Documente Academic

Documente Profesional

Documente Cultură

Clutch: Section

Încărcat de

tomallor101Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Clutch: Section

Încărcat de

tomallor101Drepturi de autor:

Formate disponibile

CL-1

CLUTCH

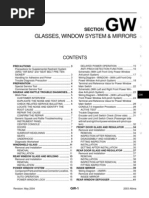

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION

A

B

CL

Revision: November 2006 2006 Altima

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) AIR BAG and SEAT BELT PRE-TEN-

SIONER ............................................................. ..... 2

Precautions ......................................................... ..... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH TROUBLESHOOTING CHART .................. ..... 4

CLUTCH PEDAL ........................................................ 5

Components ............................................................. 5

Removal and Installation ..................................... ..... 5

INSPECTION AFTER REMOVAL .................... ..... 5

On-vehicle Inspection and Adjustment ..................... 6

CLUTCH FLUID .......................................................... 7

Air Bleeding Procedure ............................................ 7

CLUTCH MASTER CYLINDER .................................. 8

Components ............................................................. 8

CLUTCH MASTER CYLINDER .......................... ..... 8

REMOVAL ............................................................. 8

INSTALLATION ..................................................... 8

CLUTCH RESERVOIR TANK .................................. 9

REMOVAL ............................................................. 9

INSTALLATION ..................................................... 9

Disassembly and Assembly ..................................... 9

DISASSEMBLY ..................................................... 9

INSPECTION AFTER DISASSEMBLY ............ ..... 9

ASSEMBLY ........................................................... 9

OPERATING CYLINDER ....................................... ....11

Removal and Installation ..................................... ....11

REMOVAL ............................................................11

INSTALLATION ................................................ ... 11

Disassembly and Assembly ................................. ... 11

DISASSEMBLY ................................................ ... 11

INSPECTION AFTER DISASSEMBLY ................ 12

ASSEMBLY ...................................................... ... 12

CLUTCH PIPING .................................................... ... 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................ ... 13

CLUTCH RELEASE MECHANISM ........................... 14

Removal and Installation (QR engine models) .... ... 14

REMOVAL ........................................................... 14

INSPECTION AFTER REMOVAL ....................... 14

INSTALLATION ................................................ ... 15

Removal and Installation (VQ engine models) ....... 16

REMOVAL ........................................................... 16

INSPECTION AFTER REMOVAL ....................... 16

INSTALLATION ................................................ ... 17

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL ... 18

Removal and Installation ........................................ 18

REMOVAL ........................................................... 18

INSTALLATION ................................................ ... 18

Inspection and Adjustment after Removal .............. 19

CLUTCH DISC ................................................. ... 19

CLUTCH COVER ................................................ 19

FLYWHEEL ...................................................... ... 19

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 20

Clutch Control System ......................................... ... 20

Clutch Master Cylinder ........................................... 20

Clutch Operating Cylinder ................................... ... 20

Clutch Disc .......................................................... ... 20

Clutch Cover ........................................................ ... 20

Clutch Pedal ........................................................... 20

CL-2

PRECAUTIONS

Revision: November 2006 2006 Altima

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) AIR BAG and SEAT

BELT PRE-TENSIONER ECS00IYV

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

G To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

G Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

G Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions ECS00939

G Recommended fluid is brake fluid DOT 3.

G Never reuse drained brake fluid.

G Be careful not to splash brake fluid on painted areas.

G When removing and installing clutch piping, use Tool.

G Use new brake fluid to clean or wash all parts of master cyl-

inder and operating cylinder.

G Never use mineral oils such as gasoline or kerosene. It will

ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do not

use compressed air.

SBR686C

PREPARATION

CL-3

D

E

F

G

H

I

J

K

L

M

A

B

CL

Revision: November 2006 2006 Altima

PREPARATION PFP:00002

Special Service Tools ECS0093A

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tools ECS0093B

Tool number

(Kent-Moore No.)

Tool name

Description

ST20630000

(J-26366)

Clutch aligning bar

Installing clutch cover and clutch disc

a: 15.8 mm (0.622 in) dia.

b: 22.9 mm (0.902 in) dia.

c: 45.0 mm (1.772 in)

ST20050240

( )

Diaphragm spring adjusting wrench

Adjusting unevenness of diaphragm spring of

clutch cover

a: 150 mm (5.91 in)

b: 25 mm (0.98 in)

NT405

NT404

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

Removing and installing clutch piping

a: 10 mm (0.39 in)

Power tool Loosening bolts and nuts

NT360

PBIC0190E

CL-4

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Revision: November 2006 2006 Altima

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING PFP:00003

NVH TROUBLESHOOTING CHART ECS0093C

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference page

C

L

-

6

C

L

-

7

C

L

-

5

C

L

-

9

E

M

-

6

9

,

"

R

e

m

o

v

a

l

a

n

d

I

n

s

t

a

l

l

a

t

i

o

n

"

(

Q

R

2

5

D

E

)

,

E

M

-

2

1

5

,

"

R

e

m

o

v

a

l

a

n

d

I

n

s

t

a

l

l

a

t

i

o

n

"

(

V

Q

3

5

D

E

)

C

L

-

1

2

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

C

L

-

1

9

,

"

F

L

Y

W

H

E

E

L

"

SUSPECTED PARTS (Possible cause)

C

L

U

T

C

H

P

E

D

A

L

(

I

n

s

p

e

c

t

i

o

n

a

n

d

a

d

j

u

s

t

m

e

n

t

)

C

L

U

T

C

H

L

I

N

E

(

A

i

r

i

n

l

i

n

e

)

M

A

S

T

E

R

C

Y

L

I

N

D

E

R

P

I

S

T

O

N

C

U

P

(

D

a

m

a

g

e

d

)

O

P

E

R

A

T

I

N

G

C

Y

L

I

N

D

E

R

P

I

S

T

O

N

C

U

P

(

D

a

m

a

g

e

d

)

E

N

G

I

N

E

M

O

U

N

T

I

N

G

(

L

o

o

s

e

)

R

E

L

E

A

S

E

B

E

A

R

I

N

G

(

W

o

r

n

,

d

i

r

t

y

o

r

d

a

m

a

g

e

d

)

C

L

U

T

C

H

D

I

S

C

(

O

u

t

o

f

t

r

u

e

)

C

L

U

T

C

H

D

I

S

C

(

R

u

n

o

u

t

i

s

e

x

c

e

s

s

i

v

e

)

C

L

U

T

C

H

D

I

S

C

(

L

i

n

i

n

g

b

r

o

k

e

n

)

C

L

U

T

C

H

D

I

S

C

(

D

i

r

t

y

o

r

b

u

r

n

e

d

)

C

L

U

T

C

H

D

I

S

C

(

O

i

l

y

)

C

L

U

T

C

H

D

I

S

C

(

W

o

r

n

o

u

t

)

C

L

U

T

C

H

D

I

S

C

(

H

a

r

d

e

n

e

d

)

C

L

U

T

C

H

D

I

S

C

(

L

a

c

k

o

f

s

p

l

i

n

e

g

r

e

a

s

e

)

D

I

A

P

H

R

A

G

M

S

P

R

I

N

G

(

D

a

m

a

g

e

d

)

D

I

A

P

H

R

A

G

M

S

P

R

I

N

G

(

O

u

t

o

f

t

i

p

a

l

i

g

n

m

e

n

t

)

P

R

E

S

S

U

R

E

P

L

A

T

E

(

D

i

s

t

o

r

t

i

o

n

)

F

L

Y

W

H

E

E

L

(

D

i

s

t

o

r

t

i

o

n

)

Symptom

Clutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1 2 3 4 5 5 5 5 5 5 6 6 7

CLUTCH PEDAL

CL-5

D

E

F

G

H

I

J

K

L

M

A

B

CL

Revision: November 2006 2006 Altima

CLUTCH PEDAL PFP:46540

Components ECS0093D

Removal and Installation ECS0093E

Refer to CL-5, "Components" .

INSPECTION AFTER REMOVAL

G Inspect clutch for bending, damage and welding cracks. Replace if necessary.

G Make sure that the assist spring and return spring have not lost their spring. Replace if necessary.

1. Clutch pedal bracket 2. Clutch interlock switch 3. Bushing

4. Assist spring 5. Bushing 6. Snap pin

7. Stopper rubber 8. Clutch pedal 9. Stopper bolt

10. ASCD clutch switch 11. Clevis pin

WCIA0436E

CL-6

CLUTCH PEDAL

Revision: November 2006 2006 Altima

On-vehicle Inspection and Adjustment ECS0093F

1. Check to see if the clutch pedal clevis pin floats freely in the bore

of the clutch pedal. It should not be bound by the clevis or clutch

pedal.

a. If the pin is not free, check that the ASCD switch or pedal stop-

per bolt is not applying pressure to the clutch pedal causing the

pin to bind. To adjust, loosen the ASCD switch or pedal stopper

bolt lock nut and turn the ASCD switch or pedal stopper bolt.

b. Tighten the lock nut.

c. Verify that the clutch pedal clevis pin floats freely in the bore of

the clutch pedal. It should not be bound by the clevis or clutch

pedal.

d. If the pin is still not free, remove the pin and check for deforma-

tion or damage. Replace the pin if necessary. Leave the pin

removed for step 2.

2. Check the clutch pedal stroke for free range of movement.

a. With the clutch pedal clevis pin removed, manually move the

pedal up and down to determine if it moves freely.

b. If any sticking is noted, replace the related parts (clutch pedal,

pedal bracket, assist spring and bushing). Reassemble the

pedal and re-verify that the clevis pin floats freely in the bore of

the pedal.

3. Adjust the clearance C while fully depressing the clutch pedal

(with the clutch interlock switch) as shown.

4. Check the clutch hydraulic system components (clutch master

cylinder, clutch operating cylinder, Clutch withdrawal lever and

clutch release bearing) for sticking or binding.

a. If any sticking or binding is noted, repair or replace the related

parts as necessary.

b. If the hydraulic system was necessary, bleed the clutch hydrau-

lic system. Refer to CL-7, "Air Bleeding Procedure" .

NOTE:

Do not use a vacuum assist or any other type of power bleeder

on this system. Use of a vacuum assist or power bleeder will not

purge all of the air from the system.

WCIA0146E

Clearance C : 0.1 - 1.0 mm (0.004 - 0.039 in)

SCL800

CLUTCH FLUID

CL-7

D

E

F

G

H

I

J

K

L

M

A

B

CL

Revision: November 2006 2006 Altima

CLUTCH FLUID PFP:00017

Air Bleeding Procedure ECS0093G

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all the air from the system.

G Bleed air according to the following procedure.

G Carefully monitor fluid level at reservoir tank during bleeding operation.

G When bleeding the air from the clutch fluid, first bleed the air from the operating cylinder air bleed valve

and then from the bleed connector air bleed valve.

1. Top off reservoir with new recommended brake fluid.

2. Connect a transparent vinyl tube to the air bleeder valve on the

clutch operating cylinder.

3. Fully depress the clutch pedal several times.

4. With clutch pedal depressed, open the bleeder valve to release air.

5. Close the bleeder valve.

6. Repeat steps 3 through 5 until clear brake fluid comes out of the air bleeder valve.

7. Perform steps 1 through 6 for bleeding air from the air bleeder

valve on the bleed connector.

WCIA0199E

Air bleeder valve : 5.9 - 9.8 Nm (0.6 - 1.0 kg-m, 52 - 87 in-lb)

LCIA0102E

CL-8

CLUTCH MASTER CYLINDER

Revision: November 2006 2006 Altima

CLUTCH MASTER CYLINDER PFP:30610

Components ECS0093H

CLUTCH MASTER CYLINDER ECS0093I

REMOVAL

1. Drain the brake fluid from the clutch hydraulic system.

CAUTION:

Do not splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

2. Remove clutch line using a flare nut wrench.

3. Remove hose clamp and hose from clutch master cylinder.

4. Remove snap pin from clevis pin, then remove clevis pin from push rod and clevis.

5. Remove the clutch master cylinder nuts, then remove the clutch master cylinder from the vehicle.

INSTALLATION

1. Check position of clevis and push rod. If measurement is outside

standard length, adjust position of clevis and push rod.

2. Connect the clutch line to the master cylinder assembly, and

hand-tighten the flare nut.

3. Install the master cylinder assembly, tighten the nuts to specification.

4. Install clutch reservoir tank hose and hose clamp to the clutch master cylinder assembly.

5. Tighten the clutch line flare nut to specification using a flare nut torque wrench.

1. Clutch master cylinder 2. Return spring 3. Piston assembly

4. Push rod 5. Stopper 6. Stopper ring

7. Dust cover 8. Clevis 9. Hose clamp

10. Hose 11. Reservoir cap 12. Reservoir tank

13. Bracket 14. Nipple 15. Pin

WCIA0429E

Length L : 119.5 mm (4.70 in)

SCIA5158E

Clutch master cylinder nuts : 7.8 10.8 Nm (0.8 1.6 kg-m, 9 12 ft-lb)

CLUTCH MASTER CYLINDER

CL-9

D

E

F

G

H

I

J

K

L

M

A

B

CL

Revision: November 2006 2006 Altima

6. Attach clevis and clevis pin to clutch pedal.

7. Attach snap pin to clevis pin.

8. Inspect and adjust the clutch pedal and bleed the air from the clutch hydraulic system. Refer to CL-6, "On-

vehicle Inspection and Adjustment" and CL-7, "Air Bleeding Procedure" .

CLUTCH RESERVOIR TANK ECS0093J

REMOVAL

1. Drain the brake fluid from the clutch hydraulic system.

CAUTION:

Do not splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

2. Remove the clamp, then remove the hose from the clutch reservoir tank.

3. Remove the clutch reservoir tank to bracket nuts, then remove the clutch reservoir tank from the vehicle.

INSTALLATION

1. Install the clutch reservoir tank and nuts to the bracket and hand-tighten.

2. Install the hose and clamp to the clutch reservoir tank.

3. Tighten the clutch reservoir tank nuts to specified torque.

Disassembly and Assembly ECS0093K

DISASSEMBLY

1. Loosen the push rod lock nut A, then remove clevis and lock

nut A if necessary.

CAUTION:

Clutch pedal height is controlled with position of clevis and

push rod.

2. Remove the dust cover.

3. Remove the stopper ring and stopper, and remove the push rod

from the cylinder body. During removal, keep the push rod

depressed, to prevent the piston inside master cylinder from

popping out.

4. Remove the piston assembly from the cylinder body.

INSPECTION AFTER DISASSEMBLY

Inspect for the following, and replace parts as necessary.

G Damage, wear, rust, and pinholes on the cylinder inner wall

G Damage and deformation of the reservoir tank

G Weak spring

G Crack and deformation of the dust cover

ASSEMBLY

1. Apply rubber lubricant to the sliding part of piston assembly, and insert piston assembly.

2. After installing stopper to push rod, install a new stopper ring while keeping piston assembly depressed by

hand, so that piston assembly will not pop out.

CAUTION:

Stopper ring cannot be reused. Always use a new stopper ring to assemble.

3. Install dust cover.

4. Install nipple and pin to cylinder body.

5. Install clevis to push rod.

Clutch line flare nut : 15 - 18 Nm (1.5 1.8 kg-m, 11 13 ft-lb)

Reservoir tank bracket bolts : 5.1 6.5 Nm (0.52 0.66 kg-m, 46 57 in-lb)

Reservoir tank to bracket nuts

(for QR25DE engine models) : 2.9 5.9 Nm (0.3 0.6 kg-m, 26 52 in-lb)

(for VQ35DE engine models) : 5.1 6.5 Nm (0.52 0.66 kg-m, 46 57 in-lb)

SCL725

CL-10

CLUTCH MASTER CYLINDER

Revision: November 2006 2006 Altima

6. Check and adjust position of clevis on push rod. After adjusting

L, tighten lock nut to the specified torque.

Length L : 119.5 mm (4.70 in)

Lock nut A tightening

torque

: 7.8 - 11.8 Nm (0.8 - 1.2 kg-m,

69 - 104 in-lb)

SCIA5158E

OPERATING CYLINDER

CL-11

D

E

F

G

H

I

J

K

L

M

A

B

CL

Revision: November 2006 2006 Altima

OPERATING CYLINDER PFP:30620

Removal and Installation ECS0093L

REMOVAL

1. Drain brake fluid from hydraulic clutch system.

CAUTION:

Do not splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

2. Remove union bolt and clutch hose from operating cylinder.

3. Remove operating cylinder bolts, and remove cylinder from

vehicle.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

G Install the clutch hose without twisting it.

G The copper washer of the union bolt cannot be reused. Always use a new copper washer when

installing the clutch hose.

G After installation, bleed the air from the clutch hydraulic system. Refer to CL-7, "Air Bleeding Pro-

cedure" .

Disassembly and Assembly ECS0093M

DISASSEMBLY

G Remove dust cover, and remove piston assembly from cylinder body.

1. Cylinder body 2. Piston spring 3. Piston cup

4. Piston 5. Push rod 6. Dust cover

7. Air bleeder 8. Union bolt 9. Copper washer

10. Clutch hose

WCIA0196E

WCIA0197E

CL-12

OPERATING CYLINDER

Revision: November 2006 2006 Altima

INSPECTION AFTER DISASSEMBLY

Inspect for following, and replace parts as necessary.

G Damage, foreign material, wear, rust, and pinholes on the cylinder inner surface, piston, and sliding part of

piston cup

G Weak spring

G Crack and deformation of dust cover

ASSEMBLY

Assembly is in the reverse order of disassembly.

G Apply recommended rubber grease to piston cup and piston before assembly.

CLUTCH PIPING

CL-13

D

E

F

G

H

I

J

K

L

M

A

B

CL

Revision: November 2006 2006 Altima

CLUTCH PIPING PFP:30650

Removal and Installation ECS0093N

REMOVAL

1. Remove fuel filter mounting bracket.

2. Remove air cleaner to electronic throttle control actuator tube

and air cleaner case (upper). Refer to EM-17, "Removal and

Installation" (QR25DE), EM-118, "Removal and Installation"

(VQ35DE).

3. Drain the brake fluid from the hydraulic clutch system.

CAUTION:

Do not splash brake fluid on painted areas; it may cause

paint damage. If brake fluid is splashed on painted areas,

wash it away with water immediately.

4. Remove flare nut using a flare nut wrench.

5. Remove clutch hose and clutch tube.

INSTALLATION

1. When installing clutch hose to bracket, face lock plate in the cor-

rect direction as shown to secure clutch hose.

CAUTION:

Install clutch hose without twisting or bending it.

2. Tighten flare nut to the specification, using a flare nut wrench.

CAUTION:

Be careful not to damage flare nut and clutch tube.

3. Install clutch hose to operating cylinder, and tighten the union

bolt to the specified torque.

4. After installation, bleed the air from the clutch hydraulic system.

Refer to CL-7, "Air Bleeding Procedure" .

WCIA0437E

SCL730

Flare nut : 15 - 18 Nm (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

Clutch hose union bolt : 17 - 20 Nm (1.7 - 2.0 kg-m,

12 - 14 ft-lb)

WCIA0197E

CL-14

CLUTCH RELEASE MECHANISM

Revision: November 2006 2006 Altima

CLUTCH RELEASE MECHANISM PFP:30502

Removal and Installation (QR engine models) ECS0093O

REMOVAL

1. Remove manual transaxle from vehicle. Refer to MT-17, "Removal and Installation" .

2. Move withdrawal lever enough to remove release bearing, and remove release bearing from withdrawal

lever.

3. Remove withdrawal lever retainer spring.

4. Pull out withdrawal lever and remove dust cover.

INSPECTION AFTER REMOVAL

G Replace the release bearing if it is seized, damaged, faulty in

rotation direction, or has poor aligning function.

G Replace the withdrawal lever if its contact surface is worn abnor-

mally.

G Replace the dust seal if it is deformed or cracked.

LCIA0030E

SCL733

CLUTCH RELEASE MECHANISM

CL-15

D

E

F

G

H

I

J

K

L

M

A

B

CL

Revision: November 2006 2006 Altima

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

G Clean old grease and abrasive materials off the grease application areas.

G Apply grease to the specified points as shown.

G Apply approximately 1 mm (0.04 in) thick coat of clutch sleeve grease to withdrawal lever and holder

spring frictional surfaces.

G Apply a coat of clutch sleeve grease to the grooves on contact surfaces of the withdrawal lever ball pin

and inner surface of release bearing; make sure that grease is flush with grooves.

G Apply a thin coat of clutch sleeve grease to release bearing frictional surface. After grease application,

install release bearing. Wipe off excess grease forced out during bearing installation.

CAUTION:

G Before installing the manual transaxle to the vehicle, check that each sliding surface slides

smoothly by operating withdrawal lever.

G Be careful with the orientation of the installation.

SCL815

CL-16

CLUTCH RELEASE MECHANISM

Revision: November 2006 2006 Altima

Removal and Installation (VQ engine models) ECS00BT2

CAUTION:

When installing the holder spring pay attention to the direction of the bearing retainer.

REMOVAL

1. Remove manual transaxle from vehicle. Refer to MT-80, "Removal and Installation" .

2. Move withdrawal lever enough to remove release bearing from input shaft, then remove release bearing

from withdrawal lever.

3. Remove withdrawal lever snap spring.

4. Pull out withdrawal lever and remove dust cover.

INSPECTION AFTER REMOVAL

G Replace the release bearing if it is seized, damaged, faulty in

rotation direction, or has poor aligning function.

G Replace the withdrawal lever if its contact surface is worn abnor-

mally.

G Replace the dust seal if it is deformed or cracked.

1. Snap spring 2. Release bearing non-separate type 3. Holder spring

4. Withdrawal lever 5. Dust cover

WCIA0408E

SCL733

CLUTCH RELEASE MECHANISM

CL-17

D

E

F

G

H

I

J

K

L

M

A

B

CL

Revision: November 2006 2006 Altima

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

G Clean old grease and abrasive materials off the grease application areas.

G Apply grease to the specified points as shown.

G Apply approximately 1 mm (0.04 in) thick coat of clutch sleeve grease to withdrawal lever and holder

spring frictional surfaces.

G Apply a coat of clutch sleeve grease to the grooves on contact surfaces of the withdrawal lever ball pin

and inner surface of release bearing; make sure that grease is flush with grooves.

G Apply a thin coat of clutch sleeve grease to release bearing frictional surface. After grease application,

install release bearing. Wipe off excess grease forced out during bearing installation.

CAUTION:

G Before installing the manual transaxle to the vehicle, check that each sliding surface slides

smoothly by operating withdrawal lever.

G When assembling, make sure that both ends of the snap

spring touch the end face of the withdrawal lever.

G Be careful with the orientation of the installation.

SCL815

PCIB0837E

CL-18

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Revision: November 2006 2006 Altima

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL PFP:30100

Removal and Installation ECS0093P

CAUTION:

G Do not clean the clutch disc with solvent.

G When installing, do not get grease from the main drive shaft onto the clutch disc friction surface.

G If the flywheel needs to be removed, align the dowel pin with the smallest hole of the flywheel.

Refer to EM-76, "ASSEMBLY" in CYLINDER BLOCK (QR25DE), EM-241, "Dowel Pin Alignment" in

CYLINDER BLOCK (VQ35DE).

REMOVAL

1. Remove the manual transaxle from the vehicle. Refer to MT-17, "Removal and Installation" (5 M/T), MT-

80, "Removal and Installation" (6 M/T).

2. Evenly loosen the bolts holding the clutch cover, using power tool. Then remove the clutch cover and the

clutch disc.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not allow grease to contaminate clutch facing.

G Install the clutch cover and disc using Tool.

G Tighten the clutch cover bolts in two steps using the numerical

order as shown.

1. Flywheel 2. Clutch disc 3. Clutch cover

4. Washer 5. Main drive shaft

WCIA0147E

Tool number : ST20630000 (J-26366)

First step : 10 - 20 Nm (1.0 - 2.0 kg-m, 7 - 14 ft-lb)

Final step : 35 - 44 Nm (3.5 - 4.5 kg-m, 26 - 32 ft-lb)

WCIA0472E

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

CL-19

D

E

F

G

H

I

J

K

L

M

A

B

CL

Revision: November 2006 2006 Altima

Inspection and Adjustment after Removal ECS0093Q

CLUTCH DISC

G Check clutch disc for wear of facing.

G Check clutch disc for backlash of spline and runout of facing.

G Check clutch disc for burns, discoloration or oil or grease leak-

age. Replace if necessary.

CLUTCH COVER

G Check clutch cover installed on vehicle for unevenness of dia-

phragm spring toe height.

G If out of limit, adjust the height using Tool.

FLYWHEEL

G Check contact surface of flywheel for slight burns or discolora-

tion. Repair flywheel with emery paper.

G Check the flywheel runout. Refer to EM-95, "MOVEMENT

AMOUNT OF FLYWHEEL (M/T MODEL)" (QR25DE), EM-240,

"FLYWHEEL RUNOUT (M/T)" (VQ35DE).

Wear limit of facing sur-

face to rivet head

: 0.3 mm (0.012 in)

SCL229

Maximum backlash of spline

(at outer edge of disc)

: 1.0 mm (0.039 in)

Runout limit QR25DE: 1.0 mm (0.039 in)

VQ35DE: 0.7 mm (0.028 in)

Distance of runout check

point (from hub center)

QR25DE: 230 mm (9.06 in)

VQ35DE: 240 mm (9.45 in)

SCL221

Uneven limit : 1.0 mm (0.039 in)

Tool number : ST20050240 ( )

PCIB0276E

SCL349

CL-20

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: November 2006 2006 Altima

SERVICE DATA AND SPECIFICATIONS (SDS) PFP:00100

Clutch Control System ECS0093R

Clutch Master Cylinder ECS0093S

Unit: mm (in)

Clutch Operating Cylinder ECS0093T

Unit: mm (in)

Clutch Disc ECS0093U

Clutch Cover ECS0093V

Clutch Pedal ECS0093W

Unit: mm (in)

Type of clutch control Hydraulic

Inner diameter 15.87 (5/8)

Engine QR25DE VQ35DE

Inner diameter 19.05 (3/4) 17.46 (11/16)

Engine QR25DE VQ35DE

Model 240 250

Facing size (Outer dia. inner dia. thickness)

240 mm 160 mm 3.5 mm (9.45

in 6.30 in 0.138 in)

250 mm 170 mm 3.2 mm

(9.84 in 6.69 in 0.126 in)

Thickness of disc assembly

With load

8.1 mm (0.319 in)

with 5,884 N (600 kg, 1,323 lb)

7.4 mm (0.291 in)

with 8,340 N (850 kg, 1875 lb)

Wear limit of facing surface to rivet head 0.3 mm (0.012 in)

Facing runout limit 1.0 mm (0.039 in) 0.7 mm (0.028 in)

Distance of runout check point (from the hub center) 230 mm (9.06 in) 240 mm (9.45 in)

Maximum spline backlash (at outer edge of disc) 1.0 mm (0.039 in)

Engine QR25DE VQ35DE

Model 240 250

Set load 5,884 N (600 kg, 1,323 lb) 8,340 N (850 kg, 1,875 lb)

Set height 38 mm (1.50 in) 40.5 (1.59 in)

Uneven limit of diaphragm spring toe height 1.0 mm (0.039 in)

Clearance C between pedal stopper rubber and clutch interlock

switch threaded end while clutch pedal is fully depressed.

0.1 - 1.0 (0.004 - 0.039)

S-ar putea să vă placă și

- Brake System: SectionDocument36 paginiBrake System: Sectiontomallor101Încă nu există evaluări

- Nissan Xterra 2006 Service ManualDocument30 paginiNissan Xterra 2006 Service ManualAllen Pingleton100% (1)

- 2003 Nissan Altima 2.5 Serivce Manual PSDocument30 pagini2003 Nissan Altima 2.5 Serivce Manual PSAndy DellingerÎncă nu există evaluări

- Clutch: SectionDocument16 paginiClutch: Sectiontomallor101Încă nu există evaluări

- Clutch: SectionDocument22 paginiClutch: SectionMatea Virgil SorinÎncă nu există evaluări

- 2003 Nissan Altima 2.5 Serivce Manual MADocument38 pagini2003 Nissan Altima 2.5 Serivce Manual MAAndy DellingerÎncă nu există evaluări

- Brake Control System: SectionDocument30 paginiBrake Control System: Sectionpaleta tapiaÎncă nu există evaluări

- Nissan Navara Workshop Manual CLDocument22 paginiNissan Navara Workshop Manual CLbdsisira89% (9)

- Engine Cooling System GuideDocument27 paginiEngine Cooling System GuideMrihexÎncă nu există evaluări

- Starting & Charging System: SectionDocument32 paginiStarting & Charging System: SectionSonia GarciaÎncă nu există evaluări

- Accelerator Control System GuideDocument4 paginiAccelerator Control System Guidesamuray_ixÎncă nu există evaluări

- Power Steering System: SectionDocument26 paginiPower Steering System: SectionSilvio ServinÎncă nu există evaluări

- Section: I BodyDocument28 paginiSection: I BodyNeil MundowaÎncă nu există evaluări

- Sistema Refrigeración Motor 350zDocument34 paginiSistema Refrigeración Motor 350zERIC JHEYSON URICAY LIZARRAGAÎncă nu există evaluări

- Accelerator Control System: SectionDocument4 paginiAccelerator Control System: Sectiontomallor101Încă nu există evaluări

- 2006 Nissan Almera Classic B10 Service Repair Manual PDFDocument10 pagini2006 Nissan Almera Classic B10 Service Repair Manual PDFfjskedmmsme0% (2)

- Clutch: SectionDocument21 paginiClutch: Sectionpenk ypÎncă nu există evaluări

- Section: I BodyDocument28 paginiSection: I BodyLino Bello RezamanoÎncă nu există evaluări

- 2007 Nissan Frontier 74Document30 pagini2007 Nissan Frontier 74Mardelis cisnerosÎncă nu există evaluări

- WW PDFDocument36 paginiWW PDFRony CentenoÎncă nu există evaluări

- CL PDFDocument21 paginiCL PDFSebastián PeñaÎncă nu există evaluări

- Suspensión TractorDocument40 paginiSuspensión Tractor65truck03Încă nu există evaluări

- Power Steering System: SectionDocument28 paginiPower Steering System: SectionLino Bello RezamanoÎncă nu există evaluări

- Low Tire Pressure Warning System Troubleshooting GuideDocument38 paginiLow Tire Pressure Warning System Troubleshooting GuideLino Bello RezamanoÎncă nu există evaluări

- Brake System: SectionDocument34 paginiBrake System: SectiontsudsingÎncă nu există evaluări

- Manual Compactador Ingersoll RandDocument176 paginiManual Compactador Ingersoll Randricardorojasweb91% (33)

- Heater & Air Conditioning System: SectionDocument38 paginiHeater & Air Conditioning System: SectionNestor RosalesÎncă nu există evaluări

- 2005 Nissan Sentra 50457Document40 pagini2005 Nissan Sentra 50457Juan CarlosÎncă nu există evaluări

- Signa EXCITE & EXCITE PLUS Field Replaceable Units (FRU)Document42 paginiSigna EXCITE & EXCITE PLUS Field Replaceable Units (FRU)Marckus BrodyÎncă nu există evaluări

- Bomba HidraulicoDocument38 paginiBomba HidraulicomayestrikÎncă nu există evaluări

- Section: I BodyDocument28 paginiSection: I BodyJBÎncă nu există evaluări

- Clutch: SectionDocument19 paginiClutch: SectionEduardo ColinÎncă nu există evaluări

- Power Steering System: SectionDocument36 paginiPower Steering System: SectionJBÎncă nu există evaluări

- BRCDocument70 paginiBRCtomallor101Încă nu există evaluări

- Seat Belt Control System: SectionDocument27 paginiSeat Belt Control System: SectionАндрей НадточийÎncă nu există evaluări

- Nissan-X-Trail 2005Document36 paginiNissan-X-Trail 2005ryanto wawan noviarnoÎncă nu există evaluări

- MAINTENANCE MANUAL OVERVIEWDocument38 paginiMAINTENANCE MANUAL OVERVIEWtomallor101Încă nu există evaluări

- Brake System: SectionDocument42 paginiBrake System: Sectiontomallor101Încă nu există evaluări

- Maintenance: SectionDocument38 paginiMaintenance: Sectionfearimus1Încă nu există evaluări

- Manual Air Conditioner: SectionDocument76 paginiManual Air Conditioner: SectionEduardo ColinÎncă nu există evaluări

- CL PDFDocument22 paginiCL PDFhuberÎncă nu există evaluări

- 31TH 2001Document47 pagini31TH 2001Michael FodorÎncă nu există evaluări

- Ps 1Document28 paginiPs 1Hawkar SuleimanÎncă nu există evaluări

- Power Steering System: SectionDocument38 paginiPower Steering System: Sectiondavid94navarroÎncă nu există evaluări

- Sistema de Control de Refrigeración de Motor Nissan 350Z CoupeDocument26 paginiSistema de Control de Refrigeración de Motor Nissan 350Z CoupeHendrick CepedaÎncă nu există evaluări

- Cooling SystemDocument32 paginiCooling Systemshortbus22Încă nu există evaluări

- 2003 Nissan Altima 2.5 Serivce Manual GWDocument62 pagini2003 Nissan Altima 2.5 Serivce Manual GWAndy Dellinger100% (1)

- Engine Cooling System: SectionDocument32 paginiEngine Cooling System: SectionskpppÎncă nu există evaluări

- Engine Cooling System: SectionDocument22 paginiEngine Cooling System: Sectionfrank1220uÎncă nu există evaluări

- 2008 Nissan Teana J32 Service Manual-AccDocument4 pagini2008 Nissan Teana J32 Service Manual-AccMrihexÎncă nu există evaluări

- Fuj I200 Adj + ReplDocument37 paginiFuj I200 Adj + ReplBrian CarrollÎncă nu există evaluări

- Engine Cooling System: SectionDocument29 paginiEngine Cooling System: SectionDozer KamilÎncă nu există evaluări

- WT Nissan Titán 2006Document38 paginiWT Nissan Titán 2006Marco BrupenÎncă nu există evaluări

- JAIC automatic air conditioner troubleshootingDocument196 paginiJAIC automatic air conditioner troubleshootingFelipe Farfan100% (1)

- GW PDFDocument40 paginiGW PDFROSILENE PASSOSÎncă nu există evaluări

- Driver Information System: SectionDocument56 paginiDriver Information System: SectionminaryÎncă nu există evaluări

- Ventilation System: SectionDocument18 paginiVentilation System: SectionRuhu royÎncă nu există evaluări

- Parts List Service: Container Refrigeration Unit Models 69NT20 - 254 - 5 Thru - 56Document32 paginiParts List Service: Container Refrigeration Unit Models 69NT20 - 254 - 5 Thru - 56Ilyas Rangga RamadhanÎncă nu există evaluări

- Rules of the Trade - NassarDocument4 paginiRules of the Trade - Nassartomallor101Încă nu există evaluări

- 30 Rules Master Swing TraderDocument2 pagini30 Rules Master Swing Tradertomallor101100% (2)

- Trading Barefoot - Herron, RyanDocument2 paginiTrading Barefoot - Herron, Ryantomallor101Încă nu există evaluări

- How To Choose Winning Stocks - PrasadDocument2 paginiHow To Choose Winning Stocks - Prasadtomallor101Încă nu există evaluări

- Fibonacci in The Modern Age - UnknownDocument3 paginiFibonacci in The Modern Age - Unknowntomallor101Încă nu există evaluări

- FFDDocument34 paginiFFDtomallor101Încă nu există evaluări

- Financial Behavior - Baker, KentDocument1 paginăFinancial Behavior - Baker, Kenttomallor101Încă nu există evaluări

- FsuDocument22 paginiFsutomallor101Încă nu există evaluări

- Gann Simplified - Droke, ClifDocument4 paginiGann Simplified - Droke, Cliftomallor101Încă nu există evaluări

- DiDocument68 paginiDitomallor101Încă nu există evaluări

- Developing An Annual Trading PL - Carter, JohnDocument2 paginiDeveloping An Annual Trading PL - Carter, Johntomallor101Încă nu există evaluări

- FFDDocument34 paginiFFDtomallor101Încă nu există evaluări

- DiDocument68 paginiDitomallor101Încă nu există evaluări

- EcDocument1.306 paginiEcOlivier DuvalÎncă nu există evaluări

- BRCDocument70 paginiBRCtomallor101Încă nu există evaluări

- EcDocument1.306 paginiEcOlivier DuvalÎncă nu există evaluări

- Front Axle: SectionDocument14 paginiFront Axle: Sectiontomallor101Încă nu există evaluări

- Brake System: SectionDocument34 paginiBrake System: Sectiontomallor101Încă nu există evaluări

- Brake System: SectionDocument34 paginiBrake System: Sectiontomallor101Încă nu există evaluări

- AvDocument158 paginiAvtomallor101Încă nu există evaluări

- CoDocument52 paginiCotomallor101Încă nu există evaluări

- Brake Control System: SectionDocument94 paginiBrake Control System: Sectiontomallor101Încă nu există evaluări

- EXDocument13 paginiEXtomallor101Încă nu există evaluări

- ExtDocument47 paginiExttomallor101Încă nu există evaluări

- Brake System: SectionDocument42 paginiBrake System: Sectiontomallor101Încă nu există evaluări

- Car LCDocument16 paginiCar LCtomallor101Încă nu există evaluări

- Car MaDocument23 paginiCar Matomallor101Încă nu există evaluări

- Car IdxDocument9 paginiCar Idxtomallor101Încă nu există evaluări

- Car MTDocument45 paginiCar MTtomallor101Încă nu există evaluări

- Catalogo 777G PDFDocument737 paginiCatalogo 777G PDFGildasio GilÎncă nu există evaluări

- PDF CrackDocument8 paginiPDF CrackFlor MaríaÎncă nu există evaluări

- Parts Manual: Model T425A Engine BrakesDocument4 paginiParts Manual: Model T425A Engine BrakesFilipposÎncă nu există evaluări

- 2W PricelistDocument369 pagini2W PricelistMihir MehraÎncă nu există evaluări

- (x4) Problem 5 - 9 Multi Stage CompressionDocument15 pagini(x4) Problem 5 - 9 Multi Stage CompressionLester Alfred M. OlasimanÎncă nu există evaluări

- 20CMHDocument41 pagini20CMHMuhammad Safri Adi ZamilÎncă nu există evaluări

- Sinocmp Hydraulic Pump Parts Com BuscaDocument83 paginiSinocmp Hydraulic Pump Parts Com BuscaMARCO CHELIÎncă nu există evaluări

- Hydraulic and Pneumatic ActuatorsDocument17 paginiHydraulic and Pneumatic ActuatorsKAMALJEET SINGHÎncă nu există evaluări

- Dynamic Force Analysis 2Document41 paginiDynamic Force Analysis 2Prem sharmaÎncă nu există evaluări

- Litostroj Power Group offers spherical valves, butterfly valves and energy dissipating valvesDocument2 paginiLitostroj Power Group offers spherical valves, butterfly valves and energy dissipating valvesZohaibÎncă nu există evaluări

- 04-07 Delta TuningDocument3 pagini04-07 Delta Tuningr100% (1)

- Water Level Controller ManualDocument2 paginiWater Level Controller Manualprabhyodh singhÎncă nu există evaluări

- SERIES 4300: Equal Suction & Discharge Vertical In-Line Split CouplerDocument29 paginiSERIES 4300: Equal Suction & Discharge Vertical In-Line Split Couplerspeedy712Încă nu există evaluări

- Etl 89400691 000700 Innopro en 01Document137 paginiEtl 89400691 000700 Innopro en 01Eren akarsuÎncă nu există evaluări

- LK-1900B P PDFDocument108 paginiLK-1900B P PDFAchmad RezaÎncă nu există evaluări

- Alternating Current GeneratorsDocument28 paginiAlternating Current GeneratorsLouise UmaliÎncă nu există evaluări

- 6-Speed Manual Gearbox 02QDocument246 pagini6-Speed Manual Gearbox 02QPaloma Smith100% (2)

- 12LD 435-2 12LD 435-2/B1 12LD 475-2 12LD 475-2 EPA: Work Shop Manual 12LD Series Engines, Cod. 1-5302-460 - 3 EdDocument50 pagini12LD 435-2 12LD 435-2/B1 12LD 475-2 12LD 475-2 EPA: Work Shop Manual 12LD Series Engines, Cod. 1-5302-460 - 3 EdRolandas PetkusÎncă nu există evaluări

- DENSO Toyota price list spare partsDocument18 paginiDENSO Toyota price list spare partsSam RyanÎncă nu există evaluări

- Listagem de Pecas DynapacDocument2.838 paginiListagem de Pecas DynapacMARCO CHELIÎncă nu există evaluări

- Generator CourseDocument61 paginiGenerator Courseprasad5034Încă nu există evaluări

- Manual de Servico Brastemp bnq11 Wfw94hexDocument86 paginiManual de Servico Brastemp bnq11 Wfw94hexDimasÎncă nu există evaluări

- Pitch Regulated Wind Turbine With Optitip and OptispeedDocument6 paginiPitch Regulated Wind Turbine With Optitip and OptispeedBala Murugan100% (2)

- Ic-M700pro SM 5Document202 paginiIc-M700pro SM 5backup mailÎncă nu există evaluări

- Manual Centrifuga de CanastaDocument26 paginiManual Centrifuga de CanastaSalocinÎncă nu există evaluări

- 0332 v11 T6Document38 pagini0332 v11 T6sumitÎncă nu există evaluări

- Propulsion: EASA Part-66 Cat-B2 Module-14 Shahzad KhalilDocument56 paginiPropulsion: EASA Part-66 Cat-B2 Module-14 Shahzad KhalilSK91% (11)

- Geared Machines W125 W125R W140: Inventio AgDocument12 paginiGeared Machines W125 W125R W140: Inventio AgRodrigo Rodrigues PaixãoÎncă nu există evaluări

- Don'T Forget The Cat E-Trim Codes and Files: Avoid Costly RepairsDocument2 paginiDon'T Forget The Cat E-Trim Codes and Files: Avoid Costly Repairsguayanecitro100% (1)

- MBW126 - Club Buyers Guide 2Document7 paginiMBW126 - Club Buyers Guide 2Marko MataijaÎncă nu există evaluări