Documente Academic

Documente Profesional

Documente Cultură

Domestic LPG Refrigerator

Încărcat de

Krishna RamaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Domestic LPG Refrigerator

Încărcat de

Krishna RamaDrepturi de autor:

Formate disponibile

www.SeminarsTopics.

com

DOMESTIC LPG REFRIGERATOR

ABSTRACT

Domestic refrigerators annually consume approximately 17,500 metric

tons of traditional refrigerants such as Chlorofluorocarbon (CFC) and

Hydroflourocarbon (HFC) which contribute to very high Ozone Depletion

Potential (ODP) and Global Warming Potential (GWP). Good progress is being

made with the phase out of CFC 22 from new equipment manufacture by

replacing LPG since it possesses an environmentally friendly nature with no ODP.

LPG is expected to results in comparable product efficiencies based on its

characteristics. Therefore, this two types of refrigerants (LPG and CFC 22) to be

examined using a modified domestic refrigerator in term of their performance

characteristics parameters such as pressure and temperature at specified

location at the refrigerator and the safety requirements while conducting the

experiment. Based on the present work, it is indicate that the successful of using

LPG as an alternative refrigerant to replace CFC 22 in domestic refrigerators is

possible by getting LPG COP as 13 compared to 10 for CFC22.

INTRODUCTION

In India, more than 80% of the domestic refrigerator utilize HFC 134a as

refrigerant, due to its excellent thermodynamic and thermo physical properties.

But, HFC 134a has a high global warming potential (GWP) of 1300. There is a

need of assess various refrigerant option considering the existing refrigerators in

the field and for the future market.

CFCs are principally destroyed by ultraviolet radiations in the

stratosphere; the chlorine released in the high stratosphere catalyzes the

decomposition of ozone to oxygen; and ultraviolet radiations penetrates to

lower altitudes. Credible calculations of the magnitude of the effect (Hoffman

1987) and his team predicted 3% global ozone emissions of 700 thousand

www.SeminarsTopics.com

tonnes/year after a hundred years. The ozone impact of car air conditioners also

can not be ignored. Hydrofluorocarbons (HFCs) can be thought of as a

replacement, but unfortunately the radiation properties of HFCs like R-134a

make them powerful global warming agents. HFC 134a and the HC blend have

been reported to be substitutes for CFC 12, but they have their own drawbacks

in energy efficiency, flammability and serviceability aspects of the systems. HFC

134a is not miscible with mineral oil, and hence, polyol ester oil is recommended,

which is highly hygroscopic in nature. This hygroscopicity demands stringent

service practices, which otherwise results in moisture entry into the system.

Thus, hydrocarbon refrigerants; particularly LPG serves as the best contender to

replace CFCs from domestic refrigerator as well as car air conditioners.

LPG consists mainly of propane (R-290) and butane (R-600), and LPG is

available as a side product in local refineries. In Cuba for already several

decades LPG is used as a drop-in refrigerant. LPG mixtures have composition of

a commercial LPG mixture suitable as drop-in replacement for R-12 was

calculated crudely as 64% propane and 36% butane by mass. Liquefied

petroleum gas (LPG) of 60% propane and 40% commercial butane has been

tested as a drop-in suitable for R 134a in a single evaporator domestic

refrigerator with a total volume of 10 ft3.

PROPERTIES

o Colourless.

o Odourless. (Its normal to odorise LPG by adding an

o Odorant prior to supply to the user, to aid the detectionof any leaks).

o Flammable.

o Heavier than air.

o Approximately half the weight of water.

o Non-toxic but can cause asphyxiation.

o LPG expands upon release and 1 litre of liquid will form approximately 250

litres of vapour.

A Good Mixture : LPG is mainly Propane (C3H8), Butane (C4H10) or a mix

of Propane/Butane. Since LPG has such a simple chemical structure, it is

among the cleanest of any alternative fuel.

Boiling Point : LPGs boiling point ranges from -42 C to 0 C depending on

its mixture percentage of Butane and Propane.

www.SeminarsTopics.com

Combustion : The combustion of LPG produces carbon dioxide (CO2) and

water vapour but sufficient air must be available. Inadequate appliances

flueing or ventilation can result in the production of carbon monoxide

which can be toxic.

Vapour Pressure: LPG is a stored as a liquid under pressure. It is almost

colourless and its weight is approximately half that of an equivalent

volume of water. The pressure inside a closed container in which LPG is

stored is equal to the vapour pressure of the liquid and corresponds to its

temperature.

Ignition Temperature: The temperature required to ignite LPG in air is

around 500 C.

Calorific Value: The calorific value of LPG is about 2.5 times higher than

that of main gas so more heat is produced from the same volume of gas.

Toxicity : LPG is a colourless, odourless and non-toxic gas. It is supplied

commercially with an added odorant to assist detection by smell.LPG is

an excellent solvent of petroleum and rubber product and is generally

non-corrosive to steel and copper alloys.

Safety : LPG is just as safe as any other fuel. In fact, it is safer than most

fuels because neither LPG itself nor the end products that are produced

by burning LPG in a suitable appliance are poisonous to inhale. Since LPG

cannot burn without air, there can never be a Flash-back into the

cylinder.

You can feel safe with LPG as the most through precaution are taken

to ensure your safety. All you have to do is to handle it correctly whilst adhering

to the simple instructions provided.

Propane : suitable for use in all conditions. It is the only

LPG product suitable for cold climates (such as the UK and

Canada) because of its low boiling point of -43.6 F

(-42 C).

www.SeminarsTopics.com

Butane : suitable for use in hot climate only because of its

higher boiling point of 22.9 F (-5 C).

Propane/Butane mixtures : suitable for use in moderate

Climates

THE LPG REFRIGERATION CYCLE

i. LPG Gas Cylinder: The LPG gas cylinder, LPG flows through the pipe and

reaches to the capillary tube. LPG gas pressure is approximate 80-100 psi.

ii. Capillary Tube:As the capillary tube, capillary tube downs the pressure up

to less than 1 psi.

iii. Evaporator:In the evaporator LPG is converted into the vapour from with

low pressure. After passing through the evaporator low pressure and

temperature LPG vapour absorbs heat from the chamber system.

iv. Gas Burner:After performing the cooling effect, low pressure LPG gas goes

into the burner where the burns.

PARTS OF REFRIGERATORS

LPG GAS CYLINDER

LPG is Liquefied Petroleum Gas. This is general description of Propane (C3H8)

and Butane (C4H10), either stored separately or together as a mix.

This is because these gases can be liquefied at a normal temperature by

application of a moderate pressure increases, or at normal pressure

by application of LPG using refrigeration. LPG is used as a fuel for domestic,

industrial, horticultural, agricultural, cooking, heating and drying

processes. LPG can be used as an automotive fuel or as

propellant for aerosol, in addition to other specialist applications. LPG

can also be used to provide lighting

through the use of pressure lanterns.

CAPILLARY TUBE

www.SeminarsTopics.com

The capillary tube is the commonly used throttling device in the domestic

refrigeration. The capillary tube is a copper tube of very small internal

diameter. It is of very long length and it is coiled to several turns

so that it would occupy less space. The internal diameter of the

capillary tube used for the refrigeration applications varies from 0.5

to 2.28 mm (0.020 to 0.09 inch). The capillary tube is shown in

picture. When the refrigerant enters in the capillary tube, its pressure

drops down suddenly due to very small diameter. The decrease in pressure of

the refrigerant through the capillary depends on the diameter of capillary and

the length of capillary. Smaller is the diameter and more is the length of capillary

more is the drop in pressure of the refrigerant as it passes through it.

EVAPORATOR

The evaporators are another important parts of the refrigeration systems. It

through the evaporators that the cooling effect is produced in the refrigeration

system.It is in the evaporators when the actual cooling effect takes place in

the refrigeration systems. For many people the evaporator is the main part of

the refrigeration system, consider other part as less useful. The evaporators

are heat exchanger surface that transfer the heat from the substance to

be cooled to the

refrigerant, thus removing the heat from the from the substance. The

evaporators are used for wide variety of diverse application in

refrigeration and hence the available in wide variety of shape, sizes

and designs. They are also classified in different manner depending on the

method of feeding the refrigerant, construction of the evaporator, direction of

air circulation around the evaporator, application and also the refrigerant

control.

In the domestic refrigerators the evaporators are commonly known as freezers

since the ice is made in these compartment.

In the evaporators the refrigerant enters at very low pressure and

temperature after passing through the capillary tube. This refrigerant absorbs

the heat from the substance that is to be cooled so the refrigerant

gets heated while the substance gets cooled. Even after cooling the substance

the temperature of the refrigerant leaving the evaporator is less than the

substance.

In the large refrigeration plants the evaporator is used for chilling water. In such

cases shell and tube type of heat exchanger are used as the evaporators. In

such plants the evaporators are classified as:

www.SeminarsTopics.com

(1). Dry expansion type of evaporators

(2). Flooded type of the evaporators

The evaporators are classified based on the construction as:

(1). Bare tube evaporators

(2). Plate surface evaporators

(3). Finned evaporators

(4). Shell and tube evaporator

(5). Shell and coiled evaporator, and

(6). Tube-in-tube evaporator

The evaporators are classified based on mode of heat transfer

(1). Natural convection evaporator, and

(2). Forced convection evaporator

The evaporators are classified based on operating conditions

(1). Frosting evaporator,

(2). Non-frosting evaporator, and

(3). Defrosting evaporator

PRESSURE GAUGES

Many techniques have been developed for the measurement of pressure

and vacuums. Instruments used to measure pressure are called pressure gauges

or vacuum gauges.A manometer could also referring to a pressure

measuring instrument, usually limited to measuring pressures near to

atmospheric. The term manometer is often used to refer specifically to liquid

column hydrostatic instruments.

STAINLESS STEEL PRESSURE GAUGE

Catering to the requirements of to power and allied Industry, we offer

quality array of stainless steel, weather proof pressure gauges.

Renowned for offering resistance in corrosive environments and modes, these

find wide application in power generation, pollution control equipment,

chemicals and petrochemicals and also exploration. These gauges

are available in 63mm, 100mm, and 150mm sizes and can be customized as per

client.

www.SeminarsTopics.com

BOURDON GAUGE

A Bourdon gauge uses a coiled tube, which, as it expands due to pressure

increases cases a rotation of an arm connected to the tube.In 1849 the

Bourdon tube pressure gauge was patented in France by Eugene Bourdon.

The pressure sensing element is a closed coiled tube connected to

the chamber or pipe in while the pressure is to be sensed. As the gauge

pressure increases the tube will tend to uncoil, while a reduced gauge

pressure will patented France by Eugene Bourdon.

The pressure sensing el cause the tube to coil more tightly. This motion is

transferred through a linkage to a gear train connected to an indicating

needle. The needle in presented in front of a card face inscribed with the

pressure indications associated with particular needle deflections. In a

barometer, the Bourdon tube is sealed at both ends and the absolute pressure

of the ambient atmosphere is sensed. Differentials Bourdon gauges use two

Bourdon tubes and a mechanical linkage that compares the readings.

HIGH PRESSURE PIPES

The range of high pressure pipes covers most application where there is a

requirement to transfer gas at high pressure. They consist of a steel pipe with

a steel ball fitted to both ends. Two swivelling connection nipples

press these balls against the seating of the connecting hole and

thus sealing against gas leakage

Wide range of pipes.

All pipes are pressure tested to 100 M Pa (14,500 psi) over

recommended working pressure.

CONSTRUCTION OF THE LPG REFRIGERATOR

The LPGrefrigerator shown in figure. We make the one box of the plywood. The

plywood sheet size is 12mm for used the LPG refrigerator. The size of the

refrigerator is 724*457*381 mm3. The evaporator is fitted on the upper portion of

box inside.

www.SeminarsTopics.com

Inside the refrigerator, we also put the thermo-coal sheet, because of the cold

air cannot the transfer from inside to outside of refrigerator.

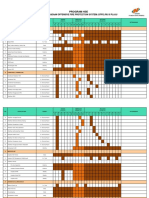

Fig 3.1 :- Construction of the LPG refrigerator

The schematically diagram of the LPG refrigeration system is shown in next

page. The gas tank is connect by pipes to the capillary tube. The capillary tube

is fitted with evaporator. The evaporator coiled end is connect to the stove by

another gas circulation pipe. When two pressure gauge is put between capillary

tube and gas tank, and another is put the end of the evaporator.

WORKING LPG REFRIGERATOR

The basic idea behind LPG refrigeration is to use the evaporation of a LPG to

absorb heat. The simple mechanism of the LPG refrigeration working is shown in

figure.

www.SeminarsTopics.com

Fig 3.2 Working of LPG Refrigerator

LPG is stored in the LPG cylinder under high pressure.

When the gas tank of regulators is opened then high

pressure LPG passes in gas pipe. This LPG is going by

high pressure gas pipe in capillary tube.

High pressure LPG is converted in low pressure at

capillary tube with enthalpy remains constant.

After capillary tube, low pressure LPG is passed through

evaporator. LPG is converted into low pressure and

temperature vapour from and passing through the

evaporator which absorbs heat from the chamber. Thus

the camber becomes cools down. Thus we can achieve

cooling effect in refrigerator.

After passing through the evaporator low pressure LPG

is passed through pipe by burner. And we can uses the

low pressure of LPG is burning processes.

www.SeminarsTopics.com

CAUSES AND PRECAUTION

Explosion in space Any refrigerant with vapour pressure above ambient

can flash to a larger volume. The potential increase in volume is greater if

combustion of lubricant or refrigerant occurs. Explosion venting may be

necessary to limit pressure rise to what the space can safely withstand. 2

kPa can blow window glass off a building.

Fire Combustible lubricant and refrigerant must be discharged safely

outside a building when a fire occurs especially if the heat of combustion

exceeds 200 MJ.

Asphyxiation or poisoning All refrigerants except air and oxygen are

asphyxiations. Ventilation must prevent serious injury or death on a sudden

total release of refrigerants. The quantity of ventilation necessary varies

greatly between refrigerants.

Flying metal System must comply with piping and pressure vessels codes.

Corrosion or chemical reaction LPG refrigerants are non-reactive and

chemically stable at refrigeration temperature.

Chemical or cold burns Accidental contact between skin and cold metal

must be prevented by insulation. Accidental releases of liquid refrigerant

must drain safely.

ADVANTAGE OF LPG

The advantages of LPG are as follows :

Clean burning.

Effects of corrosions are greatly reduced.

Instantly control the flame temperature.

Avoids scaling and decarburising of parts.

Environmentally friendly fuel, with minimal sulphur

www.SeminarsTopics.com

content and sulphur-free emissions.

Very high efficiency with direct firing system instant heat

for faster warm-up and cool-down.

LPG is easily liquefied and stored in pressure containers. It

can be easily transported in cylinder or tanks.

ADVANTAGES:

The cooling capacity of LPG is 10% higher than R-12 and the vapour

pressure is appropriate.

LPG is naturally occurring and non-toxic.

Use of LPG as a refrigerant also improves the overall efficiency by 10 to

20%.

The ozone depletion potential (ODP) of LPG is 0 and

Global warming potential (GWP) is 8 which is

Significantly negligible as compared to other refrigerant.

Apart from environment friendly, use of also LPG gives us lot of cost

advantages.

LPG does not form acids and thereby eliminates the problem with

blocked capillaries.

There is 60% reduction in weight of the system due to higher density of

LPG.

The fridge works when electricity off.

It is efficient to save fuel.

No pollution

The units are effectively silent in operation.

Running cost is zero.

Eliminates the compressor and condenser.

DISADVANTAGES:

LPG is explosive in nature.

Do not maintain constant pressure in LPG cylinder.

Put the LPG cylinder is inverted position.

After the refrigeration processes, the exhaust of LPG is burn into burner.

Because of the exhausted vapour LPG

www.SeminarsTopics.com

cannot converted again liquid phase , because the this process is very

costly.

The prevention of leakage of the LPG is the major problem in LPG

refrigeration system. Because of the LPG is highly flammable.

CONCLUSION:

After performing this project LPG Refrigeration, we conclude that refrigeration

effect is produced with the use of LPG.

From observation table, we conclude that, the regulating valve is fully open

that, we achieve the chamber temperature down from 38C to 10C in a 100

minute. We achieve the evaporator temperature down from 1C to -9.3C in a

same time interval.

We put the water in one plastic bottle in the evaporator. The initial

temperature of water is 35 C. From observation table, we conclude that, the

condition of regulating valve is fully opened, the same time period we achieve

the temperature of water is 0.30 C.

We also conclude that, the capillary tube is maximum pressure of gas cylinder

is reduces the less then of 1 psi. The capillary tube is more suitable throttling

device in LPG refrigeration system.

This system is cheaper in initial as well as running cost. It does not require an

external energy sources to run the system and no moving part in the system so

maintenance is also very low.

We also conclude that, we try the burnt to the exhaust LPG, the pressure of

exhaust gas is less than 1 psi, the small flame produce by the burner.

This system most suitable for hotel, industries, refinery, chemical industries where

consumption of LPG is very high.

BIBLIOGRAPHY :

http://www.hychill.com.au/pdf/pasolpgr.pdf

www.e-lpg.com

http://www.google.com/g

www.dynatempintl.com

www.lpgforyou.com

http://www.brighthub.com/engineering/mechanical.aspx

www.SeminarsTopics.com

http://coolingdevice.net/4.html

http://howstuffworks.com/refrigerator.htm

www.indiamart.com

A Textbook of Refrigeration and Air Conditioning by R.S.KHURMI &

J.K.GUPTA

Performance and safety of LPG Refrigerant, The University of New South

Wales, Australia.

Applications of Refrigeration & Air Conditioning, Lesson 3, Version 1 ME,

IIT Kharagpur 1

A Textbook of Thermal Engineering, By R.S.KHURMI & J.K.GUPTA

Arora, C.P, Refrigeration & Air Conditioning, Tata McGraw Hill Company

Limited, New Delhi.

S-ar putea să vă placă și

- ACDELCO U7001 Fuel Selector Valve InstallationDocument2 paginiACDELCO U7001 Fuel Selector Valve InstallationAVATAVA100% (1)

- HW 1 2Q1314 QuestionaireDocument1 paginăHW 1 2Q1314 QuestionairejenninajubanÎncă nu există evaluări

- Tedy Assignm Answer 1Document5 paginiTedy Assignm Answer 1Abdisa Gemechu0% (1)

- Assignment 12Document7 paginiAssignment 12Anonymous mqIqN5zÎncă nu există evaluări

- Elements of Energy Systems 2Document21 paginiElements of Energy Systems 2Marcial Jr. MilitanteÎncă nu există evaluări

- Assignment 2Document1 paginăAssignment 2dhrumilÎncă nu există evaluări

- Honda GD1250 (20-24 HP) 3-Cyl. Diesel Engine - Review and SpecsDocument4 paginiHonda GD1250 (20-24 HP) 3-Cyl. Diesel Engine - Review and SpecsWidi PrasetyoÎncă nu există evaluări

- RefrigerationDocument8 paginiRefrigerationHectorCabz0% (1)

- Design and Fabrication of An Ice Cube Making MachineDocument7 paginiDesign and Fabrication of An Ice Cube Making MachineJunjun AguirreÎncă nu există evaluări

- FLR - Performance of A Tubular CondenserDocument12 paginiFLR - Performance of A Tubular CondenserNazario Emil LintagÎncă nu există evaluări

- Actual Vapor Compression Refrigeration Cycle Part 1Document12 paginiActual Vapor Compression Refrigeration Cycle Part 1jjÎncă nu există evaluări

- 20 18 1.724 36 T Rtot A Q : Chapter 4 - Heating and Cooling Load CalculationDocument8 pagini20 18 1.724 36 T Rtot A Q : Chapter 4 - Heating and Cooling Load CalculationdpadrianÎncă nu există evaluări

- Rac Problems Set 1Document6 paginiRac Problems Set 1Mohammad Umair100% (1)

- Formula Summary: Monday, 12 April 2021 10:17 AMDocument45 paginiFormula Summary: Monday, 12 April 2021 10:17 AMJads CayabyabÎncă nu există evaluări

- Assignment 5Document2 paginiAssignment 5hossamkandil7Încă nu există evaluări

- Ref MathDocument7 paginiRef MathMd.Tanvir RahmanÎncă nu există evaluări

- 13 Spring Problems and Solutions For MEXT 2019Document34 pagini13 Spring Problems and Solutions For MEXT 2019Hatsady ThonginÎncă nu există evaluări

- Refrigeration Midterm Exam ###Document3 paginiRefrigeration Midterm Exam ###Patience LastyÎncă nu există evaluări

- Chapter 1Document8 paginiChapter 1Von A. Damirez0% (1)

- Quality of Refrigerant ThermodynamicsDocument8 paginiQuality of Refrigerant ThermodynamicsPokemon BhalooÎncă nu există evaluări

- Rac Solution Set BDocument12 paginiRac Solution Set BxofigoÎncă nu există evaluări

- Student - S Trivia Exam 2Document6 paginiStudent - S Trivia Exam 2Marcial Militante100% (1)

- SHEET4 AnswersDocument20 paginiSHEET4 AnswersHamadaMohassabÎncă nu există evaluări

- Thermodynamics Onkar SinghDocument18 paginiThermodynamics Onkar SinghSaurabh JainÎncă nu există evaluări

- Refrigeration-Systems Part 1Document11 paginiRefrigeration-Systems Part 1Sean GuanzonÎncă nu există evaluări

- Pipe SimulationDocument101 paginiPipe Simulationnathaniel villanuevaÎncă nu există evaluări

- Machine Design CouchingDocument403 paginiMachine Design CouchingJomari DichosoÎncă nu există evaluări

- 3 Diesel PerformanceDocument10 pagini3 Diesel PerformanceyanyanÎncă nu există evaluări

- Answer SheetDocument7 paginiAnswer SheetCharles Michael Bautista Hosmillo100% (1)

- PP ManualDocument50 paginiPP ManualMohammad RehmanÎncă nu există evaluări

- Part I Refrigeration Chapter 1Document43 paginiPart I Refrigeration Chapter 1eskewt0% (1)

- Ref Systems Lecture Notes 1Document9 paginiRef Systems Lecture Notes 1Retro GamerÎncă nu există evaluări

- Step 1: Draw A Diagram To Represent The SystemDocument7 paginiStep 1: Draw A Diagram To Represent The SystemRyan Cristian BorsigueÎncă nu există evaluări

- Heat Transfer Problem SetDocument6 paginiHeat Transfer Problem Setkim dianonÎncă nu există evaluări

- Module 5 Activity No. 4Document1 paginăModule 5 Activity No. 4dracarysÎncă nu există evaluări

- Tables Stoecker and JonesDocument11 paginiTables Stoecker and JonesGenard RantaelÎncă nu există evaluări

- Module 6 Reciprocating COMPRESSORDocument30 paginiModule 6 Reciprocating COMPRESSORSylvesterÎncă nu există evaluări

- Refrigeration Paper in IJSER FormatDocument14 paginiRefrigeration Paper in IJSER Formattitto84886Încă nu există evaluări

- Fans and BlowersDocument2 paginiFans and BlowersNeil RubsÎncă nu există evaluări

- Macabeo Me150p E01 Hw1 Chapter14&15Document24 paginiMacabeo Me150p E01 Hw1 Chapter14&15Patricia MacabeoÎncă nu există evaluări

- Pipe Problems Looks Fam 2Document178 paginiPipe Problems Looks Fam 2Eep Jay0% (1)

- InDocument17 paginiInVon A. DamirezÎncă nu există evaluări

- Green BookDocument16 paginiGreen BookYanna AbilaÎncă nu există evaluări

- Pipe Flashing Problems 3Document45 paginiPipe Flashing Problems 3kristan7Încă nu există evaluări

- Pressure Vessel Topic ES9Document11 paginiPressure Vessel Topic ES9killuaÎncă nu există evaluări

- Tutorial 1& 2 - SolDocument10 paginiTutorial 1& 2 - SolAli ZaghloulÎncă nu există evaluări

- Solved Problems A Solved Refrigeration ProblemsDocument29 paginiSolved Problems A Solved Refrigeration Problemsbasil.delacruzÎncă nu există evaluări

- Hvac Rpoblems NewDocument20 paginiHvac Rpoblems NewGrace Joy CariÎncă nu există evaluări

- Lab Report 2 (Me160p-2, Bellen)Document14 paginiLab Report 2 (Me160p-2, Bellen)AndreÎncă nu există evaluări

- Steam EnginesDocument6 paginiSteam Engineschat2adiÎncă nu există evaluări

- CHAPTER 10 Cooling Load January 2012Document50 paginiCHAPTER 10 Cooling Load January 2012Franky FlamÎncă nu există evaluări

- Question BAB 5Document3 paginiQuestion BAB 5Justin GriffithÎncă nu există evaluări

- Chapter 7Document6 paginiChapter 7Marco LuigiÎncă nu există evaluări

- Lecture Notes On Compressor 2019 PDFDocument21 paginiLecture Notes On Compressor 2019 PDFJerome MaldaÎncă nu există evaluări

- ME Con-1 Mock-1Document15 paginiME Con-1 Mock-1vidya chakitwarÎncă nu există evaluări

- Domestic LPG Refrigerator: Domestic Refrigerators Annually Consume Approximately 17,500 MetricDocument13 paginiDomestic LPG Refrigerator: Domestic Refrigerators Annually Consume Approximately 17,500 MetricRituraj ThakurÎncă nu există evaluări

- LPG RefrigeratorDocument29 paginiLPG RefrigeratorSodum MaheswarreddyÎncă nu există evaluări

- Major Project On Zero Cost LPG Refrigerator: Submitted by Guided byDocument26 paginiMajor Project On Zero Cost LPG Refrigerator: Submitted by Guided byAditya MishraÎncă nu există evaluări

- LPG Gas Refregration SystemDocument19 paginiLPG Gas Refregration Systemaman shaikhÎncă nu există evaluări

- RefrigerationDocument16 paginiRefrigerationKundan sharma100% (1)

- Zero Cost Refrigeration SystemDocument48 paginiZero Cost Refrigeration SystemKritisundar GarnayakÎncă nu există evaluări

- U.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.De la EverandU.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.Încă nu există evaluări

- Travel Currency Card TNCDocument10 paginiTravel Currency Card TNCKrishna RamaÎncă nu există evaluări

- Verilog CodesDocument10 paginiVerilog CodesKrishna RamaÎncă nu există evaluări

- Amplitude Modulation and DemodulationDocument5 paginiAmplitude Modulation and DemodulationKrishna RamaÎncă nu există evaluări

- P EffectDocument19 paginiP EffectKrishna RamaÎncă nu există evaluări

- The Sixth Sense Technology: Dr. Ambedkar Institute of Technology Department of EceDocument24 paginiThe Sixth Sense Technology: Dr. Ambedkar Institute of Technology Department of EceKrishna RamaÎncă nu există evaluări

- Applets - Unit8 OopsDocument34 paginiApplets - Unit8 OopsKrishna RamaÎncă nu există evaluări

- Resume 2Document2 paginiResume 2Krishna RamaÎncă nu există evaluări

- Unit 4 Pollution PDFDocument22 paginiUnit 4 Pollution PDFKrishna RamaÎncă nu există evaluări

- Jntu Hyd 2 2ece PDC Set 2Document18 paginiJntu Hyd 2 2ece PDC Set 2Krishna RamaÎncă nu există evaluări

- Unit 1 Intro To Op AmpDocument31 paginiUnit 1 Intro To Op AmpKrishna RamaÎncă nu există evaluări

- 2ece-Eee - Edc Lab ManualsDocument108 pagini2ece-Eee - Edc Lab ManualsKrishna RamaÎncă nu există evaluări

- Unit 8 Towards Sustainable FutureDocument19 paginiUnit 8 Towards Sustainable FutureKrishna RamaÎncă nu există evaluări

- Unit 3 BiodiversityDocument17 paginiUnit 3 BiodiversityKrishna RamaÎncă nu există evaluări

- Es Introduction ClassDocument1 paginăEs Introduction ClassKrishna RamaÎncă nu există evaluări

- Cyliner HeadDocument45 paginiCyliner HeadJonoAlexisDang-awanQuibanÎncă nu există evaluări

- RCM Otto Rider Floor Sweeper - Sweepers AustraliaDocument5 paginiRCM Otto Rider Floor Sweeper - Sweepers AustraliaCharlie CollettÎncă nu există evaluări

- Mte 4 ReportDocument8 paginiMte 4 ReportZeke KazamiÎncă nu există evaluări

- An Idea Whose Time Has ComeDocument12 paginiAn Idea Whose Time Has ComeWilliam Cristofer Romero Romero100% (1)

- Procesos - Petroquimicos Hydrocarbon ProcessingDocument304 paginiProcesos - Petroquimicos Hydrocarbon ProcessingJhonny Ibarra Agreda100% (1)

- BMW x3 Transfer Case Oil XferDocument4 paginiBMW x3 Transfer Case Oil Xfersimon_someone217Încă nu există evaluări

- BME ManualDocument32 paginiBME ManualSudhanshuAtkareÎncă nu există evaluări

- G4-228 (7-18c) 24RCL (KG2204) SpecDocument4 paginiG4-228 (7-18c) 24RCL (KG2204) SpecService Brags & Hayes, Inc.100% (1)

- OISD GDN-115 Fire Fighting Equipment in Petroluem IndustryDocument70 paginiOISD GDN-115 Fire Fighting Equipment in Petroluem Industryarjumand mahak50% (2)

- Types of S CompoundsDocument36 paginiTypes of S CompoundsMahesh sinhaÎncă nu există evaluări

- Morse Test On Multi Cylinder Petrol EngineDocument4 paginiMorse Test On Multi Cylinder Petrol Engineمصطفى العباديÎncă nu există evaluări

- Dispenser Ordering Step 1 of 4Document10 paginiDispenser Ordering Step 1 of 4Carlos RondonÎncă nu există evaluări

- Problem and Its SettingsDocument35 paginiProblem and Its SettingsSharra Julia Alano Castillo100% (1)

- Herramientas para Distrbucion PDFDocument106 paginiHerramientas para Distrbucion PDFJorge Taffur100% (1)

- Performance Analysis of Shell and Tube As Preheater Fuel For BiodieselDocument10 paginiPerformance Analysis of Shell and Tube As Preheater Fuel For BiodieselAchmad WijayaÎncă nu există evaluări

- UH-60 Fuel SystemDocument15 paginiUH-60 Fuel SystemYung Chun LinÎncă nu există evaluări

- BMW 5 Series SedanDocument23 paginiBMW 5 Series SedanEmolNZÎncă nu există evaluări

- A2 001 Offshore Wireline UnitDocument2 paginiA2 001 Offshore Wireline UnitMohamed AkakÎncă nu există evaluări

- Organic Chemistry: TerminologiesDocument14 paginiOrganic Chemistry: TerminologiesGirvin DjapardiÎncă nu există evaluări

- MO MSC 102 SummaryDocument20 paginiMO MSC 102 SummarySUNILÎncă nu există evaluări

- Energy Engineering Lab: Department of Chemical Engineering University of Engineering & Technology, LahoreDocument10 paginiEnergy Engineering Lab: Department of Chemical Engineering University of Engineering & Technology, LahoreiqraSarfrazÎncă nu există evaluări

- Matrix Training & Program HSE - OFPS Plaju 19.56Document4 paginiMatrix Training & Program HSE - OFPS Plaju 19.56NurhalizaÎncă nu există evaluări

- Water Mist Fire Suppression: How Less Water Has A Big ImpactDocument6 paginiWater Mist Fire Suppression: How Less Water Has A Big ImpactSI Comércio e ServiçosÎncă nu există evaluări

- Simulated DistillationDocument10 paginiSimulated DistillationNicolette CaseÎncă nu există evaluări

- List of Companies in Jubail Re-Imbursment Tuv Procedure Qualification Criteria Assessment RaghdaDocument4 paginiList of Companies in Jubail Re-Imbursment Tuv Procedure Qualification Criteria Assessment RaghdaMuhammad ShoaibÎncă nu există evaluări

- Camp/Accommodation Audit/Annual Inspection Form: A. Camp Management & Records Yes No N/ADocument9 paginiCamp/Accommodation Audit/Annual Inspection Form: A. Camp Management & Records Yes No N/Asudeesh kumarÎncă nu există evaluări

- Online Auction O&K Excavator Parts of Handelsonderneming Het Zuiden B.VDocument35 paginiOnline Auction O&K Excavator Parts of Handelsonderneming Het Zuiden B.VWaldek LipskiÎncă nu există evaluări