Documente Academic

Documente Profesional

Documente Cultură

Multiple Transformer Temperature Monitoring with SMS Alerts

Încărcat de

Badar Sharif0 evaluări0% au considerat acest document util (0 voturi)

297 vizualizări4 paginiMultiple Transformers oil temperature monitoring with automatic circuit breaker operation with SMS based alerts this project aims at monitoring the oil temperature of a Multiple Transformers continuously and protects them from overheating. Failures in a transformer can easily cost several million dollars to either repair or replace, and will also cause a loss of service to customers and revenue until the symptom is found and repaired. Since the oil is present inside the transformer there is a necessity to develop a system which can sense the temperature of the oil inside the

Descriere originală:

Titlu original

SET-291. Multiple Transformers Oil Temperature Monitoring With SMS Alerts

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMultiple Transformers oil temperature monitoring with automatic circuit breaker operation with SMS based alerts this project aims at monitoring the oil temperature of a Multiple Transformers continuously and protects them from overheating. Failures in a transformer can easily cost several million dollars to either repair or replace, and will also cause a loss of service to customers and revenue until the symptom is found and repaired. Since the oil is present inside the transformer there is a necessity to develop a system which can sense the temperature of the oil inside the

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

297 vizualizări4 paginiMultiple Transformer Temperature Monitoring with SMS Alerts

Încărcat de

Badar SharifMultiple Transformers oil temperature monitoring with automatic circuit breaker operation with SMS based alerts this project aims at monitoring the oil temperature of a Multiple Transformers continuously and protects them from overheating. Failures in a transformer can easily cost several million dollars to either repair or replace, and will also cause a loss of service to customers and revenue until the symptom is found and repaired. Since the oil is present inside the transformer there is a necessity to develop a system which can sense the temperature of the oil inside the

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

Multiple Transformers oil temperature monitoring with automatic

circuit breaker operation with SMS based alerts

This project aims at monitoring the oil temperature of a multiple transformers

continuously and protects them from overheating. Since transformers are vital elements

of the electric power transmission and distribution infrastructure, they need to be

monitored to prevent any potential faults. Failures in a transformer can easily costs

several million dollars to either repair or replace, and will also cause a loss of service to

customers and revenue until the symptom is found and repaired.

In transformers the need for monitoring the oil temperature is very much

necessary. Turning the transformers OFF whenever the temperature is greater than its

maximum operating temperature protects the transformer from damage and also the life

time of the transformers can also be increased. Since the oil is present inside the

transformer there is a necessity to develop a system which can sense the temperature of

the oil inside the transformer and automatically switches O! the "ircuit brea#er if

temperature exceeds the limit and also informs the electricity department through S$S to

predefined numbers and also alerts through %"& display. The oil temperature of multiple

transformers can be continuously monitored on %"& display provided in the system.

'e developed this project, which is relatively inexpensive to sense the

temperature. The temperature is read by the (&" )(nalog to &igital "onverter* module

of the microcontroller +nit. This (&" data is processed and converted into the actual

temperature reading by the microcontroller.

The microcontroller is provided with the instructions such as maximum Threshold

temperature after which the transformer need be turned OFF etc. The microcontroller will

dynamically decide the status to which the transformer should be driven OFF depending

on the temperature input received from the temperature sensor. The controller also

displays the oil temperature over an %"& display for the reference of us.

www.mycollegeproject.com Ph: +91 9490219339, 040-23731030

Ameerpet : A-8, 2

nd

loor, !"re#$ co"rt, %e&'de (m$ge ho&p't$l, Ameerpet, )*+!,A-A+ 73.

Santoshnagar: .pp: /$gn$ )yperm$r#et, 0$nto&hn$g$r 1-,o$d&, )*+!,A-A+ 2 39.

The objectives of the project include:

1. "ontinous oil temperature reading of multiple transformers.

2. ,S$ S$S based alerts.

-. %"& displays based visual alerts and continous monitoring.

.. /eliable for industrial needs

The project provides us exposure on:

0. Initiali1ation of (&" module of microcontroller.

2. Temperature sensor characteristics.

-. 3mbedded " programming.

.. 4"5 designing.

6. Serial communication protocols.

7. ,S$ modem.

8. %"& interfacing to $icrocontroller.

The major building blocks of this project are:

0. /egulated power supply.

www.mycollegeproject.com Ph: +91 9490219339, 040-23731030

Ameerpet : A-8, 2

nd

loor, !"re#$ co"rt, %e&'de (m$ge ho&p't$l, Ameerpet, )*+!,A-A+ 73.

Santoshnagar: .pp: /$gn$ )yperm$r#et, 0$nto&hn$g$r 1-,o$d&, )*+!,A-A+ 2 39.

2. $icrocontroller.

3. Temperature sensors.

.. /elay with driver.

5. ,S$ modem.

7. %"& display with driver.

8. /eset.

9. "rystal oscillator.

:. %3& indicators.

Softwares used:

0. 4I"" compiler for 3mbedded " programming.

2. 4I" #it 2 programmer for dumping code into $icro controller.

-. 3xpress S"; for "ircuit design.

.. 4roteus for hardware simulation.

Regulated Power Suppl:

!lock "iagram:

www.mycollegeproject.com Ph: +91 9490219339, 040-23731030

Ameerpet : A-8, 2

nd

loor, !"re#$ co"rt, %e&'de (m$ge ho&p't$l, Ameerpet, )*+!,A-A+ 73.

Santoshnagar: .pp: /$gn$ )yperm$r#et, 0$nto&hn$g$r 1-,o$d&, )*+!,A-A+ 2 39.

www.mycollegeproject.com Ph: +91 9490219339, 040-23731030

Ameerpet : A-8, 2

nd

loor, !"re#$ co"rt, %e&'de (m$ge ho&p't$l, Ameerpet, )*+!,A-A+ 73.

Santoshnagar: .pp: /$gn$ )yperm$r#et, 0$nto&hn$g$r 1-,o$d&, )*+!,A-A+ 2 39.

S-ar putea să vă placă și

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsDe la EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsÎncă nu există evaluări

- Advanced Temperature Measurement and Control, Second EditionDe la EverandAdvanced Temperature Measurement and Control, Second EditionÎncă nu există evaluări

- Temperature Based Fan Speed ControlDocument2 paginiTemperature Based Fan Speed ControlBasil KuriakoseÎncă nu există evaluări

- Unit 5Document38 paginiUnit 5rohanrec92Încă nu există evaluări

- Avr+lcd ReportDocument95 paginiAvr+lcd ReportyrikkiÎncă nu există evaluări

- Motor Protection Against Single Phasing and OverheatingDocument14 paginiMotor Protection Against Single Phasing and OverheatingPanje DarlingtonÎncă nu există evaluări

- DT-Sense Gas SensorDocument20 paginiDT-Sense Gas SensorErma Sulistyo RÎncă nu există evaluări

- Design and Implementation of Motor Speed Control and Temperature Sensing Unit Using PIC ControllerDocument4 paginiDesign and Implementation of Motor Speed Control and Temperature Sensing Unit Using PIC Controllerijsret100% (1)

- HVS-355. Solar Based Industrial Boiler ControllerDocument3 paginiHVS-355. Solar Based Industrial Boiler ControllerHari Babu100% (1)

- PLC Based Induction Motor Fault Detection TechniqueDocument7 paginiPLC Based Induction Motor Fault Detection Techniquedhaval2430Încă nu există evaluări

- Engine Oil Level and Temperature Monitoring SystemDocument3 paginiEngine Oil Level and Temperature Monitoring SystemElakkiya KarthicÎncă nu există evaluări

- Project ReportDocument78 paginiProject ReportSana SadafÎncă nu există evaluări

- AEM Undocumented Settings v1Document13 paginiAEM Undocumented Settings v1Franklyn RamirezÎncă nu există evaluări

- Motor Protection ReportDocument28 paginiMotor Protection ReportpnkjinamdarÎncă nu există evaluări

- EEE 805 Assignment Questions For Chapter 20Document11 paginiEEE 805 Assignment Questions For Chapter 20ayeniÎncă nu există evaluări

- SET-04. Construction of Central Control Unit For IrrigationDocument0 paginiSET-04. Construction of Central Control Unit For IrrigationragvshahÎncă nu există evaluări

- Technical Specification Guide: 1.0 General Information/ 2.0 Product Features/ Product FunctionsDocument3 paginiTechnical Specification Guide: 1.0 General Information/ 2.0 Product Features/ Product FunctionsMohamed WahidÎncă nu există evaluări

- Flash Flood IntimationDocument2 paginiFlash Flood IntimationKakarlaAnilkumarÎncă nu există evaluări

- Hawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsDocument4 paginiHawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsRochdi BahiriÎncă nu există evaluări

- PWM Based Three Phase Induction Motor Speed ControllerDocument4 paginiPWM Based Three Phase Induction Motor Speed ControllerMusthafa KadershaÎncă nu există evaluări

- 1.multi Sensor-Smoke, Temperature and Metal Based Security Robot Using ZigbeeDocument5 pagini1.multi Sensor-Smoke, Temperature and Metal Based Security Robot Using ZigbeePidikiti Surendra BabuÎncă nu există evaluări

- Eat Produktions GMBH (Scandi-Tool)Document28 paginiEat Produktions GMBH (Scandi-Tool)kossamosÎncă nu există evaluări

- Optimize Power Factor with CIRCUTOR's Computer-8d RegulatorDocument29 paginiOptimize Power Factor with CIRCUTOR's Computer-8d RegulatorSergio100% (1)

- Two Marks Questions Mechatronics (MH1031) Unit - 1Document12 paginiTwo Marks Questions Mechatronics (MH1031) Unit - 1cakejhÎncă nu există evaluări

- Automatic Ac Onoff System in CarsDocument3 paginiAutomatic Ac Onoff System in CarsVenkatesan RamamoorthyÎncă nu există evaluări

- Project ProposalDocument8 paginiProject ProposalShafin Al Asad ProticÎncă nu există evaluări

- PS48300-25 System Test ManualDocument9 paginiPS48300-25 System Test ManualleonardomarinÎncă nu există evaluări

- Design and Cons-Wps OfficeDocument3 paginiDesign and Cons-Wps OfficeSamuel OlusanyaÎncă nu există evaluări

- Mbmuazu@abu Edu NGDocument17 paginiMbmuazu@abu Edu NGJuan AlvarezÎncă nu există evaluări

- 586-Automatic Transformer Heat Reduction SystemDocument4 pagini586-Automatic Transformer Heat Reduction SystemAmit Mohapatra100% (1)

- Automatic Transfer SwitchesDocument4 paginiAutomatic Transfer Switchestorjanice100% (1)

- Weather Monitoring System Using MicrocontrollerDocument3 paginiWeather Monitoring System Using Microcontrollersdo6289 AtpadiÎncă nu există evaluări

- Galaxy R Service Manual PDFDocument58 paginiGalaxy R Service Manual PDFPedro Bortot56% (9)

- PLC Based Temperature ControllerDocument3 paginiPLC Based Temperature Controllerblack jackÎncă nu există evaluări

- XBEE Based Transformer Protection and Oil TestingDocument3 paginiXBEE Based Transformer Protection and Oil TestingijsretÎncă nu există evaluări

- A Smart GSM Based Embedded Solution For Continuous Remote Monitoring of Cardiac PatientsDocument24 paginiA Smart GSM Based Embedded Solution For Continuous Remote Monitoring of Cardiac PatientsG NAVEEN KUMARÎncă nu există evaluări

- Smart KitchenDocument9 paginiSmart KitchenJerinjÎncă nu există evaluări

- HGM6300D V2.1 enDocument34 paginiHGM6300D V2.1 enSteven BaynesÎncă nu există evaluări

- Digital Sensor: SupplyDocument6 paginiDigital Sensor: SupplyYUDI WAHYUDI 17249Încă nu există evaluări

- Measuring Winding Hot SpotsDocument3 paginiMeasuring Winding Hot SpotsThameemul BuhariÎncă nu există evaluări

- Chapter 3 - Measurement Case StudiesDocument15 paginiChapter 3 - Measurement Case StudiesfarizahÎncă nu există evaluări

- Jet Irc 006196Document6 paginiJet Irc 006196Issa BakariÎncă nu există evaluări

- Digicold Digicold Digicold Digicold: SeriesDocument4 paginiDigicold Digicold Digicold Digicold: SeriesdbricchiÎncă nu există evaluări

- 15.TouchScreen Based Temperature Monitoring and Control System PDFDocument0 pagini15.TouchScreen Based Temperature Monitoring and Control System PDFaamreen818Încă nu există evaluări

- Fuel Monitoring and Electronics Control of Dispenser For Fuel StationDocument6 paginiFuel Monitoring and Electronics Control of Dispenser For Fuel StationYasir ShukryÎncă nu există evaluări

- Humidifier ProjectDocument45 paginiHumidifier ProjectdubstepoÎncă nu există evaluări

- Dayananda Sagar College of Engineering: Mini-Project Report (Microprocessors)Document13 paginiDayananda Sagar College of Engineering: Mini-Project Report (Microprocessors)Nandan MaheshÎncă nu există evaluări

- Manual Smartgen HGM 6320 - Ced 100ksDocument35 paginiManual Smartgen HGM 6320 - Ced 100ksddedaniel80% (5)

- Hammer Quick Lessons PDFDocument19 paginiHammer Quick Lessons PDFsebasfarsaÎncă nu există evaluări

- Saini Science Projects Mob. 9255747495: MajorDocument4 paginiSaini Science Projects Mob. 9255747495: MajorVinod KumarÎncă nu există evaluări

- Aircraft Flying Project (PRINT OUT)Document24 paginiAircraft Flying Project (PRINT OUT)Priyanka KumariÎncă nu există evaluări

- Automatic microcontroller-based soil moisture monitoring and pump control systemDocument53 paginiAutomatic microcontroller-based soil moisture monitoring and pump control systemArun AndaniÎncă nu există evaluări

- MCP9808T E MS A Digital Temperature Sensor For Consumer ElectronicsDocument4 paginiMCP9808T E MS A Digital Temperature Sensor For Consumer ElectronicsjackÎncă nu există evaluări

- Automatic Temperature Control in Furnace Using PLCDocument19 paginiAutomatic Temperature Control in Furnace Using PLCAhammedali Ch0% (1)

- REC ManualDocument45 paginiREC Manualshiva shakthyÎncă nu există evaluări

- Vega MFMDocument4 paginiVega MFMNaga Muneendra Reddy KotaÎncă nu există evaluări

- The Load Monitoring and Protection On Electricity Power Lines Using GSM NetworkDocument6 paginiThe Load Monitoring and Protection On Electricity Power Lines Using GSM NetworkPrashant Sangulagi100% (1)

- PID Water Temperature ControlDocument5 paginiPID Water Temperature Controllalalalisa 03Încă nu există evaluări

- Projects With Microcontrollers And PICCDe la EverandProjects With Microcontrollers And PICCEvaluare: 5 din 5 stele5/5 (1)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneDe la EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneÎncă nu există evaluări

- ILLUMINATION LECTURE 02Document44 paginiILLUMINATION LECTURE 02Badar SharifÎncă nu există evaluări

- Flywheel: Flywheels-Function Need and OperationDocument11 paginiFlywheel: Flywheels-Function Need and OperationKristian John B Rabino100% (2)

- Introduction To FlywheelsDocument4 paginiIntroduction To FlywheelsKVVÎncă nu există evaluări

- The International System of Units (SI) Converter PDFDocument27 paginiThe International System of Units (SI) Converter PDFMaey AkimÎncă nu există evaluări

- Chapter 3: Structures: TrussesDocument19 paginiChapter 3: Structures: TrussesBadar Sharif100% (1)

- Automatic Street Light Control Using LDRDocument39 paginiAutomatic Street Light Control Using LDRAyush Kumar100% (1)

- Flamanville France Nuclear Power Plant WallchartDocument1 paginăFlamanville France Nuclear Power Plant WallchartArzu AkarÎncă nu există evaluări

- Introduction To The Multi MeterDocument3 paginiIntroduction To The Multi MeterFaiz FauziÎncă nu există evaluări

- Rpdir-L12 Shielding WebDocument73 paginiRpdir-L12 Shielding WebWiie ArdiÎncă nu există evaluări

- OSHA Citations Against O&G and Ducci ElectricDocument107 paginiOSHA Citations Against O&G and Ducci ElectricRepublican-AmericanÎncă nu există evaluări

- Chapter 2 Structure of AtomsDocument16 paginiChapter 2 Structure of AtomsCherry T CYÎncă nu există evaluări

- Multidisciplinary Nature of Environmental StudiesDocument6 paginiMultidisciplinary Nature of Environmental StudiesWiz Calvin ManutdÎncă nu există evaluări

- Pt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldDocument1 paginăPt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldBerchÎncă nu există evaluări

- FAI Services Overview SHORTDocument58 paginiFAI Services Overview SHORTMariela CarrilloÎncă nu există evaluări

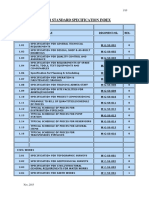

- Water Standard Specification Index As On Dec 2015Document10 paginiWater Standard Specification Index As On Dec 2015afp15060% (1)

- Graviner MK6 Oil Mist DetectorDocument4 paginiGraviner MK6 Oil Mist DetectorDhanielÎncă nu există evaluări

- 3512TA - 1000kVA - LV - Spec Sheet PDFDocument5 pagini3512TA - 1000kVA - LV - Spec Sheet PDFavinash_1229Încă nu există evaluări

- Every Emergency.: C Safe Marine Generator SetsDocument4 paginiEvery Emergency.: C Safe Marine Generator SetsBrillyanÎncă nu există evaluări

- IFFCO Urea ProcesspdfDocument3 paginiIFFCO Urea ProcesspdfBalas43Încă nu există evaluări

- Water Level IndicatorDocument5 paginiWater Level IndicatorRahul JadhavÎncă nu există evaluări

- Distillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedDocument3 paginiDistillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedReyes, Ishmael Edward John U.Încă nu există evaluări

- Germany and Japan's Remarkable Post-WWII Economic ComebackDocument5 paginiGermany and Japan's Remarkable Post-WWII Economic ComebackHANNALEEÎncă nu există evaluări

- KRYPTOSPHERE TechnologyDocument20 paginiKRYPTOSPHERE TechnologySoniale Sánchez GómezÎncă nu există evaluări

- Makerere University Civil Engineering Assignment on Nalubaale DamDocument8 paginiMakerere University Civil Engineering Assignment on Nalubaale DamRobert WalusimbiÎncă nu există evaluări

- Damper mechanism details for Atlas Copco rock drills under 40 charactersDocument27 paginiDamper mechanism details for Atlas Copco rock drills under 40 characterssalvador341100% (2)

- Section 08 - ECD ManagementDocument75 paginiSection 08 - ECD ManagementRicardo VillarÎncă nu există evaluări

- Theory of The Triple Constraint - A Conceptual Review: December 2012Document8 paginiTheory of The Triple Constraint - A Conceptual Review: December 2012Keyah NkonghoÎncă nu există evaluări

- FMC1278Document132 paginiFMC1278Herick Douglas PereiraÎncă nu există evaluări

- Wind Energy - University QuesDocument2 paginiWind Energy - University QuesKsn Hari100% (2)

- Universal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysDocument21 paginiUniversal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysBrianHazeÎncă nu există evaluări

- Load Flow and SC ETAPDocument4 paginiLoad Flow and SC ETAPmuraliÎncă nu există evaluări

- Deepwater Training Seminar Presented ToDocument36 paginiDeepwater Training Seminar Presented ToSergio Jesus MarquezÎncă nu există evaluări

- High Voltage Products Reliable Products - EN PDFDocument102 paginiHigh Voltage Products Reliable Products - EN PDFSiva ReddyÎncă nu există evaluări

- Zaman of Chapter 1 - Introduction of HydraulicsDocument35 paginiZaman of Chapter 1 - Introduction of HydraulicsFatin HazwaniÎncă nu există evaluări

- Units: Muhammad AhsanDocument2 paginiUnits: Muhammad AhsanAreeb WaseemÎncă nu există evaluări