Documente Academic

Documente Profesional

Documente Cultură

StirnradAufsGetriebmitHo Bothner LG ENG

Încărcat de

Dara SatwikDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

StirnradAufsGetriebmitHo Bothner LG ENG

Încărcat de

Dara SatwikDrepturi de autor:

Formate disponibile

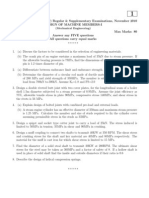

Helical I Bevel Helical Gear Units

Nomenclature

/'

250

Size

Output shaft style

Style

Solid shaft

Symbol

No symbOl

Hollow shaft with key connection

Hollow shaft with Shrink disc connection

Mounting arrangement

N

= Foot mounted, Solid output shaft

= Foot mounted, Hollow output shaft

= Shaft mounted, Hollow output shaft

No. of stages

S

= Single

= Double

T = Triple

Q

= Quadruple

Type of gear units

H

= Helical Gear Units

B = Bevel-Helical Gear Units

Details required in orders :

Type of gear units

No. of stages

Input power and Speed

Transmission ratio - i

Handing and Direction of rotation

Shaft disposition

Mounting position and arrangement

Size

Example:

Helical Gear Unit, Triple stage, Power = 80 kW, Input speed = 1500 rpm, Transmission ratio i = 28, Rl- Handing, Hollow output shaft with shrink disc

connection, Horizontal, Foot mounted, Type HTAD, Size 250.

Example:

Bevel Helical Gear Unit, Triple stage, Power = 120 kW, Input speed = 1500 rpm, Transmission ratio i = 40, LR - Handing, Solid output shaft,

Horizontal, Foot mounted, Type BTN, Size 320.

- 1 -

Helical I Bevel Helical Gear Units

Introduction. Design Features

INTRODUCTION

These Gear Units are available in parallel shaft helical units in single, double, triple and quadruple reduction gear stages having a maximum output torque rating uplO

950 kNm. And in right angled shaft bevel helical units in double, triple and quadruple reduction gear stages having a maximum output torque raling uplo 600 kNm.

The modular design and construction of this series, offer many engineering and performance advantages induding high degree of interchangeability of parts

and sub assemblies.

Design of these Gear Units, made with gearing details following addendum modification based on the latest findings of gear design with the help of latest computer

software programmes has been finalised keeping the most favourable ratio distribution and the no. of teeth, module, helix angle, face width combination in order to

achieve the optimum evenly distributed power rating in various stages and to get the highest diameter for the shaft extension of the input shaft quite comparable to

the shaft diameter of the prime mover.

DESIGN FEATURES

Gears

Single helical gears, profile ground with the latest technique for tip relief and face crowning in the modem gear grinding machines are made out of NiCrMo case

hardening alloy steel. This ensures high standards of accuracy to relevant ISO I DIN I AGMA standards to achieve quiet running characteristics. Spiral bevel

gears are produced in the most modem Bevel generating machines and finished by lapping in dedicated machines, after case hardening.

Gear casing

Gear casings, created using the latest techniques of 30 modeling possess the most modern styling and the rigidity. For all Helical Gear units and For Bevel Helical

Gear units sizes upto 320, are made of close grained Cast Iron to achieve favourable vibration dampening properties.

Other features are:

- Case design is made using the latest FEA techniques to get high strength to weight ratio.

- Horizontal split case design for ease of maintenance

Inspection cover provided for viewing gear contacts during maintenance shut downs.

- Provision of oil level dipstick, ventilator with dust proof filler and drain plugs. Optionally oil level sight glass can be provided in place of dipstick.

- Gear casing in fabricated steel construction as alternative for all Helical Gear Units and for Bevel Helical Gear Units Sizes upto 320. For Bevel Helical Gear Units

Sizes 360 and above, Casing is in fabricated steel construction only.

Bearings

Amply proportioned roller bearings are used to support all the shafts. For three and four stage design, the input shaft will have shorter span to avoid harmful

deflection on load.

Backstops (Holdback units)

When required to operate on non-reversing drives, back stops can be fitted. The backstops are of centrifugal lift off type and are located on the pinion shafts.

They have adequate capacities to with stand the full rated torque.

Cooling

Depending on the application and rating requirement, Gear Units are cooled b~' :

- Normal cooling by convection from the external surfaces of the gear case.

Mechanical fan fitted to high speed shaft which is effective for either direction of rotation.

- Cooling water coil fitted in bottom half of gear case, dipped in the lubrication oil sump.

- Fan and cooling coil.

- Separate oil cooler, used in conjunction with forced lubrication system.

Base plates

Base plates can be supplied for assemblies comprising of Gear Units and foot mounted motors correctly aligned and connected by flexible couplings. Coupling guards

can also be provided. Such requirements are supplied on specific request.

Shaft mounted Gear Units I Hollow Output shaft Gear Units

M

Shaft mounted Gear Units can be mounted on the driven machine shaft extension by using keys or with "Shrink Disc device. Alternatively foot mounted Gear Units

with hollow output shaft can be mounted on a common base plate with prime mover and coupling, the complete assembly being mounted on the driven machine shaft

extension. In both the types, the connection to the foundation is to be made using Torque arm. Torque arm I Shrink Disc I Base plate are supplied as optional extra,

on specific request.

Motorised Gear Units

Gear Units are available as assemblies comprising standard flange mounted (B5 type) motors directly mounted on input shaft line with the use of adaptor housings.

Motor and Gear Unit shafts are connected by flexible couplings. Specify the scope relevant to the requirement.

Lubrication

lubrication in most instances is by the transfer of oil to the mesh points by gear dipping in the sump of Gear Unit bottom half. Wherever high pitch line speeds causing

detrimental churning of lubricant are encountered, force lubrication system is provided for effective spraying of oil to the mesh points. Quantity of oil for normal

dip I splash lubrication is given in the dimension tables. For grade of oil refer "Guidelines for Selection" sheet.

Note: As improvements in design are continually being made, the specification given in this publication is not to be regarded as final

and binding.Details pertaining to dimensions and rating capacities are subject to alteration without notice.Always insist for certified

drawing,which will be sent on request.

- 2 -

Helical I Bevel Helical Gear Units

Guidelines for Selection

GUIDELINES FOR SELECTION

Select Gear Unit Design

Parallel shaft (Helical) or Right angled shaft (Beve! Helical)

Foot mounted (Solid Output shaft) or Shaft mounted (Hollow Output shaft) with I without Foot

i req

required transmission ratio

'N

nominal ratio

[rpm)

input speed

"2

[rpm)

output speed

Determine required transmission ratio

P req

[kWj

required Mechanical Power Capacity

PN

[kW]

nominal Mechanical Power Capacity

Pd

[kWj

absorbed power of connected driven machine,

if not known

take consumed power of prime mover

If Hollow Output shaft Key connection or Shrink Disc connection

" 1

Output shaft configuration - Horizontal or Vertical

"1

req = n2

Select appropriate nearest nominal ratio

'N

, 1

mechanical service factor, refer Table 2

Determine required Mechanical Power Capacity

'2

frequency starts factor, refer Table 3

P req = P d xf 1 xf 2

, t

thermal service factor, refer Table 4

Select Gear Unit Type and Size

P G1

[kW]

Thermal Power Capacities of Gear Units

without additional cooling

P G2

[kW]

Thermal Power Capacities of Gear Units

with Fan cooling

P G3

[kW]

Thermal Power Capacities of Gear Units

with Cooling coil

P G4

[kWj

Thermal Power Capacities of Gear Units

with Fan and Cooling coil

Type based on Gear Unit design with appropriate nearest nominal ratio and

Size using P N

~ P req

Select Type of cooling

natural Air cooling

(without additional cooling)

;, P

d

with Fan cooling

;,

with Cooling coil

;, P ~

d

;, P d ~

;, P >

d

with Fan and Cooling coil

with external Cooler

(please refer to us)

Pd

P G1 x 't

P G2 x 't

P G3 X't

P G4 x 't

P G4 X't

EXAMPLE

Given Data

Prime mover: Electric motor

Driven machine: Belt Conveyor (Uniform loading)

Power

Power

Pd

80 kW

Parallel shaft

Speed

n2

52 rpm

Hollow Output shaft with Foot

Duty

24 hr I day

With Shrink Disc connection

Starts per hour

Horizontal Output shaft

Speed

90 kW

n 1 : 1500 rpm

Running time per hour

ED

Ambient temperature

Gear Unit Design

100%

50 C

Q

Gear Unit Design

Foot mounted, Helical, Horizontal Hollow Output with Shrink Disc connection

Required transmission ratio

.

,

Nominal ratio

iN = 28

Required Mechanical Power Capacity

P req = P d xf 1 xf 2

Gear Unit Type and Size

According to Gear Unit design and Nominal ratio, Gear Unit Type is selected as HTAD

n1

1500

= = - - = 28.8

req

n2

52

= 80 x1.25x1.08

= 108 kW

According to required Mechanical Power Capacity Gear Unit Size 250 with P N = 115 kW is selected

Type of Cooling

P d =80kW

P G1 xf t = 110xO.63 = 69.3

P G2 xf t = 170xO.7 = 119

kW

Pd

>

kW

Pd

<

PG1 xf t

PG2 xf t

Additional cooling required.

Fan cooling sufficient

CONCLUSION

Helical Gear Unit, Triple Stage, Horizontal, Foot mounted, Hollow Ouput shaft Type HTAD, Size 250, 28:1 nominal ratio with Fan cooling is selected.

The Mechanical Power Capacities (P N ) in kW, given in Rating sheets are applicable for Uniform load (i.e. shock free operation) for a period of 10 hours per day and

can accomodate the following peak load conditions.

- not more than four peaks per eight hours period,

- the time duration of each peak shall not exceed five(5) seconds,

- each peak shall not exceed 200 percent of the Mechanical Power Capacity.

The Rating sheets also show the Thermal Power Capacities under various conditions. These Power Capacities are given with a Thermal Service Factor of 1 for 20 C

Q

ambient temperature and 100% running time per hour. For other ambient temperatures and running time per hour take appropriate Thermal Service Factor, f t from

Table 4.

- 3 -

Helical I Bevel Helical Gear Units

Guidelines for Selection

TABLE 1 - LOAD CLASSIFICATION

Driven Machine

Type of

Load

U

M

M

Blowers

centrifugal

lobe

vane

M

U

Brewing and distilling

bottling machinery

brew kellies continuous duty

cookers - continuous duty

mash tubs - continuous duty

scale hopper frequent starts

Can filling machines

Cane knives

Car dumpers

Car pullers

Clarifiers

Classifiers

Clay working machinery

brick press

briqutte machine

clay working machinery

pug mill

u

u

u

U

M

U

M

H

M

U

M

H

H

M

M

lobe

reciprocating

multi - cylinder

single - cylinder

U

M

M

H

loaded or fed

,crew

u

u

u

u

u

u

u

u

Conveyors heavy duty

not uniformly fed

apron

assembly

bell

bucket

chain

flight

live roll

oven

M

M

M

M

M

reciprocating

""ew

shaker

Cranes

main hoists

bridge travel

trolley travel

Crusher

0"

stone

sugar

H

H

M

Dredges

cable reels

conveyors

cutter head drives

jig drives

maneuvering winches

pumps

screen drive

stackers

utility winches

Uniform load

Consult Manufacturer

main hoist

auxiliary hoist

boom, luffing

rotating, swing or slew

tracking, drive wheels

bucket - uniform load

bucket-heavy load

bucket - continuous

centrifugal discharge

escalators

freight

gravity discharge

man lifts

passenger lifts

-

U

M

U

U

U

M

M

M

M

U

apron

belt

disc

reciprocating

"'"'w

M

M

H

H

M

M

H

M

M

cereal cooker

dough mixer

meat grinders

Generators - hot welding

Hammer mills

Hoists

heavy duty

medium duty

skip hoist

M

M

U

H

M

M

U

M

M

U

H

H

driving processing equipment

light

other line shafts

M

U

U

M

M

M

M

M

M

M

U

M

H

H

M

M

M

M

M

M

cod

M

M

H

Mixers

M

M

U

M

Oil industry

M

M

H

H

chillers

oil well pumping

paraffin filter press

rotary kilns

M

M

Paper mills

H

M

M

M

H

H

H

H

agitators (mixers)

barker - auxiliaries - hydraulic

bar1ter mechanical

barker - drum

beater and pulper

bleacher

calenders

calenders - super

converting machine,

except cutters - plalers

conveyors

M

M

M

rood>

cutters - platers

cylinders

dryers

felt stretcher

felt whipper

jordans

log haul

",esses

H

U

pulp machine reel

stock chest

H

M

M

M Moderate Shock Load

- 4 -

suction rotl

washers and thickners

winders

Printing presses

Pullers

barge haul

M

M

H

H

M

U

M

H

M

U

H

H

M

M

M

H

M

H

M

M

M

M

M

M

Pumps

cola.,.

Load

concrete mixers - continuous

concrete mixers - intermillent

constant density

variable density

Type of

M

H

plain

wedge bar

tumbling barrels

Driven Machine

centrifugal

proportiOfling

reciprocating

single acting,3 or more cylinders

double acting,2 or more cylinders

single acting,1 or two cylinders

double acting, single cylinder

draw bend1 caniage and main drive

pinch, dryer and saubber

rolls-reversing

slitters

table conveyors non-reversing

group drives

individual drives

reversing

wire drawing and flattening machine

wire winding machine

Mills rotary type

ball

cement kilns

dryers and coolers

kilns - other than cement

pebble

lumber industry

barkers - hyOraulic - mechanical

burner conveyor

chain saw and drag saw

chain transfer

craneway transfer

de-barking drum

edger feed

gang feed

green chain

live rolls

log deck

log haul - incline

log haul - well type

log tuming device

main log conveyor

off bearing rolls

planer feed chains

planer floor chains

planer tilting hOist

re-saw merry-go-round conveyor

roll cases

slab conveyor

small waste conveyor - belt

tipple hoist conveyor

tipple hoist drive

transfer conveyors

transfer rolls

tray drive

trimmer feed

waste conveyor

M

M

M

M

Metal mills

Laundry washers reversing

laundry tumblers

Line shafts

small waste conveyor - chain

starting table

bending roll

punch press - gear driven

notching press - belt driven

plate planers

tapping machine

other machine tools

main drives

auxiliary drives

Load

Machine tools

Fans

centrifugal

cooling towers

induced draft

forced draft

induced draft.

large. mini etc.

large, industrial

light smaller diameler

Type of

Driven Machine

Elevators

Food industry

beef slicer

Conveyors - uniformly

apron

assembly

belt

bucket

chain

flight

oven

Load

Feeders

Compressors

centrifugal

Type of

Dry dock cranes

Agitators

pure liquids

liquids and solids

liquids - variable density

Driven Machine

gear type

lobe, vane

U

M

M

M

u

u

Rubber and Plastic industries

crackers

laboratory equipment

mixing mills

refiners

rubber calenders

rubber mill - 2 on line

rubber mill - 3 on line

sheeter

tyre building machines

tyre and tube press openers

tubers and strainers

warming mills

Sand muller

Sewage disposal equipment

bar screens

chemical feeders

collectors

dewatering screws

scum breakers

slow Of rapid mixers

thickeners

vaceum fillers

H

M

H

M

M

M

U

M

M

M

M

u

u

U

M

M

M

M

M

Screens

air washing

rotary - stone or gravel

travelling water intake

Slab pushers

Steering gear

Stockers

Sugar industry

cane knives

crushers

mills

M

U

M

u

M

M

Textile industry

batchers

calenders

cards

dry cans

dryers

dyeing machinery

knitting machines

looms

mangles

nap",,",

pads

range drives

slashers

soapers

spinners

tenter frames

washers

winders

Windlass

H - Heavy Shock load

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

Helical! Bevel Helical Gear Units

Guidelines for Selection

TABLE 2 - MECHANICAL SERVICE FACTOR - f 1

Load Classifications of

Duration

Driven Machine

of

Uniform

Moderate

Heavy

load

shock load

shock load

hours per day

Elec. motor,

upto 3

0.80

1.00

1.50

Steam turbine,

over 3 uplc 10

1.00

1.25

1.75

Hydraulic molor

over 10

1.25

1.50

2.00

Multi-cylinder

uplc 3

1.00

1.25

1.75

Internal

ovef 3 uplc 10

1.25

1.50

2.00

Combustion engine

over 10

1.50

1.75

2.25

Single-cylinder

uplc 3

1.25

1.50

2.00

Internal

ovef 3 uplc 10

1.50

1.75

2.25

Combustion engine

over 10

1.75

2.00

2.50

Prime mover

service

TABLE 4 - THERMAL SERVICE FACTOR - f I

Type of cooling

Ambien

Running time in any hour

tempe-

ED

ralure

100%

80%

60%

40%

20%

WC

1.12

1.34

1.57

1.79

2.05

Gear Units

20'C

1.00

1.20

1.40

1.60

1.80

without

30C

0.88

1.06

1.23

1.41

1.58

additional cooling

40C

0.75

0.90

1.05

1.20

1.35

50'C

0.63

0.76

0.88

1.01

1.13

10C

1.15

1.38

1.61

1.84

2.07

Gear Units

20'C

1.00

1.20

1.40

1.60

1.80

with

30'C

0.90

1.08

1.26

1.40

1.62

Fan

40C

0.80

0.96

1.12

1.29

1.44

50'C

0.70

0.84

0.98

1.12

1.26

10C

1.10

1.32

1.54

1.76

1.98

Gear Units

20'C

1.00

1.20

1.40

1.60

1.80

with

30'C

0.90

1.08

1.26

1.44

1.62

Cooling coil

40'C

0.85

1.02

1.19

1.36

1.53

50'C

0.80

0.96

1.12

1.29

1.44

10C

1.12

1.34

1.57

1.79

2.05

Gear Units

20'C

1.00

1.20

1.40

1.60

1.80

Determine the Type of load Uniform (U) Moderate shock (M) or

Heavy shock (H) from Table 1.

TABLE 3 - FREQUENCY STARTS FACTOR - f 2

Mechanical Service Factor - f 1

Starts per hour

0.8

1

1.00

1.00

1.25

1.00

1.5

1.00

1.75

1.00

1.00

2t020

1.20

1.10

1.08

1.07

1.07

1.06

21 to 40

1.30

1.20

1.17

1.16

1.15

1.08

with

30'C

0.92

1.10

1.29

1.47

1.66

41 to 80

1.50

1.40

1.25

1.23

1.18

1.10

Fan & Cooling Coil

40C

0.83

1.00

1.16

1.33

1.50

81 to 160

1.60

1.50

1.35

1.30

1.20

1.10

50'C

0.78

0.94

1.09

1.25

1.40

161 to 320

2.00

1.80

1.70

1.60

1.50

1.40

LUBRICANTS

Recommended Oil Viscosity

# Ambient

temperature

(C)

Gear Units are supplied without oil. Before putting it in operation,

ISO Viscosity Grade ( mm 2/s at 40C)

ensure that they are filled to correct oil levels, as per the markings

Load classifications of Driven machine (from Table 1)

of dipsticks, with proper grade of lubricants, given in the tables.

Uniform

Moderate Shock

Heavy Shock

load (U)

Load (M)

Load (H)

# For other Ambient temperatures and Load classifications, please

refer to us

o to 50

VG320

VG 320

VG460

Castrol

Esso

Mobil

Shell

Castrol Alpha

SPARTAN

Mobilgear

Shell Macoma

SP 320

EP 320

632

320

Castrol Alpha

SPARTAN

Mobilgear

Shell Macoma

SP460

EP460

634

460

Examples of Lubricants

Viscosity ISO-VG at

40C In mm 2 Is

VG 320

VG460

- 5 -

Helical Gear Units, Double Stage

Horizontal

Power Ratings

Type

HDN, HDAH, HDAD

HDOH, HDOD

HR -120

Mechanical Capacities PN in kW

Nom.

Ratio

'N

Speed (rpm)

Input Output

6.3

n,

n,

112

125

140

160

180

200

225

250

280

320

1500

238

159

119

43.2

60

41

31.3

84

58

44.2

130

88

67

174

119

91

240

166

127

330

225

173

455

315

240

640

440

335

920

630

480

1350 1880 2720 3830

920 1280 1860 2650 3710 5090 7120

700

980 1420 2030 2850 3910 5420 8420

76

52

40

114

78

59

150

101

77

210

140

110

310

210

161

410

275

215

580

27.3

53

36.1

400

305

810

560

425

1280 1760 2670 3440

880 1210 1840 2380 3380 48SO 6370

680

930 1410 1790 2590 3570 4820 7190

68

46.8

35.8

99

67

51

140

95

70

190

130

95

275

186

141

370

255

195

520

355

275

710

485

370

1130

780

600

1560 2360 3130

1070 1620 2120 3030 4060 5860

820 1240 1620 2330 3110 4350 6350

61

41

92

62

130

86

47.3

65

185

125

90

250

170

130

340

230

175

470

320

240

670

450

350

1040

720

550

1390

81

55

160

110

82

225

151

115

295

200

160

420

290

220

590

400

305

910

630

480

1280

880

670

1330

1720

1010

1370

145

97

73

200

136

103

265

183

140

380

260

200

540

370

275

840

570

440

1120

770

590

1700

2330

1180

900

1000

750

20.9

27.6

1500

1000

750

188

125

34.7

23.8

47.4

94

18.2

32.5

24.8

1500

167

111

83

32.3

43.6

22.1

29.8

22.8

1000

750

3780 5150

2900

4020

2460

3350

4650

1880

2570

3640

5210

1570

2230

1220

1710

2970

2280

4320

3340

4610

1420

2020

2630

3840

2930

4250

5760

1930 2540

13.5

18.2

33.9

25.9

48.5

36.7

120

80

60

22.4

15.1

11.4

31.2

21.4

16.3

42

28

62

42

32

87

59

115

79

45.3 59

175

120

90

235

170

130

340

225

170

470

320

240

750

520

395

980

680

520

1430

980

740

2070

1110

1520

1980

107

71

54

20.1

38.5

210

150

115

295

200

155

425

290

220

670

465

355

880

610

465

1340

920

710

1270

950

1720

1320

2370

1810

3440

20.1

160

110

82

3440 4950

14.4

77

110

75

53

40.2 56

2580

10.5

57

38.3

28.9

1620

13.7

27.6

18.8

18.3

25

70

48.1

18.3

26.5

36.7

140

95

72

192

135

100

265

183

139

380

260

198

610

415

320

810

560

425

1160

800

610

1110

13

99

67

51

1570

1220

3170

2180

1670

4450

17.1

52

35.1

2280

12.5

9.5

35

24

1620

1000

750

94

63

47

3030

2280

3330

1500

1000

750

83

56

42

16.5

11.3

31.4

21.4

16.4

45.7

128

87

32.2

66

176

120

92

240

164

124

350

235

185

520

355

270

740

510

390

1520

1020

23.3

89

60

45

1110

30.8

62

42.2

8.6

21.8

14.9

11.3

2810

1930

1470

4020

2780

2170

3110

1500

1000

750

75

50

38

14.1

19.5

57

38

29

115

76

59

156

107

82

215

150

115

305

210

160

480

330

250

650

445

340

930

630

475

1350

920

700

1860

13.3

40

27

80

9.5

7.2

25.8

17.6

13.5

1240

2460

1670

990

1290

3600

2400

1920

2800

1500

1000

67

45

33

12.9

17.9

12.2

23.6

34

23.3

49.8

66

45.4

34.6

140

94

71

185

125

98

260

179

137

440

300

230

590

405

310

840

570

430

1180

33.6

25.4

99

67

52

1550

1060

2250

1540

810

1180

3150

2160

1650

2560

360

400

450

500

560

630

710

800

1180

1500

14

1000

750

1500

20

800

17.7

1000

750

18

710

72

1500

16

2170 2880

1500 1930 2680

1140 1520 2080

630

49.6

1000

750

22.4

750

25.8

560

35

23.8

1500

134

89

67

500

28.9

750

29

960

730

450

110

73

41.6

56

1000

150

100

75

31.1

400

55

10

12.5

16.9

360

38

26

19.9

1500

11.2

22.6

39.9

1000

7SO

29.6

211

141

106

1500

7.1

Gear Unit Sizes

19.6

14.9

8.7

6.6

10.2

9.3

37.8

21.3

26.3

16.1

12.3

20.1

17.7

98

67

51

54

41

760

580

840

790

790

620

2040

1400

1070

2580

3660

Thermal Capacities PG in kW

Nominal

Ratio

'N

Input

Speed

n,

Gear Unit Sizes

112

125

140

160

180

200

225

250

280

320

Thermal Capacities PG1 For Gear Units Without Cooling in kW

750

31

26

24

40

35

32

50

46

41

63

55

53

80

72

67

100

92

90

122

120

110

155

150

142

205

190

180

245

240

230

305

290

285

390

380

370

480

470

465

630

620

610

770

760

980

960

1500

1000

750

25

22

20

34

29

26

43

37

34

56

48

44

73

61

58

94

84

76

120

108

100

150

135

125

190

175

162

240

230

210

300

280

275

380

360

350

470

460

450

610

580

570

760

740

730

970

960

940

1140

1430

650

1000

1200

1)

1)

1)

1)

1)

1)

1)

1)

1)

6.3

1500

to

1000

12.5

14

to

22.4

1160

1460

1180

1160

Thermal Capacities PG2 For Gear Units With Fan Cooling in kW

1000

750

52

40

33

66

53

45

83

66

58

110

85

75

135

105

100

165

145

130

205

180

170

260

220

210

330

280

260

405

370

340

500

450

420

580

530

800

730

680

1500

1000

750

45

34

30

58

44

38

75

56

50

95

70

62

120

95

85

155

123

106

200

162

140

250

210

180

315

270

240

395

350

300

490

440

400

630

570

520

780

700

650

970

900

850

1240

1140

1030

1)

1)

1)

450

440

425

540

520

510

680

660

650

830

800

780

880

870

860

1)

1)

1)

1)

1)

1)

1)

800

720

670

1000

1200

1100

1050

1400

1)

1)

1)

1)

1)

1)

1)

6.3

1500

to

12.5

14

to

22.4

920

880

1150

Thermal Capacities PG3 For Gear Units With Cooling Coil in kW

6.3

to

22.4

1500 148

1000 136

750 121

165

156

140

186

181

162

200

195

188

225

215

205

250

235

230

265

260

250

295

290

280

345

340

330

390

380

370

Thermal Capacities PG4 For Gear Units With Fan & Cooling Coil in kW

6.3

to

22.4

1500 170

1000 150

750 130

190

170

150

220

200

180

250

225

210

280

250

240

310

290

270

350

320

310

400

360

350

For ratings above 1500rpm and below 750rpm input speed, refer to us

Intermediate ratios are also possible, for details refer to us

460

430

410

550

510

480

650

600

560

920

860

1300

1250

Gear units with ratings in bold figures (and marked. ) require force lubrication.

1) Thermal ratings on request.

- 8 -

Helical Gear Units, Double Stage,

Horizontal, Shaft mounted,

Hollow Output Key connection

HDOH

Type

HD -124

PRINCIPAL DIMENSIONS (mm)

r - - - - n5- - - - - - - - j

r- k5~k5

k'

"

05

k2

k2

rS.

",

"'

t--

-+

",

"'L

"

"

"'

"' --jf-.----O,

-~=t=~n~2;-::=t---.,

Handing I Direction of rotation

~~

M r- I-:

1"\-1- ---o

~~ U~

~13

U~~ to

- - -- ---

___

13

U

U

LL

d,

1,

d,

DL

'N

1,

'N

14 - 16

6.3 - 12.5

d,

~~u~

~~

LR

RR

DR

Output shaft

1,

k,

d ll

k ll

Input shaft

Size

~~

- ---

RL

-~~

Housing

O2

k2

k5

h,

hJ

n,

n2

0,

'N

18-22.4

112

28

50

24

40

24

40

105

1)

1)

55

102.5

132

147

332

93

135

192

125

32

60

28

50

24

40

115

1)

1)

65

110

139

162

362

105

160

215

140

38

60

32

60

28

50

125

1)

1)

70

117.5

147

188

410

115

180

240

160

42

70

32

60

32

60

140

1)

1)

85

135

170

208

450

128

190

272

180

50

90

42

70

38

60

150

262

190

100

150

185

228

490

140

215

305

200

55

90

48

80

42

70

165

276

200

110

165

202

253

540

150

240

340

225

65

105

50

90

48

80

185

331

235

120

177.5

215

282

606

175

270

385

250

75

120

55

90

55

90

210

331

255

140

200

238

312

666

190

300

430

0>24

m6

Torque reaction bolt holes

Size

as

05

h5

n5

Approx. Approx.

'5

weight

oil qty.

kg.

litres

112

25

16

80

257

16

48

1.5

125

28

18

92

282

18

65

2.2

30

20

103

320

23

90

3.1

160

32

22

115

367

23

125

4.4

180

40

25

130

410

26

165

200

45

30

145

450

30

230

8.5

225

50

35

160

515

35

315

12.5

250

55

40

180

565

40

425

17.5

- Tolerance field for input shaft extensions

0:s24 : kG

for output shaft bores

02 : H7

for torque reaction bolt holes

05 :

H11

- Dimensions are subject to modification. Get certified Principal Dimensional

drawing while ordering.

- Shaft extension, with parallel key to IS:2048 1 DIN 6885 part 1 and threaded

centre hole. For details refer to sheet ST-001.

- Gear units are shown with Cast Iron casing, alternatively fabricated steel

casing, can also be given. Specify while ordering.

- Special input extension, on request.

- For more details of hollow output shaft refer to sheet 5T-002.

- Sizes 280 and above can also be supplied in key connection design. For

dimensional details, refer to us

- 1) Details on request.

- 12 -

Helical Gear Units, Double Stage,

Horizontal, Shaft mounted,

Hollow Output Shrink Disc connection

HOOD

Type

HD -125

PRINCIPAL DIMENSIONS (mm)

r - - - - nsi

-----;==1-

----1'

----t-

k4

Os

IJ

t--

k2

"i

Shrink

,sc

~s.

'"

.c

...,

j-

,,0

1-

'"

.c

-,

- ...,

.c

~

---.l

-t

"

.c

n, ~:--- 0' ~~==~n;2==r---<~~

Handing I Direction of rotation

M=~

"'rtf- ---

H~

,:~::

~~ ~'tt:Jl-tt

~ t8H+ blJ

"~~ to . -RL

Size

112

125

140

160

180

200

225

250

280

320

360

400

450

500

560

630

710

Size

112

125

140

160

180

200

225

250

280

320

360

400

450

500

560

630

710

d,

I,

d,

I,

'N

iN

6.3 -12.5

14 - 16

28

32

38

42

50

55

65

75

85

95

50

60

60

70

90

90

105

120

140

160

'N

6.3-12.5

100

180

180

110

120

210

240

140

150

240

170

270

180

310

d,

iN

iN

18-22.4

24

40

24

40

28

50

32

60

38

60

42

70

48

80

55

90

105

60

70

120

iN

14 - 20

22.4

24

28

32

32

42

48

50

55

60

70

75

90

95

110

120

130

140

40

50

60

60

70

80

90

90

105

120

120

160

160

180

210

210

240

tt-1{3tt~b"

~

M ~J

LL

Input shaft

70

80

90

100

110

120

120

120

140

160

180

180

210

210

d"

105

115

125

140

150

165

185

210

235

260

1)

1)

1)

1)

262

276

331

331

400

400

280

310

350

390

410

460

450

530

610

670

720

1)

1)

500

~ttEJI

'-~~

LR

Output shaft

.,

L~~

- _. .

- - ----

T~

"

DR

Housing

RR

Shrink disc

'"

O2

OJ

k2

k.

Size

h,

hJ

n,

n2

0,

1)

1)

1)

1)

190

200

235

255

60

65

70

80

95

110

120

135

140

160

102.5

147.5

110

160

117.5

177.5

135

150

165

205

225

245

80 - 60

90 - 65

100 - 70

110 - 80

320

68

75

80

90

105

120

130

145

150

170

200

230

250

295

335

375

147

162

188

208

228

253

282

312

349

389

332

362

410

450

490

540

606

666

740

820

93

105

115

128

140

150

175

190

200

220

135

160

180

190

215

240

270

300

330

365

192

215

240

272

305

340

385

430

480

545

385

395

440

480

530

1)

1)

180

200

230

260

300

340

370

170

190

220

245

285

325

355

280

315

345

380

425

470

530

405

450

505

550

600

670

730

437

487

537

597

667

747

837

918

1538

384

1718

440

398

445

505

557

624

694

780

610

1378

238

275

305

337

354

300

177.5 262.5

125 - 95

140 - 110

155 - 120

175-135

195-140

220-160

240 - 170

260 - 190

300 - 220

340 - 245

380 - 285

420 - 325

460 - 355

1018

1118

1238

Torque reaction bolt holes

Appro~

Appro,.

weight

kg.

oil qty.

48

65

90

125

165

230

315

425

595

820

1.5

2.2

3.1

4.4

6

8.5

12.5

- Dimensions are subject to modification. Gel certified Principal Dimensional

17.5

Gear units are shown with Cast Iron casing, altematively fabricated steel

Os

Os

hS

nS

25

28

30

32

40

45

50

55

60

70

80

90

105

105

110

110

130

16

18

20

22

25

30

35

40

40

45

50

55

60

65

70

80

90

80

92

103

115

130

145

160

180

200

230

260

290

325

370

420

460

520

257

282

320

367

410

450

515

565

630

715

795

895

1000

1120

1225

1380

1490

'S

16

18

23

23

26

30

35

40

40

45

55

57

65

75

85

95

100

1090

1530

2130

3030

4030

5630

7730

litres

24

35

49

68

98

137

192

275

385

680

770

860

960

1080

1210

- Tolerance field

for input shaft extensions 0!5 24 : kG

for output shaft bores 02 & 03

24 < 0

100 : m6

0>100:n6

H7

for torque reaction bolt holes 05 : H11

drawing while ordering.

- Shaft extension, with parallel key to IS:2048 I DIN 6885 part 1 and threaded

centre hole. For details refer to sheet ST-001.

casing, can also be given. Specify while ordering.

- Special input extension, on request.

- For more details of hollow output shaft refer to sheet ST-003.

- 1) Details on request.

- 13I

Helical Gear Units, Triple Stage

~pe

HTN,HTAH,HTAD

Horizontal

Power Ratings

HTOH, HTOD

HR - 130

Mechanical Capacities PN in kW

Speed (rpm)

Output

Input

Nom.

Ratio

'N

n,

22.4

25

28

31.5

35.5

1500

1000

7SO

1500

1000

7SO

1500

1000

7SO

1500

1000

7SO

1500

1000

750

67

45

33

60

40

30

54

1500

38

25

1000

750

40

1500

1000

750

45

1500

1000

750

50

1500

56

1000

63

71

80

90

26.8

48

32

23.8

42

28.2

21.1

18.8

33

22.2

16.7

30

20

15

26.8

17.9

13.4

23.8

1000

15.9

750

11.9

1500

21.1

1000

750

1500

1000

750

1500

14.1

7SO

1500

1000

750

1500

1000

7SO

112

36

750

1500

1000

100

n2

10.6

18.8

12.5

9.4

16.7

11.1

8.3

15

10

7.5

13.4

8.9

6.7

Gear Unit Sizes

125

18

12.3

25.9

17.7

9.3

13.5

15.9

23.4

19.9

34.2

10.8

16

23.1

180

54

36

27

49

32

8.3

12.2

17.4

24.2

14.4

20.7

14.1

10.7

18.4

29.6

9.9

7.5

12.7

140

200

75

52

39

63

43

32.1

47.4

45

20

30

15.1 . 22.1

27.5

39

18.5

26

14

19.6

24.1

35

16.2

23

57

39

29

51

34

26

48

31

82

54

12.3

17.5

23.7

31

21.6

44

29

7.7

21.8

14.7

11.1

15.5

22.7

13.4

19.1

27

9.1

7

12.9

18.1

9.7

11.8

17.3

13.7

24.2

37

26

19.1

33

8

6.1

11.7

8.9

16.5

12.6

22.7

16.5

10.7

15.3

10.3

21.1

14.4

29

42

19.6

15.5

28.1

21.6

24.7

16.8

36

12.8

19

33

8.7

6.6

12.6

11.5

16.9

7.8

6

11.5

8.8

10.4

14.8

10.1

7.1

5.4

9.4

6.4

4.9

8.5

5.8

4.4

7.7

5.2

4

6.7

4.5

3.5

6.1

4.2

3.2

5.4

3.7

2.8

4.8

3.3

2.5

4.4

3

2.3

4.1

2.8

2.1

9.6

7.3

5.5

9.5

6.5

4.9

8.4

5.7

4.4

7.7

5.2

4

6.3

4.3

3.3

5.8

3.9

3

5.3

3.6

2.7

160

38.9

26.2

7.9

11

13.3

19.1

9

7

13

9.9

12.1

17.3

11.8

8.2

6.4

10.9

7.5

5.8

9.4

6.6

5.1

8.5

5.8

4.4

7.7

5.3

4

9

15.1

10.3

7.8

13.4

22.4

15.2

11.6

20.1

13.6

10.4

18

225

105

70

53

93

63

41.1

75

50

38.1

66

44.3

33.5

58

39.1

30

52

35

27

47

32

24.2

24.7

22.7

17.5

30

20.1

15.6

250

140

94

73

122

196

135

102

177

84

120

63

91

115

156

75

105

57

80

101

139

69

94

52

71

127

90

60

86

45.1

65

81

115

54

75

42

57

72

101

68

49

37

52

66

89

44.4

61

33.9 45.7

58

80

54

39

30

41.7

70

52

35.1

47.5

27

36.9

47.1

63

32.2 43.5

24.9 33.7

41.1

57

28.5 39.6

85

58

27

18

37.2

49

25.4

33.1

25.2

45

31

40.6

77

52

39.5

66

44.7

34.1

59

27.7

21.1

40.3

30.7

13.9

19.3

11.8

16.5

11.3

24.7

16.5

12.9

32.1

22.4

17.4

21

14

11

29.6

20.7

7.7

6

48.2

44.2

9.3

11.1

280

195

145

255

173

132

230

155

120

205

140

107

185

125

95

165

115

86

150

100

77

135

90

68

120

80

61

110

72

55

93

63

30.7

12.4

8.5

15

10

7.6

320

21.8

9.2

7

8.2

6.4

280

16.1

23.2

360

420

275

225

385

265

205

345

235

181

320

215

166

285

190

1SO

255

173

132

230

157

120

210

144

109

183

125

96

166

114

87

151

103

78

138

94

71

124

84

64

107

73

56

98

67

51

400

580

400

305

5SO

375

285

490

335

255

425

290

225

395

270

205

360

245

188

315

215

165

290

197

150

250

170

130

220

151

115

200

137

104

179

122

93

157

107

81

144

98

75

127

86

66

450

810

580

425

810

560

420

710

480

365

395

300

510

345

260

450

310

235

400

275

210

365

250

191

325

225

171

295

200

153

260

179

137

215

150

114

197

137

103

176

121

91

6SO

920

500

700

860 1220

590

830

4SO

640

790 1110

530

750

410

570

710 1000

480

670

370

510

640

890

455

640

330

470

570

790

380

530

420

295

510

710

350

485

260

370

450

640

310

440

340

235

410

570

275

390

210

295

360

500

245

350

185

265

470

330

220

315

170

235

290

410

199

270

154

205

255

360

178

245

137

185

400

450

500

560

630

710

800

270

260

2SO

260

2SO

225

340

330

315

330

315

295

420

410

390

410

390

370

520

510

490

510

490

470

6SO

640

620

640

620

600

780

760

780

760

740

990

970

990

960

940

420

380

360

400

360

340

530

490

470

510

465

445

650

590

570

640

570

540

800

7SO

710

780

710

670

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

430

425

420

550

540

520

640

620

610

750

720

720

1)

1)

1)

1)

1)

1)

1)

1)

1)

730

700

670

880

810

780

1040

1)

1)

1)

1)

1)

1)

1)

1)

1)

660

445

340

580

500

560

630

710

1220 1670 2330

820 1140 1600 2160

630

890 1220 1710

800

3380

2590

1080 1520 2120

740

580

1060

790

14SO

1100

2010

1510

2930

2240

1280 1770

970 1370

1720

2620

1170

1620

1220

2310

1770

1470

2120

1620

930 1340 1870

890

2000

1530

1040

790

1370

930

700

1110

1320

1010

1930

1470

1220

1690

900

1290

1060

810

1540

1420

1980

1370

1020

1220

820

620

1090

740

560

970

650

510

870

590

460

770

530

410

700

485

375

620

425

325

560

385

295

490

335

255

950

720

1270

850

640

1110

750

570

990

680

520

890

610

465

780

530

405

710

485

370

1170

1760

1180

910

1570

1070

820

1420

960

730

1300

890

680

1190

820

620

10SO

720

5SO

Thermal Capacities PG in kW

Nominal

Ratio

'N

Input

Speed

n,

Gear Unit Sizes

125

140

160

180

200

225

250

280

320

360

Thennal CapaciUes PG1 For Gear Units Without Cooling in kW

22.4

to

40

45

to

112

1500

1000

7SO

1S00

1000

750

22

20

17

20

17

16

31

28

25

28

25

22

44

40

35

40

35

32

55

SO

46

SO

46,

42

71

65

60

65

60

55

90

82

75

82

75

68

110

105

98

105

98

90

138

130

122

130

122

112

174

168

155

165

155

140

215

210

195

210

195

175

Thennal Capacities PG2 For Gear Units With Fan Cooling in kW

22.4

to

1500

1000

40

45

750

1500

to

1000

112

750

75

65

61

72

63

58

90

83

78

88

80

75

110

100

95

106

95

90

140

130

125

138

128

120

170

160

152

163

153

140

220

205

196

205

195

180

270

250

240

260

245

230

340

320

305

325

305

290

Thermal Capacities PG3 For Gear Units With Cooling Coil in kW

22.4

to

1500

1000

112

750

100

96

92

120

115

110

140

132

126

170

160

150

200

195

190

250

245

240

290

280

270

360

350

340

Thermal Capacities PG4 For Gear Units With Fan & Cooling Coil in kW

22.4

to

1500

1000

112

750

133

122

120

157

150

144

185

172

167

220

210

200

260

255

250

For ratings above 1500rpm and below 750rpm input speed, refer to us

Intermediate ratios are also possible, for details refer to us

Gear units with ratings in bold figures ( and marked ) require force lubrication.

1) Thermal ratings on request.

- 14 -

340

325

320

385

360

360

490

465

450

590

550

540

980

940

Helical Gear Units, Triple Stage,

HTOH

Type

Horizontal, Shaft mounted,

Hollow Output Key connection

HD -134

PRINCIPAL DIMENSIONS (mm)

kS~kS

k,

I,

05

k2

k2

's

I'

'"'"

t-'"'"

L

.+

-"

">

'"

'"

0, ----j;=~~~~n~z;_==j------<

n, -1

Handing I Direction of rotation

...... t~,

.

:. : ::cc t~

------I~

~*

8,

DL

LL

RL

t5

d,

I,

'N

d,

d,

I ,

'N

5671

22.4 - 50

I,

k,

dlf

kif

Oz

kZ

.8

DR

RR

Housing

Output shaft

d,

I,

lI-tH

LR

Input shaft

Size

,~

kS

h,

hJ

n,

nZ

0,

iN

'N

80100

112

125

19

35

16

30

16

30

16

30

115

185

160

65

110

139

162

324

97

160

278

140

24

40

19

35

19

35

16

30

120

185

165

70

117.5

147

182

402

100

180

310

160

28

50

24

40

24

40

19

35

130

220

170

85

135

170

202

442

110

190

352

180

32

60

28

50

24

40

24

40

145

246

190

100

150

185

228

480

108.5

208.5

395

200

38

60

32

60

28

50

24

40

160

262

200

110

165

202

253

540

130

240

440

225

42

70

32

60

32

60

28

50

175

292

215

120

177.5

215

278

590

143

265

497

250

50

90

42

70

38

60

32

60

200

292

235

140

200

238

308

650

158

293

555

0>24

rn6

Torque reaction bolt holes

Size

05

hs

ns

Approx. Approx.

'5

weight

kg.

- Tolerance field for input shaft extensions

0~24

for output shaft bores

oil qty.

fOf torque reaction boll holes

: kG

Oz : H7

05 : H11

litres

125

28

18

92

343

18

70

3.3

140

30

20

103

380

23

96

4.6

160

32

22

115

427

23

135

180

40

25

130

475

27

180

8.5

200

45

30

145

530

30

250

11.5

225

50

35

160

602

35

335

15.5

250

55

40

180

670

42

460

21

Dimensions are subject to modification. Gel certified Principal Dimensional

drawing while ordering.

Shaft extension. with parallel key to 15:20481 DIN 6885 part 1 and threaded

centre hole. For details refer to sheet 8T-001.

Gear units are shown with Cast Iron casing, alternatively fabricated steel

casing, can also be given. Specify while ordering.

- Special input extension, on request.

For more details of hollow output shaft refer to sheet ST-002.

- Sizes 280 and above can also be supplied in key connection design. For

dimensional details, refer to us

- 18-

Helical Gear Units, Triple Stage,

Horizontal, Shaft mounted,

Hollow Output Shrink Disc connection

HTOD

Type

HD -135

PRINCIPAL DIMENSIONS (mm)

r----

n5 - - - - - - - - ,

"

D5

Shrink

Disc

os

I

."c

t-"

-- '"

,,0

1-

.c

--.l

.c

- n

'4---- 0'

---~==_::;n;2==~-~~~

Handing I Direction of rotation

~~

u

~~

u

~r u~

~~

u

E3

h~i:l

RL

.~

.rr~

DL

LL

~i:l

Input shaft

Size

125

140

160

180

200

225

250

280

320

360

400

450

500

560

630

710

800

Size

125

140

160

180

200

225

250

280

320

360

400

450

500

560

630

710

800

I ,

d,

I ,

d,

I ,

d,

d,

'N

'N

'N

22.4 - 50

56 - 71

60 - 100

112

35

40

50

60

60

70

90

90

105

16

19

24

28

32

32

42

48

50

30

35

40

50

60

60

70

80

90

iN

'N

22.4 . 50

75 120

85 140

95 160

100 180

110 180

120 210

130 210

145 240

5690

55

90

60 105

70 120

75 120

90 160

100 180

110 180

120 210

16

19

24

24

28

32

38

42

48

D5

h5

18

20

22

25

30

35

40

40

45

50

55

60

65

70

80

90

100

92

103

115

130

145

160

180

200

230

260

310

330

370

420

460

520

580

n5

343

380

427

475

530

602

670

735

845

930

1040

1170

1310

1465

1650

1850

2080

16

16

19

24

24

28

32

38

42

k,

d"

k"

D2

DJ

k2

k4

30

30

35

40

40

50

60

60

70

115

120

130

145

160

175

200

225

255

185

185

220

246

262

292

292

332

400

160

165

170

190

200

215

235

275

310

75

80

90

105

120

130

145

150

170

65 110

70 117.5

80 135

95 150

110 165

120 177.5

135 200

140 230

160 250

295

335

375

275

305

345

385

400

460

520

595

400

442

480

530

610

335

370

445

485

510

180

200

230

260

300

340

370

410

170

190

220

245

285

325

355

395

405

450

505

550

600

670

730

825

160

177.5

205

225

245

262.5

size

h,

hJ

90 65

100 - 70

110 - 80

162

182

202

228

253

278

308

347

387

324

402

442

480

540

590

650

736

816

125 - 95

140-110

155 - 120

175135

195-140

220160

DR

Housing

Shrink disc

I ,

n,

n2

97

100

110

160

180

190

108.5 208.5

130 240

143 265

158 293

165 330

189 364

0,

278

310

352

395

440

497

555

620

705

iN

100-112

48

50

60

60

70

85

90

100

Torque reaction bolt holes

5

28

30

32

40

45

50

55

60

70

80

90

105

105

110

110

130

140

30

35

40

40

50

60

60

70

80

RR

Output shaft

'N

19

24

28

32

38

42

50

55

65

LR

'5

18

23

23

27

30

35

42

40

48

55

57

65

75

85

95

100

110

80

90

105

105

120

140

160

180

Approx.

weight

kg.

70

96

135

180

250

335

460

630

880

1180

1680

2280

3250

4450

6250

9000

11600

Approx.

oil qty.

Iitres

3.3

4.6

6

8.5

11.5

15.5

21

31

42

57

81

112

152

205

285

395

550

280

315

345

380

425

470

530

605

240 - 170

260 - 190

300220

340 - 245

380 - 285

420325

460 - 355

500395

434

484

537

597

667

747

837

937

910 188

1010 215

1118 240

1238 277

1378 324

1538 344

1718 400

1918 448

398

445

505

557

624

694

780

868

Tolerance field

for input shaft extensions

for output shaft bores

,,~

D2&

24 : k6

24 < 0.:$100: m6

0>100:nG

DJ : H7

for torque reaction bolt holes 05 : H11

- Dimensions are subject to modification. Get certified Principal Dimensional

drawing while ordering.

- Shaft extension, with parallel key to 15:2048/ DIN 6885 part 1 and threaded

centre hole. For details refer to sheet ST-001.

- Gear units are shown with Cast Iron casing, altematively fabricated steel

casing, can also be given. Specify while ordering.

- Special input extension, on request.

- For more details of hollow output shaft refer to sheet ST-003.

- 19 -

790

880

995

1110

1240

1400

1570

1760

Helical Gear Units, Quadruple Stage

Horizontal

Power Ratings

Type

HQN, HQAH, HQAD

HQOH, HQOD

HR 140

Mechanical Capacities PN in kW

Nom.

Ratio

Input

Output

'N

"1

"2

180

200

225

250

280

320

360

400

450

13.4

10.9

15.5

42.9

61

8.9

6.7

7.4

5.6

10.3

22.2

15.5

30

112

1500

1000

29.9

41.9

12

20.6

15.7

95

65

22.8

31.9

49.5

134

91

70

198

138

106

9.9

6.8

5.2

13.3

19.8

27.6

1000

750

12

8

6

9.1

6.9

13.8

18.8

14.3

38

26.3

20

55

37.7

87

59

28.7

45.2

121

83

63

1500

10.7

11.8

34.7

49

7.1

5A

18.2

12.7

24.1

1000

750

8.8

5.9

45

16.5

9.8

12.5

23.8

18.2

33.4

25.4

76

52

39A

105

72

55

1500

1000

750

9A

6.3

4.7

7.9

5.3

4.1

10.3

7

5A

15.9

21.8

14.8

30.6

20.9

44.2

69

30.1

46.9

11.3

15.9

22.9

35.7

1500

8.3

5.6

4.2

7.1

4.8

3.7

9.4

6.4

4.9

14.7

10.3

19.9

27.8

38.9

62

13.6

26.5

42.5

7.9

10.4

19

14.5

20.3

32.6

7.5

5

3.8

6.5

4A

3.4

8.2

5.6

4.3

12.9

9

6.9

17.9

24.6

56

12.2

16.8

35.3

24

13

18.6

37.9

29.2

6.7

4.5

3.3

5.9

4

3.1

7.5

5.1

4

11.9

16.3

8.3

6.4

11.1

31.1

21.3

51

34.4

8.6

22.4

15.3

11.9

16.5

26.7

1500

1000

750

6

4

3

5.3

3.6

2.8

6.8

4.7

3.6

10.6

7A

5.7

14.3

19.8

28A

44.2

9.8

7.6

13.6

19.5

15.1

30.3

1500

1000

4.6

3.2

2.5

6

4.2

3.2

9.4

6.5

5

12.9

17.3

750

5.4

3.6

2.7

8.9

6.9

12

9.3

1500

1000

750

4.8

3.2

2.4

4.2

2.9

2.3

5.3

3.7

2.9

8.5

6

4.6

11.7

1500

1000

750

4.2

2.8

2.1

3.8

2.6

2

4.9

3A

2.7

1500

1000

750

3.8

2.5

1.9

3.3

2.3

1.8

1500

33

2.2

1.7

3

2

1.5

Speed (rpm)

750

1500

125

140

160

180

1000

750

1500

200

1000

750

1500

1000

224

750

250

280

315

355

400

450

1000

750

1500

1000

500

750

1500

560

1000

750

1500

1000

630

750

Gear Unit Sizes

560

630

710

800

260

176

135

380

260

200

510

355

270

700

480

365

1050

176

123

94

235

161

123

335

230

175

460

320

245

630

430

325

950

650

495

162

112

86

210

140

110

305

210

159

415

285

215

560

380

285

820

560

430

93

63

48.3

146

100

77

189

129

98

270

183

139

375

255

195

495

340

260

730

495

380

84

58

44.1

131

90

68

170

116

89

245

166

127

330

225

173

450

305

235

660

450

345

154

105

81

215

147

114

300

205

158

410

2.80

38.9

114

78

59

215

580

395

305

67

46

35.3

101

69

53

138

94

73

196

134

104

265

181

140

370

250

195

530

360

280

90

61

120

83

23.5

61

42

32

64

170

117

91

240

166

129

330

220

172

480

330

255

24.7

17.1

39.9

53

27.6

36.8

81

55

13.3

21.4

28

42.1

109

76

59

150

104

81

215

150

116

295

205

159

420

290

225

15.8

22.7

36.4

48.5

8.2

6.3

11

8.5

15.8

25A

33.5

72

48.7

99

69

12.3

19.7

25.5

37.1

54

136

95

74

193

135

104

265

186

144

380

265

205