Documente Academic

Documente Profesional

Documente Cultură

Fuse

Încărcat de

Alonso CoradoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fuse

Încărcat de

Alonso CoradoDrepturi de autor:

Formate disponibile

- 1 -

Est. 1997/12/10

Rev.20 2002/11/27

SC Protector

Self Control Protector

I nnovative way of safety control for Li-ion rechargeable battery

At any moment, SC Protector system monitors the voltage of Li-ion rechargeable battery and its heater

fuses the fuse at the same instant when the system detects the overcharge. Usual protection element

takes long time to work because it works due to temperature rise of battery cells.

The difference of SC Protector provides you high degree of freedom in the design of protection circuit.

1. Application

Typical application of protection for a Lithium ion rechargeable battery from overcharging is shown

in the figure below.

When the voltage between a and b exceeds the pre-set limit value, the output of the voltage detector

I C becomes high and the FET is switched on. As a result, current flow through the heater of the

protector, the fuses melt, and the battery stops to be charged any longer.

Since the two fuses cut-off the voltage supplies from the charger and the battery, the SC Protector

stops to be heated immediately and thus, the safety control protection is provided against both excess

voltage and excessive heating.

Sony Chemicals Corporation

SI P Division

1-11-2, Osaki, Shinagawa-ku, Tokyo, 141-0032 J apan

TEL+81-3-5435-3943 FAX+81-3-5435-3072

a

b

Charger

c

d

FET

- 2 -

2. Characteristics of SC Protector

2.1. Necessity

2.1.1. Reliability of the protection circuit

All Li-ion rechargeable battery packs are

equipped with at least one protection

circuit (ex.I C+FET).

I n this case, when an I C or FET breaks,

overcharge cant be controlled any more,

and the temperature rise of the battery

cell can invite very dangerous

thermo-runaway leading to smoking or

firing.

The trouble of the I C and FET actually

occurs.

Therefore, double protection is needed to

ensure the safety of Li-ion battery packs.

2.1.2. The weak points of conventional double protection elements.

Protection devices such as temperature fuses and bimetals work by conducting the temperature

rise in the battery to the inside of it via package or lead wire. Hence, they have a disadvantage

that the response speed is slow, and the response speed fluctuates depending on the installation

location of the device.

These elements obstruct a cost reduction since it is incompatible with the reflow soldering due

to their structures, and must depend on manual soldering.

By using SC Protector, the battery cells wont become dangerous condition even if IC or FET breaks.

2.2. Characteristics

1) One device can protect against

both overcharging and overcurrent.

2) Protection against overcharging is

directly performed by the battery cell

voltage, ensuring high accuracy and

quick response, and the response speed

does not fluctuate depending on the

location and condition of installation.

3) At the same time of protection

against overcharging, since it is

constructed to send current to the

heater via the fuse element, the fuse

element forcibly fused by the heating of the heater and, upon the cutoff of charging circuit,

the current to the heater automatically stops, and hence, SC Protector itself never

overheated.

4) Abundant product lineup allows the selection of protector with optimal operating

voltage and operating current depending on the cell structure of battery pack, ensuring

high degree of freedom in the design of protection circuit.

5) I t is compatible with automatic mounting using general-purpose chip mounter, and at

the same time, compatible with the reflow soldering, contributing to the reduction of parts

mounting cost.

SC Protector has the strong points as shown above and it meets the safety requirement without

spoiling the strong point of miniature of the Li-ion battery.

I C for protection

FET Trouble?

NTC

Thermistor

T

Trouble?

FET

Battery

cell

Overcharge =Danger

SCP protects from overcharge

and over current =Safe

FET

T

FET

SC Protector

S

e

n

s

i

n

g

e

l

e

m

e

n

t

S

w

i

t

c

h

i

n

g

e

l

e

m

e

n

t

Double protection circuit using SC Protector

Battery

cell

I C for protection

Trouble?

Basic circuit with troubles

- 3 -

3. Relations between the fusion state and the operation mode

The operation mode can be estimated by the fusion state of the fuse element.

3.1. Heater operation

I n the case of overvoltage, Both two sides of the middle electrode are fused by the heater

operation. Because the fuses are heated until the charge to the heater is stopped.

Only one side may be cut when the protection circuit is designed so that charging to the

heater stops by cutting of one side of the middle electrode.

For the heater operation, it is characterized as Fuses like flow into the middle electrode.

<Features of the heater operation>

! Fuses like flow into the middle electrode

! Both two side (or one side) is fused

3.2. Current operation

I n the case of overcurrent operation, basically, only one position of the fuse is cut because

it is the same operation mode as the conventional electric current fuse. When the current

exceeds 50A, two positions are cut occasionally.

For the current operation, it is characterized as The cutting position isn't fixed, I t cuts

like bursting.

<Features of the current operation>

! Cutting position isnt fixed

! I t cuts like bursting

! One position is cut basically (Over 50A,

two positions are cut occasionally)

- 4 -

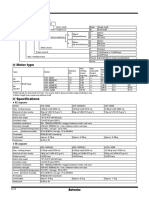

4. Basis of selection

Current-carrying capacity

(*2)

Number of cells in series Special edition

(*6)

Price

(*1)

Soldering

Nominal

Rated current

25! 40! 60!

Current-rush

withstand

(*3)

1cell 2cells 3cells 4cells 20V or more

5A 7.0A 6.0A 5.0A 30A-5ms

SFD-045A SFD-125A SFD-145B SFD-165A

7A 8.0A 7.0A 6.5A 80A-5ms

SFD-047A SFD-127A SFD-147B SFD-167A

8A 9.0A 8.5A 7.0A 80A-5ms SFD-048A SFD-128B SFD-148B -

Standard

(Exclude

SFD-16x)

Reflow

Max

260!

12A

13.5A 12.0A 10.0A 100A-10ms

(*4)

- SFG-1212A SFG-1412A -

6A 7.0A 6.5A 5.5A 36A-5ms

SFE-046A SFE-086A SFE-126A SFE-146A SFE-246A

Low

Reflow

Max

245!

8A 9.0A 8.5A 7.0A

50A-5ms

100A-0.5ms

(*5)

SFE-048A SFE-088A SFE-128A SFE-148A -

Common model of thermal fuse with heater

Soldering iron

Spot reflow

10A

7A at 40!

(Fusing-off by 9A at 40!)

-

(*1) I t is a relative expression between SFD/SFG and SFE.

(*2) I t is the typical value that is calculated from 100 , the temperature that we confirmed the reliability with our companys standard PCB (0.6t Glass

Epoxy single-sided copper-clad laminates). I t is influenced by thermal capacity of PCB and so we recommend checking it with your PCB.

25 , 40 and 60 are ambient temperature.

The temperature that we confirmed the reliability is not a critical condition. SCP fusing-off temperature is 200 or more.

Current-carrying capacity is measured in thermal equilibrium condition. Therefore, if Current-carrying time is short, Current-carrying

capacity will increase.

(*3) I t is the test condition (5ms-On, 995ms-Off, 5000cycle) that we confirmed the reliability. But it is not necessarily a critical condition for SCP.

(*4) I t is the test condition (10ms-On, 9990ms-Off, 1000cycle) that we confirmed the reliability. But it is not necessarily a critical condition for SCP.

(*5) We recommend using I C that can interrupt current by 0.5ms or less when SFE-xx8A is adopted in the module that has 80A or more rush current.

(*6) SFD-16xA is special edition that has high operating voltage. Therefore, we recommend using SFx-14xx for 4cells in series.

- 5 -

5. External view & Equivalent circuit

5.1. SFC series (Rated current 5A)

5.2. SFD/SFE series (Rated current 5-8A)

5.3. SFG series (Rated current 12A)

5.4. SFH series (Rated current 12A)

7

5.4

3

.

2

4

1 2 3

4

1

2

3

4

1

4

3

1

4

3

1.45max

1.35max

Ceramic 4,6-nylon

4,6-nylon

Ceramic

unit mm

unit mm

Heater

Fuse

Heater

Fuse

7

5.4

3

.

2

4

1

3

4

1

3

4

unit mm

unit mm

Heater Fuse

1

2

3

4

1

3

4

Heater Fuse

2

1.45max

4,6-nylon

Ceramic

1.35max

Ceramic 4,6-nylon

- 6 -

2.9 1.2 (2.9)

1

.

2

2

.

8

4

0

.

2

1.2 1.2 1.2

1.05

1.05 (0.65) 0.65

1 2 3

4 4 - R0.2

7.0 0.2

6. Terminal Size (Unit: mm. Not in scale.)

6.1. SFC series (Rated current 5A)

6.2. SFD/SFE series (Rated current 5-6A)

6.3. SFD series (Rated current 7A)

3

.

2

0

1.2 0.1

5.40

+0. 3

- 0. 2

2.10

1.2 0.1 0.40 1.2 0.1 2.20

3-R0.2

+

0

.

3

-

0

.

2

1

.

2

0

2

.

0

0

1 3

4

3

.

2

0

1.2 0.1

5.40

+0. 3

- 0. 2

2.10

1.2 0.1 0.40

1.2 0.1

2.20

3-R0.2

+

0

.

3

-

0

.

2

1

.

2

0

2

.

0

0

1 3

4

0

.

6

7

5

Black insulation glass (15um or less)

- 7 -

2.9 1.2 (2.9)

0

.

9

2

.

0

3

.

0

4

0

.

2

1.4 1.2 1.4 0.75 0.75 (0.75) 0.75

1

4

3

4 - R0.2

(

0

.

2

)

(

0

.

4

)

3

.

6

7.0 0.2

6.4. SFD/SFE series (Rated current 8A)

6.5. SFG series (Rated current 12A)

The unevenness of the circular

arc part is typical 15um.

3

.

2

0

1.2 0.1

5.40

+0. 3

- 0. 2

2.10

1.2 0.1

0.40

1.2 0.1

2.20

3-R0.2

+

0

.

3

-

0

.

2

1

.

2

0

1

.

2

0

1 3

4

1

.

8

2

5

2-R0.35

1

.

4

7

5

3.70

- 8 -

7. Specification

7.1. General

SC Protector

Qualification UL248-14 (File No. E167588) TUV (Certificate No. J 9650637)

Rated voltage(*) 36VDC

Rated breaking capacity 50A

(*) is the maximum voltage can be cut off by fuse. I t is not the operational voltage of the heater.

7.2. SFC series

for 1-2 cells in series for 3 cells in series for 4 cells in series

SFC-0405B SFC-1205A SFC-1605A

Rated current 5A

Size 7.0 4.0 1.45

Electrode Ag-Pd

Fuse resistance 1-3 (Typical) 15 3m

Operating electric power 3.5 22W

Operating voltage 4.0 9.0V 7.8 17.9V 8.5 19.3V

Heater resistance 4.1 0.4 16.0 1.5 18.9 1.9

Marking

Reflowing temperature"MAX# 260

7.3. SFD series

SFD-04X for 1-2 cells in series SFD-045A SFD-047A SFD-048A

Rated current 5A A 8A

Size 5.4 3.2 1.35

Electrode Au plated Ag-Pt

Fuse resistance (Typical) 12 2m 6.5 1.5m 5.5 1.0m

Operating electric power 3.5 22W 4.0 22W

Operating voltage 4.0 9.0V 4.3 9.0V

Heater resistance 4.1 0.4

Marking

Reflowing temperature"MAX# 260

SFD-12X for 3 cells in series SFD-125A SFD-127A SFD-128B

Rated current 5A A 8A

Size 5.4 3.2 1.35

Electrode Au plated Ag-Pt

Fuse resistance (Typical) 12 2m 6.5 1.5m 5.5 1.0m

Operating electric power 3.5 22W 4.0 22W

Operating voltage 7.5 17.0V 6.5 13.6V

Heater resistance 14.6 1.5 9.4 0.9

Marking

Reflowing temperature"MAX# 260

SC 5A SF

0405B

SC 5A SF

1205A

SC 5A SF

1605A

5A SF

SC 10

7A SF

SC 10

8A SF

SC 10

5A SF

SC 30

7A SF

SC 30

8A SF

SC 31

- 9 -

SFD-14X for 4 cells in series SFD-145B SFD-147B SFD-148B

Rated current 5A A 8A

Size 5.4 3.2 1.35

Electrode Au plated Ag-Pt

Fuse resistance (Typical) 12 2m 6.5 1.5m 5.5 1.0m

Operating electric power 3.5 22W 4.0 22W

Operating voltage 9.7 19.6V 10.3 19.6V

Heater resistance 22.0 4.4

Marking

Reflowing temperature"MAX# 260

SFD-16X for High Voltage SFD-165A SFD-167A

Rated current 5A A

Size 5.4 3.2 1.35

Electrode Au plated Ag-Pt

Fuse resistance (Typical) 12 2m 6.5 1.5m

Operating electric power 3.5 22W

Operating voltage 11.1 25.0V

Heater resistance 31.6 3.2

Marking

Reflowing temperature"MAX# 260

7.4. SFE series

SFE-04X for 1 cell in series SFE-046A SFE-048A

Rated current 6A 8A

Size 5.4 3.2 1.35

Electrode Ag-Pt

Fuse resistance (Typical) 9 2m 5 1.5m

Operating electric power 3.5 22W 3.5 20W

Operating voltage 4.0 8.2V 4.0 7.0V

Heater resistance 3.8 0.7 3.5 1.0

Marking

Reflowing temperature"MAX# 245

SFE-08X for 2 cells in series SFE-086A SFE-088A

Rated current 6A 8A

Size 5.4 3.2 1.35

Electrode Ag-Pt

Fuse resistance (Typical) 9 2m 5 1.5m

Operating electric power 3.5 22W 3.5 20W

Operating voltage 5.6 10.2V 5.6 9.8V

Heater resistance 6.9 2.1

Marking

Reflowing temperature"MAX# 245

6A SF

SC 1B

8A SF

SC 1B

6A SF

SC 2B

8A SF

SC 2B

5A SF

SC 51

7A SF

SC 51

8A SF

SC 51

5A SF

SC 40

7A SF

SC 40

- 10 -

SFE-12X for 3 cells in series SFE-126A SFE-128A

Rated current 6A 8A

Size 5.4 3.2 1.35

Electrode Ag-Pt

Fuse resistance (Typical) 9 2m 5 1.5m

Operating electric power 3.5 22W 3.5 20W

Operating voltage 7.8 16.0V 8.0 14.1V

Heater resistance 14.6 2.9 14.2 4.2

Marking

Reflowing temperature"MAX# 245

SFE-14X for 4 cells in series SFE-146A SFE-148A

Rated current 6A 8A

Size 5.4 3.2 1.35

Electrode Ag-Pt

Fuse resistance (Typical) 9 2m 5 1.5m

Operating electric power 3.5 22W 3.5 20W

Operating voltage 9.7 19.6V 11.2 19.6V

Heater resistance 22.0 4.4 27.6 8.3

Marking

Reflowing temperature"MAX# 245

SFE-24X for 5-6 cells in series SFE-246A SFE-248A(*)

Rated current 6A 8A

Size 5.4 3.2 1.35

Electrode Ag-Pt

Fuse resistance (Typical) 9 2m 5 1.5m

Operating electric power 3.5 22W 3.5 18W

Operating voltage 14.1 26.1V 15.8 26.3V

Heater resistance 44.0 13.0 55.0 16.5

Marking

Reflowing temperature"MAX# 245

(*) under development

6A SF

SC 3B

8A SF

SC 3B

6A SF

SC 5B

8A SF

SC 5B

6A SF

SC 6B

8A SF

SC 6B

- 11 -

7.5. SFG series

for 1 cell in series for 3 cells in series for 4 cells in series

SFG-0412A(*) SFG-1212A SFG-1412A

Rated current 12A

Size 7.0 4.0 1.45

Electrode Ag-Pt

Fuse resistance (Typical) 3 1m

Operating electric power 6 35W

Operating voltage 4.0 7.0V 7.8 13.8V 10.5 18.5V

Heater resistance 2.0 0.6 7.8 2.3 14.0 4.2

Marking

Reflowing temperature"MAX# 260

(*) under development

7.6. SFH series

for 1 cell in series for 3 cells in series for 4 cells in series

SFH-0412A(*) SFH-1212A(*) SFH-1412A(*)

Rated current 12A

Size 5.4 3.2 1.35

Electrode Ag-Pt

Fuse resistance (Typical) 3 1m

Operating electric power 5 30W

Operating voltage 4.0 7.1V 7.7 13.8V 10.4 18.5V

Heater resistance 2.4 0.7 9.1 2.7 16.4 4.9

Marking

Reflowing temperature"MAX# 260

(*) under development

12A G1

SC SF

12A H1

SC SF

12A H3

SC SF

12A H4

SC SF

12A G3

SC SF

12A G4

SC SF

- 12 -

8. Temperature profile of reflow soldering

The temperature shown below is the temperature of the electrode portion of SC Protector.

8.1. Temperature profile of 245 peak

Applicable to: SFC, SFD, SFE, SFG, SFH Type

8.2. Temperature profile of 260 peak

Applicable to: SFC, SFD, SFE, SFG, SFH Type (Not applicable to SFE Type)

Over 135 : 120s

0 30 60 90 120 150 180 210

200

100

0

T

e

m

p

e

r

a

t

u

r

e

Time [s]

Pre-heat

Peak 245

180 -190 : 60s

0 30 60 90 120 150 180 210

200

100

0

Over 230 : 30s

Peak 260

Over 230 : 30s

Pre-heat

T

e

m

p

e

r

a

t

u

r

e

Time [s]

- 13 -

9. Voltage operation

9.1. Operating electric power and Operating voltage

1) Operating electric power range: Electricity Power applied to heater

2) Operating voltage range: Values are calculated from operating electric power range and heater

resistance. Protector operation is normal under voltage applied to heaters in these

ranges. Operating voltage range is adjustable by regulating heater resistance.

(Operating voltage[V] Operating electric power [W] Heater resistance[ ] )

9.2. Voltage operation test method

1) Connect SC Protector with a constant power

supply.

2) Apply a current to the heater.

3) Measure the time the fuses take to melt.

9.3. Operation time by the heater (Electricity vs. clearing time at 25$)

0.1

1

10

100

0 5 10 15 20 25 30 35 40

Electric Power(W)

C

l

e

a

r

i

n

g

T

i

m

e

(

s

)

SFC-5A

SFD-5A

SFD-7A%8A

SFE-6A

SFE-8A

SFG-12A

1

4

3

- 14 -

9.4. Operation time by the heater (Voltage vs. clearing time at 25$)

9.5. Operation time by the heater (Ambient temperature vs. clearing time)

0.&

&

&0

&00

0 5 10 15 20 25

Voltage(V)

C

l

e

a

r

i

n

g

T

i

m

e

(

s

)

SFC-0405B

SFC-1205A

SFC-1605A

SFD-045A

SFD-047A%048A

SFD-125A

SFD-127A

SFD-128B

SFD-145B

SFD-147B%148B

SFE-126A

SFE-128A

SFE-146A

SFE-148A

SFG-1212A

SFG-1412A

for 4cells

in series

for 3cells

in series

for 1-2cells

in series

1

10

100

-40 -20 0 20 40 60 80 100

Ambient temperature

C

l

e

a

r

i

n

g

T

i

m

e

(

s

)

SFC-5A (3.5W)

SF'-5( (3.5W)

SFD-7A%8A (3.5W)

SFE-6A (3.5W)

SFE-8A (3.5W)

SFG-12A (6W)

- 15 -

10. Current interrupting time (at25$)

10.1. Current interrupting time (Ambient temperature vs. Clearing time by Rated Current * 2)

0.0001

0.001

0.01

0.1

1

10

100

0 20 40 60 80 100 120 140 160

Current(A)

C

l

e

a

r

i

n

g

T

i

m

e

(

s

)

SFC-5A

SFD-5A

SFD-7A%8A

SFE-6A

SFE-8A

SFG-12A

1

10

100

-40 -20 0 20 40 60 80 100

Ambient Temperature($)

C

l

e

a

r

i

n

g

T

i

m

e

(

S

)

SFC-5A

SF'-5(

SFD-7A%8A

SFE-6A

SFE-8A

SFG-12A

- 16 -

11. Others

11.1. Catalog data is the typical value.

1) Catalog data is not a guaranteed value.

2) Catalog data is measured with our companys standard PCB (0.6t Glass Epoxy

single-sided copper-clad laminates). The characteristics are influenced by thermal capacity

of PCB. Generally, when thermal capacity of PCB increases, Current-carrying capacity will

increase and Clearing-time will be long.

11.2. Please select the product on the basis of [Current-carrying capacity].

1) Nominal rated current is provided on the basis of UL standard (The maximum

temperature rise on body or contact that is passed the current shall not exceed 70C) and so

it is not Current-carrying capacity. Therefore, please select a product on the basis of

Current-carrying capacity instead of Nominal rated current.

2) Current-carrying capacity is influenced by thermal capacity of PCB. Therefore we

recommend checking it on your PCB.

3) We accept the test (Current-carrying capacity and Clearing-characteristics and so on) with

your PCB. Please request to us unreservedly.

11.3. Current-carrying capacity

1) Current-carrying capacity is the current-carrying value that SCP reaches temperature

that we confirmed the reliability in our company.

2) The temperature that we confirmed the reliability is 100 . But it is not a critical

condition for SCP. For example, if SCP temperature exceeds it, SCP is not immediately

fusing-off like a common thermal fuse. SCP fusing-off temperature is 200 or more and so

it has much more capability for the temperature rise.

3) Current-carrying capacity is measured in thermal equilibrium condition so that if

Current-carrying time is short, Current-carrying capacity will increase.

11.4. Precautions regarding handling

1) Make sure that the terminals of this product are connected on the lands of the circuit

board, and that the resistance between terminal1-4 and 3-4 are rated heater resistance.

2) Ultrasonic cleansing or immersion cleansing must not be done for SCP. When cleansing is

done, flux in element flows, and the specification will not be satisfied. These products after

cleansing will be not guaranteed.

Sony Chemicals Corporation

SI P Division

1-11-2, Osaki, Shinagawa-ku, Tokyo, 141-0032 J apan

TEL+81-3-5435-3943 FAX+81-3-5435-3072

S-ar putea să vă placă și

- Aspen Custom Modeler Equations of The Flash Model PDFDocument5 paginiAspen Custom Modeler Equations of The Flash Model PDFkiny81Încă nu există evaluări

- Expt 2 DC Compound Generator Using SimulinkDocument5 paginiExpt 2 DC Compound Generator Using SimulinkJay Em100% (1)

- Cable Reel Leroy Somer - enDocument16 paginiCable Reel Leroy Somer - enEmerson BatistaÎncă nu există evaluări

- Simple LCC Resonant Half Bridge Converter Solution: NCP160 (2) 2 + NCL30059Document21 paginiSimple LCC Resonant Half Bridge Converter Solution: NCP160 (2) 2 + NCL30059alokÎncă nu există evaluări

- L293D Motor Control Shield: FeaturesDocument6 paginiL293D Motor Control Shield: FeaturesJefferson HenriqueÎncă nu există evaluări

- Product Spec - ST3151A04-8 Ver 2.2 20141112Document24 paginiProduct Spec - ST3151A04-8 Ver 2.2 20141112Birciu ValiÎncă nu există evaluări

- PDFDocument2 paginiPDFFlorian LeordeanuÎncă nu există evaluări

- UP5135 DC20v 100A MeterDocument1 paginăUP5135 DC20v 100A Meterdanielstancu883296Încă nu există evaluări

- 45 - Altivar 61 Plus Variable Speed DrivesDocument130 pagini45 - Altivar 61 Plus Variable Speed Drivesabdul aziz alfiÎncă nu există evaluări

- Eu-R SAA ULDocument74 paginiEu-R SAA ULCarlos Alberto de Andrade Freitas Junior100% (1)

- Air Circuit Breakers - AH TypeDocument12 paginiAir Circuit Breakers - AH TypeSanjay JoshiÎncă nu există evaluări

- LHB Eog Power CarDocument41 paginiLHB Eog Power Carvishak MkÎncă nu există evaluări

- Designing TurbogeneratorDocument6 paginiDesigning TurbogeneratorMadhan GopalÎncă nu există evaluări

- Calculate Size of Diesel GeneratorDocument1 paginăCalculate Size of Diesel GeneratorIonut ArdeleanÎncă nu există evaluări

- En Relee de Timp SchrackDocument36 paginiEn Relee de Timp SchrackAnthony Adams50% (2)

- Easy Weld MIG NB-500D ManualDocument20 paginiEasy Weld MIG NB-500D ManualDavy R.K.Încă nu există evaluări

- Making CoilsDocument9 paginiMaking CoilsSleshi MekonnenÎncă nu există evaluări

- UPS Easy 3S OperationDocument48 paginiUPS Easy 3S Operationacodr83Încă nu există evaluări

- Technology: 2 Phase DC Motor Drive Ic General DescriptionDocument13 paginiTechnology: 2 Phase DC Motor Drive Ic General DescriptionalexÎncă nu există evaluări

- OPzV GelDocument1 paginăOPzV GelSINES France100% (1)

- Power Genius Meters PDFDocument2 paginiPower Genius Meters PDFAritheertham SaravananÎncă nu există evaluări

- Amtech Basler Offers Solution For Replacing ABB1000-15 With DECS200 Digital Excitation SystemDocument4 paginiAmtech Basler Offers Solution For Replacing ABB1000-15 With DECS200 Digital Excitation SystemRamakrishnan AlagarsamyÎncă nu există evaluări

- TNY278PNDocument4 paginiTNY278PNJose BenavidesÎncă nu există evaluări

- Catalogue Multi 9 Merlin Gerin PDFDocument2 paginiCatalogue Multi 9 Merlin Gerin PDFOrlando VilladiegoÎncă nu există evaluări

- Uar4N: User ManualDocument40 paginiUar4N: User ManualArtur EckertÎncă nu există evaluări

- FRENIC Ace Solar Pumping ManualDocument78 paginiFRENIC Ace Solar Pumping ManualSINES FranceÎncă nu există evaluări

- Minarc Evo 150 Service Manual PDFDocument31 paginiMinarc Evo 150 Service Manual PDFselmir_9Încă nu există evaluări

- Dual Synchronous Buck Converter: BD93291EFJDocument25 paginiDual Synchronous Buck Converter: BD93291EFJDjalma MotaÎncă nu există evaluări

- MosfetSIC, Trad Double Pulse FixtureDocument6 paginiMosfetSIC, Trad Double Pulse FixtureManuel SierraÎncă nu există evaluări

- Presto 190gc IngDocument18 paginiPresto 190gc Ingandreiion100% (1)

- Sm34 Controller WSNMPDocument2 paginiSm34 Controller WSNMPBraian AvellaÎncă nu există evaluări

- Fuses in Parallel Fuses in Parallel: ConfidentialDocument10 paginiFuses in Parallel Fuses in Parallel: ConfidentialJonny Cristhian Otero Baca100% (1)

- Service Manual: KD-G111, KD-G117Document153 paginiService Manual: KD-G111, KD-G117boroda2410Încă nu există evaluări

- Brochure DEYE Hybride SUN XKDocument6 paginiBrochure DEYE Hybride SUN XKSINES FranceÎncă nu există evaluări

- Rev: A: Page Title of SchematicDocument35 paginiRev: A: Page Title of SchematicLuis Alberto ArizaÎncă nu există evaluări

- Talus 200I (En)Document31 paginiTalus 200I (En)Marius NagyÎncă nu există evaluări

- Sew EncoderDocument24 paginiSew EncodersanatikalaÎncă nu există evaluări

- ABB Drives Rtac-01 Pulse Encoder Interface Module User's ManualDocument23 paginiABB Drives Rtac-01 Pulse Encoder Interface Module User's ManualJohn SimancaÎncă nu există evaluări

- Universal IC 555 BuckDocument7 paginiUniversal IC 555 BuckSingam Sridhar100% (1)

- Abb Utilities GMBH: Remote Terminal Unit Connections and Settings Analog Input 23ae21Document7 paginiAbb Utilities GMBH: Remote Terminal Unit Connections and Settings Analog Input 23ae21TalibÎncă nu există evaluări

- 14 20B10PDocument43 pagini14 20B10PJimmy Fonseca GarbanzoÎncă nu există evaluări

- Transistor (PNP) : 1. Base 2. Emitter 3. Collector Z ZDocument2 paginiTransistor (PNP) : 1. Base 2. Emitter 3. Collector Z ZRaj ChoudharyÎncă nu există evaluări

- Aspire Manual PumpDocument19 paginiAspire Manual Pumpsouhaib alviÎncă nu există evaluări

- InteliMains 210 DatasheetDocument4 paginiInteliMains 210 DatasheetMaylen Rivas0% (1)

- Fault, Protection and Failure Indications in PSE Soft StarterDocument5 paginiFault, Protection and Failure Indications in PSE Soft StartermichaelÎncă nu există evaluări

- Fabricantes PSU 2the MaxDocument51 paginiFabricantes PSU 2the Maxhoaxnet100% (1)

- Installation and Maintenance: This Manual Is To Be Given To The End UserDocument12 paginiInstallation and Maintenance: This Manual Is To Be Given To The End UserHoang GiangÎncă nu există evaluări

- Introduction Features: Ultra Fast High PSRR Low Noise CMOS Voltage RegulatorDocument11 paginiIntroduction Features: Ultra Fast High PSRR Low Noise CMOS Voltage RegulatorkalanghoÎncă nu există evaluări

- Stepper Motor Control Through RF LinkDocument12 paginiStepper Motor Control Through RF Linkmrx1061100% (1)

- Motor de Passo A16K-G268Document3 paginiMotor de Passo A16K-G268Edson DinizÎncă nu există evaluări

- CONTACTORDocument6 paginiCONTACTORGenrry EchaccayaÎncă nu există evaluări

- Avr 20 DatakomDocument2 paginiAvr 20 DatakomMiguel Angel Pavon CarbonellÎncă nu există evaluări

- Aj Power Ats Panels Handbook-En-rev3Document44 paginiAj Power Ats Panels Handbook-En-rev3Fernando QuisberthÎncă nu există evaluări

- BLDC 5015aDocument5 paginiBLDC 5015aroozbehxoxÎncă nu există evaluări

- Ferrite Transformer Turns Calculation With ExampleDocument4 paginiFerrite Transformer Turns Calculation With ExampleKerlin Sanabria0% (1)

- Qep R5 50Hz 1P Avr Itr 12V: EngineDocument2 paginiQep R5 50Hz 1P Avr Itr 12V: EngineKen VikstromÎncă nu există evaluări

- NX 0614T - 1214T: 159-352 KW Chiller, Air Source For Outdoor InstallationDocument67 paginiNX 0614T - 1214T: 159-352 KW Chiller, Air Source For Outdoor Installationsantifer26Încă nu există evaluări

- SCCM8048 IiDocument13 paginiSCCM8048 IiMilan NecakovÎncă nu există evaluări

- TLP 250 ADocument6 paginiTLP 250 AbnnmailÎncă nu există evaluări

- ULN2004APG Datasheet en 20101203Document13 paginiULN2004APG Datasheet en 20101203Kirk Freire LópezÎncă nu există evaluări

- HDCSD9Document68 paginiHDCSD9gabir980% (1)

- Transistor P2N06CLDocument7 paginiTransistor P2N06CLPauloPecegueiroÎncă nu există evaluări

- Sizing of Power Cables For Circuit Breaker Controlled Feeders Part 1Document5 paginiSizing of Power Cables For Circuit Breaker Controlled Feeders Part 1Ko PaukÎncă nu există evaluări

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsDe la EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsÎncă nu există evaluări

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionÎncă nu există evaluări

- Themaclassic F30E and F30E SB Instructions For Use Installation and ServicingDocument52 paginiThemaclassic F30E and F30E SB Instructions For Use Installation and ServicingAlonso CoradoÎncă nu există evaluări

- Yamaha FZ6-SS (SSC) 2004 Service ManualDocument432 paginiYamaha FZ6-SS (SSC) 2004 Service ManualBivol LeonidÎncă nu există evaluări

- Draw On Google Earth and Export The Objects To AutoCAD - DevCADLispDocument14 paginiDraw On Google Earth and Export The Objects To AutoCAD - DevCADLispAlonso CoradoÎncă nu există evaluări

- Samsung 713BNDocument46 paginiSamsung 713BNAlonso CoradoÎncă nu există evaluări

- SD6109Document10 paginiSD6109Alonso Corado100% (1)

- TL866 ProgDocument9 paginiTL866 ProgAlonso CoradoÎncă nu există evaluări

- Alarma GarajDocument1 paginăAlarma GarajAlonso CoradoÎncă nu există evaluări

- FSC v5535 z17mDocument31 paginiFSC v5535 z17mAlonso CoradoÎncă nu există evaluări

- HP Pavilion Dv6 Dv7 Quanta Ut12 Rev 1a SCHDocument48 paginiHP Pavilion Dv6 Dv7 Quanta Ut12 Rev 1a SCHAlonso CoradoÎncă nu există evaluări

- PlotterGraphtec 07I107EDocument5 paginiPlotterGraphtec 07I107EAlonso CoradoÎncă nu există evaluări

- DeltaSol BS Plus V2.MonenDocument52 paginiDeltaSol BS Plus V2.MonenAlonso CoradoÎncă nu există evaluări

- Steca PV Off Grid enDocument31 paginiSteca PV Off Grid enAlonso CoradoÎncă nu există evaluări

- ABS Submersible Sewage Pump AFP M8 M9Document2 paginiABS Submersible Sewage Pump AFP M8 M9Alonso CoradoÎncă nu există evaluări

- Trasfo CurentDocument11 paginiTrasfo CurentAlonso CoradoÎncă nu există evaluări

- Control Stations Comex: Selection ChartDocument2 paginiControl Stations Comex: Selection ChartAlonso CoradoÎncă nu există evaluări

- 1006 MTL 4840 HartDocument14 pagini1006 MTL 4840 HartAlonso CoradoÎncă nu există evaluări

- Ba Sar1!07!16 Norm enDocument48 paginiBa Sar1!07!16 Norm enAlonso CoradoÎncă nu există evaluări

- Aisikai Auto Transfer Switch DocumentationDocument7 paginiAisikai Auto Transfer Switch DocumentationAlonso Corado100% (1)

- Power ControlDocument96 paginiPower ControlAlonso CoradoÎncă nu există evaluări

- TUTO 5 TransformerDocument2 paginiTUTO 5 TransformerVievie Le BluewberrietrufflesÎncă nu există evaluări

- Multi VerseDocument82 paginiMulti VerseAntito123Încă nu există evaluări

- Force, Work, Power and Energy - Daily Home Assignment 02 - (Victory 2024 - ICSE)Document2 paginiForce, Work, Power and Energy - Daily Home Assignment 02 - (Victory 2024 - ICSE)44 A Ritam BeraÎncă nu există evaluări

- Huawei SPD IntroductionDocument3 paginiHuawei SPD Introductionlkt_pestech100% (1)

- Electronic Materials: Mid - ReviewDocument20 paginiElectronic Materials: Mid - Reviewchinh buiÎncă nu există evaluări

- Mitsubishi PS21767-VDocument9 paginiMitsubishi PS21767-VMadai Sanchez TopeteÎncă nu există evaluări

- f4 F Instruction-ManualDocument45 paginif4 F Instruction-ManualCsaba TimarÎncă nu există evaluări

- DCMT Lecture Notes Full - 230406 - 110711Document111 paginiDCMT Lecture Notes Full - 230406 - 1107114402 Ajesh RÎncă nu există evaluări

- MecE 331 Design Project 1Document12 paginiMecE 331 Design Project 1Saad NavaidÎncă nu există evaluări

- SM 9412Document30 paginiSM 9412Elton RibeiroÎncă nu există evaluări

- Lecture-III Basics of Pinch Analysis - 2Document35 paginiLecture-III Basics of Pinch Analysis - 2Chalachew NigussieÎncă nu există evaluări

- Power II 2015 2016 Tutorials PDFDocument42 paginiPower II 2015 2016 Tutorials PDFMohamad SannanÎncă nu există evaluări

- Random Irregular WaveDocument9 paginiRandom Irregular WaveBagus Bagaskara PutraÎncă nu există evaluări

- Lecture Notes On Quantum PhysicsDocument109 paginiLecture Notes On Quantum PhysicsGoogle SucksÎncă nu există evaluări

- JEE Main Online Exam 2019: (Memory Based Paper)Document6 paginiJEE Main Online Exam 2019: (Memory Based Paper)Deepak SainiÎncă nu există evaluări

- AerodynamicsDocument42 paginiAerodynamicsFreda FungÎncă nu există evaluări

- Fed Motors Insulation PDFDocument6 paginiFed Motors Insulation PDFJaime Vanegas IriarteÎncă nu există evaluări

- Mesh Analysis (Maxwell's Loop Current Technique)Document20 paginiMesh Analysis (Maxwell's Loop Current Technique)Taranga SenÎncă nu există evaluări

- Epm Group AssignmentDocument10 paginiEpm Group AssignmentMuhammad ZikryÎncă nu există evaluări

- Science: Quarter 2 - Module 6 Electromagnetism in Everyday LifeDocument68 paginiScience: Quarter 2 - Module 6 Electromagnetism in Everyday LifeJacob Dy67% (3)

- Physics Unit 3B PDFDocument7 paginiPhysics Unit 3B PDFZubanaÎncă nu există evaluări

- CV - Taruna Mandiri ElektrindoDocument2 paginiCV - Taruna Mandiri ElektrindoJD JayÎncă nu există evaluări

- Transformer Reactance Calculations With Digital ComputersDocument7 paginiTransformer Reactance Calculations With Digital ComputersHarmonyÎncă nu există evaluări

- Reshuffling 1 Paper 2Document13 paginiReshuffling 1 Paper 2Rachit JainÎncă nu există evaluări

- Industrial Chemistry and Tribology Topic 5Document18 paginiIndustrial Chemistry and Tribology Topic 5Gonzales Frank Lioyd Bhong100% (1)