Documente Academic

Documente Profesional

Documente Cultură

ME2402-Computer Integrated Manufacturing

Încărcat de

Larry Smith0 evaluări0% au considerat acest document util (0 voturi)

256 vizualizări6 paginicomputer integrated manufacturing

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentcomputer integrated manufacturing

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

256 vizualizări6 paginiME2402-Computer Integrated Manufacturing

Încărcat de

Larry Smithcomputer integrated manufacturing

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 6

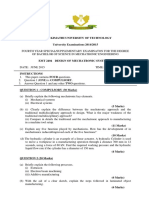

ME2402 COMPUTER INTEGRATED MANUFACTURING

IV year Mechanical Engg.

Subject code/Name: ME2402-COMPUTER INTEGRATED MANUFACTURING

Year/Sem: IV/VII

UNIT-I (COMPUTER AIDED DESIGN)

PART-A (2 MARKS)

1. Distinguish between reflection and scaling transformations.

2. What is sculptured surface?

3. What is meant by geometry and topology?

4. List any four rules of dimensioning.

5. What are the drawing features of CAD package?

6. What are the advantages of solid modeling?

7. Define wire frame modeling

8. What is meant by parametric modeling?

9. Define solid modeling

10. Differentiate between redraw and regenerate?

11. What is scaling, editing, dimensioning?

12. Describe the features of CAD?

13. What are the advantages and disadvantages of CAD?

14. What is surface modeling?

15. Explain labeling, zoom and pan.

16. Define CAD/CAM.

PART-B (16 MARKS)

1. Write short notes on solid modeling, wireframe modeling and surface modeling.

2. Explain the boundary representation form in solid modeling.

3. Explain the concept of design and CAD facility.

4. Explain the features of CAD

5. Differentiate between redraw and regenerate.

6. Explain the typical cad command structure.

7. Explain parametric and feature based modeling.

8. Explain the advantages and disadvantages of a CAD.

9. Explain the CAD commands in related to CAD Packages.

10. Explain the different forms of solid modeling.

UNIT-II (COMPONENTS OF CIM)

PART-A (2 MARKS)

1. What is the meaning of CIM?

2. What are the product related activities of a company?

3. How the CIM is differs from CAM?

4. List some CIM hardware and CIM software?

5. What is CIM?

6. What are the main elements of a CIM system?

7. Name any four activities of a manufacturing plant which can be carried out through

computer control.

8. What is the role of CIM in manufacturing?

9. Define Islands of automation.

10. How the manufacturing industries can be grouped?

11. Define: Product development cycle.

12. Define electronic data interchange.

13. What is manufacturing automation protocol?

14. What is production planning?

15. What is meant by physical distribution?

16. What are plant operations?

17. Bring out some benefits of implementing a CIM system?

18. What is meant by inventory control

19. What is meant by MAP?

20. What is the difference between product layout and process layout?

21. What do you mean by CIM architecture, CIMOSA, PDM, CSMA/CD?

22. Define Topology. List different types of Topology.

23. What is communication network? List its types.

24. What are the functions of network management?

PART-B

1. Briefly explain the nature and role of the elements of CIM system.

2. Describe the basic activities that must be carried out in a factory to convert raw

materials into finished product.

3. Describe the need for CIM and issues addressed by CIM.

4. Discuss the stages in the product development cycle and the importance of each stage.

5. What do you understand by term islands of automation? List and explain any six

islands of automation.

6. Draw the CIM wheel and explain its different segments in relation to CIM scope?

7. Differentiate dedicated system from open system.

8. Explain the changes in manufacturing and management scenes in the recent past that

led to the development of CIM?

9. What is network? And explain various advantages of network.

10. Write short notes on LAN, MAN, and WAN.

11. What is network management? Discuss various functions of it.

12. Explain CIMOSA model with neat diagram?

UNIT-III (GROUP TECHNOLOGY AND COMPUTER AIDED PROCESS PLANNING)

PART-A (2MARKS)

1. Define Group Technology (GT).

2. List out the stages in Group Technology.

3. Define Part families.

4. What are the methods available for solving problems in GT?

5. Explain the two categories of attributes of parts.

6. List out the premises for the developed of DCLASS code.

7. What are the applications of GT?

8. What is Process planning?

9. What are the results of Process Planning?

10. List out the facility design layouts using G.T.

11. Define part family.

12. List out the types of machine cell design.

13. What are the benefits of group technology?

14. List the advantages of cellular manufacturing.

15. What are the applications of robots in CIM environment?

16. List the various coding system widely used GT

17. What is the role of GT in CIM environment?

18. What are the basic approaches of CAPP?

19. What is CMPT?

20. What is MPS?

PART-B

1. Explain about Optiz classification and coding system.

2. Explain retrieval and generative CAPP systems.

3. Discuss about MICLASS and DCLASS classification and coding system.

4. Briefly discuss the various benefits of implementing a GT in a firm. Also bring out the

advantages and limitations of using GT.

5. (a) Describe the composite part concept in cellular manufacturing.

(b)Discuss the importance of process planning in product development

6. Explain the role G.T. in CAD/CAM integration.

7. Briefly write about i) Composite part concept &ii) Key machine concept.

8. What is meant by physical distribution? Explain its various activities?

9. Explain why the GT is important in achieving CAD&CAM integration?

10. Explain in brief of the following.

a. Optiz coding system.

b. MICLASS.

c. DCLASS.

d. PFA.

UNIT IV SHOP FLOOR CONTROL AND INTRODUCTION TO FMS

PART-A (2MARKS)

1. What is meant by FMS?

2. What are the components of FMS?

3. Mention different type of layout in FMS.

4. Difference between FMS and FMC.

5. List out the advantages of implementing FMS.

6. What is meant by automated material handling system?

7. What is SFC?

8. What is meant by FDCS?

9. Distinguish between online and offline data collection system.

10. List out various data input techniques of FDC.

PART-B

1. What is meant by FMS and how it differs from other manufacturing systems?

2. Explain various components of FMS? And list out applications, advantages,

disadvantages of FMS.

3. What is PDM? Explain its role in CIM implementation?

4. What is shop floor control? And what are the functions of SFC? Explain various phases

of SFC.

5. Explain in detail the process planning activities?

6. Explain about the automated data collection.

7. What is FMS and explain its components.

8. Explain material handling and storage system.

9. Explain bar code technology?

10. Explain the FMS Layout and its application and benefits.

UNIT V COMPUTER AIDED PLANNING AND CONTROL AND COMPUTER

MONITORING

PART-A (2MARKS)

1. List the source of input data to MRP and output of MRP

2. What is CAPP?

3. What is data modeling?

4. What are data associations?

5. List some important features of DBMS.

6. Classify data models.

7. What are the basic approaches of CAPP?

8. What is CMPT?

9. What is MPS?

10. What is PFA?

11. What is the weakness of PFA?

PART-B

1. Describe the different plant operations.

2. What is the role of business and financial management of a Company?

3. Explain the types of production monitoring systems.

4. Explain the process control layout and its strategies.

5. Explain the material requirements planning.

6. What is meant by CAPP? List out the benefit of CAPP system?

7. Explain the various steps involved in Production flow analysis.

8. What are data models? Explain them.

9. Explain the technological frame work of process planning by using block diagram also

explain why process planning is important in achieving the integration of CAD/CAM?

10. Explain MAP and TOP?

S-ar putea să vă placă și

- Superfan Brochure AllmodelsDocument20 paginiSuperfan Brochure Allmodelsbluewindinnovations2023Încă nu există evaluări

- 52-Ceiling Fan CalculationsDocument1 pagină52-Ceiling Fan Calculationstidjani86Încă nu există evaluări

- Aerodynamics 2 Notes For All UnitDocument44 paginiAerodynamics 2 Notes For All UnitSejal JoshiÎncă nu există evaluări

- Vocabulary For SpeakingDocument21 paginiVocabulary For SpeakingLINARA AXMEDOVAÎncă nu există evaluări

- 7th Sem Mechanical Hydraulic Unit5 NotesDocument14 pagini7th Sem Mechanical Hydraulic Unit5 Notesnikhiljm100% (1)

- Design and Manufacturing of Motorsports PDFDocument10 paginiDesign and Manufacturing of Motorsports PDFVaisakhan.A.SÎncă nu există evaluări

- P&E Development - JLR Lecture 2011Document63 paginiP&E Development - JLR Lecture 2011Jiunn Yih100% (1)

- Computer Aided ManufacturingDocument28 paginiComputer Aided ManufacturingSheik AbdullahÎncă nu există evaluări

- A Project Report On Aerodynamic and Structural Analysis of Winglets by Using Composite Material. Department of Aeronautical EngineeringDocument50 paginiA Project Report On Aerodynamic and Structural Analysis of Winglets by Using Composite Material. Department of Aeronautical EngineeringGoutham KrsÎncă nu există evaluări

- 9A01301 Mechanics of SolidsDocument4 pagini9A01301 Mechanics of SolidssivabharathamurthyÎncă nu există evaluări

- Cad Notes ModulewiseDocument178 paginiCad Notes Modulewiselalith sunkojuÎncă nu există evaluări

- GB SpringDocument69 paginiGB Springshivkumar1587100% (1)

- Lecture04 Pneumatic and Hydraulic Actuator-2Document41 paginiLecture04 Pneumatic and Hydraulic Actuator-2Ilyana Sahira MurizanÎncă nu există evaluări

- NASA Supercritical AirfoilsDocument76 paginiNASA Supercritical AirfoilsDhruv Shihora100% (1)

- Resume and Cover LetterDocument3 paginiResume and Cover LetterJesse Caudle100% (1)

- PDR Final ProjectDocument14 paginiPDR Final ProjectHarshit AgarwalÎncă nu există evaluări

- Project Details 6511Document4 paginiProject Details 6511Kaushik Samineni100% (1)

- Ferrari 75 Years - (Dennis Adler..-2021)Document345 paginiFerrari 75 Years - (Dennis Adler..-2021)Imad Yared100% (1)

- Understanding Winglets TechnologyDocument7 paginiUnderstanding Winglets Technologymohammadrezamadadi100% (1)

- English For Teachers 11 PDED 0021/DED 0321: Oral Presentation SkillsDocument30 paginiEnglish For Teachers 11 PDED 0021/DED 0321: Oral Presentation SkillsMzee MsideeÎncă nu există evaluări

- Design of Helical and Leaf SpringsDocument92 paginiDesign of Helical and Leaf Springs208W1A1027Sec-A LINGAMANENI KOWSHIKÎncă nu există evaluări

- Intro To ELYSIUM CADdoctor Translation and HealingDocument15 paginiIntro To ELYSIUM CADdoctor Translation and Healingnitouch3564Încă nu există evaluări

- Modatek Level 2 Robot TrainingDocument166 paginiModatek Level 2 Robot TrainingIvan Paul Medellin CastroÎncă nu există evaluări

- Invertec STT PDFDocument145 paginiInvertec STT PDFAltai OspanÎncă nu există evaluări

- Road Load Power EquationsDocument38 paginiRoad Load Power EquationsAndré RavazziÎncă nu există evaluări

- MS Project ManualDocument12 paginiMS Project ManualRehan RafiqÎncă nu există evaluări

- Template For Extended Abstract ETMN ConferenceDocument2 paginiTemplate For Extended Abstract ETMN ConferencecrocoreaderÎncă nu există evaluări

- 0326 Me 2303 Design of Machine ElementsDocument3 pagini0326 Me 2303 Design of Machine ElementsSaravanan MathiÎncă nu există evaluări

- Assembly Frame: Trim 1 Trim 2 Chassis Line Final Line Sub-Assembly LinesDocument30 paginiAssembly Frame: Trim 1 Trim 2 Chassis Line Final Line Sub-Assembly LinesTarang GuptaÎncă nu există evaluări

- Design Exploration - Judd KaiserDocument30 paginiDesign Exploration - Judd KaiserSangbum KimÎncă nu există evaluări

- Chapter Five: Inimization of OnductedDocument27 paginiChapter Five: Inimization of Onductedligrav007Încă nu există evaluări

- Mid-Term Exam: Notes: Answer All Three QuestionsDocument2 paginiMid-Term Exam: Notes: Answer All Three Questionsseraj sersawiÎncă nu există evaluări

- AM PL E: Ondokuz Mayis University International Student ExamDocument20 paginiAM PL E: Ondokuz Mayis University International Student ExamPrayer SmithÎncă nu există evaluări

- Seema Brain Openers Kuruskhetra: Sure Shot Questions With Clear Answers To Crack Spoken Round of IeltsDocument56 paginiSeema Brain Openers Kuruskhetra: Sure Shot Questions With Clear Answers To Crack Spoken Round of IeltsSej PatelÎncă nu există evaluări

- SpringDocument30 paginiSpringlin_meckylogiÎncă nu există evaluări

- Basic Mechanical Engineering SyllabusDocument3 paginiBasic Mechanical Engineering SyllabusKarthickÎncă nu există evaluări

- Curriculum Guide Creo Elements Direct 18-1Document37 paginiCurriculum Guide Creo Elements Direct 18-1Larisa LoredanaÎncă nu există evaluări

- Dieter & Schmidt, "Engineering Design", Mcgraw Hill Education (India) Edition 2013Document3 paginiDieter & Schmidt, "Engineering Design", Mcgraw Hill Education (India) Edition 2013Aswith R ShenoyÎncă nu există evaluări

- Electric Vehicle Battery Technologies: January 2013Document44 paginiElectric Vehicle Battery Technologies: January 2013VENKATA SWAMY NAIDU NIMMAKAYALAÎncă nu există evaluări

- Kaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities PDFDocument7 paginiKaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities PDFanhthoÎncă nu există evaluări

- Training Report For AltairDocument4 paginiTraining Report For AltairRavi Teja KondetiÎncă nu există evaluări

- AutoCAD Release HistoryDocument4 paginiAutoCAD Release Historyjoabjim8392Încă nu există evaluări

- E2-FINAL Test 1Document3 paginiE2-FINAL Test 1English EnglishÎncă nu există evaluări

- York Budgetary Price Non-Ducted 070712 (I)Document3 paginiYork Budgetary Price Non-Ducted 070712 (I)daveleyconsÎncă nu există evaluări

- Robocon 2010 ReportDocument46 paginiRobocon 2010 ReportDebal Saha100% (1)

- Emt 2402 Design of Mechatronic Systems 1Document2 paginiEmt 2402 Design of Mechatronic Systems 1STAR BOYÎncă nu există evaluări

- ARaymond QC Thermal-Management Booklet 2019Document16 paginiARaymond QC Thermal-Management Booklet 2019TUNCAY GUMUSÎncă nu există evaluări

- Vehicle Layout Transmission SystemsDocument38 paginiVehicle Layout Transmission SystemsKhan Liyaqat100% (1)

- Qs For InterviewDocument4 paginiQs For InterviewАнђелка ГемовићÎncă nu există evaluări

- SIM908 Reference Design Guide Application Note V1.00Document17 paginiSIM908 Reference Design Guide Application Note V1.00jonydanceÎncă nu există evaluări

- Chapter 3 - Case Studies of Static AnalysisDocument80 paginiChapter 3 - Case Studies of Static AnalysisJCavalcanti de OliveiraÎncă nu există evaluări

- Visual Studio 2010 EditionsDocument5 paginiVisual Studio 2010 EditionsKenneth SyÎncă nu există evaluări

- Writing Task 2Document154 paginiWriting Task 2Nguyen Long100% (1)

- How To Write A Thesis Statement - IELTS AdvantageDocument10 paginiHow To Write A Thesis Statement - IELTS AdvantageBrijesh SavliyaÎncă nu există evaluări

- Depreciation CH 10Document40 paginiDepreciation CH 10احمد عمر حديدÎncă nu există evaluări

- ME101 Course Syllabus Summer14Document2 paginiME101 Course Syllabus Summer14Abdo BedirÎncă nu există evaluări

- Part - A (2 Marks Each)Document4 paginiPart - A (2 Marks Each)sithananthansithuÎncă nu există evaluări

- Me2402 QBDocument4 paginiMe2402 QBRajendira PrasadÎncă nu există evaluări

- CIM All Units Imp - Quest.Document5 paginiCIM All Units Imp - Quest.S A ABDUL SUKKURÎncă nu există evaluări

- Computer Integrated ManufacturingDocument5 paginiComputer Integrated ManufacturingbalamaddysweetÎncă nu există evaluări

- 20041709Document62 pagini20041709Larry SmithÎncă nu există evaluări

- ME 1004 NUCLEAR ENGINEERING Questions Bank 2014 Vidyarthiplus (V+) Blog - A Blog For StudentsDocument14 paginiME 1004 NUCLEAR ENGINEERING Questions Bank 2014 Vidyarthiplus (V+) Blog - A Blog For StudentsLarry SmithÎncă nu există evaluări

- Ansys PDFDocument2 paginiAnsys PDFLarry SmithÎncă nu există evaluări

- Group Technology (GT)Document15 paginiGroup Technology (GT)Larry SmithÎncă nu există evaluări

- Group Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Document30 paginiGroup Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Larry SmithÎncă nu există evaluări

- Cellular Manufacturing & Group TechnologyDocument24 paginiCellular Manufacturing & Group TechnologyLarry SmithÎncă nu există evaluări

- Grouptechnology1 131203094018 Phpapp01Document9 paginiGrouptechnology1 131203094018 Phpapp01Larry SmithÎncă nu există evaluări

- Group Technology: Job Shop Production System Batch Production System Mass Production SystemDocument11 paginiGroup Technology: Job Shop Production System Batch Production System Mass Production SystemLarry SmithÎncă nu există evaluări

- Gtbylathu 101231003739 Phpapp01Document25 paginiGtbylathu 101231003739 Phpapp01Larry SmithÎncă nu există evaluări

- Grouptechnology 140807034542 Phpapp01Document8 paginiGrouptechnology 140807034542 Phpapp01Larry SmithÎncă nu există evaluări

- Benefits of CIMDocument24 paginiBenefits of CIMLarry SmithÎncă nu există evaluări

- Ai DataDocument8 paginiAi Dataapi-413617976Încă nu există evaluări

- IDBS BiTs Set2Document4 paginiIDBS BiTs Set2Kumara Swamy BÎncă nu există evaluări

- Eee 407 Control Engineering IIDocument39 paginiEee 407 Control Engineering IIIbrahim Dalafika AbdullahiÎncă nu există evaluări

- OOAD & UML Interview QuestionsDocument2 paginiOOAD & UML Interview QuestionsvenkateshraoÎncă nu există evaluări

- OpenAI Unveils GPT-4, A New Foundation For ChatGPT - ComputerworldDocument4 paginiOpenAI Unveils GPT-4, A New Foundation For ChatGPT - ComputerworldshotatekenÎncă nu există evaluări

- ME354 2016 17 2nd SemesterDocument2 paginiME354 2016 17 2nd SemesterKartikeyaÎncă nu există evaluări

- Software Project Management: Project Time Management: by Dr. Hammad QureshiDocument21 paginiSoftware Project Management: Project Time Management: by Dr. Hammad QureshiWaseem KhanÎncă nu există evaluări

- ERP Sintayehu DemekeDocument108 paginiERP Sintayehu DemekeGebiremariam DemisaÎncă nu există evaluări

- Executive Summary of The 14 Toyota Way PrinciplesDocument5 paginiExecutive Summary of The 14 Toyota Way Principlesmuhammad naufalÎncă nu există evaluări

- Student Name: - : TRUE/FALSE - Write 'T' If The Statement Is True and 'F' If The Statement Is False. 1)Document44 paginiStudent Name: - : TRUE/FALSE - Write 'T' If The Statement Is True and 'F' If The Statement Is False. 1)Joker csgoÎncă nu există evaluări

- Quiz On Speech ModelsDocument19 paginiQuiz On Speech ModelsRalph Melchor LacangÎncă nu există evaluări

- Artificial Intelligence: "PR TeemuenrDocument472 paginiArtificial Intelligence: "PR TeemuenrutkarshÎncă nu există evaluări

- Decoding and Encoding of MemoryDocument2 paginiDecoding and Encoding of MemoryErwin James GragedaÎncă nu există evaluări

- Software Testing Process in Agile DevelopmentDocument66 paginiSoftware Testing Process in Agile DevelopmentgeongeoÎncă nu există evaluări

- Chapter 3 Dan Analisis 4.2Document7 paginiChapter 3 Dan Analisis 4.2Fadli AtmajayaÎncă nu există evaluări

- Inneed Intelligent Cloud: ContactDocument17 paginiInneed Intelligent Cloud: ContactMinhaz AhmedÎncă nu există evaluări

- Toyota Production SystemDocument37 paginiToyota Production Systemjaiswalswatin87100% (1)

- Ergonomocs Slide 1 PDFDocument22 paginiErgonomocs Slide 1 PDFMD Al-AminÎncă nu există evaluări

- Modern Systems Analysis and Design: The Systems Development EnvironmentDocument33 paginiModern Systems Analysis and Design: The Systems Development EnvironmentKasyfiJohanÎncă nu există evaluări

- CML Kaneko 1992Document5 paginiCML Kaneko 1992Swathi SÎncă nu există evaluări

- ISO 9001-2015 Transition Workshop (Auditors)Document96 paginiISO 9001-2015 Transition Workshop (Auditors)S K GARGÎncă nu există evaluări

- Well-Posedness and Internal StabilityDocument48 paginiWell-Posedness and Internal StabilityAparna AkhileshÎncă nu există evaluări

- Updated Resume (Techolution)Document1 paginăUpdated Resume (Techolution)mani MONEYÎncă nu există evaluări

- UNIT - I Basic Concepts of MCSDocument19 paginiUNIT - I Basic Concepts of MCSsagar029Încă nu există evaluări

- Motion Control of Single Link Flexible Joint Robot Manipulator Using ANFIS MATLAB SimulationDocument10 paginiMotion Control of Single Link Flexible Joint Robot Manipulator Using ANFIS MATLAB SimulationMiddle East Journal of Applied Science & TechnologyÎncă nu există evaluări

- TestingDocument34 paginiTestingPSIEBELÎncă nu există evaluări

- Chapter Five: System Implementation and MaintenanceDocument17 paginiChapter Five: System Implementation and MaintenanceAli HussenÎncă nu există evaluări

- BE Project Report 1Document25 paginiBE Project Report 1saniya sayedÎncă nu există evaluări

- Content at Glance: Acknowledgement 1 1. InintroductionDocument46 paginiContent at Glance: Acknowledgement 1 1. InintroductionNimesh SommanekÎncă nu există evaluări

- ProZ UK ListDocument14 paginiProZ UK ListMeriç TürkmenÎncă nu există evaluări