Documente Academic

Documente Profesional

Documente Cultură

Chopra 03 Chapter

Încărcat de

Rashadafaneh0 evaluări0% au considerat acest document util (0 voturi)

88 vizualizări56 paginiChopra 03 chapter

Titlu original

Chopra 03 chapter

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentChopra 03 chapter

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

88 vizualizări56 paginiChopra 03 Chapter

Încărcat de

RashadafanehChopra 03 chapter

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 56

Supply/Demand Chain

Introduction, Overview and Strategy

These slides address chapters 1 through 3 of the

textbook, with some information already found in the

earlier Sustainable Demand Chain Management: an

Introduction de-emphasized

While the slide decks are based on the textbook, they

have been customized for this class

Additional materials are often included

Professorial commentary that expresses a different

viewpoint than in the text will be noted in a different color

1-1

1-2

Overview of Course

1. Chapters 1-3 + additional slide deck: Introduction, Overview

and Strategy

2. Chapters 4-6: Network Planning and Distribution

3. Chapters 8-9: Aggregate Planning

4. Chapters 10-11, 13+ additional slide deck: Inventory and

Transportation

5. Chapter 17: Supply Chain Coordination

1-3

Who Needs to Know About this

Topic?

Anyone involved in a manufacturing or service

industry where capacities and raw materials cannot be

obtained or expanded without a time or cost penalty

Executives and Entrepreneurs must understand the strategic

importance of the Supply Chain

Managers, Consultants and Software Designers need to be

able to analyze, design, and implement Supply Chain

solutions

1-4

Supply Chain Management is not

Learned just Through a Textbook

The best solution to a Supply Chain problem may not win

An elegant, mathematically complex LP presented such that only Ph.D.s

understand may not be the best practical solution to the problem at hand.

And even if it is, it is not the one that will be awarded the contract!

Supply Chain Practitioners need soft skills

Work effectively with clients and team members, including being

responsive to questions and requests

You must package and sell your proposed solution

Supply Chain Practitioners need hard skills

Lots of data, need to understand processes and interactions with IT

Work usually involves creating or adapting large-scale computer models

The class is designed for you to practice both hard and soft skills

1-5

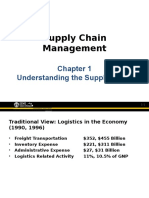

Traditional View: Logistics in the

US Economy (2006, 2007)

Freight Transportation $809, $856 Billion

Inventory Expense $446, $487 Billion

Administrative Expense $50, $54 Billion

Total Logistics Costs $1.31, $1.4 Trillion

Logistics Related Activity 10%, 10.1% of GNP

About 21% of total costs for a manufacturing firm

Logistical costs percentages are higher in the EU

But supply chain is more than logistics.

Source: 18

th

and 19

th

Annual State of Logistics Report Logistics Magazine

1-6

Supply Chain Management:

Mishaps and Opportunities

Estimated that the grocery industry could save $30 billion (10%

of operating cost) by using effective logistics and supply chain

strategies

A typical box of cereal spends 104 days from factory to sale

A typical car spends 15 days from factory to dealership

Compaq estimates it lost $.5 billion to $1 billion in sales in

1995 because laptops were not available when and where

needed

When the 1 gig processor was introduced by AMD, the price of

its previous version, the 800 megabyte processor, dropped by

30%

What happened to firms who had stockpiled those?

1-7

Chapter 1 Outline

What is a Supply Chain? (We covered this earlier)

Decision Phases in a Supply Chain

Process View of a Supply Chain

The Importance of Supply Chain Flows

A Brief Review of Material to Date

Typical stages: (from a demand chain perspective)

customers<retailers<distributors<manufacturers<suppliers

All stages may not be present- Can you think of some well

known companies that are missing a stage?

What stage is always present?

The obvious flow is the movement of products from

suppliers to the customer, but also includes movement

of information, funds, and products in both directions

Reverse logistics is an important facet of both sustainability

and CRM initiatives, will be discussed later.

1-8

1-9

The Objective of a Supply Chain

Sources of supply chain revenue: the customer

Sources of supply chain cost: flows of information,

products, or funds between stages of the supply chain

Supply chain management is .

Book: the management of flows between and among

supply chain stages to maximize total supply chain

profitability

Professor commentary: is the coordination of business

functions within an organization and its channel partners in

order to provide goods and services to fulfill customer

demand responsively, efficiently and sustainably

1-10

Dell Computer: Illustration of

Supply Chain Success

Example: Dell receives $1000 from a customer for a

computer (revenue)

Supply chain incurs costs (information, storage,

transportation, components, assembly, etc.)

Difference between $1000 and the sum of all of these

costs is the supply chain profit

Time value of money often plays a role

Supply chain profitability is the total profit to be shared

across all stages of the supply chain

Supply chain success should be measured by total supply

chain profitability, not profits at an individual stage

In practice this may be difficult when stages are separate firms

1-11

Decision Phases of a Supply Chain

1. Supply chain strategy (also called chain design)

2. Supply chain planning

3. Supply chain operation

1-12

Supply Chain Strategy (or Design)

Decisions about the structure of the supply chain and what

processes each stage will perform

Strategic supply chain decisions

Locations and capacities of facilities

Products to be made or stored at various locations

Modes of transportation

Information systems

Supply chain design must support strategic objectives

Supply chain design decisions are long-term and

expensive to reverse must take into account market

uncertainty

Decisions often analyzed first through models and simulations

1-13

Supply Chain Planning

Definition of a set of policies that govern short-term

operations - typically a quarter to a couple years

Fixed by the supply configuration from previous phase

Typically starts with a forecast of demand in the coming year

Planning decisions:

Which markets will be supplied from which locations

Planned buildup of inventories, inventory policies

Subcontracting, backup locations

Timing and size of market promotions

Must consider demand uncertainty, exchange rates,

competition over the time horizon

1-14

Supply Chain Operations

Time horizon is weekly or daily

Decisions regarding individual customer orders

Supply chain configuration is fixed and operating

policies are determined

Goal is to implement the operating policies as

effectively as possible

Allocate orders to inventory or production, set order

due dates, generate pick lists at a warehouse, allocate

an order to a particular shipment, set delivery

schedules, place replenishment orders

Much less uncertainty (due to short time horizon)

1-15

Process View of a Supply Chain

Cycle view: processes in a supply chain are divided

into a series of cycles, each performed at the

interfaces between two successive supply chain stages

We will not be emphasizing the cycle view in class, as not

all chains have all stages present

Push/pull view: processes in a supply chain are

divided into two categories depending on whether

they are executed in response to a customer order

(pull) or in anticipation of a customer order (push)

1-16

Push/Pull View of Supply Chains

Actions initiated from Suppliers Retail/Customer

Initiated Action

The barrier between push

And pull may vary for different

companies and industries

PUSH PROCESSES PULL PROCESSES

1-17

Push/Pull View of

Supply Chain Processes

Supply chain processes fall into one of two categories

depending on the timing of their execution relative to

customer demand

Pull: execution is initiated in response to a customer order

(reactive)

Push: execution is initiated in anticipation of customer

orders (speculative)

Push/pull boundary separates push processes from

pull processes

The relative proportion of push and pull processes can have

an impact on supply chain performance

2-18

Outline: Chapter 2 - Chain Performance:

Achieving Strategic Fit and Scope

Competitive and supply chain strategies

Achieving strategic fit

Expanding strategic scope

2-19

Competitive and Supply

Chain Strategies

Competitive strategy: defines the set of customer needs a firm

seeks to satisfy through its products and services

Product development strategy: specifies the portfolio of new

products that the company will try to develop

Marketing and sales strategy: specifies how the market will be

segmented and product positioned, priced, and promoted

Supply chain strategy:

determines the nature of material procurement, transportation of

materials, manufacture of product or creation of service, distribution of

product

Consistency and support between supply chain strategy, competitive

strategy, and other functional strategies is important

2-20

The Value Chain: Linking Supply

Chain and Business Strategy

New

Product

Development

Marketing

and

Sales

Operations Distribution Service

Overall Competitive Strategy

Product Dev.

Strategy

Marketing

Strategy

Supply Chain Strategy

2-21

Achieving Strategic Fit

Strategic fit:

Consistency between customer priorities of competitive

strategy and supply chain capabilities specified by the

supply chain strategy

Competitive and supply chain strategies have the same

goals

A company may fail because of a lack of strategic fit

or because its processes and resources do not provide

the capabilities to execute the desired strategy

Example of strategic fit Dells varied sales channels

2-22

How is Strategic Fit Achieved?

Step 1: Understanding the customer and the supply

chain uncertainty

Step 2: Understanding the supply chain capabilities

Step 3: Achieving strategic fit

2-23

Step 1: Understanding the Customer

and Supply Chain Uncertainty

Identify the needs of the customer segment being served

Quantity of product needed in each lot

Response time customers will tolerate

Variety of products needed

Service level required

Price of the product

Desired rate of innovation in the product

Demand uncertainty: How much does customer demand for a

product vary?

Are there particular needs related to Sustainability?

2-24

Step 1: Understanding the Customer

and Supply Chain Uncertainty

Key Point: Implied Demand Uncertainty is more than

just Demand Uncertainty

Demand uncertainty: uncertainty of customer demand for a

product

I mplied demand uncertainty: resulting uncertainty for the

supply chain given the portion of the demand the supply chain

must handle and the attributes the customer desires from the

product and the experience of purchasing it:

For example: if customers require very fast service or if they are many

varieties of the product (and customers are picky about what they get)

implied demand uncertainty is higher.

2-25

Impact of Customer Needs on Implied

Demand Uncertainty

Customer Need Causes implied demand

uncertainty to increase because

Range of quantity required increases Wider range of quantity required

implies greater variance in demand

Lead time required to decrease Less time to react to orders

Variety of products required increases Demand per product becomes more

disaggregated

Number of channels through which

product may be acquired increases

Total customer demand is now

disaggregated over more channels

Rate of innovation must increase New products tend to have more

uncertain demand

Required service level must increase Firm now has to handle unusual

surges in demand

Supply Uncertainty

Now turn away from demand briefly to look at other side of the

coin: Supply

Supply Uncertainty variability associated with getting the

right amount of the product at the right time

Will increase with.

Unpredictable/low yields problematic issue from high tech

(semiconductor) to low tech- traditional agriculture)

Limited/inflexible supply capacity

Evolving production process

First step to achieving strategic fit is to understand customers

and their inherent implied demand uncertainty, and also

consider effects from Supply Uncertainty, mapping both onto

the implied uncertainty spectrum

1-26

2-27

Implied Uncertainty Spectrum

Predictable

supply and

demand

Salt at a

supermarket

A new

communication

device

Highly uncertain

supply and demand

Figure 2.2: The Implied Uncertainty (Demand and Supply)

Spectrum

Predictable supply and uncertain

demand or uncertain supply and

predictable demand or somewhat

uncertain supply and demand

An existing

automobile

model

There are exceptions- for example, with salt, think of Fleur de Sel or pink Himalayan salt!

Many firms have attempted to move their products upstream, eg. Fresh Choice: bagged salads

2-28

Step 2: Understanding the

Supply Chain Capabilities

How does the firm best meet demand?

One dimension describing the chain is supply chain responsiveness

respond to wide ranges of quantities demanded

meet short lead times

handle a large variety of products

build highly innovative products

meet a very high service level

There is a cost to achieving responsiveness

Supply chain efficiency: cost of making and delivering the product

to the customer

Increasing responsiveness usually results in higher costs, lowing efficiency

Second step to achieving strategic fit is to map the supply chain on

the responsiveness spectrum

2-29

High Low

Low

High

Responsiveness

Cost

Understanding the Supply Chain: Cost-

Responsiveness Efficient Frontier

2-30

Responsiveness Spectrum

I ntegrated

steel mill-

Production

scheduled

months in

advance

7-11 J apan,

Changes

merchandise

Mix by location

and time of day

Highly

efficient

Highly

responsive

Somewhat

efficient

Somewhat

responsive

Hanes

Apparel,

Traditional

Make-to-stock

Manufacturer

With lead-times

of several weeks

Most

automotive

Production, large

Variety of products

in a few weeks,

Some customization

So now we have two spectrums (lines)- what do you think is next?

2-31

Step 3: Achieving Strategic Fit

Third Step is to ensure that what the supply chain does well is

consistent with target customers needs

All functions in the value chain must support the competitive

strategy to achieve strategic fit

Barilla Pasta and Apple Computer are examples of companies

that are in the Zone

Do you think their supply chain strategies are similar?

Key points

There is no one right supply chain for all companies

there is a right supply chain strategy for a given competitive strategy

In balancing efficiency and responsiveness, it is still critical to

remember sustainability

2-32

Achieving Strategic Fit Shown on the

Uncertainty/Responsiveness Map

Implied

uncertainty

spectrum

Responsive

supply chain

Efficient

supply chain

More

Certain

Highly

Uncertain

Responsiveness

spectrum

2-33

Comparison of Efficient and

Responsive Supply Chains

Efficient Responsive

Primary goal Lowest cost Quick response

Product design strategy Min product cost Modularity to allow

postponement

Pricing strategy Lower margins Higher margins

Mfg strategy High utilization Capacity flexibility

Inventory strategy Minimize inventory Buffer inventory

Lead time strategy Reduce but not at expense

of greater cost

Aggressively reduce even if

costs are significant

Supplier selection strategy Cost and, typically lower

quality

Speed, flexibility, quality

Transportation strategy Greater reliance on low cost

modes

Greater reliance on

responsive (fast) modes

2-34

Other Issues Affecting Strategic Fit

1. Multiple products and customer segments

2. Product life cycle

3. Competitive changes over time

4. Sustainability

2-35

Multiple Products and

Customer Segments

Firms sell different products to different customer

segments (with different implied demand uncertainty)

The supply chain has to be able to balance efficiency

and responsiveness given its portfolio of products and

customer segments

Two approaches:

1. Different supply chains for different products/customers

or

2. Tailor supply chain to best meet the needs of each products

demand. Example: W.W. Grainger, MRO

2-36

Product Life Cycle

The demand characteristics of a product and the needs

of a customer segment change as a product goes

through its life cycle

Examples: pharmaceutical firms, Intel

As the product goes through the life cycle, the supply

chain changes from one emphasizing responsiveness to

one emphasizing efficiency

Supply chain strategy must evolve throughout life cycle

Early: uncertain demand, high margins (time is important),

product availability is most important, cost is secondary

Late: predictable demand, lower margins, price is important

2-37

Competitive Changes Over Time

Competitive pressures can change over time

More competitors may result in an increased emphasis

on variety at a reasonable price

The Internet makes it easier to offer a wide variety of

products

The supply chain must change to meet these changing

competitive conditions

Example Dell used to sell PCs and laptops only via internet,

but now also sells at Wal-Mart

Sustainability

Consider both Ethical as well as Environmental issues

Sustainability policies may be driven by either

regulation or risk factors

WEEE- EU regulation forced electronics providers to

rethink SCs

Supplier risk

Demand risk, consumer expectations

May be complex relationships between

responsiveness, efficiency and sustainability issues

Sometimes, but not always, involving tradeoffs

2-38

2-39

Expanding Strategic Scope

Scope of strategic fit : The functions and stages within a supply

chain that devise an integrated strategy with a shared objective

One extreme: each function at each stage develops its own strategy

Other extreme: all functions in all stages devise a strategy jointly

From least to most evolved/expanded.

1. Intracompany intraoperation scope silos!

2. Intracompany intrafunctional scope

3. Intracompany interfunctional scope

4. Intercompany interfunctional scope - CPFR

5. Agile Intercompany, interfunctional scope - 3+ companies

Obstacles to Achieving Strategic Fit

In short: todays business environment is more

challenging for companies

1. Increasing variety of products

2. Shorter product life cycles (technology development, trend)

3. Increasingly picky customers

4. Fragmentation of chain ownership

5. Globalization, on supply-side and also the demand side*

6. Rapidly changing business environment

7. Difficulties with executing new strategies

8. Especially for 2007-2011 timeframe- economic cycle

2-40

*see the P&G Swiffer in Italy story

3-41

Outline: Chapter 3- Supply Chain

Drivers and Metrics

Drivers of supply chain performance

A framework for structuring drivers

Detailed view for each driver and appropriate metrics

3-42

Drivers of Supply Chain Performance

1. Facilities

places where inventory is stored, assembled, or fabricated

production sites and storage sites

2. Inventory

raw materials, WIP, finished goods within a supply chain

inventory policies

3. Transportation

moving inventory from point to point in a supply chain

combinations of transportation modes and routes

4. Information

data & analysis regarding inventory, transportation, facilities throughout the chain

potentially the biggest driver of chain performance

5. Sourcing

functions a firm performs and functions that are outsourced

6. Pricing

Price associated with goods and services provided by a firm to the supply chain

3-43

A Framework for

Structuring Drivers

Competitive Strategy

Supply Chain

Strategy

Efficiency

Responsiveness

Facilities Inventory Transportation

Information

Supply chain structure

Cross Functional Drivers

Sourcing Pricing

Logistical Drivers

** also includes Sustainability

**

3-44

Facilities

Role in the supply chain- the where

manufacturing or storage (warehouses)

Role in the competitive strategy

economies of scale (efficiency priority)

larger number of smaller facilities (responsiveness priority)

Components of facilities decisions

Location

centralization (efficiency) vs. decentralization (responsiveness)

other factors to consider (e.g., proximity to customers)

Capacity (flexibility versus efficiency)

Manufacturing methodology (product focused versus process focused)

Warehousing methodology (SKU storage, job lot storage, cross-docking)

Overall trade-off: Responsiveness versus efficiency

3-45

Inventory

Role in the supply chain

Exists because of a mismatch between supply and demand

Source of cost and influence on responsiveness

Given Littles Law, if throughput=demand, then inventory synonymous

with material flow time

Role in the competitive strategy

If responsiveness is a strategic competitive priority, a firm can locate

larger amounts of inventory closer to customers

If cost is more important, inventory can be reduced (or consolidated

further away) to make the firm more efficient

Example: High-service department store: Nordstroms

We will spend 2 chapters in this class on inventory policies!

3-46

Components of Inventory

Decisions

Cycle inventory

Average amount of inventory used to satisfy demand between shipments

Depends on lot size

Safety inventory

inventory held in case demand exceeds expectations

costs of carrying too much inventory versus cost of losing sales

Seasonal inventory

inventory built up to counter predictable variability in demand

cost of carrying additional inventory versus cost of flexible production

Overall trade-off: Responsiveness versus efficiency

more inventory: greater responsiveness but greater cost

less inventory: lower cost but lower responsiveness

3-47

Transportation

Role in the supply chain

Moves the product between stages in the supply chain

Impact on responsiveness and efficiency

Faster transportation allows greater responsiveness but lower efficiency

Also affects inventory and facilities

Role in the competitive strategy

If responsiveness is a strategic competitive priority, then faster

transportation modes can provide greater responsiveness to customers

who are willing to pay for it

Can also use slower transportation modes for customers whose priority

is price (cost)

Can also consider both inventory and transportation to find the right

balance

3-48

Components of

Transportation Decisions

Mode of transportation:

air, truck, rail, ship, pipeline, electronic transportation

Utilization and backhaul rates should be considered

vary in cost, speed, size of shipment, flexibility, carbon footprint

Route and network selection

route: path along which a product is shipped

network: collection of locations and routes

In-house or outsource (see driver #5)

Overall trade-off: Responsiveness versus efficiency

3-49

Information

Role in the supply chain

The connection between the various stages in the supply chain allows

coordination between stages

Crucial to daily operation of each stage in a supply chain e.g.,

production scheduling, inventory levels

Role in the competitive strategy

Allows supply chain to become more efficient and more responsive at

the same time (reduces the need for a trade-off)

Need to ask: what information is most valuable?

3-50

Components of Information

Decisions

Components of information decisions

Push (MRP) versus pull (need demand information across

all stages)

Coordination and information sharing

Forecasting and aggregate planning

Enabling technologies include the following:

EDI

Internet

ERP systems

Supply Chain Management software

RFID

Still some tradeoff exists: Responsiveness versus efficiency

3-51

Sourcing

Role in the supply chain

Set of business processes required to purchase goods and services in a chain

Examples: contract manufacturers, Transportation/Inventory services- 3PL

Supplier selection, single vs. multiple suppliers, contract negotiation

Role in the competitive strategy

Sourcing decisions are crucial because they affect the level of efficiency and

responsiveness in a supply chain

In-house vs. outsource decisions- improving efficiency and responsiveness

Example: Expedited delivery usually requires Parcel Delivery

Components of sourcing decisions

Perform a task in-house versus outsource?

Supplier evaluation and selection

Procurement process

Overall trade-off: balance profitability (Risk? Ethical issues?)

3-52

Pricing

Role in the supply chain

Pricing determines the amount to charge customers

Pricing strategies can be used to match demand and supply

Role in the competitive strategy

Firms can utilize optimal pricing strategies to improve efficiency and

responsiveness

Low price and low product availability; vary prices by response times

Components of pricing decisions

Pricing and economies of scale

Everyday low pricing versus high-low pricing

Fixed price versus menu pricing

Overall trade-off: Increase the firm profits

We will explore effects from some of these pricing decisions later

Metrics

The performance for these supply chain drivers can be quantified

with metrics. Heres some examples we will work with during

this term:

1. Facilities: Capacity, Utilization rate, per unit production cost

2. Inventory: Days-OnHand (Dollars-OnHand), Safety Stock, Stockout %

3. Transportation: Fraction transported by mode, inbound/outbound

shipment size, inbound/outbound transportation cost per unit

4. Information: Forecast error, ratio of demand variability to order variability

5. Sourcing: supplier lead time, average purchase price, supplier reliability

6. Pricing: profit margin, fixed cost per order, variable cost per unit

Certain metrics will be more important than others for different

firms with different supply chain strategies

Information Overload: SCOR has over 150+ KPIs

3-53

1-54

Summary of Learning Objectives-

Chapter 1

What are supply chain stages?

What are the three flows within a supply chain?

What are the three key supply chain decision phases

and what is the significance of each?

What is the push/pull view of a supply chain?

What is the goal of a supply chain and what is the

impact of supply chain decisions on the success of the

firm?

2-55

Summary of Learning Objectives

for Chapter 2

Why is achieving strategic fit critical to a companys

overall success?

How does implied demand uncertainty differ from

demand uncertainty?

How does a company achieve strategic fit between its

supply chain strategy and its competitive strategy?

What are some complications to achieving this fit?

3-56

Summary of Learning Objectives

for Chapter 3

What are the major drivers of supply chain

performance?

What is the role of each driver in creating strategic fit

between supply chain strategy and competitive strategy

(or between implied demand uncertainty and supply

chain responsiveness)?

What are some relevant metrics?

In the remainder of the course, we will learn how to make

decisions with respect to these drivers in order to achieve

strategic fit and surmount these obstacles

S-ar putea să vă placă și

- Logistics in Manufacturing, Supply Chain, and DistributionDe la EverandLogistics in Manufacturing, Supply Chain, and DistributionÎncă nu există evaluări

- In The Name of Allah Almighty The Most Merciful and The Most BeneficentDocument85 paginiIn The Name of Allah Almighty The Most Merciful and The Most Beneficentmuwadit AhmedÎncă nu există evaluări

- ASCM NotesDocument4 paginiASCM NotesJanmejai BhargavaÎncă nu există evaluări

- Supply Chain ManagementDocument11 paginiSupply Chain ManagementMd NematullahÎncă nu există evaluări

- Supply ChainDocument35 paginiSupply ChainRayhan Atunu0% (1)

- Gestión de La Cadena GlobalDocument5 paginiGestión de La Cadena Globalcarolina burgos herreraÎncă nu există evaluări

- Achieving Strategic Fit and ScopeDocument10 paginiAchieving Strategic Fit and ScopeLaila RashedÎncă nu există evaluări

- Supply Chain Management - Chopra/MeindlDocument8 paginiSupply Chain Management - Chopra/Meindlchin_a40% (5)

- Management II notesDocument48 paginiManagement II notesdgvcxbqvk2Încă nu există evaluări

- Indroduction To Supply Chain 1Document38 paginiIndroduction To Supply Chain 1Tansen John100% (2)

- SCM solutionDocument10 paginiSCM solutionArafat SipuÎncă nu există evaluări

- SCM 1Document25 paginiSCM 1Gaurav YadavÎncă nu există evaluări

- Chopra Scm5 Ch01Document27 paginiChopra Scm5 Ch01Zohaib AhsonÎncă nu există evaluări

- Push Pull Boundary SCMDocument40 paginiPush Pull Boundary SCMniteshaptÎncă nu există evaluări

- DR - Debmalya Ghosh: © 2007 Pearson Education 1-1Document23 paginiDR - Debmalya Ghosh: © 2007 Pearson Education 1-1Ruchi KumariÎncă nu există evaluări

- Lecture1515 - 26553 - Lecture 15 Supply Chain Management BasicsDocument51 paginiLecture1515 - 26553 - Lecture 15 Supply Chain Management BasicsAman kumar singhÎncă nu există evaluări

- What is a supply chainDocument14 paginiWhat is a supply chainaliÎncă nu există evaluări

- Supply Chain Management: Peeyush Pandey Assistant Professor IIM RohtakDocument30 paginiSupply Chain Management: Peeyush Pandey Assistant Professor IIM RohtakSanyam JainÎncă nu există evaluări

- Introduction to Supply Chain ManagementDocument47 paginiIntroduction to Supply Chain ManagementEmanuelle BakuluÎncă nu există evaluări

- KUL 1 Chopra INTRO Sept2011Document48 paginiKUL 1 Chopra INTRO Sept2011Uge HolicÎncă nu există evaluări

- Supply Chain Drivers & Key MetricsDocument45 paginiSupply Chain Drivers & Key MetricsMatee Khan0% (1)

- 1.1 What Is A Supply Chain?Document5 pagini1.1 What Is A Supply Chain?chitraÎncă nu există evaluări

- Session 1 & 2 - Understanding The Supply ChainDocument78 paginiSession 1 & 2 - Understanding The Supply ChainasaqÎncă nu există evaluări

- SUPPLY CHAIN CONCEPTS AND STAGESDocument90 paginiSUPPLY CHAIN CONCEPTS AND STAGESPrateek DixitÎncă nu există evaluări

- Chapter 1Document33 paginiChapter 1projects_masterz100% (1)

- Strategic Supply Chain AnalysisDocument25 paginiStrategic Supply Chain AnalysislordraiÎncă nu există evaluări

- SCM-StudyNotes M5Document7 paginiSCM-StudyNotes M5Anoop MadangarliÎncă nu există evaluări

- Managing Supply Chains: Session 2Document25 paginiManaging Supply Chains: Session 2Malik Muhammad SufyanÎncă nu există evaluări

- CH 01Document38 paginiCH 01asd.ksa1090Încă nu există evaluări

- Understanding The Supply ChainDocument34 paginiUnderstanding The Supply ChainNauryzbek MukhanovÎncă nu există evaluări

- Understanding SCM: Supply Chain Strategy and DesignDocument48 paginiUnderstanding SCM: Supply Chain Strategy and Designpartha080Încă nu există evaluări

- Global Supply Chain Management Notes-Msc Procurement and Logistics-Sept, 2023Document85 paginiGlobal Supply Chain Management Notes-Msc Procurement and Logistics-Sept, 2023hassan28sepÎncă nu există evaluări

- SCLMDocument6 paginiSCLMPraveen HansÎncă nu există evaluări

- 1 Global Logistics IntroductionDocument47 pagini1 Global Logistics IntroductionChanTheFireGodÎncă nu există evaluări

- SCM Session 1 and 2Document34 paginiSCM Session 1 and 2Pranav GargÎncă nu există evaluări

- Logistics and Supply Chain Management: Dr. R. S. GhoshDocument164 paginiLogistics and Supply Chain Management: Dr. R. S. Ghoshamitrao1983Încă nu există evaluări

- Chopra3 PPT ch01Document39 paginiChopra3 PPT ch01Rachel HasibuanÎncă nu există evaluări

- Tutorial 7Document6 paginiTutorial 7jaslynÎncă nu există evaluări

- Understanding The Supply ChainDocument33 paginiUnderstanding The Supply ChainZain ZulfiqarÎncă nu există evaluări

- Chopra Scm5 Ch06Document32 paginiChopra Scm5 Ch06nomanashrafÎncă nu există evaluări

- Supply Chain ManagementDocument14 paginiSupply Chain Managementعبد المجيد ياسر عبد المجيد غانمÎncă nu există evaluări

- Understanding The Supply ChainDocument32 paginiUnderstanding The Supply ChainGuarantee International CollegeÎncă nu există evaluări

- Chapter 1: Understanding The Supply ChainDocument5 paginiChapter 1: Understanding The Supply ChainFidan MehdizadəÎncă nu există evaluări

- Building Strategic Frameworks for Supply Chain AnalysisDocument9 paginiBuilding Strategic Frameworks for Supply Chain AnalysisKarthik TambralliÎncă nu există evaluări

- Supply Chain Performance Achieving Strategic Fit & ScopeDocument23 paginiSupply Chain Performance Achieving Strategic Fit & ScopeUsman Ali AkbarÎncă nu există evaluări

- SCM - An OverviewDocument50 paginiSCM - An OverviewPooja NagleÎncă nu există evaluări

- Understanding the Importance of Supply Chain ManagementDocument27 paginiUnderstanding the Importance of Supply Chain ManagementParth Kapoor100% (1)

- Supply Chain: Supply Chain Management Is Primarily Concerned With The Efficient Integration ofDocument24 paginiSupply Chain: Supply Chain Management Is Primarily Concerned With The Efficient Integration ofFavaz PgnÎncă nu există evaluări

- Introduction To Supply Chain ManagementDocument45 paginiIntroduction To Supply Chain ManagementAsha ChikkaputtegowdaÎncă nu există evaluări

- Supply ChainDocument5 paginiSupply ChainashishÎncă nu există evaluări

- Supply Chain Management GuideDocument3 paginiSupply Chain Management GuidepushkarÎncă nu există evaluări

- International Trade & Supply Chain StrategiesDocument7 paginiInternational Trade & Supply Chain StrategiesLasseÎncă nu există evaluări

- Tóm Tắt Supply ChainDocument11 paginiTóm Tắt Supply ChainHà PhươngÎncă nu există evaluări

- SCM1Document37 paginiSCM1hasib_ahsanÎncă nu există evaluări

- Week 1-Intro To GSCMDocument34 paginiWeek 1-Intro To GSCMAkhmad YunaniÎncă nu există evaluări

- Chopra Scm5 Ch01 GeDocument31 paginiChopra Scm5 Ch01 Geফয়সাল হোসেন100% (1)

- Unit 5Document7 paginiUnit 5Sheela AngelÎncă nu există evaluări

- Chapter 1 - SCMDocument27 paginiChapter 1 - SCMAmelia SoniaÎncă nu există evaluări

- Operations and Supply Chain StrategiesDocument7 paginiOperations and Supply Chain StrategiesManoj AgarwalÎncă nu există evaluări

- Logistics and Supply Chain Management Lecture Notes-2: Understanding The Supply ChainDocument4 paginiLogistics and Supply Chain Management Lecture Notes-2: Understanding The Supply ChainRymme jonesÎncă nu există evaluări

- Markstrat References Articles July 2014Document3 paginiMarkstrat References Articles July 2014RashadafanehÎncă nu există evaluări

- Markstrat References Articles July 2014Document3 paginiMarkstrat References Articles July 2014RashadafanehÎncă nu există evaluări

- Role of Internal Audit in Engineering ProjectDocument3 paginiRole of Internal Audit in Engineering ProjectRashadafanehÎncă nu există evaluări

- Defensive Routines and Theories-In-Use of Engineering and Non-Engineering ManagersDocument11 paginiDefensive Routines and Theories-In-Use of Engineering and Non-Engineering ManagersRashadafanehÎncă nu există evaluări

- Conceptual and Theoretical FrameworksDocument11 paginiConceptual and Theoretical FrameworksRashadafanehÎncă nu există evaluări

- Our Iceberg Is MeltingDocument22 paginiOur Iceberg Is Meltingasm123123Încă nu există evaluări

- The Role of Developing Countries Governments in HRD Programs The Egyptian ExperienceDocument7 paginiThe Role of Developing Countries Governments in HRD Programs The Egyptian ExperienceRashadafanehÎncă nu există evaluări

- Coll Is 1996Document3 paginiColl Is 1996RashadafanehÎncă nu există evaluări

- Does Corporate Strategy MatterDocument23 paginiDoes Corporate Strategy MatterRashadafanehÎncă nu există evaluări

- Changing Face of The Federal WorkforceA Symposium On DiversityDocument81 paginiChanging Face of The Federal WorkforceA Symposium On DiversityRashadafanehÎncă nu există evaluări

- Project Audit Methodology GuideDocument28 paginiProject Audit Methodology GuideRashadafanehÎncă nu există evaluări

- 2009 2 AustinDocument32 pagini2009 2 AustinChrizt ChrisÎncă nu există evaluări

- Comprehensive Exam StudentsDocument2 paginiComprehensive Exam StudentsRashadafanehÎncă nu există evaluări

- Question #If You Deposit $2100 Per YearDocument2 paginiQuestion #If You Deposit $2100 Per YearRashadafanehÎncă nu există evaluări

- Afaneh+odeh 16.09.2015Document14 paginiAfaneh+odeh 16.09.2015RashadafanehÎncă nu există evaluări

- Bonds Characteristics Risk Types Markets Costs QuizDocument2 paginiBonds Characteristics Risk Types Markets Costs QuizRashadafanehÎncă nu există evaluări

- Fall2014 - Applied Stat and DOEDocument4 paginiFall2014 - Applied Stat and DOERashadafanehÎncă nu există evaluări

- Midterm Exam FormulaDocument2 paginiMidterm Exam FormulaRashadafanehÎncă nu există evaluări

- Guide To Using MinitabDocument14 paginiGuide To Using MinitabMohammed Abdul Naseer0% (1)

- Methods For Finding The Rate of Return: Lecture No. 25 Contemporary Engineering EconomicsDocument16 paginiMethods For Finding The Rate of Return: Lecture No. 25 Contemporary Engineering EconomicsRashadafanehÎncă nu există evaluări

- CH 07Document111 paginiCH 07RashadafanehÎncă nu există evaluări

- Cee CHDocument39 paginiCee CHRashadafanehÎncă nu există evaluări

- Coca Cola SWOT 2015Document4 paginiCoca Cola SWOT 2015RashadafanehÎncă nu există evaluări

- Lec 1Document27 paginiLec 1RashadafanehÎncă nu există evaluări

- David Sm13 PPT 01Document46 paginiDavid Sm13 PPT 01sonicgeatÎncă nu există evaluări

- The Nature of Strategic Management: Chapter OneDocument41 paginiThe Nature of Strategic Management: Chapter OneMeIn YeEÎncă nu există evaluări

- Appendix 6 QMDocument1 paginăAppendix 6 QMRashadafanehÎncă nu există evaluări

- Data Monitor Report - Soft DrinksDocument26 paginiData Monitor Report - Soft DrinksKhushi SawlaniÎncă nu există evaluări

- TQMDocument3 paginiTQMRashadafanehÎncă nu există evaluări

- Department of Industrial Engineering: Prerequisite For Masters in Engineering ManagementDocument2 paginiDepartment of Industrial Engineering: Prerequisite For Masters in Engineering ManagementRashadafanehÎncă nu există evaluări

- Multiple Hearth Furnaces B3Document3 paginiMultiple Hearth Furnaces B3Ossy DewintaÎncă nu există evaluări

- Life Cycle of A Ship - ShippipediaDocument3 paginiLife Cycle of A Ship - ShippipediaarvindkaushikÎncă nu există evaluări

- p5 p6 m3 Industrial Robots and Flexible Manufacturing Systems in Engineering2Document5 paginip5 p6 m3 Industrial Robots and Flexible Manufacturing Systems in Engineering2hi_am_balajiÎncă nu există evaluări

- Lean Management AssignmentDocument14 paginiLean Management AssignmentElorm Oben-Torkornoo100% (1)

- General NotesDocument1 paginăGeneral NotesalayshahÎncă nu există evaluări

- EOQ ProblemsDocument6 paginiEOQ ProblemsDaneen GastarÎncă nu există evaluări

- Welding Defects GuideDocument61 paginiWelding Defects GuideJayaneela PrawinÎncă nu există evaluări

- BHEL MECHANICAL Training ReportDocument118 paginiBHEL MECHANICAL Training Reportgopikrishnandotpilla50% (2)

- 3-D Scroll CompressorDocument8 pagini3-D Scroll Compressorlist16947100% (1)

- Replacement Kits for Kobelco ExcavatorsDocument125 paginiReplacement Kits for Kobelco ExcavatorsSHANE100% (1)

- BBA 603 Production Operations ManagementDocument2 paginiBBA 603 Production Operations ManagementKavya KhandelwalÎncă nu există evaluări

- Case Study: ChallengeDocument2 paginiCase Study: Challengeeng13Încă nu există evaluări

- Trade Direction and Trade Pattern of The IndustryDocument4 paginiTrade Direction and Trade Pattern of The IndustryRebeka HossainÎncă nu există evaluări

- Astm C267Document6 paginiAstm C267Hà KhểnhÎncă nu există evaluări

- Maruti Suzuki - CSDocument5 paginiMaruti Suzuki - CSNambi Rajan100% (1)

- Final Project-JohanseinDocument79 paginiFinal Project-JohanseinJohan SeinÎncă nu există evaluări

- Polymer Waste: Controlled Breakdown or Recycling? by Brigitta BODZAY and György BÁNHEGYI, Ijdst v22n2 (2016) Paper 6Document40 paginiPolymer Waste: Controlled Breakdown or Recycling? by Brigitta BODZAY and György BÁNHEGYI, Ijdst v22n2 (2016) Paper 6György BánhegyiÎncă nu există evaluări

- Competitive Analysis of Godrej With SamsungDocument49 paginiCompetitive Analysis of Godrej With SamsungPrem NautiyalÎncă nu există evaluări

- Detailed Project Report of News Print Paper Mill5Document5 paginiDetailed Project Report of News Print Paper Mill5Umais QureshiÎncă nu există evaluări

- Wood Construction Guide PDFDocument84 paginiWood Construction Guide PDFVladislavs PozņaksÎncă nu există evaluări

- Management ScienceDocument6 paginiManagement ScienceDalia Joy ChanÎncă nu există evaluări

- Aluminium Extrusion Training Workshop GuideDocument68 paginiAluminium Extrusion Training Workshop GuideChitranjan Kumar100% (1)

- Four Ways Supply Chain Company ProfileDocument9 paginiFour Ways Supply Chain Company ProfilekalanziÎncă nu există evaluări

- Penerapan QCC Pada Sub Divisi Penjualan Proyek PT Bintang AnugerahDocument18 paginiPenerapan QCC Pada Sub Divisi Penjualan Proyek PT Bintang AnugerahKarloÎncă nu există evaluări

- Hardness Test ProcedureDocument5 paginiHardness Test Procedurefebinjohns87100% (1)

- Raffmetal: UNI EN 1676 and 1706Document2 paginiRaffmetal: UNI EN 1676 and 1706Anshuman RoyÎncă nu există evaluări

- Improve productivity and equipment efficiency through Total Productive MaintenanceDocument392 paginiImprove productivity and equipment efficiency through Total Productive MaintenanceYogaditya ModukuriÎncă nu există evaluări

- s08 02 Christensen Conf Ang PDFDocument56 paginis08 02 Christensen Conf Ang PDFsempatik721100% (1)

- DFMA MaterialsDocument19 paginiDFMA MaterialsdharmeshÎncă nu există evaluări

- Conclusion and RecommendationDocument14 paginiConclusion and RecommendationAnita KhanÎncă nu există evaluări

- University of Chicago Press Fall 2009 CatalogueDe la EverandUniversity of Chicago Press Fall 2009 CatalogueEvaluare: 5 din 5 stele5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDe la EverandUniversity of Chicago Press Fall 2009 Distributed TitlesEvaluare: 1 din 5 stele1/5 (1)