Documente Academic

Documente Profesional

Documente Cultură

21734

Încărcat de

Jeef100%(4)100% au considerat acest document util (4 voturi)

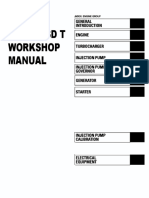

177 vizualizări67 paginiLandking series diesel engines, developed by European R&D center of weiChai power, are mature products with world-class technology. Friendly tips from WeiChai Power: In order to improve your operation efficiency and reduce cost, please read the manual carefully for proper use and maintenance.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentLandking series diesel engines, developed by European R&D center of weiChai power, are mature products with world-class technology. Friendly tips from WeiChai Power: In order to improve your operation efficiency and reduce cost, please read the manual carefully for proper use and maintenance.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(4)100% au considerat acest document util (4 voturi)

177 vizualizări67 pagini21734

Încărcat de

JeefLandking series diesel engines, developed by European R&D center of weiChai power, are mature products with world-class technology. Friendly tips from WeiChai Power: In order to improve your operation efficiency and reduce cost, please read the manual carefully for proper use and maintenance.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 67

Maintenance for Landking

WP10 E III Di l E i WP10 Euro III Diesel Engines

Respected customers:

Thank you for using Landking Euro III diesel engines of WeiChai Power Thank you for using Landking Euro III diesel engines of WeiChai Power.

Landking series diesel engines, developed by European R&D center of

WeiChai Power integrating the most advanced technology of internal

combustion engines, are mature products with world-class technology.

Friendly tips fromWeiChai Power: Friendly tips from WeiChai Power:

In order to improve your operation efficiency and reduce cost, please

read the manual carefully for proper use and maintenance. Special

fittings and oil should be adopted.

WeiChai Power

Contents

Regular inspection for Landking Euro III diesel Regular inspection for Landking Euro III diesel

engines

1 Cooling System 1. Cooling System

2. Lubricating System

3 Fuel System 3. Fuel System

4. Electrical System

5. Mechanical Transmission System

Maintenance for Landking Euro III Diesel

Engines

Attention Points for Operating Landking Euro III Attention Points for Operating Landking Euro III

Diesel Engines

The Way of Maintenance for Landking WP10 The Way of Maintenance for Landking WP10

Diesel Engines

Regular inspection for Landking Euro III diesel

engines

1. Cooling system

Before starting the engine should check

coolant level, check whether the cooling

. system is leaking or not.

Check whether water temperature is at the

required range or not when the engine is

running.

The normal water

When water temperature is too high,

please check:

the tension of water pump belt

temperature under the

sea-level of 3000

meters is 80~95

the tension of water pump belt

the tension of fan belt

thermostat

diagram of water temperature in cab diagram of water temperature in cab

Must use liquid coolant when ambient temperature

is below 4!

Recommendation

Long-acting liquid coolant

B d

-25 -35 -45

Brand

-25 -35 -45

above-25 above -35 above-45

Applied

temperature

above-25 above -35 above-45

2. Lubricating system

1Check the height of oil level before drive every day.

2How to check? The vehicle is parking on the plain road, before

start or stop for 15 minutes till the engine cools, pull out oil dipstick to

check oil level: When the level is below the lower limit of oil dipstick or

above the upper limit, its forbidden to start the engine.

Before replace oil, firstly, loosen the whorl plug at the bottom of oil pan.

After used oil is drained out tighten the plug Then open the oil filling cap After used oil is drained out, tighten the plug. Then open the oil filling cap

to fill CF-4 oil up to the limit required, then tighten the cap.

upper limit

lower limit

The position of oil filling inlet

oil filling inlet of 1st

li d k cylinder rocker arm

cover

WP6/WP10/WP12 series WP12 series

Recommend CF-4 oil to be used in Landking Eurodiesel engines. High

quality oil is allowed to replace low quality oil. The specification of common oil is

as follows:

Viscosity grade

0W-30 5W-30 10W-30 15W-40 20W-50

Applied

temperature

-40

30

-30

35

-2535 -2040 -1550

Please use right oil according to ambient temperature,

otherwise, engine trouble can occur.

Notice: WP10 diesel engine must use CF 15W/40 oil.

Common sense: performances of different brands of oil at the

temperature of -35C

0W-30

5W-30

10W-30 10W-40 15W-40

3. Fuel supply system

Landking Euro

diesel engines

apply high

pressure CR made

by Bosh and parts by Bosh, and parts

of the main

systems as the

right Figure:

common rail

high pressure

fuel pump

fuel injector

ECU

fuel filter

3.1Deflating Air from Fuel Supply System

Mixed air-fuel in the low pressure fuel passage could possibly be

caused by new engines, old engines not used for a long time, or fuel

tank empty pipe leakage which can result in difficult starting tank empty, pipe leakage, which can result in difficult starting.

Therefore, deflating air by hand before start is necessary as the

following way:

3.1Deflating Air From Fuel Supply System

1.Make sure enough fuel in the tank before 1.Make sure enough fuel in the tank before

deflate air.

2.loosen deflating bolt (refer to the right 2.loosen deflating bolt (refer to the right

Figure ).

3.Press hand pump until no air bubble 3.Press hand pump until no air bubble

spraying out from the deflating bolt.

4.Tighten deflating bolt then start the engine 4.Tighten deflating bolt, then start the engine.

Dont overexert loosening or tightening deflating bolt, so

as to avoid damaging.

Special Attentions: Special Attentions:

1.Dont forcibly start engine by the starter before deflate air from the low pressure fuel

passage, otherwise, the electric system could be damaged, and the starter even

could be burnt out.

2.Fuel must be filled in when fuel pointer reaches the red warning line, 2. p g ,

otherwise, air could easily penetrate into the fuel passage.

3.2Drain Water from Fuel Pre-filter

If theres water in the fuel supply system, high pressure fuel pump and fuel

injector could be easily damaged or invalidated. injector could be easily damaged or invalidated.

Pl i di ll i t h th th Please periodically inspect whether theres

water in the filter cup of pre-filter or not,

so as to drain water in time

drain water from water

collector collector

3.2Drain Water from Fuel Pre-filter

The method to drain water :

1. Open drain plug (2) at the bottom of water collector (1) to drain off water;

2. Tighten the drain plug again 2. Tighten the drain plug again.

Lightly loosen or tighten the plastic

plug so as to prevent it fromdamaging plug, so as to prevent it from damaging.

Special Attention:

Because of fuel quality differences in different places,

b t t h d i i l t l i t th t

drain water from

about two-hour driving later, please inspect the water

level of water collector after refill fuel.

drain water from

water collector

3.3 Fuel Selection

Theres no more special requirements about fuel quality for

Landking Euro III diesel engines than that for

mechanical pump diesel engines. Please try your best

to avoid using low quality fuel ! g q y

Special Attention:

Recommend using qualified fuel to guarantee

p

Recommend using qualified fuel to guarantee

the quality of fuel filled.

Common sense

40 30 20 10 0 10 20 30 40

8 5#

ambient temp.

4

0#

-5

-10#

-5

-20#

35#

10#

-14

-29

-35#

-50#

-29

-45

Fuel brand doesnt mean the ambient temperature the fuel can fit, but the freezing

point at which the fuel cant flow under certain temperature.

4. Electrical System

Landking Euro III diesel engines are with ECU, sensors and electrically controlled fuel

injectors, etc. Too high voltage or current can damage electrical system. Generators of

Landking Euro III series diesel engines, with rated voltage of 28v,have transistor

regulators (breakdown diode) Therefore please pay attention to the following aspects regulators (breakdown diode). Therefore, please pay attention to the following aspects

when electrically weld whole vehicle:

Cut off electricity supply before weld;

Special generators for Landking Euro III engines must be used. Special generators for Landking Euro III engines must be used.

1Close the control switch of battery, and cut

off negative electrode of battery jar.

2 Pull out the wiring harness connecter connecting

with ECU.

Pull out the collector as the following g

steps:

push aside the locking slice of

collector, and press it into its bottom. p

pull out the collector.

Dont shake to avoid ECU stitch bending.

Identify positive and negative electrode of electricity supply when connect

ECU with electricity supply to avoid ECU burning out.

3Welding operation

4Plug into the wiring harness collector connecting

with ECU with ECU.

plug into the collector in the following steps:

Gently and properly put the collector in the ECU groove and Gently and properly put the collector in the ECU groove, and

press it into its bottom;

Shut down the locking slice.

Notice: Not allowed to frequently pull out and plug the ECU

collector, thereby avoiding influencing message connecting of

ECU ECU.

5Connect negative electrode of battery jar, open the

control switch of battery.

When pull out or plug ECU, pay attention to :

Must cut off electricity supply for ECU

before pull out or plug ECU. Dont touch ECU

stitch by hand. stitch by hand.

Dont forcibl dra electrical ire of hole Dont forcibly draw electrical wire of whole

vehicle or electric wiring harness. Hold the

disconnection locking buckle when need to

disconnect connectors Dont drawthe disconnect connectors. Dont draw the

electrical wire against damaging.

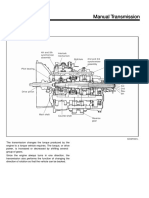

5. Mechanical transmission

system

Inspect mechanical transmission system of

external diesel engines before running external diesel engines before running,

such as tensity and wearing of the belt.

Belt can be automatically tightened through

tension pulley. Press belt by hand to check

tension of the belt.

fan bracket fan bracket

adding grease inlet

Maintenance for Diesel Engines g

P i ff i l l i lif f di l i Proper maintenance can effectively prolong service life of diesel engines,

decrease trouble rate and reduce cost.

Maintenance contents : Maintenance contents :

Replace fuel filter element and oil filter element;

Clean and check air filter element. Replace it every 5 times of cleaning.

Maintenance interval: Maintenance interval:

Maintenance should be done in time at Landking Euro service stations

accordingto the following requirements: according to the following requirements:

1 Truck 1. Truck

Maintenance for highway trucks according to the following

standard: standard:

l d t d l d t d l d load rated load rated load

1

st

maintenance

New vehicle run 3000 km or for 50hrs

periodical

maintenance

Every 40000km or

500hrs

Every 30000km or

500hrs

maintenance

500hrs 500hrs

Maintenance for non-highway truck (including cement mixing vehicle) according to the

following standard:

load

rated load rated load

1

st

maintenance

New vehicle run for 50hrs or 3000kms

periodical

maintenance

Every 300hrs or

20000km

Every 200hrs or 15000km

maintenance 20000km

2. Bus 2. Bus

Maintenance for bus (city bus, dedicated bus for workers )according to the

followingstandard: following standard:

1st

i t

New vehicle run 50hrs or 3000km

maintenance

New vehicle run 50hrs or 3000km

i di l periodical

maintenance

Every 300hrs or 20000km

Maintenance for passenger bus, sight seeing bus according to the

followingstandard: following standard:

1st

i t

New vehicles run 3000km or 30hrs

maintenance

New vehicles run 3000km or 30hrs

periodical

maintenance

Every 30000km or 300hrs

maintenance

3. Construction Machinery 3. Construction Machinery

Maintenance for loader, excavating machine, road roller and crane, etc

according to the following standard:

1st

maintenance

New vehicle run for 50hrs or 3000km

periodical

maintenance

Every 200hrs or 10000km

Special attention: Please properly shorten periodical

maintenance interval or mileage under severe work condition.

Operators of diesel engines must carefully read Operation and

Maintenance Manual, and well understand the structure of diesel Maintenance Manual, and well understand the structure of diesel

engines, strictly comply with the operation and maintenance

stipulated in the Operation and Maintenance manual.

Based on the maintenance requirements stipulated in the manual,

please periodically inspect diesel engines and replace oil in

accordance with work condition.

Maintenance Guide for Landking Euro Diesel Engines

Maintenance on mechanical system of Landking Euro Diesel Engines is

i il ith th t f E II similar with that of Euro II.

For the trouble on electronically controlled system of Landking Euro Diesel

Engines users may go to Wei Chai Euro maintenance station nearby Dont Engines, users may go to Wei Chai Euro maintenance station nearby. Dont

dismantle or repair fuel supply system and electronically controlled system

privately, so as to avoid unnecessary loss.

Special attention:

When repair or replace components of diesel engines, pay attention

to :

Landking Euro III series diesel engines have high performance, therefore,

maintenance should be done in accordance with Maintenance Manual and Parts

C t l f W i Ch i P L dki E III i di l i Pl Catalogue of Wei Chai Power Landking Euro III series diesel engines. Please

purchase special fittings to ensure the performance, reliability and service life

of diesel engines of diesel engines.

Attention points for operating diesel engines

1. Accelerator Pedal Operation of EuroDiesel Engines

L dki E di l i d t l t l t d l ith l t Landking Euro diesel engines adopt electro-accelerator pedal with electro-

structure sensor inside. Recommend that users placidly accelerate or decelerate

d h d i t ff ti f l i speed when drive to ensure more effective fuel-saving.

2. Time selection for shifting the gear

Operating points of diesel engines influence fuel economy, but gear selection when

drive also has a great impact on fuel saving. Generally, high gear saves fuel. g p g y, g g

AShift the first gear to start.

BBefore shift high gear, the speed of diesel engines should be accelerated

to about 1200 r/min.

2. Time selection for shifting the gear

CIn order to avoid high speed, but low gear, should positively shift high gear to

make diesel engines run at the range of economical speed if work condition make diesel engines run at the range of economical speed if work condition

permitted.

Special Attention: For mechanical gear-box, whole vehicle matched with Special Attention: For mechanical gear box, whole vehicle matched with

Landking Euro III diesel engines stop injecting fuel when sliding with shifting the

gear, which is more fuel-saving than that when sliding with neutral gear.

3. Economical Speed of Diesel Engines

diesel engine

economical speed

diesel engine

series

economical speed

WP6

1200-1800

WP10WP10N

1100-1600

WP12WP12N

1100 1600

WP12WP12N

1100-1600

4.Usage of WEVB

Recommend to use WEVB when run downward the

long slope ( WeiChai patent of safety brake system long slope ( WeiChai patent of safety brake system

for engines)

WEVB is controlled by electronically controlled unit.

When WEVB works, the diesel engine doesnt inject

fuel to save fuel.

WEVB cant work when the speed of diesel engines is less

than 800 r/min.

Four Special Attentions for Landking Euro III Diesel Engine Service of

Wei Chai Power

Forcible Maintenance Suggestion--- Forcible Maintenance should be done by Euro

III maintenance station of WeiChai Power in accordance with relevant requirements;

Maintenance Suggestion---Maintenance should be done by Euro III

maintenance station of WeiChai Power;

Fittings Suggestion--- Use special fittings provided byEuro III maintenance Fittings Suggestion--- Use special fittings provided byEuro III maintenance

station of Wei Chai Power;

Oil Suggestion--- Use special oil for Landking Euro III diesel engines provided by

exclusive agency of fittings.

The way of maintenance for Landking

WP10 di l i WP10 diesel engines

49

1Replace Oil and Oil Filter

Replace the oil and oil filter to clean the impurities containing in oil.

Note: The oil should be drained off when it is hot

Tool:32mm open-ended wrench

Remove the whorl plugprepare a container to collect 24L of oil

NoteHot oil can injure people.

50

1Replace Oil and Oil Filter

Tool: The special wrench for filter.

Clean the end surrounding of the filterand remove it Clean the end surrounding of the filterand remove it.

Install the ne oil filter Install the new oil filter

NoteAdjust the seal ring and

smear some lubricating oil on it while

fitting the oil filter.

51

1Replace Oil and Oil Filter

Tool:32mm open-ended wrench

Check and clean the screwthread Check and clean the screw thread

and seal ringand then install the whorl plug.

Fill th l il t th Fill the clean oil up to the upper

limitthe capacity of the oil sump is 24L

NoteSTEYR engine must use CF-4 15W/40 oil

52

1Replace Oil and Oil Filter

Run the engine at idling speed

and check the filter to find whether and check the filter to find whether

it leaks or not

Stop the engine and make the

oil run into the sump from the upper

parts 5 minutes laterthen check

the oil levelfill oil up to the upper

limit if necessary limit if necessary

53

2 Check and adjust the valve clearance

Check and adjust the valve clearance

Tool13mmsleeve wrench Tool13mm sleeve wrench

Disassemble 6 cylinder head covers

Tool 3 2 mm wrench for turning the crankshaft

T th fl h l til it l d th k it Turn the flywheel until its scale and the mark on its

housing are aligned, push the piston to the position

of TDC of compression stroke of 1st cylinder p y

(the intake and exhaust valve of 1 cylinder are closed)

54

2Check and adjust the valve clearance

ToolClearance gauge

The clearance of intake valve is0 30mm The clearance of intake valve is0.30mm

The clearance of exhaust valve is 0.40mm

The clearance for WEVB system is0.25mm.

Note: When check the clearance of valvethe engine should be at the cool

condition-its temperature is less than 60.When the clearance guage glides condition its temperature is less than 60.When the clearance guage glides

between the top of valve rod and rocker arm and can be felt retarded and

stickythe measuring result is proper

55

2Check and adjust the valve clearance

After WEVB system is used, the adjustment method of exhaust valve clearance is

as follows (see Fig. 2 for part serial numbers) ( g p )

1. Valve clearance adjusting nut 2. Regulating bolt assembly 3. Exhaust valve

rocker arm assembly 4. Steel ball 5. Valve rocker arm piston 6. Rocker arm

i t i 7 N dl 8 B ll l i 9 V l k t bl piston spring 7. Needle 8. Ball valve spring 9. Valve rocker arm seat assembly

10. Valve clearance adjusting screw 11. Hexagonal bolt 12. Support arm

56

2Check and adjust the valve clearance

1The cylinder piston to be adjusted is located on the top dead center of the

compression travel. p

2As shown in Fig. 2, loosen No. 2 adjusting bolt assembly. In case that the oil

seal plane of exhaust valve rocker armis not pressed first by using No 10 valve seal plane of exhaust valve rocker arm is not pressed, first by using No. 10 valve

clearance

adjusting screw at the push rod end, adjust the total valve clearance to 0.4mm. Tighten

h k t check nut.

57

2Check and adjust the valve clearance

Fig. 2 Total Valve Clearance of Cold-State Fig. 3 End Valve Clearance of

Cold-State Exhaust Valve 0.4mm Exhaust Valve 0.25mm

58

2Check and adjust the valve clearance

3Then as shown in Fig. 3, insert the clearance gauge between No. 5 valve

rocker arm rocker arm

piston and the exhaust valve rod end or valve rod cap. By turning No.2 regulating

bolt, adjust the valve clearance to 0.25mm. Tighten check nut.

C ti D i dj t t t N 2 l ti b lt til l i Caution: During adjustment, turn No. 2 regulating bolt until clearance gauge is

clamped so that No. 5 valve rocker arm piston is pressed to its bottom. There is not

clearance between No.5 valve rocker arm piston and the piston installation hole

bottom plane in exhaust valve rocker arm.

59

2Check and adjust the valve clearance

Tools6#screwdriver and14mm double offset ring wrench

The piston of 1st cylinder is at TDC of the compression stroke The piston of 1st cylinder is at TDC of the compression stroke

Check and adjust the valve clearance as step A(I-air intake Valve E-air Exhaust valve)

Adjust the clearance by gauge and tighten the fixing nut of rocker armre-check

th l till it t th i t the clearance till it meets the requirement

Step A

60

2Check and adjust the valve clearance

Turn the crankshaft 360by

the spannerit can also be turned the spannerit can also be turned

360after marking on the vibration damper.

Adj t th l l t B Adjust the valve clearance as step B

Loosen the fixing nut of rocker g

armadjust the clearance by gauge

then tighten the nut again .

61

2Check and adjust the valve clearance

Tool:13mm sleeve wrench

Install the gasket and cylinder head cover Install the gasket and cylinder head cover.

The tightening torque of bolt is

23Nm(recommended).

R l f l filt l t Replace fuel filter element

Replace fuel filter element in the following steps:

Dismantle the old fuel filter element. Remove

the water collector installed on coarse filter if reused.

62

3Replace fuel filter element

Lubricate the seal lips.

Turn the filter by hand until the Turn the filter by hand until the

seal is closed with interface.

Continue to turn the filter with hands until the filter is installed solidly (about

turns),

63

3Replace fuel filter element

E. Deflate until there is no bubble.

F. Start Engine.

G. Conduct leakage test.

H. Retighten when necessary H. Retighten when necessary

64

4 Check the air filter element

Check the air filter element

The maximumair intake resistance of the engine The maximum air intake resistance of the engine

should be 7kPa and inspection should be done at the

rated speed and full load. When the resistance reaches

th i li it ll d th i filt l t h ld the maximum limit allowedthe air filter element should

be cleaned or replaced as per the maintenance guide from

the manufacture.

65

4 Check the air filter element

Caution

Don't blow off the air filtering paper

Don't clean the air filteringpaper by water and oil

D 't b t th f ibl Don't beat the core forcibly

66

4Check the air filter element

Notelt is not allowed to use the engine without air filter otherwise the dust Notelt is not allowed to use the engine without air filterotherwise the dust

and impurity will cause early wearing of the engine.

R th filt f th i filt l t d b t th id f th l t Remove the filter core from the air filter element and beat the side of the element

lightly to make dust fall down, or blow the element backward (blow back from

inside to outside) by compressed air

67

S-ar putea să vă placă și

- AVM2-PC EnglishDocument8 paginiAVM2-PC English賴小辰Încă nu există evaluări

- Sistema Inyección CR BoschDocument8 paginiSistema Inyección CR BoschRodolfo Leiva100% (1)

- WP10series Manual PDFDocument127 paginiWP10series Manual PDFnguyenmanhquanÎncă nu există evaluări

- QY50V532 - Chasis Electrical SystemDocument24 paginiQY50V532 - Chasis Electrical SystemYulianto JoeÎncă nu există evaluări

- Tencreng0003 Ecu ControlDocument24 paginiTencreng0003 Ecu ControlAly AbdelhamedÎncă nu există evaluări

- Product Data Sheet High Pressure SensorDocument2 paginiProduct Data Sheet High Pressure SensorAntonino ScordatoÎncă nu există evaluări

- Weichai Power Euro III Engine Trouble Case濰柴动力欧三发动机案例 PDFDocument182 paginiWeichai Power Euro III Engine Trouble Case濰柴动力欧三发动机案例 PDFnay hlaing Soe100% (1)

- ETLZ0802Document2 paginiETLZ0802SoeAyeÎncă nu există evaluări

- ZOOMLION Electrical Systems GuideDocument24 paginiZOOMLION Electrical Systems GuideYulianto JoeÎncă nu există evaluări

- Injector Controller: Fuel TankDocument9 paginiInjector Controller: Fuel TankJemmy Anggara100% (2)

- Chassis Drawings SpecsDocument18 paginiChassis Drawings SpecsJordy PerezÎncă nu există evaluări

- Hit Fuel System PDFDocument22 paginiHit Fuel System PDFLinzaw OoÎncă nu există evaluări

- Dokumen - Tips - Bomba Ve VRZ Ee14e 11162 VRZ Service ManualDocument117 paginiDokumen - Tips - Bomba Ve VRZ Ee14e 11162 VRZ Service ManualAntonio GasparÎncă nu există evaluări

- 1996-2001 Fuso - Manual TransmissionDocument126 pagini1996-2001 Fuso - Manual TransmissionEliecer Bayona100% (1)

- Common Rail System Diesel Engine Technology PDFDocument26 paginiCommon Rail System Diesel Engine Technology PDFFedima100% (1)

- Weichai Power Euro III Engine Trouble Case濰柴动力欧三发动机案例 PDFDocument182 paginiWeichai Power Euro III Engine Trouble Case濰柴动力欧三发动机案例 PDFnay hlaing SoeÎncă nu există evaluări

- Howo A7 Cam Nang Sua Chua Dien00019Document1 paginăHowo A7 Cam Nang Sua Chua Dien00019manhÎncă nu există evaluări

- Nanni 5.25 Base EngineDocument211 paginiNanni 5.25 Base EnginecarylangleyÎncă nu există evaluări

- What Is Common-RailDocument30 paginiWhat Is Common-RailHari KrismantoÎncă nu există evaluări

- The Key Process of Disassembling and Assembling WP12 Diesel EngineDocument40 paginiThe Key Process of Disassembling and Assembling WP12 Diesel EnginePaul100% (1)

- Basic Info TrukDocument10 paginiBasic Info TrukAxel Mahya AvichenaÎncă nu există evaluări

- Composition and Construction of ECD-V3 Pump SystemDocument4 paginiComposition and Construction of ECD-V3 Pump SystemВячеслав ГлушакÎncă nu există evaluări

- Bab 2 ActuatorDocument31 paginiBab 2 ActuatorKusnun Riyanto100% (2)

- Fuel Injection Systems GuideDocument8 paginiFuel Injection Systems GuideGONTONI100% (1)

- Group 13eb Electronically Controlled Fuel SystemDocument23 paginiGroup 13eb Electronically Controlled Fuel SystemclaudiosilvahÎncă nu există evaluări

- Hino 500 Series - Medium Duty Trucks DetailsDocument3 paginiHino 500 Series - Medium Duty Trucks DetailsJames ContiÎncă nu există evaluări

- Diesel Injection Pump COVEC-FDocument36 paginiDiesel Injection Pump COVEC-FOlman Sandoval100% (1)

- Training of WP12 Series Diesel Engine ofDocument267 paginiTraining of WP12 Series Diesel Engine ofВиталий Щур100% (1)

- Nissan Ud Cwm454 Mhra (Spec Eng) 1Document2 paginiNissan Ud Cwm454 Mhra (Spec Eng) 1Stefanus Tedy0% (1)

- SR 300L Im e PDFDocument233 paginiSR 300L Im e PDFrendi prediantoÎncă nu există evaluări

- Common Rail Tencreng0005Document10 paginiCommon Rail Tencreng0005JAVIER ESPINOSAÎncă nu există evaluări

- DTC P0200-97 Injector Circuit - Open PDFDocument9 paginiDTC P0200-97 Injector Circuit - Open PDFMortada AlsonniÎncă nu există evaluări

- Hyundai Engine D6AB LubricationDocument16 paginiHyundai Engine D6AB LubricationBigfair HD78Încă nu există evaluări

- Bk2q-9k546-Ag 20190701 143833Document2 paginiBk2q-9k546-Ag 20190701 143833คุณชายธวัชชัย เจริญสุขÎncă nu există evaluări

- Basic Hydraulic Oil Flow For Curent Model of Kobelco CraneDocument79 paginiBasic Hydraulic Oil Flow For Curent Model of Kobelco CranePHÁT NGUYỄN THẾ100% (2)

- TR-160M Rough Terrain Crane SpecificationsDocument14 paginiTR-160M Rough Terrain Crane SpecificationsMatías Ezequiel GuardiaÎncă nu există evaluări

- 05 Toyota - 5FG 5 8Document8 pagini05 Toyota - 5FG 5 8Edwin NgÎncă nu există evaluări

- Mitsubishi 6D16-TE1 Diesel Engine SpecsDocument4 paginiMitsubishi 6D16-TE1 Diesel Engine SpecsRichart TPÎncă nu există evaluări

- Fuel Injection Pumps, In-LineDocument24 paginiFuel Injection Pumps, In-LineJose Luis CristanchoÎncă nu există evaluări

- Ar-1000m-1-90101 5 Boom + Jib RTF100-4: PH1 710001 - 00 DisplayDocument2 paginiAr-1000m-1-90101 5 Boom + Jib RTF100-4: PH1 710001 - 00 DisplaySaraiva EquipamentosÎncă nu există evaluări

- Diesel Injection Pump Service Manual: Hino E13C Common Rail SystemDocument23 paginiDiesel Injection Pump Service Manual: Hino E13C Common Rail SystemZawzaw HahaooÎncă nu există evaluări

- ECD-V4 System ExplainedDocument4 paginiECD-V4 System ExplainedВячеслав ГлушакÎncă nu există evaluări

- Fuel Injection Pump Technical Hint for Land CruiserDocument45 paginiFuel Injection Pump Technical Hint for Land CruiserВячеслав ГлушакÎncă nu există evaluări

- RSUDocument12 paginiRSUtomallor101100% (1)

- Service Manual Nissan PDFDocument39 paginiService Manual Nissan PDFayi darwisÎncă nu există evaluări

- Injector Pulse WidthDocument3 paginiInjector Pulse Widthmsaad19103564100% (1)

- d8r Aka00430Document49 paginid8r Aka00430jose67% (3)

- HP0 DENSO Fuel Injection Pump Replacement 2004 With CTFDocument6 paginiHP0 DENSO Fuel Injection Pump Replacement 2004 With CTFDenisEcheverri100% (1)

- Engine Specs Specification (Engine Mechanical (H4Dotc 2.5L Dohc Turbo) : General Description)Document14 paginiEngine Specs Specification (Engine Mechanical (H4Dotc 2.5L Dohc Turbo) : General Description)Cristobal MedinaÎncă nu există evaluări

- HP4 high-pressure compact pump overviewDocument4 paginiHP4 high-pressure compact pump overviewpepeladazoÎncă nu există evaluări

- Q Series Owner ManualDocument200 paginiQ Series Owner Manualefmartin21Încă nu există evaluări

- Howo A7 Cam Nang Sua Chua Dien00001Document1 paginăHowo A7 Cam Nang Sua Chua Dien00001manhÎncă nu există evaluări

- Manual Transmission Hyundai HeavydutyDocument82 paginiManual Transmission Hyundai HeavydutyBui Xuan DucÎncă nu există evaluări

- Manual de Emsamble RE4SDocument130 paginiManual de Emsamble RE4SJavier15818Încă nu există evaluări

- automobileTechnologyPresentation - Suzuki PDFDocument30 paginiautomobileTechnologyPresentation - Suzuki PDFvivekpattni100% (3)

- Maintenance For Landking WP10 Euro III Diesel EnginesDocument67 paginiMaintenance For Landking WP10 Euro III Diesel EnginesHải TiếnÎncă nu există evaluări

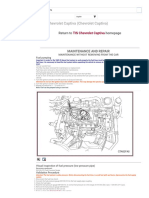

- Chevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.Document57 paginiChevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.krisdiarto@gmail.com96% (23)

- Oh LolDocument5 paginiOh Lolrhomel hamoyÎncă nu există evaluări

- Fuel System: SectionDocument18 paginiFuel System: SectionMihai IavorschiÎncă nu există evaluări

- Generator SetDocument30 paginiGenerator Setkash30Încă nu există evaluări

- 8.5. Mobilube LS 85W-90 InglesDocument2 pagini8.5. Mobilube LS 85W-90 InglesJeefÎncă nu există evaluări

- 28.3. Mobil Permazone Ready To UseDocument2 pagini28.3. Mobil Permazone Ready To UseJeefÎncă nu există evaluări

- Mobilgard ADL SeriesDocument2 paginiMobilgard ADL SeriesJeefÎncă nu există evaluări

- Mobilgrease 28Document2 paginiMobilgrease 28Jeef100% (1)

- Off-Highway Bumper To Bumper Brochure V13 Final Approved 06-02-10Document28 paginiOff-Highway Bumper To Bumper Brochure V13 Final Approved 06-02-10rafaelcardena73Încă nu există evaluări

- Exxon Aviation Oil EEDocument2 paginiExxon Aviation Oil EEJeefÎncă nu există evaluări

- Mobil Avrex S Turbo 256Document2 paginiMobil Avrex S Turbo 256JeefÎncă nu există evaluări

- Mobil Jet Oil IIDocument2 paginiMobil Jet Oil IIJeefÎncă nu există evaluări

- Mobil Avrex S Turbo 256Document3 paginiMobil Avrex S Turbo 256JeefÎncă nu există evaluări

- 8.5. Mobilube LS 85W-90 InglesDocument2 pagini8.5. Mobilube LS 85W-90 InglesJeefÎncă nu există evaluări

- Mobilgard 450Document2 paginiMobilgard 450Jeef100% (1)

- Varnish Formation 2007Document6 paginiVarnish Formation 2007JeefÎncă nu există evaluări

- Mobil Avrex S Turbo 256Document2 paginiMobil Avrex S Turbo 256JeefÎncă nu există evaluări

- Luneta MirillaDocument2 paginiLuneta MirillaJeefÎncă nu există evaluări

- Mobil SHC™ Gear SeriesDocument4 paginiMobil SHC™ Gear SeriesJeefÎncă nu există evaluări

- 21.1. Mobilarma 798 InglesDocument2 pagini21.1. Mobilarma 798 InglesJeefÎncă nu există evaluări

- Fix The Weak Link - SamplingDocument16 paginiFix The Weak Link - SamplingJeefÎncă nu există evaluări

- Mobil SHC™ Gear SeriesDocument4 paginiMobil SHC™ Gear SeriesJeefÎncă nu există evaluări

- Filter Debris Analysis Report: CriticalDocument2 paginiFilter Debris Analysis Report: CriticalJeefÎncă nu există evaluări

- Fix The Weak Link - SamplingDocument16 paginiFix The Weak Link - SamplingJeefÎncă nu există evaluări

- Monitoring Machine Wear with Oil Analysis AlarmsDocument8 paginiMonitoring Machine Wear with Oil Analysis AlarmsJeefÎncă nu există evaluări

- Mobiltrans-Hd-30 Numero Cas ModeloDocument9 paginiMobiltrans-Hd-30 Numero Cas ModeloJeefÎncă nu există evaluări

- 60 Question For Lube SuppliersDocument12 pagini60 Question For Lube SuppliersJeefÎncă nu există evaluări

- TT Turbine Oil Condition Monitoring Training Guide PDFDocument8 paginiTT Turbine Oil Condition Monitoring Training Guide PDFalvaedison00Încă nu există evaluări

- Arte Alta Folleto MobilDocument2 paginiArte Alta Folleto MobilJeefÎncă nu există evaluări

- Normas Especiales para HidraulicosDocument8 paginiNormas Especiales para HidraulicosJeefÎncă nu există evaluări

- Normas Especiales para HidraulicosDocument8 paginiNormas Especiales para HidraulicosJeefÎncă nu există evaluări

- What Is A Diesel EngineDocument2 paginiWhat Is A Diesel EngineAdefila Sunday DadaÎncă nu există evaluări

- Generator Fuel System GuideDocument4 paginiGenerator Fuel System GuidebejoythomasÎncă nu există evaluări

- 02 - N63 Engine - WBDocument82 pagini02 - N63 Engine - WBivanper100% (1)

- Hino K13D T Engine Workshop ManualDocument230 paginiHino K13D T Engine Workshop ManualАндрей100% (3)

- MAN B&W MC Engine VIT Fuel Pump OperationDocument6 paginiMAN B&W MC Engine VIT Fuel Pump OperationArun S100% (1)

- D3E800A4765-Engine Mechanical Fuel Injection and IgnitionDocument515 paginiD3E800A4765-Engine Mechanical Fuel Injection and IgnitionVitor SegniniÎncă nu există evaluări

- YAMAHA - Crypton 110 T110 E - 2005 A 2006Document57 paginiYAMAHA - Crypton 110 T110 E - 2005 A 2006MiguelAmaya100% (2)

- Touareg Component LocationsDocument18 paginiTouareg Component LocationskikoÎncă nu există evaluări

- Daihatsu DL 22Document10 paginiDaihatsu DL 22prakash buddhdev100% (1)

- 2004-01-1790 Developed Technologies of The NewDocument13 pagini2004-01-1790 Developed Technologies of The NewRicÎncă nu există evaluări

- Engine Mechanical: SectionDocument145 paginiEngine Mechanical: SectionskpppÎncă nu există evaluări

- Carburetor Marvel Schebler PartsDocument22 paginiCarburetor Marvel Schebler PartsAnderson RamalhoÎncă nu există evaluări

- Perkins New 1000 Series Engine Workshop ManualDocument290 paginiPerkins New 1000 Series Engine Workshop Manualperzaklie100% (4)

- Adjust Valve C9Document3 paginiAdjust Valve C9JebrodÎncă nu există evaluări

- Balancing of Radial and V-Shape Engine by Ijaz AliDocument20 paginiBalancing of Radial and V-Shape Engine by Ijaz AliMuhammad QasimÎncă nu există evaluări

- Japan Engine CatalgoDocument40 paginiJapan Engine CatalgoKarim Sowley DelgadoÎncă nu există evaluări

- Service Manual Trucks: Specifications, D12B D12B-345 D12B-385 D12B-425Document34 paginiService Manual Trucks: Specifications, D12B D12B-345 D12B-385 D12B-425golf1991Încă nu există evaluări

- K - Series EngineDocument10 paginiK - Series EngineMubeen Ahmed SiddiqueÎncă nu există evaluări

- Bravo Service Manual Part 1Document544 paginiBravo Service Manual Part 1carlsdigaround100% (2)

- Propulsion Engineering ME462Document2 paginiPropulsion Engineering ME462Husni mubsshirÎncă nu există evaluări

- Report Engine TestDocument53 paginiReport Engine TestAlexander AgafonoffÎncă nu există evaluări

- B Series Engine Training Torque Pt.1Document14 paginiB Series Engine Training Torque Pt.1Tri KinartoÎncă nu există evaluări

- Especificação Do Motor NORBE VIDocument2 paginiEspecificação Do Motor NORBE VIGuto MarvilaÎncă nu există evaluări

- MERCEDES P1XXX CODES Gas and Diesel PDFDocument7 paginiMERCEDES P1XXX CODES Gas and Diesel PDFAperc Taini Glbrt RmxÎncă nu există evaluări

- Ngk-Spark Plug - Ruthenium PDFDocument2 paginiNgk-Spark Plug - Ruthenium PDFPradeep Kumar SwarnkarÎncă nu există evaluări

- Supercharger ReportDocument24 paginiSupercharger ReportRohit RajÎncă nu există evaluări

- Industrial Diesel Engine: 1996 EPA and CARB Non-Road Emissions CertifiedDocument2 paginiIndustrial Diesel Engine: 1996 EPA and CARB Non-Road Emissions Certifiedporter1980Încă nu există evaluări

- Mazda R26B US - PDF (Recovered)Document20 paginiMazda R26B US - PDF (Recovered)Paul DumitruÎncă nu există evaluări

- High-Pressure Common-Rail Fuel InjectionDocument6 paginiHigh-Pressure Common-Rail Fuel InjectionAndi Anzar0% (1)

- 1st Shipment DELIVERY NOTE A80689Document2 pagini1st Shipment DELIVERY NOTE A80689Vu Duc QuangÎncă nu există evaluări