Documente Academic

Documente Profesional

Documente Cultură

Further Reading

Încărcat de

gunabaskaranDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Further Reading

Încărcat de

gunabaskaranDrepturi de autor:

Formate disponibile

Module -1: Fundamental concepts relevant to metal forming technology

Forming of materials

1. Mechanical Metallurgy, George Dieter, David Bacon, S.I. metric Ed., McGraw Hill, 1988.

Further reading:

2. Metal Forming, Mechanics and Metallurgy, Willian F. Hosford, Robert M. Caddell, Third

Ed., Cambridge University Press, 2007.

3. Fundamentals of modern manufacturing: materials, processes and systems, Mikell P.

Groover, Third Ed., John Wiley and Sons.

4. Manufacturing processes for engineering materials, SeropeKalpakjian, Steven R. Schmid,

Fifth Ed., Pearson Education, 2009.

1. Distinguish between crystalline and amorphous materials.

Quiz:

Amorphous absence of long range order.

2. How does elastic deformation and plastic deformation affect the lattice structure of crystals?

Elastic deformation causes temporary displacements of atoms. Plastic deformation causes

permanent displacement of atoms by slipping of planes of atoms against other planes.

3. Give examples for materials that do not have crystalline structure.

Glass, amorphous silica, polyethylene.

4. Which one of the following crystal structure has fewer slip systems, so that the material

having that structure is more difficult to deform at room temperature?

a) BCC, b] FCC, c] HCP

c] HCP

5. How many effective number of atoms are there in unit cell of HCP?

2 atoms per unit cell

6. Calculate the packing factor for FCC unit cell.

PF for FCC = = 0.74, where a =

7. State Hookes law.

NPTEL - Mechanical Engineering - Forming

Joint Initiative of IITs and IISc Funded by MHRD Page 1 of 4

Within elastic limit, stress is directly proportional to strain.

8. Define work hardening.

Work hardening is the increase in yield stress of a material due to prior working or straining of

the material.

9. Define instability in tension.

Instability in uniaxial tensile test refers to the highly localized deformation called necking

resulting in a state of triaxial stress.

10. What test is commonly used for determining the strength properties of brittle materials?

Three point bend test.

11. What method of hardness measurement is suitable for very thin sections like foils?

Microhardness test with loads in fraction of a kilogram.

12. Why higher value of m the strain rate sensitivity parameter results in more diffuse neck in

tensile loading?

With higher m value, the material gets stretched to a greater length before it fails, thereby

delaying necking.

13. What is the dilation of a material with a Poissons ratio of 0.5?

Zero

14. What is the significance of slip systems?

They are responsible for plastic deformation.

15. A paper clip is made of wire 1.2 mm diameter. If the original material from which the wire

is made is a rod, 15 mm in diameter, calculate the longitudinal and diametral engineering and

true strains that the wire has undergone.

Solution:

Assuming volume constancy, lf/lo = (do/df)

2

Longitudinal engg. Strain = (156-1)/1

= 156.

Diametral strain = ln(1.25/15} = -2.526.

NPTEL - Mechanical Engineering - Forming

Joint Initiative of IITs and IISc Funded by MHRD Page 2 of 4

Longitudinal true strain = ln(l/lo) = 5.043

Diametral true strains = -2,526

16. A tensile test specimen is made of a material represented by the equation = K(+ n)

n

In necking we have d/d = .

.

Determine the true strain at which necking will begin. Show that it is possible for an

engineering material to exhibit this behavior.

Now applying this condition for this material necking begins when:

Kn(+ n)

n-1 =

K(+ n)

n

17. A torsion test specimen has a radius of 25 mm, wall thickness of 3 mm and gage length of

50 mm. In testing, a torque of 900 N-m results in an angular deflection of 0.3

. Yes it is possible.

o

Solution: Shear stress = T/2R

. Determine the

shear stress, shear strain, and shear modulus assuming the specimen had not yielded.

2

=R/L = 0.2618

t = 76.39 MPa.

/ = G = 29179 MPa.

NPTEL - Mechanical Engineering - Forming

Joint Initiative of IITs and IISc Funded by MHRD Page 3 of 4

NPTEL - Mechanical Engineering - Forming

Joint Initiative of IITs and IISc Funded by MHRD Page 4 of 4

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Condition Indicators For Gearbox Condition Monitoring SystemsDocument9 paginiCondition Indicators For Gearbox Condition Monitoring Systemszao zhizhiÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Nine Dots ActivityDocument2 paginiNine Dots ActivitygunabaskaranÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Lee 2017Document78 paginiLee 2017gunabaskaranÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Standing Advt Faculty V1Document1 paginăStanding Advt Faculty V1gunabaskaranÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- PDF Safety SERVICES IndustrialSafetyDocument20 paginiPDF Safety SERVICES IndustrialSafetyhayatmdazharÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Thamizh Aa AahaDocument1 paginăThamizh Aa AahagunabaskaranÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Indian Geography - Competitive ExamDocument32 paginiIndian Geography - Competitive ExamgunabaskaranÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- RTI ManualDocument76 paginiRTI ManualgunabaskaranÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Control Chart: Basic Tools For Process ImprovementDocument70 paginiControl Chart: Basic Tools For Process ImprovementGen Sue100% (2)

- Operations (Revised) - Machineshop Production and Planning-Hemant NagareDocument0 paginiOperations (Revised) - Machineshop Production and Planning-Hemant Nagareshreyasi_mahantyÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- IPD - Tentative Course PlanDocument1 paginăIPD - Tentative Course PlangunabaskaranÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- NPDL - Lecture 11Document26 paginiNPDL - Lecture 11gunabaskaranÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Basic PLCDocument77 paginiBasic PLCrpshvju100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- 1 s2.0 S0022509614001483 Main PDFDocument18 pagini1 s2.0 S0022509614001483 Main PDFgunabaskaranÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- What Is A Programmable Logic Controller (PLC)Document5 paginiWhat Is A Programmable Logic Controller (PLC)gunabaskaranÎncă nu există evaluări

- How To Write A Research PlanDocument1 paginăHow To Write A Research PlangunabaskaranÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- SYMBOLS - Fluid PowerDocument35 paginiSYMBOLS - Fluid PowergunabaskaranÎncă nu există evaluări

- How To Write A Research PlanDocument1 paginăHow To Write A Research PlangunabaskaranÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Caller (1) Receiver (2) : Switching Center Base Station (2) Base StationDocument16 paginiCaller (1) Receiver (2) : Switching Center Base Station (2) Base StationNauman-ur-RasheedÎncă nu există evaluări

- Voter ID Form For TamilnaduDocument7 paginiVoter ID Form For TamilnaduAmit BadamÎncă nu există evaluări

- Projection of PlanesDocument14 paginiProjection of PlanesHere Estrada100% (1)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Pedestal DesignDocument2 paginiPedestal DesignRamadanÎncă nu există evaluări

- What Is Cross Drainage Works?Document39 paginiWhat Is Cross Drainage Works?Shubham GargÎncă nu există evaluări

- "Wood To Wood" Nail - Single Shear Capacity: InputDocument16 pagini"Wood To Wood" Nail - Single Shear Capacity: InputAlparslan GureÎncă nu există evaluări

- Meet The Experts - Steel JoistsDocument2 paginiMeet The Experts - Steel Joistsseth_gzbÎncă nu există evaluări

- Butress DamDocument11 paginiButress DamTamara Christensen0% (1)

- L2CIV003Document23 paginiL2CIV003Sanchay Singhal100% (1)

- Ground Improvement Technique-A. PatelDocument52 paginiGround Improvement Technique-A. PatelBT21CIV085 KS Uday BhaskarÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Asce 7 05 Seismic Provisions PDF FreeDocument66 paginiAsce 7 05 Seismic Provisions PDF FreeRyanÎncă nu există evaluări

- Analysis and Design FOR TorsionDocument40 paginiAnalysis and Design FOR TorsionIsmail A IsmailÎncă nu există evaluări

- Deepwater Horizon Blowout Preventer Failure Analysis PDFDocument83 paginiDeepwater Horizon Blowout Preventer Failure Analysis PDFHosamMohamed50% (2)

- Unit 1 Fluid Properties and Hydrostatic ForcesDocument115 paginiUnit 1 Fluid Properties and Hydrostatic ForcespoojaabanindranÎncă nu există evaluări

- Lamont BoilerDocument26 paginiLamont BoilerDr. BIBIN CHIDAMBARANATHAN0% (1)

- Válvula Anti-Retorno Rexroth - S10A1Document8 paginiVálvula Anti-Retorno Rexroth - S10A1vinícius josé zortéa merinoÎncă nu există evaluări

- RCC Principles - Construction ProcessDocument44 paginiRCC Principles - Construction ProcessDharatiSote100% (1)

- Lecture 4 - Strain Transformation and Mohr Circle For StrainDocument21 paginiLecture 4 - Strain Transformation and Mohr Circle For StrainFaran AssifÎncă nu există evaluări

- DIA 3 - 5 - Research On 40-Year Life Pavement ExtensionDocument32 paginiDIA 3 - 5 - Research On 40-Year Life Pavement ExtensionAnton AbdurrahmanÎncă nu există evaluări

- TRH14 (1985) Guidelines For Road Construction MaterialsDocument69 paginiTRH14 (1985) Guidelines For Road Construction MaterialsTensarAfrica60% (5)

- ValvesDocument7 paginiValvesAnonymous NR3qZ30Încă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Ce 5 Sem Reinforced Cement Concrete (RCC) Structures Jun 2017Document2 paginiCe 5 Sem Reinforced Cement Concrete (RCC) Structures Jun 2017Monika jainÎncă nu există evaluări

- Seismic Bracing For Fire Fighting SystemDocument29 paginiSeismic Bracing For Fire Fighting SystemSree S100% (1)

- How Bladder Pressure TankDocument16 paginiHow Bladder Pressure TankVer BautistaÎncă nu există evaluări

- Artikel Ta - B. IngDocument11 paginiArtikel Ta - B. IngDedi NurhudaÎncă nu există evaluări

- The Crystal PalaceDocument13 paginiThe Crystal PalaceNishi MansharamaniÎncă nu există evaluări

- 2933 Tencent Seafront Tower Practice On Binding BuildingsDocument8 pagini2933 Tencent Seafront Tower Practice On Binding BuildingskhatribharatÎncă nu există evaluări

- AD 301: The Use of Annex I1 of BS 5950 - 1: 2000.: Sci Advisory DeskDocument2 paginiAD 301: The Use of Annex I1 of BS 5950 - 1: 2000.: Sci Advisory DeskLightninWolf32Încă nu există evaluări

- IS - 8110 - 2000 - Well Screens and Slotted Pipes SpecificationDocument19 paginiIS - 8110 - 2000 - Well Screens and Slotted Pipes SpecificationInsta PumpsÎncă nu există evaluări

- Vernacular Construction TechniquesDocument18 paginiVernacular Construction TechniquesAnupama ChawlaÎncă nu există evaluări

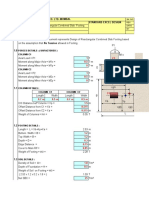

- Rectangular Combined FootingDocument38 paginiRectangular Combined FootingINNOVATIVE ENGINEERÎncă nu există evaluări

- Assessing The Accuracy of Load-Carrying Capacity Predictions of Ethiopian Standard, Compressive Force Path Method and Finite Element AnalysisDocument20 paginiAssessing The Accuracy of Load-Carrying Capacity Predictions of Ethiopian Standard, Compressive Force Path Method and Finite Element AnalysisTesfamichael AbathunÎncă nu există evaluări

- Lab Span DeflectionDocument15 paginiLab Span Deflectionliyana2030100% (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDe la EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseEvaluare: 4.5 din 5 stele4.5/5 (51)

- The Laws of Thermodynamics: A Very Short IntroductionDe la EverandThe Laws of Thermodynamics: A Very Short IntroductionEvaluare: 4.5 din 5 stele4.5/5 (10)