Documente Academic

Documente Profesional

Documente Cultură

Mahalaxmi Quality Plan For Fabrication

Încărcat de

Anonymous RXXdbl36A0 evaluări0% au considerat acest document util (0 voturi)

314 vizualizări1 paginăconstruction

Titlu original

Mahalaxmi Quality Plan for Fabrication

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentconstruction

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

314 vizualizări1 paginăMahalaxmi Quality Plan For Fabrication

Încărcat de

Anonymous RXXdbl36Aconstruction

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

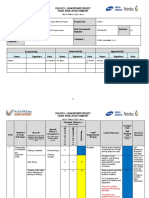

QUALITY ASSURANCE PLAN FOR WELDING / FABRICATION OF STRUCTURE IN MAHALAXMI TMT WARDHA

DESCRIPTION OF REPORT TO BE COLLECTED

1. DIMENSIONAL /FITMENT / ALIGNMENT / CHEMICAL TESTS / PHYSICAL TESTS

2. ULTRASONIC TESTS

3. MAGNETIC PARTICLE TESTS (MPT)

4. RADIOGRAPHY TEST

5. DYE PENETRATION TEST

6. WELDER'S QUALIFICATION & WELD PROCEDURE TEST

7. APPROVAL OF TEST AND REPAIR PROCEDURE

8. SURFACE PRE-PREPARATION

9. MANUFACTURER'S TEST CERTIFICATES FOR BOUGHT OUT ITEMS

10. INTERNAL INSPECTION REPORT BY CONTRACTOR

11. CALIBRATION TESTS

12. SHOP TRIAL ASSEMBLY AND MATCH MARKING FOR STRUCTURE (IF MORE THAN ONE PIECE)

13. PAINTING OF EXTERIOR SURFACE

14. REVIEW OF DOCUMENTS

Details of report

1- Fitment & alignment: fabrication tolerances shall be as per IS 7215 specifications Physical test

(sample) & chemical test (sample) should be collected applicable, if MTC is not available

2- Ultrasonic test: applicable for plates of thickness > = 20mm and all plates to be used for crane

girders. UT shall be as per ASTM a 435/ASTM a 578. UT on rounds (for) if DIA > =50mm.

a. UT SHOULD BE DONE for all grove welds in dynamically loaded structures and for other

important load bearing structure UT should be done in BUT welds. for statically loaded

structures as felt necessary during fabrication and after erection

b. All but welds shall be tested for as per AWS d 1.1:2010 or as felt necessary during

fabrication and after erection. UT on welds shall be carried out as per ANSI/AWS d1.1

:2010 chapter-6, part-f

3- Radiographic test: applicable for but welds for minimum 2% of length of each element of butt

joints made by SMAW/GMAW processes and minimum 1% of length of each element of butt

joints made by SAW process, if not indicated in the drawing/contract specification. RT on welds

shall be carried out as per ANSI/AWS D1.1:2010 CHAPTER-6, PART- E

4- Dye penetration test: applicable for all important fillet welds and groove welds for both

statically and dynamically loaded structures. Pt on welds shall be carried out as per ASTME 165.

5- Welder's qualification and weld procedures test: welding procedures (WPS/PQR) and

welder/welding operator qualifications shall be carried out as per ASME SECTION- IX- 2010

EDITION.

a. Qualified welders/ welding operators are continuously engaged in the welding activity

their WEEKLY records to be submitted to client for review & clearance.

b. If established WPS/QPR with lab test reports are available, the same shall be submitted

for review & clearance by client

6- Surface preparation & painting of exterior surface shall as per IS-5, 101, 1477 code specifications

and approved painting of fabricated structures (welds) shall be done only after clearance report

S-ar putea să vă placă și

- Health and Safety EssentialsDocument29 paginiHealth and Safety EssentialsAbdelRahman AbdelRazek RashwanÎncă nu există evaluări

- Contractor EHS Requirements StandardDocument25 paginiContractor EHS Requirements Standardamitbanerjee51Încă nu există evaluări

- BOCW and SafetyDocument31 paginiBOCW and Safetydreamboy87Încă nu există evaluări

- Safe Use of Lifting Machines and Lifting TackleDocument59 paginiSafe Use of Lifting Machines and Lifting TackleJakesÎncă nu există evaluări

- Energypac Power Generation LTD.: Daily Safety ChecklistDocument1 paginăEnergypac Power Generation LTD.: Daily Safety ChecklistMd. Ashraful IslamaÎncă nu există evaluări

- Prepared by Approved by Department Status Saurabh Kumar Praguman Verma Biw VqaDocument2 paginiPrepared by Approved by Department Status Saurabh Kumar Praguman Verma Biw VqaScientific KingÎncă nu există evaluări

- Smoke Detector ChecklistDocument1 paginăSmoke Detector ChecklistTomin ThomasÎncă nu există evaluări

- VINDAIR Construction Safety CHECK LISTDocument3 paginiVINDAIR Construction Safety CHECK LISTRamakrishna AgumbeÎncă nu există evaluări

- Potential Incident Report FormDocument1 paginăPotential Incident Report FormKumaravelÎncă nu există evaluări

- Haccp Documents 1Document26 paginiHaccp Documents 1olivia domingoÎncă nu există evaluări

- Agreement Between Alpha & Disposafe Health and Life CareDocument2 paginiAgreement Between Alpha & Disposafe Health and Life CarePrakash RathodÎncă nu există evaluări

- Fire Risk Assessment Report for JRG Automotive Industries India Pvt. LtdDocument8 paginiFire Risk Assessment Report for JRG Automotive Industries India Pvt. LtdneerajrdxÎncă nu există evaluări

- 19-F02 Lifting Machinery RegisterDocument1 pagină19-F02 Lifting Machinery RegisterSn AhsanÎncă nu există evaluări

- OPL Bolt TighteningDocument2 paginiOPL Bolt TighteningmmkattaÎncă nu există evaluări

- ARA - For Emergency Diesel GeneratorDocument4 paginiARA - For Emergency Diesel GeneratorShaikh AftabÎncă nu există evaluări

- 5.19 JSP 380KV GIS High Voltage TestDocument1 pagină5.19 JSP 380KV GIS High Voltage TestSyed Zafar Ali ShahÎncă nu există evaluări

- Electrical Safety SWPDocument12 paginiElectrical Safety SWPRavikant PandeyÎncă nu există evaluări

- Setco Automotive LTD.: Weekly Production PlanningDocument2 paginiSetco Automotive LTD.: Weekly Production PlanningDisha ShahÎncă nu există evaluări

- Sample of Method StatementDocument13 paginiSample of Method StatementMohammadImranRazaÎncă nu există evaluări

- Induction Format BHELDocument1 paginăInduction Format BHELMOJIBÎncă nu există evaluări

- ASMI-OSHMS-PR-02 - Targets and Objectives ProcedureDocument9 paginiASMI-OSHMS-PR-02 - Targets and Objectives ProcedureJHUPEL ABARIALÎncă nu există evaluări

- QAV observations closure sheet summaryDocument1 paginăQAV observations closure sheet summaryDEVENDERÎncă nu există evaluări

- RISK ASSESSMENT (Backfilling of Excavated Area)Document2 paginiRISK ASSESSMENT (Backfilling of Excavated Area)Raza Muhammad SoomroÎncă nu există evaluări

- 4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andDocument3 pagini4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andEric TingÎncă nu există evaluări

- Health Safety & Environment WI - C PDFDocument134 paginiHealth Safety & Environment WI - C PDFNilesh DeoreÎncă nu există evaluări

- L&T Chennai Metro Noise Monitoring ReportDocument1 paginăL&T Chennai Metro Noise Monitoring Reportsalman farisÎncă nu există evaluări

- Aspect Impact PressingDocument2 paginiAspect Impact Pressinglalit GuptaÎncă nu există evaluări

- Prasanna Precision Tools: SOP For Prevention of COVID - 19 at WorkplaceDocument1 paginăPrasanna Precision Tools: SOP For Prevention of COVID - 19 at WorkplaceGovind Rajan0% (1)

- Hazardous Substances RegisterDocument1 paginăHazardous Substances RegisterArmandoÎncă nu există evaluări

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument3 paginiChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpÎncă nu există evaluări

- RA Excavation & Backfilling WorkDocument6 paginiRA Excavation & Backfilling Workshamshad ahamedÎncă nu există evaluări

- Non-Conformance Report: DescriptionDocument8 paginiNon-Conformance Report: DescriptionHirushan MenukaÎncă nu există evaluări

- 04.unloading of MaterialsDocument6 pagini04.unloading of MaterialsKiran ChenchalaÎncă nu există evaluări

- Risk Assessment For Resin Injection Via HoseDocument1 paginăRisk Assessment For Resin Injection Via HoseKrishna KishoreÎncă nu există evaluări

- Check List (Pre Entry) For Gas Cutting SetDocument2 paginiCheck List (Pre Entry) For Gas Cutting SetAli KaziÎncă nu există evaluări

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (12) Tower Bolt TighteningDocument11 paginiOHS-PR-09-03-F07 JOB SAFE PROCEDURE (12) Tower Bolt Tighteningmohammed tofiqÎncă nu există evaluări

- SOP For Tree Cutting at HPCL UNNAODocument3 paginiSOP For Tree Cutting at HPCL UNNAOamankumar100% (1)

- Health, Safety and Environment Policy ManualDocument3 paginiHealth, Safety and Environment Policy ManualVikas SinghÎncă nu există evaluări

- OHSE Project HIRA - Fencing Work - R 01Document8 paginiOHSE Project HIRA - Fencing Work - R 01Pankaj SinghÎncă nu există evaluări

- Audit ComplianceDocument1 paginăAudit ComplianceNitin SharmaÎncă nu există evaluări

- Hse Ver 3Document164 paginiHse Ver 3Wajdi Merghani100% (1)

- Cube RegisterDocument148 paginiCube RegisterShesha ShayanÎncă nu există evaluări

- AE-SWM - 12B-LG-Marine-Rev-02Document61 paginiAE-SWM - 12B-LG-Marine-Rev-02Planning C7100% (1)

- DRL - Project Check List For Metal Cutting Machine: .RPM .RPMDocument1 paginăDRL - Project Check List For Metal Cutting Machine: .RPM .RPMSachin Hse Rohtak100% (1)

- Accident Incident Report (TLS)Document2 paginiAccident Incident Report (TLS)jonesÎncă nu există evaluări

- Company Logo Project: Ref No.: Rev No.: 1 of 1: Monthly Cleaning Schedule and Checklist FormDocument1 paginăCompany Logo Project: Ref No.: Rev No.: 1 of 1: Monthly Cleaning Schedule and Checklist FormMd. Ashraful IslamaÎncă nu există evaluări

- TRA FOR FRT - Rev.S2-2 (Recovered)Document31 paginiTRA FOR FRT - Rev.S2-2 (Recovered)rodman823Încă nu există evaluări

- EHS Audit Points TrackerDocument7 paginiEHS Audit Points TrackerDhinakaranÎncă nu există evaluări

- Flow Chart For Fire Drill Operation:: Emerrgency ControllerDocument1 paginăFlow Chart For Fire Drill Operation:: Emerrgency ControllerIwan Ms100% (2)

- Risk Register - 2022-23 SafetyDocument13 paginiRisk Register - 2022-23 SafetyR Sahadeo ReddyÎncă nu există evaluări

- Brand Analysis India Private Limited Risk Assessment: Risk Risk Impact C I A Risk Value Threat Miltigation PlanDocument2 paginiBrand Analysis India Private Limited Risk Assessment: Risk Risk Impact C I A Risk Value Threat Miltigation PlanTrivesh SÎncă nu există evaluări

- Instruments Calibration MonitoringDocument3 paginiInstruments Calibration MonitoringKarthi ThiyagarajanÎncă nu există evaluări

- Safe Work Procedure (Air Compressor)Document2 paginiSafe Work Procedure (Air Compressor)SURJIT SINGH100% (1)

- Construction Consortium Regional OfficesDocument97 paginiConstruction Consortium Regional OfficesMohasin KhanÎncă nu există evaluări

- COVID-19 Prevention PlanDocument12 paginiCOVID-19 Prevention PlanZubair KhanÎncă nu există evaluări

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document1 paginăRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo Rajan100% (1)

- Scaffold Inspection Report-Master ListDocument2 paginiScaffold Inspection Report-Master ListMobin Thomas AbrahamÎncă nu există evaluări

- Rimal Global Technical Services LLC.: HSE Management System ProcedureDocument1 paginăRimal Global Technical Services LLC.: HSE Management System ProcedureSreekumarÎncă nu există evaluări

- Monthly Performance Review November 2017Document11 paginiMonthly Performance Review November 2017elia nugraha adi100% (1)

- Ms For Demin Water Tank Modification Rev 1 Feb. 28 2011lastDocument9 paginiMs For Demin Water Tank Modification Rev 1 Feb. 28 2011lastsharif339100% (1)

- Construction estimate for internal road and labour quartersDocument1 paginăConstruction estimate for internal road and labour quartersAnonymous RXXdbl36AÎncă nu există evaluări

- Truck load and unload dates reportDocument2 paginiTruck load and unload dates reportAnonymous RXXdbl36AÎncă nu există evaluări

- Waste2 Steel Making and Beam Design2333444Document12 paginiWaste2 Steel Making and Beam Design2333444Anonymous RXXdbl36AÎncă nu există evaluări

- Sbi Sunita Income TaxwasteDocument2 paginiSbi Sunita Income TaxwasteAnonymous RXXdbl36AÎncă nu există evaluări

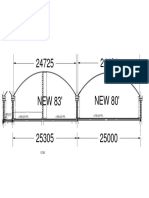

- Old Old: +850 Lev FFL +1000 Lev FFL +1000 Lev FFL +1150 Lev FFLDocument1 paginăOld Old: +850 Lev FFL +1000 Lev FFL +1000 Lev FFL +1150 Lev FFLAnonymous RXXdbl36AÎncă nu există evaluări

- Waste2 Steel Making and Beam DesignDocument4 paginiWaste2 Steel Making and Beam DesignAnonymous RXXdbl36AÎncă nu există evaluări

- To Intrest CertificateDocument1 paginăTo Intrest CertificateAnonymous RXXdbl36AÎncă nu există evaluări

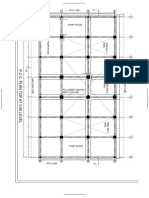

- Footing Details Control BLDDocument1 paginăFooting Details Control BLDAnonymous RXXdbl36AÎncă nu există evaluări

- Water Tank Rev PCC Top Detail at 0.6 LevDocument1 paginăWater Tank Rev PCC Top Detail at 0.6 LevAnonymous RXXdbl36AÎncă nu există evaluări

- Waste2 Steel Making and Beam Design23335555Document5 paginiWaste2 Steel Making and Beam Design23335555Anonymous RXXdbl36AÎncă nu există evaluări

- Sbi Sunita Income TaxwasteDocument2 paginiSbi Sunita Income TaxwasteAnonymous RXXdbl36AÎncă nu există evaluări

- Waste2 Steel Making and Beam Design2333Document8 paginiWaste2 Steel Making and Beam Design2333Anonymous RXXdbl36AÎncă nu există evaluări

- 3 Tundish Well Block High Grog Quality Fire Clay Bulk Density-38 To 42 4 Tundish Bricks IS8 - 58%ALUMINA 230X115X25 230X115X25Document4 pagini3 Tundish Well Block High Grog Quality Fire Clay Bulk Density-38 To 42 4 Tundish Bricks IS8 - 58%ALUMINA 230X115X25 230X115X25Anonymous RXXdbl36AÎncă nu există evaluări

- Waste2 Steel Making and Beam Design2Document4 paginiWaste2 Steel Making and Beam Design2Anonymous RXXdbl36AÎncă nu există evaluări

- STAAD Support Reaction AnalysisDocument4 paginiSTAAD Support Reaction AnalysisAnonymous RXXdbl36AÎncă nu există evaluări

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument6 pagini68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36AÎncă nu există evaluări

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument6 pagini68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36AÎncă nu există evaluări

- 68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseDocument4 pagini68 DL+WLL1: Check For Maximum and Minimum Pressure at The BaseAnonymous RXXdbl36AÎncă nu există evaluări

- STAAD Support Reaction AnalysisDocument4 paginiSTAAD Support Reaction AnalysisAnonymous RXXdbl36AÎncă nu există evaluări

- SR Ingot Footing Was2Document30 paginiSR Ingot Footing Was2Anonymous RXXdbl36AÎncă nu există evaluări

- Steel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K UrlaDocument2 paginiSteel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K Urla Steel Requir Ed For Gi Shed Sartha K UrlaAnonymous RXXdbl36AÎncă nu există evaluări

- Staad Support Reaction AnalysisDocument31 paginiStaad Support Reaction AnalysisAnonymous RXXdbl36AÎncă nu există evaluări

- S.N. Description Detail NO. NO. L BDocument2 paginiS.N. Description Detail NO. NO. L BAnonymous RXXdbl36AÎncă nu există evaluări

- Load Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Document31 paginiLoad Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Anonymous RXXdbl36AÎncă nu există evaluări

- Waste 6Document2 paginiWaste 6Anonymous RXXdbl36AÎncă nu există evaluări

- Waste 2222Document2 paginiWaste 2222Anonymous RXXdbl36AÎncă nu există evaluări

- Load Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Document31 paginiLoad Calculation For Footing & Soil:-: (Not Considered Here Since It Is Modelled in STAAD)Anonymous RXXdbl36AÎncă nu există evaluări

- Waste 5Document2 paginiWaste 5Anonymous RXXdbl36AÎncă nu există evaluări

- S.N. Detail NO. NO. L B H/D Std. WTDocument2 paginiS.N. Detail NO. NO. L B H/D Std. WTAnonymous RXXdbl36AÎncă nu există evaluări

- Steel Sections and Plates InventoryDocument2 paginiSteel Sections and Plates InventoryAnonymous RXXdbl36AÎncă nu există evaluări

- Maine Media 2017 CatalogDocument84 paginiMaine Media 2017 CatalogMark HigginsÎncă nu există evaluări

- CatharsisDocument108 paginiCatharsispoooooooooooooooooopÎncă nu există evaluări

- Julia Elliott Teaching Resume No AddressDocument3 paginiJulia Elliott Teaching Resume No Addressapi-318702213Încă nu există evaluări

- Gitten, Ariela - 7 Artists Reinventing The Ancient Art of Mosaics - ArtsyDocument17 paginiGitten, Ariela - 7 Artists Reinventing The Ancient Art of Mosaics - ArtsyPedroÎncă nu există evaluări

- The Secret of Grisly Manor WalkthroughDocument9 paginiThe Secret of Grisly Manor WalkthroughdiemkayÎncă nu există evaluări

- Reading ComprehensionDocument5 paginiReading Comprehensiondyah catur pitalokaÎncă nu există evaluări

- Painting Landscapes in WatercolorDocument68 paginiPainting Landscapes in WatercolorRicardo PereiraÎncă nu există evaluări

- Crochet Patterns Painting Ideas and More 15 New DIY CraftsDocument73 paginiCrochet Patterns Painting Ideas and More 15 New DIY Craftsmessapos100% (4)

- Production Designer Profile - Hans BacherDocument2 paginiProduction Designer Profile - Hans BacherParis100% (1)

- Principles and Elements of DesignDocument3 paginiPrinciples and Elements of DesignGarden Club of VirginiaÎncă nu există evaluări

- Chinese pagodas and the Chicago Tribune TowerDocument8 paginiChinese pagodas and the Chicago Tribune TowerJehan Mohamad100% (1)

- Campus Paper Sections ExplainedDocument25 paginiCampus Paper Sections Explainedmaria cielo bataanon88% (8)

- Tutorial - Painting A ValkyrieDocument8 paginiTutorial - Painting A Valkyrietryanotherone915Încă nu există evaluări

- HGTV Magazine - June 2013Document198 paginiHGTV Magazine - June 2013Tom Lundgreen100% (5)

- Everyday Electronics 1974 10.CV01Document6 paginiEveryday Electronics 1974 10.CV01marcosscarato0% (1)

- Thesis Report AshishDocument53 paginiThesis Report AshishSonu Sharma100% (1)

- GSAS V2.1 DES IE 09 Low Emitting MaterialsDocument2 paginiGSAS V2.1 DES IE 09 Low Emitting MaterialsManiKandanÎncă nu există evaluări

- Ben Mathis - Freelance 3d Artist - TutorialsDocument1 paginăBen Mathis - Freelance 3d Artist - TutorialsK.n.TingÎncă nu există evaluări

- CritiqueDocument2 paginiCritiqueAbba Vedea Desembrana DionglayÎncă nu există evaluări

- (Project Rastko) The HISTORY of SERBIAN CULTURE - Petar Marjanovic The TheatreDocument13 pagini(Project Rastko) The HISTORY of SERBIAN CULTURE - Petar Marjanovic The TheatreNevena MrdjenovicÎncă nu există evaluări

- Carpentry, Joinery and IronmongeryDocument15 paginiCarpentry, Joinery and IronmongeryMohamed0% (1)

- KLEEMANN Design - New Catalog For Lift Cabins, Cops-Lops and DoorsDocument77 paginiKLEEMANN Design - New Catalog For Lift Cabins, Cops-Lops and DoorsKleemmann Hellas SAÎncă nu există evaluări

- Đáp Án Bài Nghe B1 VstepDocument24 paginiĐáp Án Bài Nghe B1 VstepYến Nghĩa100% (1)

- Level B2 Word ListDocument1.231 paginiLevel B2 Word ListIvanDarioMontealegreVela100% (2)

- Florentine Baroque Art American CollectionsDocument1 paginăFlorentine Baroque Art American Collectionsthot777Încă nu există evaluări

- Glenn Adamson Thinking Through CraftDocument118 paginiGlenn Adamson Thinking Through CraftНаталья Панкина100% (4)

- GuillermoAG - Reading The ImageDocument15 paginiGuillermoAG - Reading The ImageAdrienne Villanueva100% (1)

- Architectural Building MaterialsDocument239 paginiArchitectural Building MaterialsLaurence CalpoturaÎncă nu există evaluări

- Song Words For Yr 6 7 BookletsDocument7 paginiSong Words For Yr 6 7 Bookletsadalcayde2514Încă nu există evaluări

- Group 2 BSN 2D Module 2 Workshop 2Document1 paginăGroup 2 BSN 2D Module 2 Workshop 2Jashtine JingcoÎncă nu există evaluări