Documente Academic

Documente Profesional

Documente Cultură

TAPER Grip-Twist Test Data - Rev7-03-Red PDF

Încărcat de

Gonzalo AbarcaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TAPER Grip-Twist Test Data - Rev7-03-Red PDF

Încărcat de

Gonzalo AbarcaDrepturi de autor:

Formate disponibile

TAPER THREADED

GRIP-TWIST

SYSTEM

TYPE 2

MECHANICAL

CONNECTIONS

FOR

REINFORCING

BARS

PERFORMANCE

TEST DATA

JULY 2003

INTRODUCTION

Barsplice Products, Inc. have conducted a series of tests on Taper Threaded Grip-Twist

Couplers. The

purpose of the testing is to ensure that products are manufactured to the quality standards of BPI's ISO

9001 Quality System and are capable of exceeding strength requirements of various Building Codes.

TENSILE TEST PROCEDURE

Test specimens were loaded monotonically in tension to failure to determine the capability of the splice

system. The tests were conducted in accordance with "Standard Test Methods and Definitions for

Mechanical Testing of Steel Products", ASTM A370. The testing was performed to exceed the strength

requirements of ACI (American Concrete Institute) 318, Section 12.14.3.2 and Section 21.2.6.1 using

Grade 60 reinforcing bar.

All monotonic independent tension tests were carried out in a 200 kip Satec universal testing machine,

located at the independent testing laboratory of A-Lab Inc., Dayton, OH. All monotonic in-house tension

tests were carried out in a 600 kip Forney universal testing machine, located at the Barsplice Products,

Inc. laboratory. Current calibration certificates for the test machines are on file.

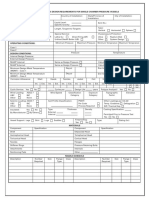

TEST RESULTS

Results of the tension testing are summarized in the following tables.

The reinforcing steel used in these tests conforms to the requirements of ASTM A615, Grade 60.

SUMMARY

(1) Tension test specimens exceeded the Type 1 strength requirements of ACI 318, Section

12.14.3.2, namely 125% x specified yield strength of Grade 60 rebar.

(2) Tension test specimens exceeded the TYPE 2 strength requirements of ACI 318-02,

Section 21.2.6.1, namely the specified tensile strength of Grade 60 rebar. ASTM A615,

Grade 60 has a specified tensile strength of 90,000 psi which is equivalent to 150% x

specified yield.

(3) The TYPE 2 strength requirements of ICBO (International Conference of Building Officials)

were met, namely the lesser value of 160% x specified yield strength of Grade 60 rebar or

95% x actual tensile strength of the rebar.

BarSplice Products, Inc., 4900 Webster Street, Dayton OH 45414, USA

GTel: (937) 275-8700 GFax: (937) 275-9566 GE-mail: bar@barsplice.com

Page 2 of 4

En Argentina:

ALCOR S.A.

Snchez de Bustamante 1818 9D (1425) Bs. As. Tel. / Fax: 4821 0500

email: info@alcor.com.ar - Web: www.alcor.com.ar

TAPER THREADED GRIP-TWIST

SYSTEM INDEPENDENT TENSILE TEST DATA

BAR

SIZE

LOAD (lbs.) STRESS IN

BAR (psi)

PERCENTAGE

fy

FRACTURE MODE

19,521 97,600 163% Bar Fracture

4

19,502 97,500 163% Bar Fracture

32,287 104,150 174% Bar Fracture

5

33,450 107,900 180% Bar Fracture

32,454 104,690 174% Bar Fracture

32,189 103,840 173% Bar Fracture

46,057 104,670 174% Bar Fracture

6

45,304 102,960 172% Bar Fracture

48,578 110,400 184% Bar Fracture

48,257 109,670 183% Bar Fracture

62,547 104,240 174% Bar Fracture

7

62,694 104,490 174% Bar Fracture

60,558 100,930 168% Bar Fracture

61,929 103,210 172% Bar Fracture

80,058 101,340 169% Bar Fracture

8

79,281 100,360 167% Bar Fracture

102,670 102,670 171% Bar Fracture

9

102,850 102,850 171% Bar Fracture

133,030 104,740 175% Bar Fracture

10

131,660 103,670 173% Bar Fracture

164,300 105,330 176% Bar Fracture

163,720 104,950 175% Bar Fracture

164,390 105,380 176% Bar Fracture

180,600 115,770 193% Bar Fracture

180,560 115,750 193% Bar Fracture

11

180,440 115,670 193% Bar Fracture

167,160 107,150 179% Bar Fracture

163,360 104,720 175% Bar Fracture

160,810 103,090 172% Bar Fracture

163,670 104,920 175% Bar Fracture

164,490 105,440 176% Bar Fracture

208,200 92,530 154% Bar Fracture

14

207,200 92,090 153% Bar Fracture

417,900 104,475 174% Bar Fracture

18

417,900 104,475 174% Bar Fracture

The specified tensile strength of ASTM A615 Grade 60 is 90,000psi, which equates to 150% x specified yield,

fy, of the bar. Results, which exceed this stress level, qualify as Type 2 under the definition issued in ACI

318-02.The data shown above is a summary of test results from individual reports issued by independent test

facilities A-Lab and HC Nutting.

TYPE 1

Develops in Tension or Compression as required, a stress in the bar of at least 125 % x Specified Yield, fy, of the

Reinforcing Bar.

TYPE 2

Meets the requirements for TYPE 1 and Develops in Tension the Specified Tensile Strength, fu, of the bar.

fu Grade 60 = 90,000psi = 150% fy Grade 60.

fu Grade 75 = 100,000psi = 133% fy Grade 75.

Page 3 of 4

The data shown above is a summary of test results from in-house test reports issued by BPI.

Page 4 of 4

TAPER THREADED GRIP-TWIST

SYSTEM IN-HOUSE TENSILE TEST DATA

BAR

SIZE

LOAD (lbs.) STRESS IN

BAR (psi)

PERCENTAGE

fy

FRACTURE MODE

34,405 110,982 185% Bar Fracture

5

32,775 105,726 176% Bar Fracture

34,990 112,871 188% Bar Fracture

35,065 112,924 188% Bar Fracture

44,662 101,506 169% Bar Fracture

6

45,952 104,436 174% Bar Fracture

46,458 105,586 176% Bar Fracture

46,804 106,374 177% Bar Fracture

63,832 106,387 177% Bar Fracture

7

63,003 105,004 175% Bar Fracture

63,978 106,630 178% Bar Fracture

80,563 101,979 170% Bar Fracture

85,341 108,026 180% Bar Fracture

84,731 107,255 179% Bar Fracture

8

86,912 110,016 183% Bar Fracture

106,887 106,887 178% Bar Fracture

108,687 108,687 181% Bar Fracture

109,332 109,332 182% Bar Fracture

9

108,826 108,826 181% Bar Fracture

130,327 102,620 171% Bar Fracture

131,072 103,206 172% Bar Fracture

155,693 122,593 204% Bar Fracture

155,431 122,387 204% Bar Fracture

10

154,196 121,414 202% Bar Fracture

174,651 111,956 187% Bar Fracture

174,008 111,543 186% Bar Fracture

175,280 112,359 187% Bar Fracture

169,615 108,728 181% Bar Fracture

11

169,420 108,602 181% Bar Fracture

222,951 99,089 165% Bar Fracture

224,553 99,801 166% Bar Fracture

225,837 100,372 167% Bar Fracture

224,423 99,744 166% Bar Fracture

224,808 99,915 167% Bar Fracture

14

381,979 95,495 159% Bar Fracture

383,939 95,485 160% Bar Fracture

405,006 101,251 169% Bar Fracture

405,250 101,312 169% Bar Fracture

378,739 94,685 158% Bar Fracture

387,115 96,779 161% Bar Fracture

18

S-ar putea să vă placă și

- Ems ThermalDocument4 paginiEms ThermalElencheliyan PandeeyanÎncă nu există evaluări

- Astm A529 1972Document5 paginiAstm A529 1972dharlanuctcom0% (1)

- Series 800 Specification SheetDocument2 paginiSeries 800 Specification SheetFEBCOÎncă nu există evaluări

- Astm A520Document3 paginiAstm A520tslia100% (1)

- KIMRAY ValveDocument16 paginiKIMRAY ValveDenny Iskandar 'S-chuck'Încă nu există evaluări

- Section-E-1001 4Document1 paginăSection-E-1001 4Miguel PacahualaÎncă nu există evaluări

- 2025 Rockwell HRDocument8 pagini2025 Rockwell HRMuhammad FahadÎncă nu există evaluări

- Gage Block TolerancesDocument6 paginiGage Block TolerancesAna Gabriela OjedaÎncă nu există evaluări

- BARUS METROPOL Type-2 Uygunluk 9nov2021Document8 paginiBARUS METROPOL Type-2 Uygunluk 9nov2021Ali KayaÎncă nu există evaluări

- 3 - BARGRIP - Test - Report - Rev Sept - 2012 PDFDocument32 pagini3 - BARGRIP - Test - Report - Rev Sept - 2012 PDFRodrigo Antonio Silva MuñozÎncă nu există evaluări

- Series 805YD Specification SheetDocument2 paginiSeries 805YD Specification SheetFEBCOÎncă nu există evaluări

- Brida MafDocument2 paginiBrida MafmisaelzaÎncă nu există evaluări

- Transient Voltage Suppressors SMBJ5V0 (C) A - SMBJ170 (C) ADocument4 paginiTransient Voltage Suppressors SMBJ5V0 (C) A - SMBJ170 (C) AonafetsÎncă nu există evaluări

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocument4 paginiLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezÎncă nu există evaluări

- HTTP WWW Impact-Test Co Uk Products 6039-Ring-Shear-Testing-System-Bromhead PDFDocument2 paginiHTTP WWW Impact-Test Co Uk Products 6039-Ring-Shear-Testing-System-Bromhead PDFDaniel Felipe Rodriguez RamirezÎncă nu există evaluări

- Rebar in Coil Qualities and CertificationsDocument4 paginiRebar in Coil Qualities and CertificationsKhairil Fajri IndragaÎncă nu există evaluări

- Bulletin 140U/Ue: Molded Case Circuit BreakersDocument64 paginiBulletin 140U/Ue: Molded Case Circuit BreakersVictor De La TorreÎncă nu există evaluări

- ASTM E92-82 - Vickers Hardness of Metallic MaterialsDocument9 paginiASTM E92-82 - Vickers Hardness of Metallic Materialsivan_vanÎncă nu există evaluări

- Hydro Static Test Pressure For Flanged FittingsDocument6 paginiHydro Static Test Pressure For Flanged FittingskuntakisÎncă nu există evaluări

- QAQC Equipment List - SET 1: 序号 Number 名称 Name 参数 parameterDocument4 paginiQAQC Equipment List - SET 1: 序号 Number 名称 Name 参数 parameterShahril ZainulÎncă nu există evaluări

- Series 957, 957N, 957ZDocument4 paginiSeries 957, 957N, 957ZWattsÎncă nu există evaluări

- CPVC Schedule 40 & Schedule 80 Pipe Specifications: ApplicationDocument11 paginiCPVC Schedule 40 & Schedule 80 Pipe Specifications: ApplicationRavikumarÎncă nu există evaluări

- KC (1) - 276.dst:: Test Object - Device SettingsDocument10 paginiKC (1) - 276.dst:: Test Object - Device SettingsTuan LanÎncă nu există evaluări

- Tabel Plat BajaDocument6 paginiTabel Plat BajaAlexander Ignatius100% (2)

- Series 806YD Specification SheetDocument2 paginiSeries 806YD Specification SheetFEBCOÎncă nu există evaluări

- Pre StressingDocument48 paginiPre StressingRameshÎncă nu există evaluări

- Monolithic Insulated Joint BrochureDocument8 paginiMonolithic Insulated Joint Brochuremarita_msÎncă nu există evaluări

- HU Figure 100 2021 RevADocument3 paginiHU Figure 100 2021 RevAmarco lezcanoÎncă nu există evaluări

- Chem Oil - Check Valve PDFDocument204 paginiChem Oil - Check Valve PDFClemente Rafael Marval EscalonaÎncă nu există evaluări

- Bondstrand 2400 SeriesDocument20 paginiBondstrand 2400 SeriesTommytoo BernalÎncă nu există evaluări

- Medidores AMERICAN METERSDocument17 paginiMedidores AMERICAN METERSRaúl PalomoÎncă nu există evaluări

- GS1LD3: Product Data SheetDocument5 paginiGS1LD3: Product Data SheetgermaneduardÎncă nu există evaluări

- Kebutuhan Peralatan: No Type Uraian QTY JumlahDocument1 paginăKebutuhan Peralatan: No Type Uraian QTY JumlahtitopardsÎncă nu există evaluări

- Stringing ChartDocument4 paginiStringing ChartHikmat B. Ayer - हिक्मत ब. ऐरÎncă nu există evaluări

- Q.Sonic 5 Path Ultrasonic Gas Meter: T 1 T 1 2 L V CosDocument4 paginiQ.Sonic 5 Path Ultrasonic Gas Meter: T 1 T 1 2 L V Cossaid250009250Încă nu există evaluări

- Jis G3444Document12 paginiJis G3444yapsguanÎncă nu există evaluări

- DS Rebar Splicing HBDocument64 paginiDS Rebar Splicing HBdarkchechoÎncă nu există evaluări

- Data KapasitorDocument7 paginiData KapasitorMuhammad Ardi AnggaraÎncă nu există evaluări

- Aluminum 2024 T6Document4 paginiAluminum 2024 T6Thiru Kumaran0% (1)

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pagini5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoÎncă nu există evaluări

- Astm A182 - Astm A182Document7 paginiAstm A182 - Astm A182phresendeÎncă nu există evaluări

- Compare Inverter - 1Document2 paginiCompare Inverter - 1joserobertosolanoÎncă nu există evaluări

- TEMA FlangesDocument38 paginiTEMA FlangesAshfaq Anwer100% (1)

- Powerware BPIII Industrial UPS: FeaturesDocument4 paginiPowerware BPIII Industrial UPS: Featuresandy175Încă nu există evaluări

- Catalogo de Shut Off (PF)Document8 paginiCatalogo de Shut Off (PF)luis_d_mÎncă nu există evaluări

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDe la EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- HALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionDe la EverandHALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionÎncă nu există evaluări

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyDe la EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinÎncă nu există evaluări

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIDe la EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffÎncă nu există evaluări

- Advances in Ceramic Armor, Bioceramics, and Porous MaterialsDe la EverandAdvances in Ceramic Armor, Bioceramics, and Porous MaterialsJerry C. LaSalviaÎncă nu există evaluări

- Columns for Gas Chromatography: Performance and SelectionDe la EverandColumns for Gas Chromatography: Performance and SelectionÎncă nu există evaluări

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationDe la EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationEvaluare: 4.5 din 5 stele4.5/5 (21)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDe la EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášÎncă nu există evaluări

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIDe la EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemÎncă nu există evaluări

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresDe la EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresEvaluare: 5 din 5 stele5/5 (1)

- TAPER GRIP-TWIST Brochure - RevB-red PDFDocument4 paginiTAPER GRIP-TWIST Brochure - RevB-red PDFGonzalo AbarcaÎncă nu există evaluări

- Rebaixamento Do Nivel de AguaDocument17 paginiRebaixamento Do Nivel de AguajcbizarretaÎncă nu există evaluări

- Slope StabilityDocument206 paginiSlope StabilityNyree WebsterÎncă nu există evaluări

- TAPER GRIP-TWIST DataSheet - RevC-red PDFDocument2 paginiTAPER GRIP-TWIST DataSheet - RevC-red PDFGonzalo AbarcaÎncă nu există evaluări

- BARSPLICER Brochure - RevB-red PDFDocument4 paginiBARSPLICER Brochure - RevB-red PDFGonzalo AbarcaÎncă nu există evaluări

- BARSPLICER Data Sheet - RevB-red PDFDocument2 paginiBARSPLICER Data Sheet - RevB-red PDFGonzalo AbarcaÎncă nu există evaluări

- Discussion AddendumClosure Design of Diagonal Cross-Bracings - Part 1 Theoretical Study Part 2 Experimental Study PDFDocument1 paginăDiscussion AddendumClosure Design of Diagonal Cross-Bracings - Part 1 Theoretical Study Part 2 Experimental Study PDFGonzalo AbarcaÎncă nu există evaluări

- Practical Application of Energy Methods To Structural Stability Problems PDFDocument9 paginiPractical Application of Energy Methods To Structural Stability Problems PDFGonzalo AbarcaÎncă nu există evaluări

- BARGRIP Brochure - RevA Red PDFDocument4 paginiBARGRIP Brochure - RevA Red PDFGonzalo AbarcaÎncă nu există evaluări

- Effective Length Factor For The Design of X-Bracing Systems PDFDocument5 paginiEffective Length Factor For The Design of X-Bracing Systems PDFGonzalo AbarcaÎncă nu există evaluări

- Design of Diagonal Cross-Bracings - Part 2 Experimental Study PDFDocument5 paginiDesign of Diagonal Cross-Bracings - Part 2 Experimental Study PDFGonzalo AbarcaÎncă nu există evaluări

- Lee Topo1Document2 paginiLee Topo1Gonzalo AbarcaÎncă nu există evaluări

- Cross Bracing PDFDocument3 paginiCross Bracing PDFGonzalo AbarcaÎncă nu există evaluări

- Design of Diagonal Cross Bracings - Part 1 Theoretical Study PDFDocument5 paginiDesign of Diagonal Cross Bracings - Part 1 Theoretical Study PDFGonzalo AbarcaÎncă nu există evaluări

- 19 Index PDFDocument17 pagini19 Index PDFGonzalo AbarcaÎncă nu există evaluări

- Chemistry ATPDocument4 paginiChemistry ATPaliza malikÎncă nu există evaluări

- DuctilityDocument3 paginiDuctilityCarlo CastorÎncă nu există evaluări

- Materials For Engineering 4 PDFDocument2 paginiMaterials For Engineering 4 PDFHimanshu MishraÎncă nu există evaluări

- Lecture 6Document26 paginiLecture 6rookeeÎncă nu există evaluări

- Model: FCD-180B / 170066: Electric Solenoid Valve 220VACDocument1 paginăModel: FCD-180B / 170066: Electric Solenoid Valve 220VACoscarÎncă nu există evaluări

- CHEM-3206 - 3206P - Final Term - ONLINE - 31.05.2021 - Physical Chemistry-IIIDocument1 paginăCHEM-3206 - 3206P - Final Term - ONLINE - 31.05.2021 - Physical Chemistry-IIIAbdullah MunawarÎncă nu există evaluări

- Chemsheets AS 1032 Relative RatesDocument9 paginiChemsheets AS 1032 Relative Ratescharlesma123Încă nu există evaluări

- Weld StrengthDocument6 paginiWeld StrengthAqil GhaffarÎncă nu există evaluări

- Effect of Different Sand Grading On Strength Properties of Cement Grout PDFDocument8 paginiEffect of Different Sand Grading On Strength Properties of Cement Grout PDFyoussefÎncă nu există evaluări

- Failure Analysis of A Bucket Elevator Shaft: Technicalarticle-Peer-ReviewedDocument7 paginiFailure Analysis of A Bucket Elevator Shaft: Technicalarticle-Peer-Revieweddouglasncamilo100% (1)

- Electromagnetic Plunger With Stopper DynamicsDocument28 paginiElectromagnetic Plunger With Stopper DynamicsCatanescu Alexandru-LaurentiuÎncă nu există evaluări

- Model Calculation of Heat Balance of Wood PyrolysiDocument10 paginiModel Calculation of Heat Balance of Wood PyrolysiqwerÎncă nu există evaluări

- Advanced Inspection MethodsDocument38 paginiAdvanced Inspection MethodsBenÎncă nu există evaluări

- Duct Work PDFDocument2 paginiDuct Work PDFRiza BahrullohÎncă nu există evaluări

- Trajectory Analysis and Staging Trades For Smaller Mars Ascent VehiclesDocument8 paginiTrajectory Analysis and Staging Trades For Smaller Mars Ascent VehiclesJuanJoÎncă nu există evaluări

- Master Course 2017 - Photonic Imaging in Neurobiology - C. LeterrierDocument56 paginiMaster Course 2017 - Photonic Imaging in Neurobiology - C. LeterrierlechristopheÎncă nu există evaluări

- GRP Pipes Fittings CatalogDocument8 paginiGRP Pipes Fittings CatalogFaseen ibnu Ameer Ahasen0% (1)

- NADCA-High Temp DieDocument12 paginiNADCA-High Temp DiejalilemadiÎncă nu există evaluări

- Thermodynamic Model SelectionDocument11 paginiThermodynamic Model SelectionKuldeep28883100% (1)

- DPP - 6Document3 paginiDPP - 6sarthak.kothiyal1576Încă nu există evaluări

- RCD Lecture 1Document26 paginiRCD Lecture 1Walter CatapangÎncă nu există evaluări

- Balistik Dalam (Bab I, Ii, Iii,... )Document61 paginiBalistik Dalam (Bab I, Ii, Iii,... )Gilang Wicaksono WJÎncă nu există evaluări

- F3 Chapter 7 Energy and PowerDocument6 paginiF3 Chapter 7 Energy and Poweramniraze bin hamzahÎncă nu există evaluări

- Astm E280Document3 paginiAstm E280hlagos123100% (1)

- Mil STD 1949Document36 paginiMil STD 1949ManivannanMudhaliarÎncă nu există evaluări

- Solid State Chemistry and It Applications Answer For QuestionDocument32 paginiSolid State Chemistry and It Applications Answer For QuestionĐặng Vũ Hoàng Đức89% (9)

- Udr 1Document2 paginiUdr 1shazanÎncă nu există evaluări

- 200 MW - Unit, Generator Seal Oil SystemDocument3 pagini200 MW - Unit, Generator Seal Oil SystemNikhilÎncă nu există evaluări

- QP Am Ii SemDocument6 paginiQP Am Ii SemnishÎncă nu există evaluări

- Solutions - Revision Book Chemistry PDFDocument89 paginiSolutions - Revision Book Chemistry PDFJatin GoyalÎncă nu există evaluări