Documente Academic

Documente Profesional

Documente Cultură

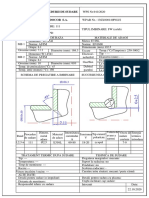

Body Flanges On Shells

Încărcat de

Padmanabhan Venkatesh0 evaluări0% au considerat acest document util (0 voturi)

91 vizualizări2 paginiASME U Form. Edition 2013

Titlu original

BPVC_VIII-1_U-1A

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentASME U Form. Edition 2013

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

91 vizualizări2 paginiBody Flanges On Shells

Încărcat de

Padmanabhan VenkateshASME U Form. Edition 2013

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

(Yes or no) (Number) (Number) (Describe) (Where and how)

10. Nozzles, inspection, and safety valve openings:

11. Supports: Skirt

12. Remarks: Manufacturers Partial Data Reports properly identified and signed by Commissioned Inspectors have been furnished for the following

items of the report:

Lugs Legs Other Attached

(Material spec. number, grade)

(Spec. no., grade) (Spec. no., grade)

[Long. (welded, dbl., sngl., lap, butt)] (No. of courses) (Eff., %) (Eff., %) [R.T. (spot

or full)]

(Time, hr) (H.T. temp.) [R.T. (spot or full)] [Girth (welded, dbl., sngl., lap, butt)]

(Corr. allow.) (Nominal thickness) (Inner diameter) [Length (overall)]

6. Shell

7. Seams

8. Heads: (a) Material (b) Material

(Internal) (Internal) (External) (External)

9. MAWP at max. temp.

Min. design metal temp.

. Hydro., pneu., or comb. test pressure .

.

at

Location (Top,

Bottom, Ends)

Minimum

Thickness

Corrosion

Allowance

Crown

Radius

(a)

(b)

Knuckle

Radius

Elliptical

Ratio

Conical

Apex Angle

Hemispherical

Radius

Flat

Diameter

Side to Pressure

(Convex or Concave)

Proof test .

FORM U-1A MANUFACTURER'S DATA REPORT FOR PRESSURE VESSELS

(Alternative Form for Single Chamber, Completely Shop or Field Fabricated Vessels Only)

As Required by the Provisions of the ASME Boiler and Pressure Vessel Code Rules, Section VIII, Division 1

(Name of part, item number, Manufacturers name and identifying stamp)

(04/14)

5. ASME Code, Section VIII, Div. 1

(Code Case number) [Special service per UG-120(d)] [Edition and Addenda, if applicable (date)]

1. Manufactured and certified by

(Name and address of Manufacturer)

2. Manufactured for

(Name and address of Purchaser)

3. Location of installation

(Name and address)

Mfr. Representative: Date:

Authorized Inspector: Date:

National Board Number:

Num & Size

Washer

(OD, ID, thk)

Washer Material Flange Thk

Body Flanges on Shells

Bolting

No. Location Min Hub Thk Bolting Material Type Material How Attached ID OD

Washer

(OD, ID, thk) Washer Material

(a)

(b)

Type ID OD Material

Bolting

Body Flanges on Heads

Location How Attached Flange Thk Min Hub Thk Num & Size Bolting Material

Purpose

(Inlet, Outlet,

Drain, etc.)

Diameter

or Size

Type

Reinforcement

Material

Location

(Insp. Open.)

Material Nozzle Thickness Attachment Details

No. Nozzle Flange Corr. Nom. Nozzle Flange

(CRN) (Drawing number)

(Horizontal or vertical, tank) (Manufacturers serial number)

(National Board number) (Year built)

4. Type

have inspected the component described in this Manufacturer's Data Report on , and state that,

to the best of my knowledge and belief, the Manufacturer has constructed this pressure vessel in accordance with ASME BOILER AND PRESSURE

VESSEL CODE, Section VIII, Division 1. By signing this certificate neither the Inspector nor his/her employer makes any warranty, expressed or

implied, concerning the pressure vessel described in this Manufacturer's Data Report. Furthermore, neither the Inspector nor his/her employer

shall be liable in any manner for any personal injury or property damage or a loss of any kind arising from or connected with this inspection.

CERTIFICATE OF SHOP/FIELD COMPLIANCE

CERTIFICATE OF SHOP/FIELD INSPECTION

expires

Date Co. name

.

Signed

(Manufacturer) (Representative)

We certify that the statements made in this report are correct and that all details of design, material, construction, and workmanship of this vessel

conform to the ASME BOILER AND PRESSURE VESSEL CODE, Section VIII, Division 1. U Certificate of Authorization Number

Vessel constructed by at

.

I, the undersigned, holding a valid commission issued by the National Board of Boiler and Pressure Vessel Inspectors and employed by

Date Signed

(Authorized Inspector) [National Board (incl. endorsements)]

Commissions

(04/14)

FORM U-1A (Back)

Mfr. Representative: Date:

Authorized Inspector: Date:

National Board Number:

S-ar putea să vă placă și

- Manufacturer Data ReportDocument3 paginiManufacturer Data Reporthaikal86100% (1)

- Standard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsedDocument4 paginiStandard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsednithyaÎncă nu există evaluări

- (Project Name) : Form No. (STR/ DS/ 0030)Document2 pagini(Project Name) : Form No. (STR/ DS/ 0030)Eyad RefaiÎncă nu există evaluări

- SAIC-W-2077 Weld Joint Identification SystemDocument1 paginăSAIC-W-2077 Weld Joint Identification Systemkarioke mohaÎncă nu există evaluări

- Nde Map & Nde Procedure (Sudah Di Revisi)Document4 paginiNde Map & Nde Procedure (Sudah Di Revisi)Hardika SambilangÎncă nu există evaluări

- QCF118 Steel Structure ErectionkDocument1 paginăQCF118 Steel Structure ErectionkminhnnÎncă nu există evaluări

- Working ITPDocument4 paginiWorking ITPStephen BoodooÎncă nu există evaluări

- Certificate of Origin Form F For China-Chile FTADocument2 paginiCertificate of Origin Form F For China-Chile FTAinspectormetÎncă nu există evaluări

- Daily Report-31 (Su Jinlong)Document3 paginiDaily Report-31 (Su Jinlong)sujinlongÎncă nu există evaluări

- PWHT Procedure For Petrol Steel - CoreDocument9 paginiPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluÎncă nu există evaluări

- Inspection and Test PlanDocument5 paginiInspection and Test Planmuhammad afrizalÎncă nu există evaluări

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument19 paginiASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplÎncă nu există evaluări

- QAP For PQR'S - For Impact TestingDocument3 paginiQAP For PQR'S - For Impact TestingDries VandezandeÎncă nu există evaluări

- PF-0004-009-QA-955-0001 Rev D Code 1Document27 paginiPF-0004-009-QA-955-0001 Rev D Code 1Rıdvan UyarÎncă nu există evaluări

- Welding Parameters Control PipelineDocument1 paginăWelding Parameters Control PipelinemusheerÎncă nu există evaluări

- Test Package - NEWDocument14 paginiTest Package - NEWDilshad AhemadÎncă nu există evaluări

- Lube Oil System Inspection Checklist: Section A - Customer DataDocument1 paginăLube Oil System Inspection Checklist: Section A - Customer DatangueadoumÎncă nu există evaluări

- Daily Fit-Up/Welding Inspection ReportDocument7 paginiDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamÎncă nu există evaluări

- Instrumentation and ControlsDocument2 paginiInstrumentation and ControlsTrí NguyễnÎncă nu există evaluări

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 paginiPackage 2s E0001 - Jupiter DCR 30-10-2021senthilÎncă nu există evaluări

- Icr-Pr-18 NDT ProcedureDocument4 paginiIcr-Pr-18 NDT ProcedureBauyrzhanÎncă nu există evaluări

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 paginiClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprÎncă nu există evaluări

- Hydrostatic Test Procedure For Ug Non-Metallic Piping SystemDocument16 paginiHydrostatic Test Procedure For Ug Non-Metallic Piping SystemabrayalamÎncă nu există evaluări

- G. Std. ITP For Pipeline Job PDFDocument4 paginiG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- Inspection Log Book PLMB - 040915Document42 paginiInspection Log Book PLMB - 040915Rahmad DesmanÎncă nu există evaluări

- Cold Tap Coating Report 2Document1 paginăCold Tap Coating Report 2Jamal BakhtÎncă nu există evaluări

- Itp TankageDocument7 paginiItp TankageIr FankovicÎncă nu există evaluări

- MD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFDocument8 paginiMD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFTran KhuynhÎncă nu există evaluări

- Receiving Material Procedure (Done) (Sudah Direvisi)Document8 paginiReceiving Material Procedure (Done) (Sudah Direvisi)Hardika SambilangÎncă nu există evaluări

- Contoh ItpDocument3 paginiContoh Itphafiz elektroÎncă nu există evaluări

- WPS Racord Intepat 2335Document1 paginăWPS Racord Intepat 2335Andrei UrsacheÎncă nu există evaluări

- 6001F Rev 07 Material, Fabrication and Installation StructureDocument83 pagini6001F Rev 07 Material, Fabrication and Installation StructurePatrickioÎncă nu există evaluări

- Inspection and Test Plan: PT. People MecDocument3 paginiInspection and Test Plan: PT. People MecHaryanto RÎncă nu există evaluări

- EM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFDocument37 paginiEM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFdang2172014Încă nu există evaluări

- Circularity Inspection Report: Shell Course (LW) CW CWDocument14 paginiCircularity Inspection Report: Shell Course (LW) CW CWaszlizaÎncă nu există evaluări

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 paginiProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarÎncă nu există evaluări

- TopCoreBelco 101 FCDocument9 paginiTopCoreBelco 101 FCCesar ArellanoÎncă nu există evaluări

- CV UpdateDocument8 paginiCV UpdateAlya Chyank San-sanÎncă nu există evaluări

- Request For NDT Test FormDocument1 paginăRequest For NDT Test FormJohn OliverÎncă nu există evaluări

- QAP For Conical StrainerDocument2 paginiQAP For Conical StrainersatishchidrewarÎncă nu există evaluări

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 paginiN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliÎncă nu există evaluări

- Rotating Itp 1Document4 paginiRotating Itp 1abdul aziz100% (1)

- Proposed WPS For API 5LDocument1 paginăProposed WPS For API 5LMecon HyderabadÎncă nu există evaluări

- Schedule of Test Welder Qualification:: 041/VIII/STWQ/2014Document2 paginiSchedule of Test Welder Qualification:: 041/VIII/STWQ/2014Muhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Tdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)Document1 paginăTdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)mÎncă nu există evaluări

- Full Water Test ProcedureDocument3 paginiFull Water Test Procedureasmira rosliÎncă nu există evaluări

- Fm-Ti-050 - Rev.0 Inspection Report Ultrasonic Examination - Eff.170107Document1 paginăFm-Ti-050 - Rev.0 Inspection Report Ultrasonic Examination - Eff.170107Jindarat KasemsooksakulÎncă nu există evaluări

- QAQC Form - ArchitechtureDocument42 paginiQAQC Form - ArchitechtureMohammad Hadoumi SaldanÎncă nu există evaluări

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDocument15 paginiPengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- Receiving Material Procedure CoverDocument1 paginăReceiving Material Procedure Covergst ajahÎncă nu există evaluări

- Code 1 WPS Rev 0 PDFDocument18 paginiCode 1 WPS Rev 0 PDFEarl HarbertÎncă nu există evaluări

- Resume - 01.03.2016Document5 paginiResume - 01.03.2016muthuswamy77Încă nu există evaluări

- Interseal 670HDocument2 paginiInterseal 670Hmadmax_mfpÎncă nu există evaluări

- Pressure Vessel ITP Rev 0Document10 paginiPressure Vessel ITP Rev 0SLC HosurÎncă nu există evaluări

- ACMV Inspeciton Check ListDocument22 paginiACMV Inspeciton Check ListNaing Win TunÎncă nu există evaluări

- RT ProcedureDocument51 paginiRT ProcedureAwale UdinÎncă nu există evaluări

- EQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Document6 paginiEQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Khalilahmad KhatriÎncă nu există evaluări

- 2G & 5GDocument2 pagini2G & 5GRahul MoottolikandyÎncă nu există evaluări

- BPVC - VIII-1 - U-2A FormDocument2 paginiBPVC - VIII-1 - U-2A FormPranesh BhatÎncă nu există evaluări

- Line Pipe Hydro Test ProcedureDocument2 paginiLine Pipe Hydro Test ProcedurePadmanabhan VenkateshÎncă nu există evaluări

- 59 CM Pe 708 Procedure FoDocument14 pagini59 CM Pe 708 Procedure FoPadmanabhan VenkateshÎncă nu există evaluări

- Pumpworks 610-BB3Document6 paginiPumpworks 610-BB3Padmanabhan VenkateshÎncă nu există evaluări

- 2673 SiRiya Thirumadal TMLDocument5 pagini2673 SiRiya Thirumadal TMLPadmanabhan VenkateshÎncă nu există evaluări

- PeriathirumozhiDocument151 paginiPeriathirumozhiPadmanabhan VenkateshÎncă nu există evaluări

- 1319 3 Guidelines For WeldingDocument64 pagini1319 3 Guidelines For Weldingg_sanchetiÎncă nu există evaluări

- Branch / Atm Locations: Branches / Atms Feedback / Complaint Fair Practices & Banking CodesDocument6 paginiBranch / Atm Locations: Branches / Atms Feedback / Complaint Fair Practices & Banking CodesPadmanabhan VenkateshÎncă nu există evaluări

- Microsoft Word - 2028B - Rev - 0Document10 paginiMicrosoft Word - 2028B - Rev - 0Padmanabhan VenkateshÎncă nu există evaluări

- SPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselDocument15 paginiSPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselPadmanabhan VenkateshÎncă nu există evaluări

- Typical Project Quality Plan & ITP CPCDocument14 paginiTypical Project Quality Plan & ITP CPCPadmanabhan Venkatesh100% (1)

- CL Fuses 8KV-15KV-23KV-38KV Data SheetDocument9 paginiCL Fuses 8KV-15KV-23KV-38KV Data SheetSamer Abdulaziz SadaqaÎncă nu există evaluări

- Mouse 200Document2 paginiMouse 200Amjad AliÎncă nu există evaluări

- Blinx01's Ultimate DVD Subbing GuideDocument12 paginiBlinx01's Ultimate DVD Subbing GuideloscanÎncă nu există evaluări

- DataDocument4 paginiDataQuế SươngÎncă nu există evaluări

- The Role of Social Media and Its Implication On Economic Growth On Society in IndiaDocument3 paginiThe Role of Social Media and Its Implication On Economic Growth On Society in IndiaSara EmamiÎncă nu există evaluări

- MGT104 Assignment 3Document11 paginiMGT104 Assignment 3Lê Hữu Nam0% (1)

- Redundant Power Supply Installation Guide EP-DCX205Document38 paginiRedundant Power Supply Installation Guide EP-DCX205Anonymous zLwP4FjLÎncă nu există evaluări

- ZzzsaDocument4 paginiZzzsanikzperaltaÎncă nu există evaluări

- SAP Fiori Deployment OptionsDocument16 paginiSAP Fiori Deployment OptionsVinaykumar PJÎncă nu există evaluări

- AAE 11.3.1 User Guide ClientDocument475 paginiAAE 11.3.1 User Guide Clientme4ias100% (2)

- ISMSBrochure 2011Document19 paginiISMSBrochure 2011Benw005Încă nu există evaluări

- Java - Informatica Scenario Based Interview Questions (Convert Columns Into Rows)Document6 paginiJava - Informatica Scenario Based Interview Questions (Convert Columns Into Rows)Sri Kanth SriÎncă nu există evaluări

- Camsco Breaker PDFDocument12 paginiCamsco Breaker PDFMichael MaiquemaÎncă nu există evaluări

- 800ma Low Dropout Positive Regulator: Features DescriptionDocument12 pagini800ma Low Dropout Positive Regulator: Features DescriptionmarcianocalviÎncă nu există evaluări

- ECSS E ST 50 03C (31july2008)Document43 paginiECSS E ST 50 03C (31july2008)jsadachiÎncă nu există evaluări

- Data CenterDocument108 paginiData CenterKhanh Nato100% (5)

- HGU User ManualDocument72 paginiHGU User Manuallomayani100% (1)

- AIX PowerHA (HACMP) CommandsDocument3 paginiAIX PowerHA (HACMP) CommandsdanilaixÎncă nu există evaluări

- Performance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsDocument4 paginiPerformance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsFredrick IshengomaÎncă nu există evaluări

- U-Joint Shaft PDFDocument5 paginiU-Joint Shaft PDFAdrian SantosÎncă nu există evaluări

- DH Xvr4b16Document3 paginiDH Xvr4b16Jumar JumadiaoÎncă nu există evaluări

- Introduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008Document20 paginiIntroduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008anilkumar18Încă nu există evaluări

- PL54 PeugeotDocument3 paginiPL54 Peugeotbump4uÎncă nu există evaluări

- High Performance HTP eDocument14 paginiHigh Performance HTP ejohnny_cashedÎncă nu există evaluări

- Family Surveyed 2017 - TimberDocument26 paginiFamily Surveyed 2017 - TimberAlibasher Macalnas0% (1)

- IEC 60364-1 Electrical Installations in Buildings PDFDocument80 paginiIEC 60364-1 Electrical Installations in Buildings PDFMarin PopescuÎncă nu există evaluări

- V$SESSIONDocument8 paginiV$SESSIONCristiano Vasconcelos BarbosaÎncă nu există evaluări

- Ict Designation FormDocument3 paginiIct Designation FormAloha Mae ImbagÎncă nu există evaluări

- Namibian Diplomatic Missions Abroad 2011Document6 paginiNamibian Diplomatic Missions Abroad 2011Milton LouwÎncă nu există evaluări

- Service Pack 2Document149 paginiService Pack 2billwong169Încă nu există evaluări