Documente Academic

Documente Profesional

Documente Cultură

Torque Charts and Pump Tutorial 3

Încărcat de

Mas Arman Tewo0 evaluări0% au considerat acest document util (0 voturi)

84 vizualizări7 paginiA gasket is any deformable material that is used to create a static seal and maintain that seal under the various conditions of a mechanical assembly. The Fluid Sealing Association represents over 85% of the manufacturing capacity for fluid sealing devices in North America. This paper will start with basic gasketing concepts and then proceed into details regarding installation and assembly.

Descriere originală:

Titlu original

Torque charts and Pump Tutorial 3

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentA gasket is any deformable material that is used to create a static seal and maintain that seal under the various conditions of a mechanical assembly. The Fluid Sealing Association represents over 85% of the manufacturing capacity for fluid sealing devices in North America. This paper will start with basic gasketing concepts and then proceed into details regarding installation and assembly.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

84 vizualizări7 paginiTorque Charts and Pump Tutorial 3

Încărcat de

Mas Arman TewoA gasket is any deformable material that is used to create a static seal and maintain that seal under the various conditions of a mechanical assembly. The Fluid Sealing Association represents over 85% of the manufacturing capacity for fluid sealing devices in North America. This paper will start with basic gasketing concepts and then proceed into details regarding installation and assembly.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 7

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

Proceedings of the Forty-First Turbomachinery Symposium

September 24-27, 2012, Houston, Texas

A GUIDE TO GASKETING PRINCIPLES AND BEST PRACTICES

Fluid Sealing Association

Gasket Division Members

994 Old Eagle School Road #1019

Wayne, PA 19087

The Fluid Sealing

Association (FSA)

is an international

trade association

founded in 1933.

Membership today

represents over 85% of the manufacturing capacity for fluid

sealing devices in North America. Our membership is most

heavily concentrated in North America, but also includes a

number of companies in Europe, Asia and South America.

Now as international trade grows throughout the world and

creates a need for universally accepted standards, we have

become international in scope.

ABSTRACT

Leakage from static joints has been found to be a major

contributor of emissions in many plants. With the collaboration

from the worlds leading gasket manufacturers, the Gasket

Division of the Fluid Sealing Association has created a training

presentation that will assist all personnel dealing with modern

gasketing applications and issues. What may appear to be a

simple and easy to install component actually requires

knowledge and understanding of its working principles and

characteristics. This paper will start with basic gasketing

concepts and then proceed into details regarding installation &

assembly. It will also address equipment and fastener

considerations, material selection and common uses. Finally,

field failure analysis techniques will be explained so that errors

in selection or installation procedures can be corrected. As the

original format of this paper is based on a digital slide

presentation, the format that follows will follow that layout.

GASKETING BASICS

What is a gasket? A gasket is any deformable material that is

used to create a static seal and maintain that seal under the

various conditions of a mechanical assembly.

What is a seal? A seal is created by compressing the gasket

material, causing it to deform and flow into the imperfections

of the sealing surfaces.

What are the physical forces involved?

What is the gasket responsible for?

Maintaining a seal for an indefinite period of time

Chemically resist the fluid being sealed

Withstand system temperatures and pressures without

serious impairment

Resist creep and crushing under load

Must not contaminate the fluid

Will not promote corrosion

Be easily removed

The integrity of a bolted joint depends on:

Selection of the correct components

Careful preparation, cleaning, and installation

Correct bolt tightening and loading

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

How/where do gaskets actually leak?

Tangential (flange-surface interface) leakage

Permeation (through gasket body) leakage

Leaks are:

Expensive

o Lost production

o Increased maintenance

o Fines

Dangerous

o Health and safety concerns

Preventable

o Installation techniques are very important

Gaskets dont fail, joints do.

Low bolting torques (inadvertently or by design)

Excessive bolt loads (no torque control)

Weak fastening materials

Inadequate lubrication of fasteners

Poor flange design and weak materials

Uneven compression

Poor gasket cutting and/or storage

Uncontrolled installation practices

Hardware considerations - flanges:

Type (RF, FF, T&G, RTJ )

Class (ASME, ANSI, DIN, BS, ISO, API, AWWA)

New or Used?

Surface Condition (Roughness, Tool Marks)

Surface Flatness

Surface Finish (according to gasket manufacturers

recommendations)

Material (Metallurgy, Polymer, Coatings)

Hardware considerations fasteners:

Material/Grade

Strength Rating

New (recommended) vs Used (common)

Clean, inspect, and replace anything defective

Anti-corrosion Coatings

Use hardened steel washers

Lubrication

INSTALLATION AND ASSEMBLY

Approximately 75-85% (taken from FSA Sealing Sense,

J anuary 2008. Pumps and Systems Magazine) of all bolted

flange joint failures relate to uncontrolled gasket installation

and joint assembly practices.

Failure analysis of 100 gaskets:

Gasket installation procedures: A guide to successful gasket

installation

Successfully sealing a flanged connection is dependent upon all

components of a well-designed flange system working well

together. This installation overview provides guidance to

maintenance operators, engineers, and fitters, to ensure

successful gasket installation and assembly of bolted flange

connections. It is intended to complement other plant-approved

installation procedures

Specific tools are required for cleaning and tensioning the

fasteners. Additionally, always use standard safety equipment

and follow good safety practices.

Calibrated torque wrench, hydraulic, or other tensioner

Wire brush (brass if possible)

Helmet

Safety goggles

Lubricant

Other plant-specified equipment

1a. Clean

Remove all foreign material and debris from:

o Seating surfaces

o Fasteners (bolts or studs)

o Nuts

o Washers

Use plant-specified dust control procedures

1b. Examine

Examine fasteners (bolts or studs), nuts, and washers

for defects such as burrs or cracks

Examine flange surfaces for warping, radial scores,

heavy tool marks, or anything prohibiting proper

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

gasket seating

Replace components if found to be defective. If in

doubt, seek advice.

2. Align flanges

Align flange faces and bolt holes without using

excessive force

Report any misalignment

3. Install gasket

Ensure gasket is the specified size and material

Examine the gasket to ensure it is free of defects

Carefully insert the gasket between the flanges

Make sure the gasket is centered between the flanges

Do not use jointing compounds or release agents on

the gasket or seating surfaces unless specified by the

gasket manufacturer

Bring flanges together, ensuring the gasket isnt

pinched or damaged

4a. Lubricate load-bearing surfaces

Use only specified or approved lubricants

Liberally apply lubricant uniformly to all thread, nut,

and washer load-bearing surfaces

Ensure lubricant doesnt contaminate either flange or

gasket face

4b. Install and tighten fasteners

Always use proper tools: calibrated torque wrench or

other controlled tensioning device

Consult your gasket manufacturer for guidance on

torque specifications

Always torque in a cross bolt tightening pattern

Tighten the nuts in multiple steps in a cross pattern

Step 1: Tighten all nuts initially by hand (Larger

bolts may require a small hand wrench.)

Step 2: Torque each nut to approximately 30% of

full torque

Step 3: Torque each nut to approximately 60% of

full torque

Step 4: Torque each nut to full torque, again using

the cross bolt tightening pattern. (Large

diameter flanges may require additional

tightening passes.)

Step 5: Apply at least one final full torque to all

nuts in a clockwise direction until all

torque is uniform. (Large diameter flanges

may require additional tightening passes.)

5. Retightening

Caution: consult your gasket manufacturer for

guidance and recommendations on re-tightening

Do not re-torque elastomer-based, asbestos-free

gaskets after they have been exposed to elevated

temperatures unless otherwise specified

Re-torque fasteners exposed to aggressive thermal

cycling

All retorquing should be performed at ambient

temperature and atmospheric pressure

Consult with the gasket manufacturer for specific

recommendations on retightening under hot

conditions

Gasket installation summary:

Clean and inspect all load bearing surfaces for defects

Follow some sort of assembly and torquing procedure

(eg. ASME PCC-1)

Use a cross-pattern torqueing procedure

Consult the gasket manufacturer for material specific

recommendations

FASTENERS

Because a tight bolted flange connection is directly dependent

on the fasteners

Use new bolts every time

Use the strongest bolt every time

Use proper lubrication every time

Consider the flange (yield) strength every time

What is the function of a bolt/fastener?

To hold things together

To transfer load

You must also take into consideration:

The overall purpose of the fastener

Thickness and material of the material being joined

The configuration of the overall joint

The operating environment

The type of loading

The following graph depicts the evenness of the bolt stress or

strain that creates and maintains the compression on the gasket.

Since these bolts are new, their performance is even and

predictable.

Due to previous torquing and the effects that temperature can

have on even the strongest bolting materials, the following

graph depicts the tremendous differences in bolt stress among

used bolts, even when installed properly.

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

Another factor often overlooked is that the installation-torque

value normally specified for a bolt-nut combination is

essentially valid only for the initial assembly of the fastener.

Continued use of the same bolt-nut assembly tends to alter and

change the coefficient of friction properties of the nut, resulting

in lower preload in the bolt after as few as five installations.

This graph illustrates this effect with data from other tests

showing that preload loss for the same fastener combination

can range as much as 30 to 60% after 10 installations. The

following graph has been adapted from "The Standard

Handbook of Fastening and J oining" Robert O. Parmley Editor-

in-Chief. ed1996.

Why use stronger bolts? Here are the yield values (we never

recommend over 80% of total yield as a safety factor) and the

corresponding torque values for 5 common -10 bolting

materials. You can clearly see that standard stainless steel bolts

(B8 Class I) are a problem. We typically recommend Grade B7

and Grade 8 bolts and studs with their corresponding nuts and

hardened flat washers. If there is a corrosive atmosphere, then

ptfe coated B7 or B8 Class II materials are recommended.

Another reason for using the ptfe coated materials is that the

ptfe acts as a lubricant.

As much as 60% - 70% of the bolt stress can be lost due to

friction between the bolts, nuts, washers, and load bearing

surfaces. We refer to this sum of friction values as nut factor

(NF) when calculating recommended assembly torque values.

All of these surfaces should be well lubricated. This slide

depicts the different torque values needed to obtain 60% yield

of the same B7 stud with differing lubrication areas. If you do

not lubricate properly, even if torque wrenches are used, you

are guessing at the load being applied to the gasket. It is also

important to note that when using PTFE coated bolts, it is

critical to follow the recommended torque values for such.

Fasteners summary: Fastener materials are some of the least

expensive items that are purchased, yet they are absolutely

critical in how our gaskets perform. And when there is a

leaking flange, the gasket, not the bolts, almost always gets the

blame. Failure analysis has proven that poor installation and

poor fasteners are responsible for more than 75% of leaks.

Gaskets will perform only as good as the fasteners and the

method of installation. Gaskets dont failjoints do. Its a

system bolts-gasket-flange.

MATERIAL SELECTION

Considerations:

Application requirements and restrictions

Environmental compliance and considerations

Financial requirements and restrictions

Material group/class considerations

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

Application requirements and restrictions:

Tightness allowable leakage rate

Temperature max/min/continuous, thermal cycling

Media gas, liquid, steam, alkalis, acids, ultra-pure,

FDA, oxygen

Pressure min/max, constant, surges

Hardware flange design, flange material, new/old,

RF, FF, available gasket load

Size 3 and 8 Class 150 loading issues, large

diameter flatness

Environmental compliance and considerations: Environmental

requirements and restrictions are more important these days

than ever before. If your company is not bound by legislation it

can often be bound by internal protocols such as ISO 14000,

BS 7750, and EMAS (Eco-Management and Audit Scheme) or

even public groups.

Clean Air Act EPA

IPPC Directive BREF documents

OSHA

TA Luft

Kyoto

End-user qualification requirements

Action groups

Publicity

Note: IPPC Directive (Integrated Pollution Prevention and

Control): The IPPC Directive has been in place for over 10

years and the Commission has undertaken a 2 year review with

all stakeholders to examine how it, and the related legislation

on industrial emissions, can be improved to offer the highest

level of protection for the environment and human health while

simplifying the existing legislation and cutting unnecessary

administrative costs. BREF documents are Best available

techniques REFerence documents

Financial requirements and restrictions: There are many

financial requirements and restrictions to consider and many of

these involve inputs from several departments. It is always

beneficial to consider long-term costs when selecting any

material but there are times where immediate financial

constraints overrule this approach.

Gasketing products come in various quality grades,

types, and price ranges. As most things in life, the

more the product costs, the better it performs and the

longer it lasts (not always, but more often than not).

Many end-user companies have supply contracts that

are set on specific financial parameters. This may limit

the type of material that can be used due to its cost.

One factor not often considered is lost production

costs. If a lower quality/cost material is used solely for

financial reasons, a premature failure or frequent

replacements may end up costing significantly more

than what a premium material may have cost from the

onset.

Similarly, repeat installation and replacement costs

more money than what is typically realized.

Material group/class considerations:

Chemical Compatibility

Thermal Stability

Blow-Out Resistance

Gas Permeability

Conformability to Surface Imperfections

Torque Retention

Creep Relaxation

Non-contamination and Particulation

FDA and other Regulatory Compliance

Now you must enter the gasketing world: Many people dont

realize the vast array of gasketing materials available. This is a

fairly comprehensive list of material groups that are common.

When you combine this list with the number of manufacturers

producing them and the number of styles in each group from

each manufacturer, you literally end up with multiple thousands

of gasketing choices available to you. It becomes a little

overwhelming.

Asbestos

Non-Asbestos

Elastomers

Carbon Fiber

Flexible Graphite

PTFE

Filled PTFE

Miscellaneous (paper, cork, etc.)

Expanded PTFE

Microcellular PTFE

O-Rings

Envelope Gaskets

Spiral Wound

Metal Reinforced

Corrugated Metal Core

Ring J oints

Form-in-Place

So how do you choose which gasket is right for you?

On your own, the right choice is very complicated

Groups, discussion boards

Gasket Manufacturers sites

Equipment Manufacturers sites

Trade Associations

Internal specifications

Supplier/engineering contracts

History

On your own, overwhelming is probably an

understatement. There are simply too many inputs of

information available that someone would have to

consider. So then how do you make the best selection?

In order to choose the right material

Get the manufacturers involved

o They are the technical experts and do not

want to see misapplications of their material

o The FSA has a data sheet that can be

completed and submitted to the manufacturer

for a complete analysis of your application

o They can provide you with recommendations

based on similar applications with other users

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

o but, they can only make recommendations

based on the accuracy and completeness of

the information you provide

COMMON INDUSTRIAL GASKET MATERIALS

Homogeneous rubber sheet

Many types of elastomeric polymers

o NBR, SBR, EPDM, FKM, FFKM

Inorganic and/or carbon fillers used to reinforce and

increase tensile strength

o Required for the integrity of the product

Finished sheets come in a variety of hardness

expressed by the Shore A hardness scale

o The lower the number the softer the material

Media compatibility depends on polymer type and

fillers

Rubber sheet compound constituents vary

o NBR sheet from manufacturer A may not

be the same as from manufacturer B

Ideal as full face gaskets with flat faced flanges

o Low compression, low load to obtain a seal

Can be crushed in a raised face flanges

Prevalent in water systems

Fiber-reinforced rubber bound

Many types of reinforcing fibers being used

NBR and SBR rubber are most common binders

Vast mixology of additional fillers

Wide range of compressibility and recovery

Coatings for anti-stick properties

Anti-swell and swell technologies

Wide array of media compatibility

Generally limited to Class 150 and 300 systems

Gasket factors vary

Torque requirements are specific

Original flange design can limit use

PTFE (virgin, filled, expanded)

Excellent sealability characteristics

Withstands aggressive chemicals

Various fillers and processes to reduce gasket creep

Conforms well to flange/surface irregularities

Very good for bolt stress limited systems

Very easy to cut and handle

Generally limited to Class 150 and 300 systems

Gasket creep can be a concern

Typically limited to 500

o

F continuous

Flexible Graphite (homogeneous, laminated)

Very good for high temperatures

Purity levels can be controlled for specific applications

Metallic cores improve robustness

Very good media compatibility

Highly compressible and conformable to imperfect

surface conditions

Must be careful of oxidizing environments

Impurities can cause quick deterioration

Can cause media contamination through particulation

Graphite is easily marked and damaged

Semi-metallic: spiral wound gaskets

Wide range of temperature and pressure limits

Density profile can be varied to accommodate

available bolt loads

Inner rings are now recommended by ASME B16.20

Improves performance and eliminates inward buckling

issues

Various filler materials available to satisfy temperature

and media compatibility requirements

Wide array of metallurgy available

Common marking system makes identification easy

Inward buckling can be an issue with no inner ring

Required seating stress is typically high

Large sizes must be carefully handled as they can be

bulky and heavy

Design tolerances can allow for sealing element

separation from the carrier ring

Semi-metallic: Serrated Metal Core with Soft Facing Material

(Kammprofile)

Robust design good for high and cycling temperature

and pressures

Excellent sealing characteristics

Good in low available stress applications

Metallurgy and facing options allow vast media

sealing capabilities

Good bolt torque retention

Design provides low creep results

Can be refaced

Metallic: Ring Type Joints (RTJ)

Typically used for very high pressure and temperature

applications

Standard designs/dimensions to ASME B16.20 and

API Specification 6A

Requires very robust specialized flanges

Flange surface finish is very important

RTJ metal hardness in critical

A general guide to product capabilities: The following charte is

intended to bring all the previous information together in a very

general format. It is by no means to scale or all inclusive. The 3

scales indicate temperature (top bar)), pressure (middle bar) and

chemical resistance (bottom bar). The scale moves from

low/weak at the left to high/aggressive on the right. It should be

noted that in order to achieve any maximum rating, the

appropriate components within any given product type must be

selected. This makes it very important to get to know your

manufacturer.

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

In order to make the best choice and avoid misapplication,

provide as much information as possible to your gasket

manufacturer.

General application description/type

Temperature (minimum, maximum, continuous)

Pressure (minimum, maximum, normal)

Thermal cycling (yes/no, range)

Vibration (yes/no, frequency)

Pressure stability (stable, intermittent, +/-)

Installation setting (new, existing)

Media being sealed (pH, concentration, specific

gravity)

Media state (liquid, gas, mixed)

Suspended particulates (yes/no, size)

Flanges (new/old, RF/FF, surface finish, groove type,

class)

Fasteners (material, grade, diameter, number, washers)

FIELD ANALYSIS AND TROUBLESHOOTING

Before doing anything in the field, make safety a number

one priority!

Is the equipment hot?

Is the equipment under pressure?

What is the media being sealed?

Wear goggles and other protective items.

Wear a safety helmet.

Follow plant safety procedures at all times,

including elevated locations.

Field analysis requires some detective work:

Verify gasketing material in the joint

Verify system media

Verify temperature and pressure

Determine if pressure or temperature spikes are

possible

Determine bolt grade, torque method, torque level,

lubrication, etc.

Inspect seating surface of the gasket

Check the impressions left by the flange on the gasket

Check for gasket treatments or coatings

Check for chemical attack

Measure gasket thickness all the way around seating

area (I.D. and O.D.) and compare variations

Important note: Most full face flanges do not allow for

adequate gasket compression on full face gaskets. Use caution

and consult your gasket manufacturer for assistance.

SUMMARY

The integrity of a bolted joint depends on

Selection of the correct components

Careful preparation, cleaning, and installation

Correct bolt tightening and loading

Contrary to common belief, gaskets rarely fail.

When dealing with gaskets ALWAYS consult with the

manufacturer and leverage their expertise.

For more information on everything sealing, please visit

www.fluidsealing.com

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Hino E13c Engine Workshop Manual PDFDocument413 paginiHino E13c Engine Workshop Manual PDFmahadeo ramphal100% (15)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Peugeot 505Document300 paginiPeugeot 505Артуро Игнасио Муньос СильваÎncă nu există evaluări

- Abus GM7000 PDFDocument60 paginiAbus GM7000 PDFcj7man8082% (11)

- Parts Manual Light Source Compact Lsck4 Lsck4 Plus ANDDocument115 paginiParts Manual Light Source Compact Lsck4 Lsck4 Plus ANDAgus LukitoÎncă nu există evaluări

- Torque of Stainless Steel, Non Ferrous TorqueDocument1 paginăTorque of Stainless Steel, Non Ferrous TorqueMas Arman TewoÎncă nu există evaluări

- ABSA News 008-V13-Iss1Document4 paginiABSA News 008-V13-Iss1Mas Arman TewoÎncă nu există evaluări

- ABSA Failure Alert IB06-003Document1 paginăABSA Failure Alert IB06-003Mas Arman TewoÎncă nu există evaluări

- Engineering Critical Analyses To BS 7910Document15 paginiEngineering Critical Analyses To BS 7910Mas Arman TewoÎncă nu există evaluări

- BS 7910Document12 paginiBS 7910Mas Arman Tewo50% (2)

- Ethylene Heat Flux John ZinkDocument4 paginiEthylene Heat Flux John ZinkMas Arman Tewo100% (1)

- 1386 - FM Front Page Industrial Burner HandbookDocument14 pagini1386 - FM Front Page Industrial Burner HandbookMas Arman Tewo0% (1)

- Tall Vertical ColumnsDocument2 paginiTall Vertical ColumnsMas Arman TewoÎncă nu există evaluări

- FEA 107 Validation ExperimentDocument7 paginiFEA 107 Validation ExperimentMas Arman TewoÎncă nu există evaluări

- Causal Factor Chart and Fault Tree TemplateDocument7 paginiCausal Factor Chart and Fault Tree TemplateMas Arman TewoÎncă nu există evaluări

- Earthquake Loading Specified in GDocument3 paginiEarthquake Loading Specified in GMas Arman TewoÎncă nu există evaluări

- Mechanical Design Internals Column Notes PDFDocument14 paginiMechanical Design Internals Column Notes PDFMas Arman TewoÎncă nu există evaluări

- Causal Factor Chart and Fault Tree TemplateDocument7 paginiCausal Factor Chart and Fault Tree TemplateMas Arman TewoÎncă nu există evaluări

- Origin of Damascus Steel PDFDocument9 paginiOrigin of Damascus Steel PDFMas Arman TewoÎncă nu există evaluări

- Decline of Islamic Science PDFDocument21 paginiDecline of Islamic Science PDFMas Arman Tewo0% (1)

- Part 1 ISLAMIC TECHNOLOGY Transfer TO THE WEST PDFDocument14 paginiPart 1 ISLAMIC TECHNOLOGY Transfer TO THE WEST PDFMas Arman TewoÎncă nu există evaluări

- Fired Heater Checklist FW PDFDocument2 paginiFired Heater Checklist FW PDFMas Arman Tewo100% (2)

- Onetuv Cheklist Design HTTPDocument3 paginiOnetuv Cheklist Design HTTPMas Arman TewoÎncă nu există evaluări

- Goodyear Heat Exchanger Rupture PDFDocument10 paginiGoodyear Heat Exchanger Rupture PDFMas Arman TewoÎncă nu există evaluări

- Sample3 Drawing PDFDocument2 paginiSample3 Drawing PDFMas Arman TewoÎncă nu există evaluări

- Lifting LugDocument24 paginiLifting LugMas Arman Tewo100% (6)

- PS-11036 Corrosion Resistant Coating For Fasteners FcaDocument23 paginiPS-11036 Corrosion Resistant Coating For Fasteners Fcabernardo1984Încă nu există evaluări

- Important Safety Instructions: WarningDocument4 paginiImportant Safety Instructions: WarningJohn LeonardÎncă nu există evaluări

- Machine Drawing ManualDocument90 paginiMachine Drawing Manualmechanical 2017-2021Încă nu există evaluări

- Установка ТНВД 2.9 3.6Document19 paginiУстановка ТНВД 2.9 3.6bogdanmichaelÎncă nu există evaluări

- SBLM2500 IND 178rev1Document18 paginiSBLM2500 IND 178rev1Daniil SerovÎncă nu există evaluări

- SKF Manual de ApertosDocument44 paginiSKF Manual de ApertosA RÎncă nu există evaluări

- A4-P 1.0 enDocument4 paginiA4-P 1.0 enshani5573Încă nu există evaluări

- Add To Favorites Contact Us SearchDocument4 paginiAdd To Favorites Contact Us SearchAhmed LepdaÎncă nu există evaluări

- W02 M58 5001Document30 paginiW02 M58 5001MROstop.comÎncă nu există evaluări

- 2003 Nissan Altima 2.5 Serivce Manual RSUDocument12 pagini2003 Nissan Altima 2.5 Serivce Manual RSUAndy Dellinger100% (1)

- C411 Agile Fiber Shelves 860647710 Jan 19Document14 paginiC411 Agile Fiber Shelves 860647710 Jan 19NancyÎncă nu există evaluări

- Compact Manual: Parts DiagramDocument4 paginiCompact Manual: Parts Diagramluismf14Încă nu există evaluări

- Volkswagen Workshop Manuals - ElectricalDocument127 paginiVolkswagen Workshop Manuals - Electricalsssf-doboj100% (1)

- Bobcat 963 Skid Steer Loader Master Illustrated Parts List Manual Book G SeriesDocument409 paginiBobcat 963 Skid Steer Loader Master Illustrated Parts List Manual Book G Seriesjakecall73% (11)

- ManualDocument15 paginiManualAndres NavarroÎncă nu există evaluări

- S03M03 ODU300 InstallDocument69 paginiS03M03 ODU300 InstallAtanda Babatunde MutiuÎncă nu există evaluări

- SWICTHESDocument28 paginiSWICTHESManoj MohanÎncă nu există evaluări

- Catalog0 Bradley PDFDocument151 paginiCatalog0 Bradley PDFJhonattan GonzalezÎncă nu există evaluări

- 4.3.5 Kwik Bolt 3 Expansion Anchor (328-352) r021 PDFDocument28 pagini4.3.5 Kwik Bolt 3 Expansion Anchor (328-352) r021 PDFMarco Antonio TeranÎncă nu există evaluări

- IEEE Guide For The Design and Testing of Transmission Modular Restoration Structure ComponentsDocument20 paginiIEEE Guide For The Design and Testing of Transmission Modular Restoration Structure ComponentsGenesis ToledoÎncă nu există evaluări

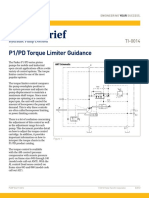

- P1PD Torque Limiter GuidanceDocument5 paginiP1PD Torque Limiter GuidancexxshÎncă nu există evaluări

- Metso Quote For SparesDocument8 paginiMetso Quote For Sparesmanian_arsÎncă nu există evaluări

- Driveshaft and AxleDocument32 paginiDriveshaft and AxleCesar GiraccaÎncă nu există evaluări

- Kom P-N ListDocument1.149 paginiKom P-N Listtheunauthorised100% (4)

- SAM Manual EDocument49 paginiSAM Manual Emath62210Încă nu există evaluări