts and lubricate

as necessary.

X

i Check the operation of all automatic multi-

blade face and by-pass dampers. Clean,

adjusts and lubricate as necessary.

X

j Check the operation of thermostat to ensure

the set temperature is achieved. Rectify or

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 3

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

replace if necessary.

k Clean all condensate pans, trays and drains.

X

4 COOLING TOWER

a Check all fan and motor bearings for

excessive noise, vibration and wear. Lubricate

with oil or grease or replace if necessary.

X

b Check the tension of all belt drives. Adjust or

replace as necessary.

X

c Clean all water screens.

X

d Check the operation of all water nozzles and

clean as necessary.

X

e Drain, clean and flush out the water tanks of

the cooling tower when found necessary.

X

f Check the float valve operation and adjust the

water level as necessary.

X

g Chemical water treatment for cooling tower to

eliminate/control micro-biological growth,

scale and corrosion.

- Field water test shall be carried out and the

result to be recorded.

X

5 ELECTRIC MOTOR

a Check all motor bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

b Check carbon brushes and slip rings of all

motors and clean as necessary. Replace

carbon brushes if necessary.

X

c Check safety devices fitted to all motors.

Clean, adjust and lubricate as necessary.

X

6 ELECTRICAL SWITCHBOARD AND

CONTROL PANEL

a Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

b Check the operation of selector switches and

stop-start button. Repair or replace as

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 4

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

c Check the routine operation of all electrical

starters, electrical control gears and ancillary

electrical apparatus. Repair or replace as

necessary.

X

d Clean or renew electric contactors as

necessary.

X

e Renew electric fuses as necessary.

X

7 PIPING AND FITTINGS

a Inspect all piping for leaks and rectify as

necessary.

X

b Inspect the chilled water pipe insulation.

Repair or replace as necessary.

X

c Inspect the condition of every valve and fitting.

Repair or replace as necessary.

X

8 DUCTING, GRILLES AND DAMPERS

a Inspect for moisture and condensation. Trace

the faults and rectify as necessary.

X

b Inspect ductwork for leaks or damages.

Repair or replace as necessary.

X

c Inspect the condition of all support, brackets

and hangers. Rectify or repair as necessary.

X

d Measure and record the air flow. Adjust and

balance the air flow as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 5

Cawangan Kejuruteraan Mekanikal - Rev.1

1.2 AIR COOLED CHILLER SYSTEM

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

1 REFRIGERANT COMPRESSOR & SYSTEM

a Take and record the reading of motor

amperage and voltage, refrigerant pressures

and temperatures, chilled water entering-

leaving temperatures, chiller load, etc.

Compare with the design technical

specifications. If abnormal, trace faults and

rectify as necessary.

X

b Check crankcase heater operation. If

abnormal, rectify as necessary.

X

c Check the purge unit operation. If abnormal,

rectify as necessary.

X

d Check all seals, gaskets and pipelines for

leaks and rectify as necessary.

X

e Check all refrigerant and oil levels, and

charge the refrigerant and oil into the

refrigerant system as necessary.

X

f Check the operation of all refrigerant controls.

Clean, adjusts, repair, replace and lubricate

as necessary.

X

g Check the operation of all safety devices.

Clean, adjust, repair, replace and lubricate as

necessary.

X

h Check the suction and discharge pressures of

all refrigerant compressors. If abnormal trace

the faults and rectify as necessary.

X

i Check all bolts and nuts for tightness and

tighten as necessary.

X

j Service the chiller including changing of

compressor oil, filter and topping up

refrigerant and carry out leak test.

X

2 WATER PUMPS

a Check all pump mechanical seals for leaks

(for pump gland leakage rate is a maximum of

10 drops per min if not specified by the

manufacturer). Adjust, re-pack and replace

pump glands or mechanical seals as

necessary.

X

b Check all pump bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 6

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

c Take reading and record the noise and

vibration levels for all pumps and compare

with the design technical

specifications/standards. If abnormal, trace

the faults and rectify as necessary.

X

d Check the alignment and condition of all

rubber couplings between pumps and drive

motors, and rectify as necessary.

X

e Check each pump mountings. Tighten all bolts

and nuts as necessary.

X

3 EVAPORATOR / AIR HANDLING UNIT

a Check all filters. Clean and renew as

necessary.

X

b Check all water coils, seals and pipelines for

leaks and rectify as necessary.

X

c Clean cooling coil with biodegradable, non-

toxic, non-corrosive and hospital grade

multiple enzymes (pH 7) cleaning agent.

X

d Purge air from all water coils.

X

e Check all fan and motor bearings for

excessive noise, vibration and wear. Lubricate

with oil or grease or replace if necessary.

X

f Check the tension of all belt drives. Adjust or

replace as necessary.

X

g Check the operation of ultraviolet air purifier

system. Repair or replace as necessary. (if

applicable)

X

h Check the operation of all automatic water

regulating valves. Clean, adjusts and lubricate

as necessary.

X

i Check the operation of all automatic multi-

blade face and by-pass dampers. Clean,

adjusts and lubricate as necessary.

X

j Check the operation of thermostat to ensure

the set temperature is achieved.

X

k Clean all condensate pans, trays and drains.

X

4 CONDENSER

a Inspect the condensing coil condition. Clean

the coils and comb the fins as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 7

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

b Inspect refrigerant leaks at joints, fittings and

piping. Repair and top up refrigerant as

necessary.

X

c Check all motor and fan bearings for

excessive noise, vibration and wear. Lubricate

with oil or grease or replace if necessary.

X

d Clean cooling coil with high pressure water

jet and biodegradable alkaline cleaning

chemicals.

X

5 ELECTRIC MOTOR

a Check all motor bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

b Check carbon brushes and slip rings of all

motors and clean as necessary. Replace

carbon brushes if necessary.

X

c Check safety devices fitted to all motors.

Clean, adjust and lubricate as necessary.

X

6 ELECTRICAL SWITCHBOARD AND

CONTROL PANEL

a Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

b Check the operation of selector switches and

stop-start button. Repair or replace as

necessary.

X

c Check the routine operation of all electrical

starters, electrical control gears and ancillary

electrical apparatus. Repair or replace as

necessary.

X

d Clean or renew electric contactors as

necessary.

X

e Renew electric fuses as necessary.

X

7 PIPING AND FITTINGS

a Inspect all piping for leaks and rectify as

necessary.

X

b Inspect the chilled water pipe insulation.

Repair or replace as necessary.

X

c Inspect the condition of every valve and fitting.

Repair or replace as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 8

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

8 DUCTING, GRILLES AND DAMPERS

a Inspect for moisture and condensation. Trace

the faults and rectify as necessary.

X

b Inspect ductwork for leaks or damages.

Repair or replace as necessary.

X

c Inspect the condition of all support, brackets

and hangers. Rectify or repair as necessary.

X

d Measure and record the air flow. Adjust and

balance the air flow as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 9

Cawangan Kejuruteraan Mekanikal - Rev.1

1.3 CENTRAL DIRECT EXPANSION SYSTEM (DX) - WATER COOLED SYSTEM

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

1 WATER COOLED PACKAGE UNIT (WCPU)

a Take and record the reading of motor

amperage and voltage and condenser water

entering-leaving temperatures, etc. Compare

with the design technical specifications. If

abnormal, trace faults and rectify as

necessary.

X

b Check crankcase heater operation. If

abnormal, rectify as necessary.

X

c Check all motor bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

d Check all seals, gaskets and pipelines for

leaks and rectify as necessary.

X

e Check all refrigerant and oil levels, and

charge the refrigerant and oil into the

refrigerant system as necessary.

X

f Check the suction and discharge pressures of

all refrigerant compressors. If abnormal trace

the faults and rectify as necessary.

X

g Check all air filters. Clean or replace as

necessary.

X

h Check the operation of ultraviolet air purifier

system. Repair or replace as necessary. (if

applicable)

X

i Inspect the condenser and clean as

necessary.

X

j Inspect leakage or clogging at drain pan and

drain line. Clean, flush, repair or replace as

necessary.

X

k Check the operation of all safety devices.

Clean, adjust, repair, replace and lubricate as

necessary.

X

l Inspect the pipe insulation. Repair or replace

as necessary.

X

m Clean the cooling coil with biodegradable,

non-toxic, non-corrosive and hospital grade

multiple enzymes (pH 7) cleaning agent.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 10

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

n Check all bolts and nuts for tightness and

tighten as necessary.

X

2 WATER PUMPS

a Check all pump mechanical seals for leaks

(for pump gland leakage rate is a maximum of

10 drops per min if not specified by the

manufacturer). Adjust, re-pack and replace

pump glands or mechanical seals as

necessary.

X

b Check all pump bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

c Check the alignment and condition of all

rubber couplings between pumps and drive

motors, and rectify as necessary.

X

d Take reading and record the noise and

vibration levels for all pumps and compare

with the design technical

specifications/standards. If abnormal, trace

the faults and rectify as necessary.

X

e Check each pump mountings. Tighten all bolts

and nuts as necessary.

X

3 COOLING TOWER

a Check all fan and motor bearings for

excessive noise, vibration and wear. Lubricate

with oil or grease or replace if necessary.

X

b Check the tension of all belt drives. Adjust or

replace as necessary.

X

c Check the float valve operation and adjust the

water level as necessary.

X

d Chemical water treatment for cooling tower to

eliminate/control micro-biological growth,

scale and corrosion.

- Field water test shall be carried out and the

result to be recorded.

X

e Clean all water screens.

X

f Check the operation of all water nozzles and

clean as necessary.

X

g Drain, clean and flush out the water tanks of

the cooling tower when found necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 11

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

4 ELECTRIC MOTOR

a Check all motor bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

b Check safety devices fitted to all motors.

Clean, adjust and lubricate as necessary.

X

c Check carbon brushes and slip rings of all

motors and clean as necessary. Replace

carbon brushes if necessary.

X

5 ELECTRICAL SWITCHBOARD AND

CONTROL PANEL

a Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

b Check the operation of selector switches and

stop-start button. Repair or replace as

necessary.

X

c Check the routine operation of all electrical

starters, electrical control gears and ancillary

electrical apparatus. Repair or replace as

necessary.

X

d Clean or renew electric contactors as

necessary.

X

e Renew electric fuses as necessary.

X

6 PIPING AND FITTINGS

a Inspect all piping for leaks and rectify as

necessary.

X

b Inspect the condition of every valve and fitting.

Repair or replace as necessary.

X

c Inspect and clean the strainers. Repair or

replace as necessary.

X

7 DUCTING, GRILLES AND DAMPERS

a Inspect for moisture and condensation. Trace

the faults and rectify as necessary.

X

b Inspect ductwork for leaks or damages.

Repair or replace as necessary.

X

c Inspect the condition of all support, brackets

and hangers. Rectify or repair as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 12

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

d Measure and record the air flow. Adjust and

balance the air flow as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 13

Cawangan Kejuruteraan Mekanikal - Rev.1

1.4 AIR COOLED PACKAGE / SPLIT DUCTED UNIT

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

1 CONDENSER

a Take and record the reading of motor

amperage and voltage, etc. Compare with the

design technical specifications. If abnormal,

trace faults and rectify as necessary.

X

b Check crankcase heater operation. If

abnormal, rectify as necessary.

X

c Inspect the condensing coil condition. Clean

the coils and comb the fins as necessary.

X

d Check all refrigerant and oil levels. Charge the

refrigerant and oil into the refrigerant system

as necessary.

X

e Inspect refrigerant leaks at joints, fittings,

piping and compressor. Repair and top up

refrigerant as necessary.

X

f Check the suction and discharge pressures of

all refrigerant compressors. If abnormal trace

the faults and rectify as necessary.

X

g Check all motor and fan bearings for

excessive noise, vibration and wear. Lubricate

with oil or grease or replace if necessary.

X

h Clean the cooling coil with high pressure

water jet and biodegradable alkaline cleaning

chemicals.

X

2 FAN COIL UNIT / AIR HANDLING UNIT

a Inspect all air filters. Clean or replace as

necessary.

X

b Inspect the operation of thermostat. Replace

as necessary.

X

c Check all motor bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

d Inspect refrigerant leaks at joints, fittings and

piping. Repair and top up refrigerant as

necessary.

X

e Inspect the drain pan for leaks or clogging.

Clean, flush and repair as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 14

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

f Inspect the pipe insulation. Repair or replace

as necessary.

X

g Clean cooling coil with biodegradable, non-

toxic, non-corrosive and hospital grade

multiple enzymes (pH 7) cleaning agent.

X

3 ELECTRIC MOTOR

a Check all motor bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

b Check carbon brushes and slip rings of all

motors and clean as necessary. Replace

carbon brushes if necessary.

X

c Check safety devices fitted to all motors.

Clean, adjust and lubricate as necessary.

X

4 ELECTRICAL SWITCHBOARD AND

CONTROL PANEL

a Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

b Check the operation of selector switches and

stop-start button. Repair or replace as

necessary.

X

c Check the routine operation of all electrical

starters, electrical control gears and ancillary

electrical apparatus. Repair or replace as

necessary.

X

d Clean or renew electric contactors as

necessary.

X

e Renew electric fuses as necessary.

X

5 DUCTING, GRILLES AND DAMPERS

a Inspect for moisture and condensation. Trace

the faults and rectify as necessary.

X

b Inspect ductwork for leaks or damages.

Repair or replace as necessary.

X

c Inspect the condition of all support, brackets

and hangers. Rectify or repair as necessary.

X

d Measure and record the air flow. Adjust and

balance the air flow as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 15

Cawangan Kejuruteraan Mekanikal - Rev.1

1.5 INVERTER / DIGITAL SCROLL MULTI SPILIT SYSTEM

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

1 CONDENSER

a Take and record the reading of compressor

motor amperage and voltage. Compare with

the design technical specifications. If

abnormal, trace faults and rectify as

necessary.

X

b Check crankcase heater operation. If

abnormal, rectify as necessary.

X

c Inspect the condensing coil condition. Clean

the coils and comb the fins as necessary.

X

d Inspect refrigerant leaks at joints, fittings,

piping and compressor. Repair and top up

refrigerant as necessary.

X

e Check the suction and discharge pressures of

all refrigerant compressors. If abnormal trace

the faults and rectify as necessary.

X

f Check all motor and fan bearings for

excessive noise, vibration and wear. Lubricate

with oil or grease or replace if necessary.

X

g Check all safety devices operation. Repair or

replace as necessary.

X

h Clean the cooling coil with high pressure

water jet and biodegradable alkaline cleaning

chemicals.

X

2 FAN COIL UNIT / AIR HANDLING UNIT

a Inspect all air filters. Clean or replace as

necessary.

X

b Inspect the functionality of the individual

remote controller. Replace as necessary.

X

c Test the operation of centralised control

system operation (individual and group

functions). Repair or replace as necessary.

X

d Check all motor bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

e Inspect refrigerant leaks at joints, fittings and

piping. Repair and top up refrigerant as

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 16

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

f Inspect the drain pan for leaks or clogging.

Clean, flush and repair as necessary.

X

g Inspect the drain pipe insulation. Repair or

replace as necessary.

X

h Clean the cooling coil with biodegradable,

non-toxic, non-corrosive and hospital grade

multiple enzymes (pH 7) cleaning agent.

X

3 ELECTRICAL SWITCHBOARD AND

CONTROL PANEL

a Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

b Check the operation of all electrical starters,

anti-recycle protection, electrical control gears

and ancillary electrical apparatus. Repair or

replace as necessary.

X

c Check the operation of selector switches and

stop-start button. Repair or replace as

necessary.

X

d Clean or renew electric contactors as

necessary.

X

e Renew electric fuses as necessary.

X

4 DUCTING, GRILLES AND DAMPERS (IF

APPLICABLE)

a Inspect for moisture and condensation. Trace

the faults and rectify as necessary.

X

b Inspect ductwork for leaks or damages.

Repair or replace as necessary.

X

c Inspect the condition of all support, brackets

and hangers. Rectify or repair as necessary.

X

d Measure and record the air flow. Adjust and

balance the air flow as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 17

Cawangan Kejuruteraan Mekanikal - Rev.1

1.6 AIR COOLED SPLIT UNIT

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

1 CONDENSER

a Take and record the reading of motor

amperage and voltage. Compare with the

design technical specifications. If abnormal,

trace faults and rectify as necessary.

X

b Inspect refrigerant leaks at joints, fittings,

piping and compressor. Repair and top up

refrigerant as necessary.

X

c Check the suction and discharge pressures of

all refrigerant compressors. If abnormal trace

the faults and rectify as necessary.

X

d Check all motor and fan bearings for

excessive noise, vibration and wear. Replace

as necessary.

X

e Inspect the filter dryer. Replace as necessary.

X

f Inspect the condensing coil condition. Clean

the coils and comb the fins as necessary.

X

g Inspect the pipe insulation. Repair or replace

as necessary.

X

h Inspect bracket / hanger and rubber padding.

Repair or replace as necessary.

X

i Clean the cooling coil with high pressure

water jet and biodegradable alkaline cleaning

chemicals.

X

2 FAN COIL UNIT / EVAPORATOR

a Inspect all the air filters. Clean or replace as

necessary.

X

b Inspect the functionality of the remote

controller. Replace as necessary.

X

c Check all motor bearings for excessive noise,

vibration and wear. Replace as necessary.

X

d Inspect refrigerant leaks at joints, fittings and

piping. Repair and top up refrigerant as

necessary.

X

e Inspect the drain pan and drain line for leaks

or clogging. Clean, flush and repair as

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 18

Cawangan Kejuruteraan Mekanikal - Rev.1

No

Item

Frequency

Every

Month

Every 3

Month

Every 4

Month

Every 6

Month

Every

Year

f Inspect the operation of drain water pump.

Repair or replace as necessary. (if fitted)

X

g Inspect the pipe insulation. Repair or replace

as necessary.

X

h Clean the cooling coil with biodegradable,

non-toxic, non-corrosive and hospital grade

multiple enzymes (pH 7) cleaning agent.

X

3 ELECTRICAL SWITCHBOARD AND

CONTROL PANEL

a Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

b Check the operation of selector switches and

stop-start button. Repair or replace as

necessary.

X

c Check the routine operation of all electrical

starters, electrical control gears and ancillary

electrical apparatus. Repair or replace as

necessary.

X

d Clean or renew electric contactors as

necessary.

X

e Renew electric fuses as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 19

Cawangan Kejuruteraan Mekanikal - Rev.1

2.0 FIRE FIGHTING SYSTEM

2.1 HOSE REEL SYSTEM

No Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

1 WATER PUMPS

a Check all pump mechanical seals for leaks

(for pump gland leakage rate is a maximum of

10 drops per min if not specified by the

manufacturer). Adjust, re-pack and replace

pump glands or mechanical seals as

necessary.

X

b Check all pump bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

c Check the alignment and condition of all

rubber couplings between pumps and driving

motors. Adjust or rectify as necessary.

X

d Check all bolts and nuts for tightness, and

tighten as necessary.

X

e Check the correct cut-in and cut-out of auto

mode operation of the pressure switch and

adjust as necessary.

X

2 ELECTRIC MOTOR

a Check all motor bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

b Check safety devices fitted to all motors.

Clean, adjust and lubricate as necessary.

X

3 SWITCHBOARD

a Inspect and check the routine operation of all

electrical starters, electrical control gears,

automatic switchover control gears, battery

charging, relays and ancillary electrical

apparatus.

X

b Clean or renew electric contactors as

necessary.

X

c Renew electric fuses, LED, push button,

ammeter, voltmeter and etc. as necessary.

X

d Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 20

Cawangan Kejuruteraan Mekanikal - Rev.1

No Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

4 WATER TANK

a Check tanks for leaks & operation of ball

valves & rectify if necessary.

X

b Check all accessories (water level indicator &

wire rope, ladder, cover, electrode and etc.).

Repair or replace as necessary.

X

c Inspect for sediment or sludge. Flush and

clean as necessary.

X

5 PIPING AND FITTINGS

a Check all piping, valve, fitting, drum goose

neck and etc. for leaks.

X

b Flush out system of all dirt.

X

c Check air release valve (ARV) for air lock in

the system and rectify accordingly.

X

d Check all bolts and nuts for tightness, and

tighten as necessary.

X

6 HOSE REEL

a Check operation of swivel joint.

X

b Clean and adjust nozzles of hoses.

X

c Test hose for leaks. Replace as necessary.

X

d Ensure the hose is not twisted or curled.

X

7 DIESEL ENGINE

a Inspect and test the automatic and manual

starting and also manual stopping of the

engine.

X

b Check all bolts and nuts for tightness, and

tighten as necessary.

X

c Check all engine foundation for cracks and

rectify as necessary.

X

d Check the tension of all belt drives. Adjust or

replace if necessary.

X

e Check all engine bearings and lubricate with

oil grease as necessary.

X

f Check the alignment and condition of all

rubber couplings between diesel engine and

water pump and rectify as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 21

Cawangan Kejuruteraan Mekanikal - Rev.1

No Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

g Check the level of the fuel, steel tube and

fitting, any sludge and sediment at the diesel

tank.

X

h Check the fuel pump filter. Clean or replace if

necessary.

X

i Inspect and check the condition of the

battery, fittings and connection. Rectify or

replace as necessary.

X

8 BASEPLATE

a Check all bolts and nuts for tightness, and

tighten as necessary.

X

9 SUPPORT AND HANGER

a Check the condition of all support, brackets

and hangers. Rectify or repair as necessary.

X

10 SIMULATION TEST

a Test run all pumps (duty and standby) for:-

i. automatic and manual mode inclusive of

starting & stopping

ii. automatic changeover operation (power

failure test)

for a minimum of 4 hose reels running

simultaneously.

X

11 PAINTING

a Check overall painting and repaint if

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 22

Cawangan Kejuruteraan Mekanikal - Rev.1

2.2 SPRINKLER SYSTEM

No Item Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

1 WATER PUMPS

a Check all pump mechanical seals for leaks

(for pump gland leakage rate is a maximum

of 10 drops per min if not specified by the

manufacturer). Adjust, re-pack and replace

pump glands or mechanical seals as

necessary.

X

b Check all pump bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

c Check the alignment and condition of all

rubber couplings between pumps and driving

motors, and rectify as necessary.

X

d Check all bolts and nuts for tightness, and

tighten as necessary.

X

e Check the correct cut-in and cut-out of auto

mode operation of the pressure switch and

adjust as necessary.

X

2 ELECTRIC MOTOR

a Check all motor bearings for excessive noise

and vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

b Check carbon brushes and slip rings of all

motors, and clean as necessary. Renew

carbon brushes as necessary.

X

c Check safety devices fitted to all motors.

Clean, adjust and lubricate as necessary.

X

3 SWITCHBOARD

a Inspect and check the routine operation of all

electrical starters, electrical control gears,

automatic switchover control gears, battery

charging, relays and ancillary electrical

apparatus.

X

b Clean or renew electric contactors as

necessary.

X

c Renew electric fuses, LED, push button,

ammeter, voltmeter and etc. as necessary.

X

d Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 23

Cawangan Kejuruteraan Mekanikal - Rev.1

No Item Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

4 WATER TANK

a Check tanks for leaks & operation of ball

valves & rectify if necessary.

X

b Check all accessories (water level indicator &

wire rope, ladder, cover, electrode and etc.)

Repair or replace as necessary.

X

c Inspect for sediment or sludge. Flush and

clean as necessary.

X

5 PIPING AND FITTINGS

a Check all piping, valve, fitting, etc. for leaks.

X

b Flush out system of all dirt.

X

c Check for air release valve (ARV) for air lock

in the system & rectify accordingly.

X

d Check and all bolts and nuts for tightness,

and tighten as necessary.

X

6 BREECHING INLET

a Inspect the condition of breeching box, door

and lock. Repair or replace as necessary.

X

b Inspect the condition of male couplings, back

pressure valve, blank caps (secured with

chains). Repair or replace as necessary.

X

7 DIESEL ENGINE

a Inspect and test automatic & manual starting

and also for manual stopping of the engine.

X

b Check all bolts and nuts for tightness, and

tighten as necessary.

X

c Check all engine foundation for cracks and

rectify as necessary.

X

d Check the tension of all belt drives, and

adjust as necessary.

X

e Check all engine bearings and lubricate with

oil or grease as necessary.

X

f Check the alignment and condition of all

rubber couplings between diesel engine and

water pump and rectify as necessary.

X

g Check the level of the fuel, steel tube &

fitting, any sludge and sediment at the diesel

tank.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 24

Cawangan Kejuruteraan Mekanikal - Rev.1

No Item Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

h Check the fuel pump filter. Clean or replace if

necessary.

X

i

Inspect and check condition of battery,

fittings and connection. Replace as

necessary.

X

8 BASEPLATE

a Check all bolts and nuts for tightness, and

tighten as necessary.

X

9 SUPPORT AND HANGER

a Check the condition of all support, brackets

and hangers. Rectify or repair as necessary.

X

10 SIMULATION TEST

a Test run all pumps (duty, standby and jockey)

for:-

i. automatic and manual mode inclusive of

starting & stopping

ii. automatic changeover operation (power

failure test)

X

11 PAINTING

a Check overall painting and repaint if

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 25

Cawangan Kejuruteraan Mekanikal - Rev.1

2.3 WET RISER SYSTEM

No Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

1 WATER PUMPS

a Check all pump mechanical seals for leaks

(for pump gland leakage rate is a maximum

of 10 drops per min if not specified by the

manufacturer). Adjust, re-pack and replace

pump glands or mechanical seals as

necessary.

X

b Check all pump bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

c Check the alignment and condition of all

rubber couplings between pumps and driving

motors, and rectify as necessary.

X

d Check all bolts and nuts for tightness, and

tighten as necessary.

X

e Check the correct cut-in and cut-out of auto

mode operation of the pressure switch and

adjust as necessary.

X

2 ELECTRIC MOTOR

a Check all motor bearings for excessive noise

and vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

b Check carbon brushes and slip rings of all

motors, and clean as necessary. Renew

carbon brushes as necessary.

X

c Check safety devices fitted to all motors.

Clean, adjust and lubricate as necessary.

X

3 SWITCHBOARD

a Inspect and check the routine operation of all

electrical starters, electrical control gears,

automatic switchover control gears, battery

charging, relays and ancillary electrical

apparatus.

X

b Clean or renew electric contactors as

necessary.

X

c Renew electric fuses, LED, push button,

ammeter, voltmeter and etc. as necessary.

X

d Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 26

Cawangan Kejuruteraan Mekanikal - Rev.1

No Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

4 WATER TANK

a Check tanks for leaks & operation of ball

valves & rectify if necessary.

X

b Check all accessories (water level indicator &

wire rope, ladder, cover, electrode and etc.).

Repair or replace as necessary.

X

c Inspect for sediment or sludge. Flush and

clean as necessary.

X

5 PIPING AND FITTINGS

a Check all water piping, valve, fitting, etc. for

leaks.

X

b Flush out system of all dirt.

X

c Check air release valve (ARV) for air lock in

the system & rectify accordingly.

X

d Check all bolts and nuts for tightness, and

tighten as necessary.

X

6 BREECHING INLET

a Inspect the condition of breeching box, door

and lock. Repair or replace as necessary.

X

b Inspect the condition of male couplings, back

pressure valve, blank caps (secured with

chains). Repair or replace as necessary.

X

7 FIRE HOSE AND LANDING VALVE

a Inspect the ease of operation and swing of

each fire hose cradle. Adjust, repair or

replace as necessary.

X

b Inspect and ensure landing valve and canvas

hose are obstruction free.

X

c Ensure the hose is not twisted or curled.

X

8 DIESEL ENGINE

a Inspect and test automatic & manual starting

and also for manual stopping of the engine.

X

b Check all bolts and nuts for tightness, and

tighten as necessary.

X

c Check all engine foundation for cracks and

rectify as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 27

Cawangan Kejuruteraan Mekanikal - Rev.1

No Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

d Check the tension of all belt drives, and

adjust as necessary.

X

e Check all engine bearings and lubricate with

oil grease as necessary.

X

f Check the alignment and condition of all

rubber couplings between diesel engine and

water pump and rectify as necessary.

X

g Check the level of the fuel, steel tube &

fitting, any sludge and sediment at the diesel

tank.

X

h Check the fuel pump filter. Clean or replace if

necessary.

X

i Inspect and check condition of battery,

fittings and connection as necessary.

X

9 BASEPLATE

a Check all bolts and nuts for tightness, and

tighten as necessary.

X

10 SUPPORT AND HANGER

a Check the condition of all support, brackets

and hangers. Rectify or repair as necessary.

X

11 SIMULATION TEST

a Test run all pumps (duty, standby and jockey)

for:-

i. automatic and manual mode inclusive of

starting & stopping

ii. automatic changeover operation (power

failure test)

X

12 PAINTING

a Check overall painting and repaint if

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 28

Cawangan Kejuruteraan Mekanikal - Rev.1

2.4 DRY RISER SYSTEM

No Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

1 PIPING AND FITTINGS

a Check all piping, valve, fitting, etc. for

damages.

X

b Check all bolts and nuts for tightness, and

tighten as necessary.

X

2 BREECHING INLET

a Inspect the condition of breeching box, door

and lock. Repair or replace as necessary.

X

b Inspect the condition of male couplings,

back pressure valve, blank caps (secured

with chains). Repair or replace as

necessary.

X

3 FIRE HOSE AND LANDING VALVE

a Inspect the ease of operation and swing of

each fire hose cradle. Adjust, repair or

replace as necessary.

X

b Inspect and ensure landing valve and

canvas hose are obstruction free.

X

c Ensure the hose is not twisted or curled.

X

4 PAINTING

a Check overall painting and repaint if

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 29

Cawangan Kejuruteraan Mekanikal - Rev.1

2.5 AUTOMATIC FIRE DETECTION AND ALARM SYSTEM (CONVENTIONAL AND

ADDRESSABLE SYSTEM)

No Item

Frequency

Every

Month

Every3

Month

Every 6

Month

Every

Year

1 ELECTRICAL

a Check wiring connection to fire alarm

console & main fire alarm panel.

X

2 MAIN FIRE ALARM PANEL AND

REPEATER PANEL

a Inspect and check the routine operation of

all electrical control, relays and ancillary

electrical apparatus.

X

b Inspect the mimic diagram for correct

indication / status.

X

c Clean and renew LED, etc. as necessary

X

d Inspect and check all cable and wiring

connections.

X

e Check all battery electrolyte level and renew

as necessary.

X

3 FIRE ALARM SYSTEM

a Check and test the operation and

functionality of at least 20% of the various

types of detectors.

X

b Check any detectors reaching the preset

dirty analog voltage limit. Clean and rectify

as necessary (for addressable system).

X

c Check and test the operation and

functionality of manual call point unit. Repair

and replace as necessary.

X

d Test the AHU, lift, smoke spill fan and

staircase pressurization tripping mechanism.

Repair or replace as necessary.

X

e Check operation of alarm bell/ sounder.

X

f Check the insulation resistance of the alarm

system and the resistance of the associated

earth continuity circuit.

X

4 Central Monitoring System (CMS)

a Check the connection and operation of

Central Monitoring System (CMS) to Bomba.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 30

Cawangan Kejuruteraan Mekanikal - Rev.1

No Item

Frequency

Every

Month

Every3

Month

Every 6

Month

Every

Year

5 PAINTING

a Check painting and repaint if necessary.

X

6 LIGHTNING AND SURGE PROTECTOR

a Check the lightning and surge protector.

Rectify or replace as necessary.

X

7 FIREMAN INTERCOM

a Check the system is in a normal-ready

condition.

X

b Check the correct operation of the master

and remote headset.

X

c Check the condition of the panel

components, battery charger, resistor wires,

zone card, bulbs, etc. Repair or replace as

necessary.

X

d Inspect the condition of the battery and its

terminal. Repair or renew as necessary.

X

e Check the wiring connection terminal. Repair

or replace as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 31

Cawangan Kejuruteraan Mekanikal - Rev.1

2.6 TOTAL FLOODING FIRE EXTINGUISHING SYSTEM (CLEAN AGENT AND CO

2

SYSTEM)

No. Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

1 CONTROL PANEL

a Inspect the condition of components,

resistors wires, zone cards and etc. Repair or

replace as necessary.

X

b Check and test AC & DC power supply and

conduct current voltage continuity and

earthing test.

X

c Inspect the condition of the battery and

battery charger. Repair or replace as

necessary.

X

d Inspect and renew electric fuses, LED, reset

button, ammeter, voltmeter and etc. as

necessary.

X

e Inspect and check all cable and wiring

connections.

X

2 DEVICES

a Check all wiring and accessories (manual

call point, audible & visual alarms, detector,

piping conduit and etc.).

X

b Check all the detectors and ensure they are

free from obstruction, dust, dirt and cobwebs.

Clean or replace as necessary.

X

3 SYSTEM EQUIPMENTS

a Inspect the condition of the fittings and

connection as necessary (container,

discharge nozzle, fire curtain and etc.).

X

b Inspect the condition and operation of the

manual key switch/pull handle. Repair or

replace as necessary.

X

c Inspect and test the correct operation of the

bell and warning light. Repair or replace as

necessary.

X

4 SIMULATION TEST

a Conduct a complete system simulation

(without discharging the gas). This includes

the testing of all detectors, ensuring the fire

curtain working properly, the correct

sequence of operation of the bell, warning

light and gas discharge time.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 32

Cawangan Kejuruteraan Mekanikal - Rev.1

No. Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

5 PAINTING

a Check overall painting and repaint if

necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 33

Cawangan Kejuruteraan Mekanikal - Rev.1

3.0 INTERNAL COLD WATER AND SANITARY PLUMBING SYSTEM

No. Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

1 WATER PUMPS

a Check all pump mechanical seals for leaks.

Replace mechanical seals as necessary.

X

b Check all pump bearings for excessive noise,

vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

c Check the alignment and condition of all

rubber couplings between pumps and driving

motors, and rectify as necessary.

X

d Check all bolts and nuts for tightness, and

tighten as necessary.

X

e Check and record the pump running

pressure.

X

2 PRESSURE VESSEL

a Inspect the pressure vessel / hydro

pneumatic tank for leaks. Replace the

diaphragm as necessary.

X

b Test the operation of pressure vessel / hydro

pneumatic tanks. Adjust the system pressure

based on the specification or as necessary.

X

3 ELECTRIC MOTOR

a Check all motor bearings for excessive noise

and vibration and wear. Lubricate with oil or

grease or replace if necessary.

X

b Check carbon brushes and slip rings of all

motors, and clean as necessary. Renew

carbon brushes as necessary.

X

c Check safety devices fitted to all motors and

clean, adjust and lubricate as necessary.

X

d Take and record the reading of motor

running amperage and voltage. If abnormal,

trace the faults and rectify or replace if

necessary.

4 SWITCHBOARD

a Inspect and check the condition and

operation of all electrical starters, electrical

control gears, automatic changeover

switches, measuring instrument (ammeters &

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 34

Cawangan Kejuruteraan Mekanikal - Rev.1

No. Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

voltmeters), ACB, MCB, MCCB, protection

relays, surge protection device, isolating

switches and ancillary electrical apparatus.

Repair or replace as necessary.

b Clean or renew electric contactors as

necessary.

X

c Renew electric fuses, LED, stop-start

buttons, selector switches, etc. as necessary.

X

d Inspect and test the control wiring and

circuitry. Retighten, repair or replace as

necessary.

X

5 WATER TANK (SUCTION AND STORAGE)

a Check tanks for leaks. Repair as necessary.

X

b Check the operation of ball valve. Repair or

replace as necessary.

X

c Check all accessories (e.g. water level

indicator & wire rope, cat ladder, cover, etc.)

Repair or replace as necessary.

X

d Inspect the condition and operation of

electrodes. Clean or replace as necessary.

X

e Inspect for sediment or sludge. Flush and

clean as necessary.

X

6 PIPING AND FITTINGS

a Inspect all piping, valve, fittings, etc. for

leaks. Repair or replace as necessary.

X

b Check and all bolts and nuts for tightness,

and tighten as necessary.

X

c Flush out system of all dirt.

X

d Inspect and clean all the strainers.

X

7 SUPPORT AND HANGER

a Check the condition of all pipe supports,

brackets and hangers. Rectify or repair as

necessary.

X

8

INTERNAL SANITARY PLUMBING

a Check access covers, caps and cleaning

eyes

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 35

Cawangan Kejuruteraan Mekanikal - Rev.1

No. Item

Frequency

Every

Month

Every 3

Month

Every 6

Month

Every

Year

b Check any water leakage at any part of

jointing of internal sanitary pipe system

X

c Check the discharge pipe system to ensure:

i) the system is clean and in good

condition.

ii) there is no blockage on the system

Repair or replace as necessary.

X

9 SIMULATION TEST

a Test run all pumps (duty and standby) for:-

i. automatic and manual mode inclusive

of starting & stopping

ii. automatic and manual changeover

operation between the duty and standby

pump to ensure even wear and tear

between all pumps.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 36

Cawangan Kejuruteraan Mekanikal - Rev.1

4.0 LIFT SYSTEM

No. Item

Frequency

Every

Month

Every 2

Month

Every 3

Month

Every 6

Month

Every

Year

1 MOTOR ROOM

a Check for abnormal noise, vibration and

temperature rise of all machines. If

abnormal, determine the source, adjust,

repair or replace as necessary.

X

b Inspect all bearings and bushes.

Lubricate or replace as necessary.

X

c Inspect gearbox oil level, condition,

leaks, play and backlash. Adjust, repair

or replace as necessary.

X

d Inspect the over speed governor for

abnormal noise and vibration. Clean,

repair or replace as necessary.

X

e Inspect the condition of all relays,

contactors and contact inside the

controller. Clean, repair or replace as

necessary.

X

f Inspect all the fuses and terminal wires.

Retighten or replace as necessary.

X

g Inspect EBOPS the condition and

operation of the battery, emergency light

and ventilation fan. Replace as

necessary.

X

h Inspect any leakage from traction

machine cover gasket and oil seals.

Repair or replace as necessary.

X

i Clean the traction machine and lift

controller.

X

j Inspect the controller cooling operation.

Replace as necessary.

X

k Check and adjust speed governor and

compensating pulley.

X

l Clean controller and its component.

X

m Clean brake wheels.

X

n Clean and adjust controller switches.

X

o Inspect and adjust brake system as

necessary.

X

p Check the governor switches.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 37

Cawangan Kejuruteraan Mekanikal - Rev.1

No. Item

Frequency

Every

Month

Every 2

Month

Every 3

Month

Every 6

Month

Every

Year

q Check and record the incoming voltage.

If abnormal, trace the faults and rectify

as necessary.

X

r Check and record the controller voltage.

If abnormal, trace the faults and rectify

as necessary.

X

s Check the operation of safety gears.

Adjust, repair or replace as necessary.

X

t Grease the secondary sheaves, car top

sheaves and counterweight top

sheaves.

X

u Check the condition of worm gears and

thrust bearing of the gear boxes (geared

m/c only). Lubricate or replace as

necessary.

X

v Check and tighten screws of controllers.

X

w Dismantle, clean and adjust the electro-

magnetic brakes of gearless machines.

X

x Test all safety devices. Repair or replace

as necessary.

X

2 HOIST WAY

a Check movement of door switches and

emergency stop switch. Adjust or

replace as necessary.

X

b Check operation of weighing devices.

Repair or replace as necessary.

X

c Inspect the condition of guide rails. Top

up rail lubricators as necessary.

X

d Clean hoist ways, beams, slow-down

cams, outside cages, rails and

counterweight rails.

X

e Clean main sheaves, secondary

sheaves and rope sheaves on car tops

and counterweight tops.

X

f Clean ropes. Oil if necessary.

X

g Inspect the operation of ventilation fan.

Clean or replace as necessary.

X

h Clean and adjust terminal limit switches

and position switches. Check rubber

rollers of terminal limit switches. Adjust

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 38

Cawangan Kejuruteraan Mekanikal - Rev.1

No. Item

Frequency

Every

Month

Every 2

Month

Every 3

Month

Every 6

Month

Every

Year

or replace as necessary.

i Check travelling cables condition and

alignment. Adjust or replace as

necessary.

X

j Check movement of limit switches.

Adjust, repair or replace as necessary.

X

k Check the operation of terminal limit

switches and final limit switches.

Replace if necessary.

X

l Check the traction rope for broken wires,

wear, elongation and even tension.

Replace if necessary.

X

m Check the compensating chains or

ropes. Adjust, repair or replace as

necessary.

X

n Check the wear of guide shoes of cars

and counterweights. Replace as

necessary.

X

o Clean all the wiring in the junction boxes

of every floor and car cages. Tighten all

screw and check the condition of cables

at conduit inlets and outlets.

X

3 LIFT CAR

a Check indicator lamps and indicators.

Replace as necessary.

X

b Check the annunciator panel and car

lights. Repair or replace as necessary.

X

c Check the alarm bell, intercom and voice

synthesizer. Repair or replace as

necessary.

X

d Check the operation of emergency light

and fan. Repair or replace as necessary.

X

e Check levelling difference, brake

slippage, acceleration, deceleration and

riding comfort.

X

f Check movement of car control buttons,

switches, etc. Repair or replace as

necessary.

X

g Inspect the function of car safety device

(safety edge/photocell/full height

sensor). Repair or replace as necessary.

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 39

Cawangan Kejuruteraan Mekanikal - Rev.1

No. Item

Frequency

Every

Month

Every 2

Month

Every 3

Month

Every 6

Month

Every

Year

h Clean and check push buttons of car

control panels. Repair or replace as

necessary.

X

i Clean and adjust safety gears.

X

j Clean and adjust door hangers, door

rails, interior of hanger case. If

necessary, adjust the rollers, car door

hangers, door connecting ropes and

chains.

X

k Check door shoes. Replace as

necessary.

X

l Check and adjust interior door switches.

Replace worn parts if necessary.

X

m Check and lubricate the bearings of door

motors.

X

4 LIFT PIT

a Inspect lift pit cleanliness and ensure the

lift pit is in dry condition.

X

b Check the compensating pulley and

compensating rope. Lubricate as

necessary.

X

c Inspect the clearance of compensating

pulley. Adjust as necessary.

X

d Clean and adjust car and counterweight

guide shoes. Adjust if necessary.

X

e Check oil of oil buffers. Top-up as

necessary.

X

f Check buffer spring. Repair or replace

as necessary.

X

5 LANDING DOOR & LIFT LOBBY

a Check and adjust door operators, door

openings mechanisms and door levers.

X

b Clean, oil and adjust door closures and

levers.

X

c Check and clean the hall buttons. Repair

or replace as necessary.

X

6 AUTOMATIC RESCUE DEVICE (ARD)

a Test the operation of ARD (power failure

X

Comprehensive Service and Maintenance Schedule Copyright CKM 2013 Page 40

Cawangan Kejuruteraan Mekanikal - Rev.1

No. Item

Frequency

Every

Month

Every 2

Month

Every 3

Month

Every 6

Month

Every

Year

test). Repair or replace as necessary.

b Inspect the battery condition and

electrolyte level. Top-up or replace as

necessary.

X

c Check the battery charger unit. Replace

as necessary.

X

7 CENTRAL SUPERVISORY PANEL

a Inspect the operation of central

supervisory panel and intercom master

unit. Repair or replace as necessary.

X

S-ar putea să vă placă și

- Q&A BANK at SIGNAL SYSTEMDocument5 paginiQ&A BANK at SIGNAL SYSTEMZulkarnain DahalanÎncă nu există evaluări

- Q&A BANK at SIGNAL SYSTEMDocument5 paginiQ&A BANK at SIGNAL SYSTEMZulkarnain DahalanÎncă nu există evaluări

- MyTNB Briefing To Developers Consultants and Contractors vFINAL New PDFDocument42 paginiMyTNB Briefing To Developers Consultants and Contractors vFINAL New PDFZulkarnain DahalanÎncă nu există evaluări

- Terec Plus 2Document2 paginiTerec Plus 2Zulkarnain DahalanÎncă nu există evaluări

- Coded Yellow and Coded RedDocument1 paginăCoded Yellow and Coded RedZulkarnain DahalanÎncă nu există evaluări

- Minutes of Meeting - TCS Interface Coordination 001Document6 paginiMinutes of Meeting - TCS Interface Coordination 001Zulkarnain Dahalan0% (1)

- Tp3 Report Vo Piling Guard House Used For Tcs VariationDocument9 paginiTp3 Report Vo Piling Guard House Used For Tcs VariationZulkarnain DahalanÎncă nu există evaluări

- Minutes of Meeting - TCS Interface Coordination 005 v00Document11 paginiMinutes of Meeting - TCS Interface Coordination 005 v00Zulkarnain DahalanÎncă nu există evaluări

- Draft-SC-comments-MSA-Single Type Toll BoothDocument24 paginiDraft-SC-comments-MSA-Single Type Toll BoothZulkarnain DahalanÎncă nu există evaluări

- Fiber Optic Cable (Original Design Vs Proposal Design)Document1 paginăFiber Optic Cable (Original Design Vs Proposal Design)Zulkarnain DahalanÎncă nu există evaluări

- JL 76 May June 2 PDFDocument25 paginiJL 76 May June 2 PDFJizelle JumaquioÎncă nu există evaluări

- Lecture 7 PDFDocument24 paginiLecture 7 PDFSubrat BarsainyaÎncă nu există evaluări

- TQ Coordination 1 23042019Document1 paginăTQ Coordination 1 23042019Zulkarnain DahalanÎncă nu există evaluări

- Monthly Log - Prolintas Tcs Tcss - 2019Document8 paginiMonthly Log - Prolintas Tcs Tcss - 2019Zulkarnain DahalanÎncă nu există evaluări

- Ir. Zulkarnain Bin Dahalan C114145Document1 paginăIr. Zulkarnain Bin Dahalan C114145Zulkarnain DahalanÎncă nu există evaluări

- Timetable SchedulingDocument19 paginiTimetable SchedulingZulkarnain DahalanÎncă nu există evaluări

- Capstone Project Sept 2018Document1 paginăCapstone Project Sept 2018Zulkarnain DahalanÎncă nu există evaluări

- Novel - Nuramira Binti ZulkarnainDocument1 paginăNovel - Nuramira Binti ZulkarnainZulkarnain DahalanÎncă nu există evaluări

- That She Loves Me So Much I'll BeDocument1 paginăThat She Loves Me So Much I'll BeZulkarnain DahalanÎncă nu există evaluări

- Contract ManagerDocument1 paginăContract ManagerZulkarnain DahalanÎncă nu există evaluări

- BanksoalanPT3 PDFDocument18 paginiBanksoalanPT3 PDFZulkarnain DahalanÎncă nu există evaluări

- Timetable Sep2018 - Hexa & Plaza - Sep 2018 - Plaza MasalamDocument19 paginiTimetable Sep2018 - Hexa & Plaza - Sep 2018 - Plaza MasalamZulkarnain DahalanÎncă nu există evaluări

- Table of Contents-Course File - Engineers in SocietyDocument1 paginăTable of Contents-Course File - Engineers in SocietyZulkarnain DahalanÎncă nu există evaluări

- Revision 1: Evaluation Form for Dissertation II (BCM653Document4 paginiRevision 1: Evaluation Form for Dissertation II (BCM653Zulkarnain DahalanÎncă nu există evaluări

- 2018#Book#OrderDocument6 pagini2018#Book#OrderZulkarnain DahalanÎncă nu există evaluări

- BACHELOR OF ENGINEERING (HONOURS) IN ELECTRICAL AND ELECTRONIC ENGINEERINGDocument6 paginiBACHELOR OF ENGINEERING (HONOURS) IN ELECTRICAL AND ELECTRONIC ENGINEERINGZulkarnain DahalanÎncă nu există evaluări

- Minutes of CCC No. 11Document4 paginiMinutes of CCC No. 11Zulkarnain DahalanÎncă nu există evaluări

- PHNEH-Leave Form-Ir. Zulkarnain Dahalan - 17072018Document1 paginăPHNEH-Leave Form-Ir. Zulkarnain Dahalan - 17072018Zulkarnain DahalanÎncă nu există evaluări

- Mar-Secm-Nt-69-18 Led Flexible Strip LightDocument2 paginiMar-Secm-Nt-69-18 Led Flexible Strip LightZulkarnain DahalanÎncă nu există evaluări

- Theory Problems of Matrices - Schaum - Frank AyresDocument231 paginiTheory Problems of Matrices - Schaum - Frank Ayresbataneja80% (10)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- RBS 2106 V3 Cabinet UpgradeDocument7 paginiRBS 2106 V3 Cabinet Upgradeamos JosephÎncă nu există evaluări

- Gpa Calculation SheetDocument1 paginăGpa Calculation SheetIryna HoncharukÎncă nu există evaluări

- 384 TungaloyDocument32 pagini384 Tungaloyp.designÎncă nu există evaluări

- Complete trip-free loop, PFC and PSC testerDocument2 paginiComplete trip-free loop, PFC and PSC testerGermanilloZetaÎncă nu există evaluări

- Eps Manual NissanDocument8 paginiEps Manual Nissanjoiler pajueloÎncă nu există evaluări

- 124C1ADocument4 pagini124C1AParthiban DevendiranÎncă nu există evaluări

- Renormalization Group: Applications in Statistical PhysicsDocument37 paginiRenormalization Group: Applications in Statistical PhysicsJaime Feliciano HernándezÎncă nu există evaluări

- Pronet Plus User ManualDocument159 paginiPronet Plus User ManualJJ LópezÎncă nu există evaluări

- 006 PVC & CPVC Schedule 80 Fittings, Unions Tank Adapters, Expansion Joints & Saddles PDFDocument92 pagini006 PVC & CPVC Schedule 80 Fittings, Unions Tank Adapters, Expansion Joints & Saddles PDFnicacio_89507470Încă nu există evaluări

- CSEC-Chemistry-p2 May-June 2012 PDFDocument20 paginiCSEC-Chemistry-p2 May-June 2012 PDFdela250% (4)

- Weld CheckDocument6 paginiWeld CheckArnold c ElverÎncă nu există evaluări

- Fault Report - Inventory Cpf1 Vs Caño LimomDocument37 paginiFault Report - Inventory Cpf1 Vs Caño LimomJessica RiveraÎncă nu există evaluări

- LAB REPORT-Rock Pore Volume and Porosity Measurement by Vacuum Saturation-GROUP - 5-PETE-2202Document13 paginiLAB REPORT-Rock Pore Volume and Porosity Measurement by Vacuum Saturation-GROUP - 5-PETE-2202Jeremy MacalaladÎncă nu există evaluări

- Harduaganj Thermal Power Plant by Geetesh SharmaDocument66 paginiHarduaganj Thermal Power Plant by Geetesh Sharmageeteshaccurate100% (1)

- Pioneer Deh-1300 1350 1390mpDocument71 paginiPioneer Deh-1300 1350 1390mpJorge LavezziÎncă nu există evaluări

- Insertion Appointment of Complete Dentures: Lec 17 4 GradeDocument15 paginiInsertion Appointment of Complete Dentures: Lec 17 4 GradeSaif Hashim100% (1)

- WPS PQR CompressedDocument5 paginiWPS PQR CompressedBalaje MantravadiÎncă nu există evaluări

- Hargreaves 2007Document15 paginiHargreaves 2007Sam GonçalvesÎncă nu există evaluări

- Is 4410 9 1982 PDFDocument25 paginiIs 4410 9 1982 PDFSameer Singh PatelÎncă nu există evaluări