Documente Academic

Documente Profesional

Documente Cultură

Cim Curriculum

Încărcat de

schriener0 evaluări0% au considerat acest document util (0 voturi)

14 vizualizări7 paginiComputer Integrated Manufacturing course is designed to expose students to the fundamentals of computerized manufacturing technology. Course will be taught using demonstration and discussion combined with individual and team-centered project based learning. In each of the learning sections students will be taught a different set of performance objectives.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentComputer Integrated Manufacturing course is designed to expose students to the fundamentals of computerized manufacturing technology. Course will be taught using demonstration and discussion combined with individual and team-centered project based learning. In each of the learning sections students will be taught a different set of performance objectives.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

14 vizualizări7 paginiCim Curriculum

Încărcat de

schrienerComputer Integrated Manufacturing course is designed to expose students to the fundamentals of computerized manufacturing technology. Course will be taught using demonstration and discussion combined with individual and team-centered project based learning. In each of the learning sections students will be taught a different set of performance objectives.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 7

Project Lead the Way

Computer Integrated Manufacturing

The purpose of the Computer Integrated Manufacturing course is to expose students

to the fundamentals of computerized manufacturing technology. The course is built

around several key concepts:

Computer Modeling using a three-dimensional, solid modeling software package with

mass property analysis.

CNC Equipment understanding the machine tools and its operating and programming

aspects.

CAM Software converting computer generated geometry into a program to drive CNC

machine tools.

Robotics using a robot for materials handling and assembly operations.

Flexible Manufacturing Systems students working in teams to design manufacturing

work cells and tabletop factory simulations.

The course will be taught using demonstration and discussion combined with individual

and team-centered project based learning. In each of the learning sections students will

be taught a different set of performance objectives.

Unit and Section Outline

Unit 1 Computer Modeling

Section 1.1 Fundamentals

Section 1.2 Object Construction

Section 1.3 Parts Modeling

Section 1.4 Creation of Working Drawings

Section 1.5 Surface Modeling

Section 1.6 Rapid Prototyping

Unit 2 CNC Machining

Section 2.1 History of Programmable Machining

Section 2.2 CNC Characteristics

Section 2.3 CNC Programming

Section 2.4 CNC Operations

Section 2.5 CAM Software

Unit 3 Robotics

Section 3.1 Introduction to Robotics

Section 3.2 Robotics and Automated Systems

Section 3.3 Robot Characteristics

Section 3.4 Robot Controllers

Section 3.5 Programming the Robot

Section 3.6 End Effectors

Section 3.7 Robot Applications

Unit 4 Computer Integrated Manufacturing

Section 4.1 Rationales for CIM Manufacturing

Section 4.2 Types of CIM Systems

Section 4.3 Components of CIM Systems

Section 4.4 CIM System Applications

Grading

The report card grade for CIMs is based on the following criteria:

Content Area Assignments (labs, test, and drawings) ...............................................................................49.0%

Effective Communicator Assignments (FMS Log & PPT)........................................................................17.0%

Complex Thinker Activities (Projects) .......................................................................................................34.0%

Full year course ( Q1 + Q2 + Q3 + Q4 + Final Exam.) / 5 = Course grade

Semester course ( Q1 + Q1 + Q2 + Q2 + Final Exam.) / 5 = Course grade

Expectations

Students are expected to meet the following criteria in class:

Good attendance

Good classroom behavior and attitude

Ability to meet deadlines

Ability to show consideration for others

Ability to solve problems

Oral articulation of thoughts and ideas

Extra Help

If a student misses class, he/she is expected to make up the work missed. Further, if they are

having trouble with the course content, they are encouraged to seek extra help either during the

school day or after school.

Unit 1 Overview

COMPUTER MODELING

SECTION 1.1: Fundamentals

In this Section, the student will review the operations of Inventor by creating,

saving, and retrieving models. They will also use coordinate systems, pull down menus,

and layering, to organize and produce models. As the student moves through this

section, the many advantages of computer modeling will become immediately obvious

Section 1.2 :Object Construction

In this Section, students will be able to produce 2D sketches using available sketching

features, apply editing techniques to produce accurate sketches, understand and apply

sketch constraints and analyze drawings with appropriate inquiry functions.

Section 1.3: Parts Modeling

In this Section, students will be able to define sketched objects with dimensions and

geometric constraints, apply necessary sketched features to generate a solid model and be

able to demonstrate the application and modifying of placed features.

Section 1.4: Creation of Drawing Views

In this Section, students will be able to develop multi-view drawings such as top, front,

right side, isometric, section and auxiliary views from the solid model. Students will be

able to demonstrate the proper application of annotations and reference dimensions while

conforming to established drafting standards.

Section 1.5: Assembly Modeling

In this Section, students will be able to create assembly models through the

integration of individual parts and sub-assemblies. They will also be able

to generate an assembly drawing, which include Views, Balloons, and Bill

Of Materials (BOM).

Unit 2 Overview

PROGRAMMABLE MACHINES

Section 2.1: The History of Programmable Machining

Students will be able to explain the history of Computer Controlled Machines charting

the growth of NC and how it has been implemented into Private Industry.

Students will be able to explain how the application of CNC machines has impacted

manufacturing.

Students will be able to explain the advantages and disadvantages of CNC

Machining.

Students will be able to chart the evolution of machine tools, controllers, and software

used in programmable machines.

Section 2.2: CNC Characteristics

Students will identify the axis relative to various CNC machines.

Students will contrast open and closed loop control systems.

Students will identify the types of drive systems used in CNC machines.

Students will be able to use the CNC control program to indicate the machine position

and then contrast that position to the relative position of the part origin (PRZ).

Students will be able to identify and explain the function of the major components of a

CNC machine tool.

Section 2.3: CNC Programming

Students will understand the difference between reference and position points.

Students will understand that axes identify CNC machine movements.

Students will understand that the axis system is a worldwide standard for machine

movement.

Students will be able to plot points using absolute, relative (incremental) and polar

coordinates.

Students will be able to identify Significant Points on geometric shapes (ex. Centerpoint,

end point).

Students will be able to identify the optimum location for the Program Reference Zero

(PRZ) point.

Students will be able to identify the three categories of machine movement: straight line,

curved line, and non-regular shape.

Students will be able to complete a preliminary planning sheet to identify necessary work

holding devices, cutting tools, reference points, machining sequences and safe operation.

Students will be able to define the term Alphanumeric Coding.

Students will be able to define the term G codes.

Students will be able to define the term M code.

Students will be able to identify the three sections of a program; Initial Commands,

Program Body, and Program End.

Students will be able to write a basic NC part program using necessary G and M codes

including remarks that describe the function of each code.

Students will be able to explore the advantages and disadvantages of shop floor

programming as well as off line programming.

Students will be able to create a simple NC part program using a text editor and a CAM

package.

Students will be able to employ a CAD/CAM/CNC software solution to create a part.

Students will be able to analyze, identify and correct errors found in NC part program

files.

Students will be able to use simulation software to graphically verify NC program

operation.

Students will be able to perform a Dry Run to verify the machine setup and program

operation.

Section 2.4: CNC Operations

Student will be able to demonstrate the ability to safely setup, maintain and operate a

CNC machine center using appropriate documentation and procedures.

Students will be able to analyze part geometry to select appropriate cutting tools and

fixturing devices needed to create the part using a CNC machine.

Students will be able to setup and edit the tool library of a CNC control program

providing offset values and tool geometry.

Students will be able to calculate and verify appropriate spindle speeds and feed rates

specific to each cutting tool utilized in an NC part program.

Students will be able to safely and accurately fixture a part in a CNC machine and set the

program reference zero (PRZ).

Students will be able to verify NC part programs using simulation software before

machining the part on a CNC device.

Students will be able to list and demonstrate all possible methods of disabling a CNC

machine in the event of an emergency.

Students will follow a safety checklist prior to running an NC part program on a CNC

machine.

Students will be able to perform a Dry Run to verify the machine setup and program

operation.

Students will be able to operate a CNC machine to cut a part to specifications.

Section 2.5 : Precision Measurement

Students will be able to measure using standard and metric systems.

Students will be able to convert measurements between metric and standard inch

systems.

Students will be able to read technical drawings identifying and understand the

dimensional tolerances and limits.

Students will be able to make precision measurements to the degree of accuracy

required by plan specification using appropriate instruments.

Students will understand how comparison instruments can be used to check

dimensions, compare shapes, indicate centers and check parallel surfaces.

Students will be aware of the importance of precision measurement in SPC and

quality control.

Section 2.6: CAM Software

Students will be able to define the acronym CAM and explain what the purpose of a CAM

package is.

Students will demonstrate their ability to operate the user interface of a CAM package and access

help using appropriate documentation and help screens.

Students will be able to perform basic file operations using a CAM package such as saving,

opening, printing and editing part program files.

Students will demonstrate an ability to import and export CAD files using a CAM

package.

Students will setup a CAM package by editing the material and tool libraries,

defining stock sizes, selecting the appropriate post processor and defining the units of measure to

be used.

Students will define and apply the fundamental and advanced milling procedure used in CAM

packages.

Students will use a CAM package to generate and edit tool paths by applying

appropriate machining processes to geometry imported from a CAD program.

Unit 3 Overview

INTRODUCTION TO ROBOTICS

Section 3.1: Introduction to Robotics

Students will explore the chronological development of automation leading to

robotics. Students will demonstrate the development of robotics from Science

Fiction. Students will identify a minimum of four dangerous and repetitive jobs

that robots are used for.

Section 3.2: Robotics and Automated Systems

Students will formulate a definition of a robot. Students will be able to classify

different types of Robots. Students will evaluate the positive impact robots have

on manufacturing. Students will discuss the social implications of robots.

Section 3.3: Robot Characteristics

Students will identify and compare the four classifications of robots. Students will

investigate a classification of robot. Students will identify and report

specifications and work envelops of robots.

Section 3.4: Mechanical Components

Students will identify and sketch the mechanical components to a robot. 3.

Students will demonstrate their understanding of the way end effectors are

specific to a process. Students will understand the various drive systems used in

robotics and analyze the advantages and disadvantages of each.

Section 3.5: Control Systems

Students will understand the basic components of robot controllers. Students will

demonstrate an understanding of control techniques and computer simulations.

Section 3.6: Programming Methods

Students will program a robot to perform several tasks. Students will program a

robot to solve a materials handling problem. Students will recognize the need for

end of arm tooling and how this tooling affects the robots operation.

Section 3.7: Industrial Robot Applications

Students will understand the necessity for specialty tooling applications in

robotics. Students will analyze and generate the solution to a robotic

manufacturing problem.

Unit 4 Overview

COMPUTER INTEGRATED MANUFACTURING

Section 4.1: Rationale for CIM Manufacturing

Students will understand how the individual components of a flexible

manufacturing system are interrelated. Students will recognize the benefits and

problems associated with CIM technology and how they affect the manufacturing

process. Students will identify some basic characteristics of a manufacturing

operation that lend themselves to computer integrated manufacturing.

Section 4.2: Types of CIM Systems

Student will identify the three categories of CIM manufacturing systems.

Students will compare and contrast the benefits and drawbacks of the three

categories of CIM manufacturing systems. Students will recognize the working

relationship between the CNC mill and the robot. The students will be able to

identify the components of a FMS.

Section 4.3: Components of CIM Systems

Students will identify and study the relationship between a CNC milling machine

interface and a jointed arm robot interface through a communication handshaking

process. Students will explore the individual components used in selected CIM

systems. Students will analyze and select components for a CIM system for a

specific industrial application. Students will understand the various applications

of a Programmable Logic Controller as related to its use in a CIM system.

Students will understand the difference between a PLC and a computer with

interface.

Section 4.4: CIM System Applications

Students will recognize and understand the necessary safety precautions

associated with a fully automated CIM system. Students will recognize and

explain the significance of teamwork and communication when they combine the

designs of the individual groups into a complete miniature FMS. Students will

demonstrate how their individual components work together to form a

complete CIM system. Students will assemble and test their individual

component designs by integrating them into a complete miniature FMS built from

the Fischertechnik models.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Journey To The ARI-ARhAyas AL-Uma-UN Core of The Krystar Seed Atom FileDocument14 paginiJourney To The ARI-ARhAyas AL-Uma-UN Core of The Krystar Seed Atom FileSungwon Kang100% (2)

- DEWA Electrical Installation Regulations Section 1 OverviewDocument123 paginiDEWA Electrical Installation Regulations Section 1 Overviewsiva_nagesh_280% (5)

- CNC Turning Programming Exellent ExplainationDocument29 paginiCNC Turning Programming Exellent ExplainationschrienerÎncă nu există evaluări

- Metal Fabrication Guide SafetyDocument46 paginiMetal Fabrication Guide SafetyRADHIKAÎncă nu există evaluări

- Space 1999 Annual 1979Document62 paginiSpace 1999 Annual 1979Brin Bly100% (1)

- Lim vs. CA DigestDocument2 paginiLim vs. CA Digestsamme1010100% (1)

- Failure AnalyzingDocument46 paginiFailure Analyzingdot11Încă nu există evaluări

- ATLAS CYLINDER LUBRICATOR MANUALDocument36 paginiATLAS CYLINDER LUBRICATOR MANUALKaleb Z king webÎncă nu există evaluări

- Case Study No. 11 - Hydroelectric Power Plant in The PhilippinesDocument26 paginiCase Study No. 11 - Hydroelectric Power Plant in The PhilippinespicefeatiÎncă nu există evaluări

- Causes of The Renaissance: Silk RoadDocument6 paginiCauses of The Renaissance: Silk RoadCyryhl GutlayÎncă nu există evaluări

- Avanto Magnet System Error MessagesDocument21 paginiAvanto Magnet System Error MessagesMuhammad Ahmad75% (4)

- MATH 8 QUARTER 3 WEEK 1 & 2 MODULEDocument10 paginiMATH 8 QUARTER 3 WEEK 1 & 2 MODULECandy CastroÎncă nu există evaluări

- Acl Data Analytics EbookDocument14 paginiAcl Data Analytics Ebookcassiemanok01Încă nu există evaluări

- Design of Helical Antennas For 433 MHZ Radio Telemetry Ground Station and Uav (Unmanned Aerial Vehicle)Document7 paginiDesign of Helical Antennas For 433 MHZ Radio Telemetry Ground Station and Uav (Unmanned Aerial Vehicle)Tiara Nira SariÎncă nu există evaluări

- Economy Profile 2016 BrazilDocument131 paginiEconomy Profile 2016 BrazilschrienerÎncă nu există evaluări

- Economy Profile 2016 BrazilDocument131 paginiEconomy Profile 2016 BrazilschrienerÎncă nu există evaluări

- Doing Business in Colombia 2013Document6 paginiDoing Business in Colombia 2013Santiago CuetoÎncă nu există evaluări

- Brazil Trade and Export GuideDocument16 paginiBrazil Trade and Export GuideschrienerÎncă nu există evaluări

- Chapter-8 RoboticsDocument22 paginiChapter-8 RoboticsschrienerÎncă nu există evaluări

- 3D Printing Infographic FINALDocument1 pagină3D Printing Infographic FINALklumer_xÎncă nu există evaluări

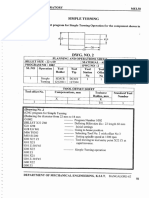

- CAD/CAM Laboratory Process PlanningDocument14 paginiCAD/CAM Laboratory Process Planningschriener50% (2)

- Accident InvestigationDocument3 paginiAccident InvestigationschrienerÎncă nu există evaluări

- Table of Contents LogisisticsDocument4 paginiTable of Contents LogisisticsschrienerÎncă nu există evaluări

- Nitro Pro 9 User Guide en PDFDocument270 paginiNitro Pro 9 User Guide en PDFReynoso RivasÎncă nu există evaluări

- Pro To Typing Powerpoint BNDocument12 paginiPro To Typing Powerpoint BNschrienerÎncă nu există evaluări

- Motoman Mh5f ManualDocument66 paginiMotoman Mh5f ManualschrienerÎncă nu există evaluări

- Motoman Mh5f ManualDocument66 paginiMotoman Mh5f ManualschrienerÎncă nu există evaluări

- MOTOMAN Mantaince ManualDocument99 paginiMOTOMAN Mantaince ManualschrienerÎncă nu există evaluări

- G CodeDocument55 paginiG CodeArman PinedaÎncă nu există evaluări

- Motoman Mh5f ManualDocument66 paginiMotoman Mh5f ManualschrienerÎncă nu există evaluări

- 3D Printing Infographic FINALDocument1 pagină3D Printing Infographic FINALklumer_xÎncă nu există evaluări

- Install KUKA - Sim 2.1 enDocument11 paginiInstall KUKA - Sim 2.1 enrx7000Încă nu există evaluări

- Machining Final Exam Test Translate PDFDocument8 paginiMachining Final Exam Test Translate PDFschrienerÎncă nu există evaluări

- Basic Manufacturing Processes Questions and Answers 07 July 2013Document0 paginiBasic Manufacturing Processes Questions and Answers 07 July 2013Felicia WagnerÎncă nu există evaluări

- KUKA PB KR AGILUS enDocument16 paginiKUKA PB KR AGILUS enIstvan VeghÎncă nu există evaluări

- Carta de Motivacion Tu Delft EnglishDocument3 paginiCarta de Motivacion Tu Delft EnglishschrienerÎncă nu există evaluări

- Sample ROBOTICS-final PDFDocument8 paginiSample ROBOTICS-final PDFschrienerÎncă nu există evaluări

- Alarme WinNC-Fanuc21 enDocument18 paginiAlarme WinNC-Fanuc21 enschrienerÎncă nu există evaluări

- Description of Classroom Management PlanDocument10 paginiDescription of Classroom Management Planapi-575843180Încă nu există evaluări

- NVH PDFDocument3 paginiNVH PDFSubhendu BarisalÎncă nu există evaluări

- Biology 11th Edition Mader Test BankDocument25 paginiBiology 11th Edition Mader Test BankAnthonyWeaveracey100% (44)

- CANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenDocument6 paginiCANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenIsmenia HelenaÎncă nu există evaluări

- IT Technician CVDocument3 paginiIT Technician CVRavi KumarÎncă nu există evaluări

- Eco 301 Final Exam ReviewDocument14 paginiEco 301 Final Exam ReviewCảnh DươngÎncă nu există evaluări

- Theories of Translation12345Document22 paginiTheories of Translation12345Ishrat FatimaÎncă nu există evaluări

- Mechanics of Materials: Combined StressesDocument3 paginiMechanics of Materials: Combined StressesUmut Enes SürücüÎncă nu există evaluări

- Percentage Practice Sheet - RBEDocument11 paginiPercentage Practice Sheet - RBEankitÎncă nu există evaluări

- Scope of Incubator CentersDocument3 paginiScope of Incubator Centersanon_542600428Încă nu există evaluări

- RRLDocument4 paginiRRLTiltshifter ViÎncă nu există evaluări

- Sri Lanka, CBSLDocument24 paginiSri Lanka, CBSLVyasIRMAÎncă nu există evaluări

- Black BeautyDocument70 paginiBlack BeautyMeryem DevirgenÎncă nu există evaluări

- Course Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataDocument61 paginiCourse Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataShekinah Vingno LingcongÎncă nu există evaluări

- Sankalp Sanjeevani NEET: PhysicsDocument11 paginiSankalp Sanjeevani NEET: PhysicsKey RavenÎncă nu există evaluări

- Synetek Controls Inc.: Ds1-S: Installation InstructionsDocument2 paginiSynetek Controls Inc.: Ds1-S: Installation Instructionsdgd_electromecÎncă nu există evaluări

- Conditional Sentences in NT Greek Ruben VideiraDocument62 paginiConditional Sentences in NT Greek Ruben Videiraruviso100% (1)

- CVR College of Engineering: UGC Autonomous InstitutionDocument2 paginiCVR College of Engineering: UGC Autonomous Institutionshankar1577Încă nu există evaluări

- SPH3U Formula SheetDocument2 paginiSPH3U Formula SheetJSÎncă nu există evaluări