Documente Academic

Documente Profesional

Documente Cultură

Is 1448 16 1990

Încărcat de

Arun RaoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Is 1448 16 1990

Încărcat de

Arun RaoDrepturi de autor:

Formate disponibile

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 1448-16 (1990): Methods of test for petroleum and its

products, Part 16: Density, Relative Density or API Gravity

of Crude Petroleum and Liquid Petroleum Products by

Hydrometer Method [PCD 1: Methods of Measurement and Test

for Petroleum, Petroleum Products and Lubricants]

I ndian Standard

METHODS OF TEST FOR PETROLEUM AND

ITS PRODUCTS

[ P:l 6 J

DENSI TY, RELATI VE DENSI TY OR API GRAVI TY OF CRUDE PETROLEUM

AND LI QUI D PETROLEUM PRODUCTS BY HYDRdMETER METHOD

( 7Wrd Revision )

!kamj Reprint MAY 1999

UDC 665617 : 5423 : 5317543

@ BIS 1990

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

September 1990 Price Group 2

( Reaffirmed 2002 )

Methods of Test for Petroleum, Petroleum Products and Lubricants Sectional Committee, PCD 1

FOREWORD

This Indian Standard ( Part 16 ) ( Third Revision ) was adopted by the Bureau of Indian Standards

on 5 January 1990, after the,draft finalized by the Methods of Test for Petroleum, Petroleum

Products and Lubricants Sectional Committee had been approved by the Petroleum, Coal and

Related Products Division Council.

IS 1448 [ P : 16 ] : 1990

I ndian Standard

METHODSOFTESTFORPETROLEUMAND

ITSPRODUCTS

[ P:16]

DENSI TY. RELATI VE DENSI TY OR API GRAVITY OF CRUDE PETROLEUM

AND LI QUI D PETROLEUM PRODUCTS BY HYDROMETER METHOD

( Third Revisiort )

1 SCOPE

1.1 This method ( Part 16 ) covers the labora-

tory determination, using a glass hydrometer,

of the density, relative density, or API gravity

of crude petroleum, petroleum products, or

mixtures of petroleum and non-petroleum pro-

ducts normally handled as liquids and having a

Reid vapour pressure of 18 bar ( 179 kPa ) or

less { see IS 1448-f P : 39 ] : 1967 ).

The values

are measured on a hydrometer at convenient

temperatures, readings of density being reduced

to 15C, and that of specific gravity and API

gravity to 156C, by means of international

standard tables. By means of these same tables,

values determined in any one of the three systems

of measurement are convertible to equivalent

values in either of the other two so that measure-

ments may be made in the units of local

convenience.

1.2 The hydrometer method is most suitable for

determining the density, relative density, or API

gravity of mobile transparent liquids. It may

also be used for viscous oils by allowing sufli-

cient time for the hydrometer to reach equili-

brium or for opaque oils by employing a suitable

meniscus correction.

1.3 When used in connection with bulk oil

measurements,

volume correction errors are

minimized by observing the hydrometer reading

at a temperature close to that of the bulk oil

temperature.

2 REFERENCES

2.1 The following Indian Standards are necessary

adjuncts to this standard:

IS No.

Tirle

1448 [ P;f6;9 ] : Methods of test for petro-

leum and its products :

[ Part : 39 ] Vapour pres-

sure by Reid method ( jirsr

revision )

3104 : 1965 Density hydrometers

3 SUMMARY OF THE METHOD

3.1 The sample is brought to prescribed tem-

perature and transferred to a cylinder at approxi-

mately the same temperature.

The appropriate

hydrometer is lowered into the sample and

allowed to settle. After temperature equilibrium

has been reached, the hydrometer scale is read

and the temperature of the sample is noted.

If

necessary, the cylinder and its contents are

placed in a constant temperature bath to avoid

excessive temperature variation during the test.

4 SIGNIFICANCE

4.1 Accurate determination of density, relative

density, or API gravity of petroleum and its

products is necessary for the conversion of

measured volumes to volumes at standard tem-

perature of 15C.

4.2 Density, relative density, or API gravity is

a factor governing the quality of crude petro-

leum; crude petroleum prices are most frequen-

tly posted against values in API. However,

this property of a petroleum product is an un-

certain indication of its quality unless correlated

with other properties.

4.3 Crude oils frequently contain dispersed

water in sufficient quantity to affect the density

or relative density, particularly if the sample has

been homogenized. When reporting density,

relative density or API gravity, any sample treat-

ment which might affect the result shall be

reported. Drying of crude oils and products

containing volatile constituents is not recom-

mended since it is very difficult to avoid changes

due to evaporation.

5 TERMINOLOGY

5.1 Density

For the purpose of this method, density is the

mass ( weight in vucuo ) of liquid per unit

volume at 15%. When reporting results, ex-

plicitly state the density in units of mass and

volume, along with the standard reference tem-

perature, for example, g/ml at 15C.

5.2 Relative Density

For the purpose of this method, relative density

is the ratio of the mass of a given volume of

liquid at 156C to the mass of an equal volume

of pure water at the same temperature.

When

reporting results, explicitly state the standard

reference temperature, for example, relative

density 156/156C.

1

I S 1448 I P : 16 ) : 1990

5.3 API Gravity

A special function of relative density 156j156C

is represented by:

API gravity, degrees

1415

= Relative density at 156/156C

- 1315

No statement of reference temperature is requir-

ed, since 156C is included in the definition.

5.4 Observed Values

Since all hydrcmeter are calibrated to read

correctly at a specified reference temperature,

values observed at otber temperatures are only

hydrometer readings and not density, relative

density, or API gravity at that other tem-

perature.

6APPARATUS

6.1 Hydrometers

Hydrometers shall be made of glass, graduated

in units of density, relative density or API

gravity as required ( see IS 3104 : 1965 ).

6.2 Thermometer

Thermometers shall conform to the following

requirements:

a) Range * -20 to +102c .

n) Interval between

figures : 2%

p) Expansion chamber : ll l ;id;w heating

q) Top finish : Ring

r) Scale error, Max : 4. OlC

s) Line width, Max : 015 mm

6.3 Hydrometer Cylinder

Hydrometer cylinder shall be of clear glass,

plastic ( see Note ) or metal. For convenience in

pouring, the cylinder may have a lip on the

rim. The inside diameter of tbe cylinder shall

be at least 25 mm greater than the outside dia-

meter of the hydrometer used in it. The height

of the cylinder shall be such tuat the hydrometer

floats in the sample with at least 25 mm clear-

ance between the bottom of the hydrometer and

the bottom of the cylinder.

NOTE - Hydrometer cylinders constructed of

plastic materials shall be resistant to discoloration

or attack by oil samples and shall not become

opaque under prolonged exposure to sunlight and

oil samples.

6.4 Constant Temperature Bath

b) Graduation

c) Immersion

d) Overall length

e) Stem diameter

f) Bulb shape

g) Bulb length

h) Bulb diameter

. 02C .

: Total

: 415 to 425 mm

: 6to8mm

: Cylindrical

: 14 to 19 mm

: 6 to 7 mm and not

greater than that

of stem

NOTE - The user shall ascertain that the instru-

ments used for this test conform lo the require-

ments set out above with respect to materials,

dimensions and scale errors. Instruments which

have been checked in this manner are satisfactory

for general use. For determinations used for fiscal

or custody transfer purposes, users may wirh to use

instruments provided with a calibration certificate

issued by a reco nized standardizing body. Such

instruments are c assed as certified and the appro- f

priate corrections given on the certificate shall be

applied to the observed readings.

j) Length of graduated

7 TEMPERATURE OF TEST

portion : 305 to 350 mm

k) Distance between

7.1 The density, relative density or API gravity

the bottom of the

by the hydrometer method is most accurate at

bulb and graduation

or near the reference temperature of 15C. This

mark at -20C : 35 to 50 mm

or any other temperature between - 18 and

m) Interval between

+9OC shall be used so far as it is consistent

longer lines : 1C

with the type of sample and necessary limiting

conditions shown in Table 1.

Constant temperature bath Tshall be used when

the nature of the sample requires a test tempe-

rature much above or below room temperature

or the requirements of 8.8 cannot otherwise be

met ( see Note ).

samp~r TYPe

Highly volatile

Moderately volatile

Moderately volatile

and viscous

Non-volatile

Table 1 Lfmiting Conditions and Test Temperatures

( CIau,w 7.1 and 7.2 )

l ai t i d noi t hg Point other Limits Test Temperatore

F;id;;pour pressure below Cool in original closed con-

tainer to 2C or lower

12oOC and below

Cool in original closed con-

tainer to 18C or lower

12OC and below Viscosity too high at 18C Heat to minimum tempera-

ture to obtain sufiicient flui-

dity that Is, 10C above pour

poiot

Above f2O.C

Use any temperature not

above the Bash voiot between

Mixtures with non-

petroleum products

-18% and !XYd as convenient

Test at 15&@2%

2

IS 1448[P:16]:1990

7.2 When the hydrometer value is to be used

to select multipliers for correcting volumes to

standard temperatures, the hydrometer reading

should be made preferably at a temperature

within f 3C of the temperature at which the

bulk volume of the oil was measured ( see

Note ). However, in cases when appreciable

amount of light fractions may be lost during

determination at the bulk oil temperature, the

limits given in Table I should be applied.

NOTE - Volume correction and density ( relative

density, API gravity ) correction tables are based

on an average expansion for a number of typical

materials. Since tbe same coe5icieots were used in

computing both sets of tables, corrections made

over the same temperature interval minimize errors

arising from possible di5ereoces between the co-

efficients of the material under test and the standard

coefficients. This effect becomes more important

as temperatures diverge significantly from 15C.

8 PROCEDURE

8.1 Adjust the temperature of the sample

according to the indications given in 7. Bring

the hydrometer cylinder ( see Note ) and

thermometer to approximately the same tempe-

rature as the sample to be tested.

NOTE - When testing completely opaque samples,

metal hydrometer cylinders shall be used. When

such cylinders are used, accurate reading of the

hydrometer can only be assured if the level of the

sample is within 5 mm of the top of the cylinder.

8.2 Transfer the sample to a clean hydrometer

cylinder without splashing to avoid the formation

of air bubbles and to reduce the evaporation of

the lower boiling constituents of the more vola-

tile sample to a minimum. Transfer highly vola-

tile samples to the cylinder by water displacement

or by siphoning ( see Note ). Remove any; air

bubbles formed after they have collected on the

surface of the sample by touching them with a

piece of clean filter paper before inserting the

hydrometer. ,

NOTE - Highly volatile samples containing alco-

hols or other water-soluble material shall always be

transferred by siphoning.

8.3 Place the cylinder containing the sample in

a vertical position in a location free from air

currents. Ensure that the temperature of the

sample does not change appreciably during, the

time necessary to complete the test; during this

period, the temperature of the surrounding

medium should not change by more than 2C.

When testing at temperatures much above or

below morn temperature, a constant tempera-

ture bath may be necessary to avoid excessive

temperature changes.

8.4 Lower the hydrometer gently into the

sample. Take care to avoid wetting the stem

above the level to which it will be immersed in

the liquid. Continuously stir the sample with the

thermometer taking care that the mercury thread

is kept fully immersed and that the stem of the

hydrometer is not wetted above the immersion

level. As soon as a steady reading is obtained,

reCord the temperature of the sample to the

nearest 02C and then remove to thermometer.

8.5 Depress the hydrometer about two scale

divisions into the liquid and then release it. The

remainder of the stem of the hydrometer which

is above the level of the liquid, shall be kept

dry as the unnecessary liquid on the stem affects

the reading obtained. With samples of low

viscosity, impart a slight spin to the hydrometer

on releasing to assist in bringing it to rest float-

ing freely away from the walls of the cylinder.

Allow sufficient time for the hydrometer to come

to rest and for all air bubbles to come to the

surface. This is particularly necessary in the case

of more viscous samples.

8.6 When the hydrometer has come to rest,

floating freely away from the walls of the cylin-

der ( see Note ), estimate the hydrometer seal e

reading to the nearest 0000 5 relative density or

density or 005 deg API. The correct hydro-

meter reading is that point on the hydrometer

scale at which the principal surface of the liquid

cuts the scale. Determine this point by placing

the eye slightly below the level of the liquid and

slowly raising it until the surface, first seen as a

distorted ellipse, appears to become a straight

lize cutting the hydrometer scale.

NOTE - When using a plastic cylinder, dissipate

any static charge by wiping the outside of the

cylinder with a damp cloth. Static charges often

build up when using such cylinders and may pre-

vent the hydrometer from floating freely.

8.7 With an opaque liquid, take a reading by

observing with the eye slightly above the plane

of the surface of the liquid, the point on the

hydrometer scale to which the sample rises.

This reading at the top of the meniscus requires

correction since hydrometers are calibrated to be

read at the principal surface of the liquid.

The

correction for the particular hydrometer in use

may be determined by observing the maximum

height above the principal surface of the liquid

to which oil rises on the hydrometer scale when

the hydrometer in question is immersed in a

transparent oil having a surface tension similar

to that of the sample under test.

8.8 Immediately after observing the hydrometer

scale value again, cautiously stir the sample with

the thermometer, keeping the mercury thread

fully immersed. Record the temperature of the

sample to the nearest 02C ( see Note ).

If thi s

temperature differs from the previous reading by

more than OYC, repeat the hydrometer, and

then thermometer observations until. the tempe-

rature becomes stable within 0~5C.

NOTE -After use at a temperature higher than

38C, allow all hydrometers of the lead shot in wax

type to drain and cool in a vertical position.

9 CALCULATION AND REPORT

9.1 Apply any relevant corrections to the

observed thermometer readings and to the

3

-

I

fSl448IP:16]:1998

hydrometer reading. For an opaque sample, make

the appropriate correction to the observed

hydrometer readings as given in 8.7. Record to

the nearest 0000 1 density, relative density or

01 deg API the final hydrometer scale reading

( see Note ). After application of any relevaot

corrections, record to the nearest 05C. the

mean of the temperature values observed im-

mediately before and after the final hydrometer

reading.

NOTE? - Hydrometer scale reading3 at tempera-

tures other than calibration temperatures ( 15C )

should not be cousidered as more than scale read-

ings since the hydrometer bulb changes with

temperature.

9.2 To convert corrected values from 9.1 to

standard temperature, use the following from

the Petroleum Measurement Tables.

9.3 When a density scaled hydrometii has been

employed, use Tables 53A, 53B or 53D to obtain

density at 15C.

9.5 When an API gravity scaled hydrometer has

been employed, use Tables SA, SB or 5D to obtain

the gravity in API degrees.

9.6 When a value is obtained with a hydrometer

scaled in one of the units dzscribzd herein and

a result is required in one of the other units,

make the conversion by one of the appropriate

tables. For conversion from density at 15C,

use Table 51; from relative density 1561 I 56C,

use Table 21; from API gravity, use Table 3.

9.7 Report the final value as density in kgllitre

( gfml ) at lSC, relative density at 1561156C

or gravity in degrees API, as applicable giving

details of the hydrometer used.

10 PRECISION

10.1 Results of duplicate tests shall not differ

by more than the following amounts:

Product Temperature Range Units Repeatability Reproducibility

Transparent, non-viscous -2 to +245C Density 0000 5 0001 2

-2 to +24.5C Relative density 0000 5 0001 2

56 to 256C API gravity 01 03

Opaque

-2 to +245C Density 0000 6 00015

-2 to +24-5X! Relative density 0000 6 0001 5

56 to 256C API gravity 02 05

9.4 When a specific gravity hydrometer has been 10.2 For very viscous products or when the

employed use Tables 23A, 23B or 23D to obtain conditions given in 10.1 are not complied with,

specific gravity 15.6/l 56C.

no specific variation can be given.

4

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods and

attending to annected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary detpik, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publication), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffiimed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue

of BIS Handbook and Standards Monthly Additions.

This Indian Standard has been developed from Dot: No. PCD 1 ( 977 )

Amend No.

Amendments Issued Since Publication

Date of Issue Text Affected

Headquarters:

BUREAU OF INDIAN STANDARDS

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 Telegrams: Manaksanstha

Telephones: 323 0131,323 33 75,323 94 02 (Common to ail offices)

Regional Offices: Telephone

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern :

Northe& :

l/14 C.I.T. Scheme VII M, V.I.P. Road, Maniktola

CALCUTlA 700054

X0.335-336, Sector 34-A, CHANDIGARH 160022

Southern : C.I.T. Campus, IV Cross Road, CHENNAI 600113

Western :

Branches :

Manakalaya, E9 MIDC, Marol, Andheri (East)

{

832 92 95,832 78 5X

MUMBAI 400093

8327891,8327892

AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI.

HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.

PATNA. PUNE. THIRUVANANTHAPURAM.

323 76 17,323 38 41

337 84 99,337 85 61

337 86 26,337 91 ?O

1

60 38 43

60 20 25

{

235 02 16,235 04 42

235 15 19,235 23 15

Printed by Reprography Unit, BE, New Delhi

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- OCMA 350 Instruction ManualDocument64 paginiOCMA 350 Instruction ManualArun RaoÎncă nu există evaluări

- Properties of SiliconDocument2 paginiProperties of SiliconArun RaoÎncă nu există evaluări

- HalliburtonDocument1 paginăHalliburtonArun RaoÎncă nu există evaluări

- BGR ApplicationFormDocument4 paginiBGR ApplicationFormArun RaoÎncă nu există evaluări

- Hydrometer InformationDocument4 paginiHydrometer InformationArun RaoÎncă nu există evaluări

- Hydrometer InformationDocument4 paginiHydrometer InformationArun RaoÎncă nu există evaluări

- National Transportation Safety Board: Astm Standard D86: "Standard Test Method For Distillation of Petroleum Products."Document14 paginiNational Transportation Safety Board: Astm Standard D86: "Standard Test Method For Distillation of Petroleum Products."Arun RaoÎncă nu există evaluări

- 2013petrodist 100CC1Document3 pagini2013petrodist 100CC1Arun RaoÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- On Purpose Propylene Production UOPDocument29 paginiOn Purpose Propylene Production UOPWiroon Tanthapanichakoon CharlesÎncă nu există evaluări

- Astm Astm d2887 PDFDocument20 paginiAstm Astm d2887 PDFharÎncă nu există evaluări

- The Petroleum System-Status of Research and Methods, 1992 PDFDocument108 paginiThe Petroleum System-Status of Research and Methods, 1992 PDFDaniela GavrilÎncă nu există evaluări

- Sr22 ChecklistDocument4 paginiSr22 ChecklistJames DunnÎncă nu există evaluări

- Aux BLRDocument28 paginiAux BLRrohit_me083Încă nu există evaluări

- Research Study Diesel To BiomassDocument9 paginiResearch Study Diesel To BiomassDarrel MagnoÎncă nu există evaluări

- Gulf Harmony: Premium Quality Rust & Oxidation (R&O) Inhibited Multipurpose Lubricating OilsDocument1 paginăGulf Harmony: Premium Quality Rust & Oxidation (R&O) Inhibited Multipurpose Lubricating Oilsatripathi2009Încă nu există evaluări

- Food Grade Phosphoric Acid in TurkeyDocument6 paginiFood Grade Phosphoric Acid in TurkeyTrisna Kumala DhaniswaraÎncă nu există evaluări

- Astm D543Document7 paginiAstm D543PE EngÎncă nu există evaluări

- Packinox Pyrolysis Gasoline HydrogenationDocument2 paginiPackinox Pyrolysis Gasoline HydrogenationCorneliuPopaÎncă nu există evaluări

- TD301 Petrol Engine Datasheet 0417 PDFDocument3 paginiTD301 Petrol Engine Datasheet 0417 PDFAman BARIHAÎncă nu există evaluări

- Basai 1 PDFDocument79 paginiBasai 1 PDFBurra DayanandamÎncă nu există evaluări

- General Requirements For ValvesDocument16 paginiGeneral Requirements For ValvesKrishna Prasad R100% (1)

- Aspenhysys Petroleumassaysandoilcharacterizationslideshare 190305003017 PDFDocument215 paginiAspenhysys Petroleumassaysandoilcharacterizationslideshare 190305003017 PDFJAIDEEP VAIDYAÎncă nu există evaluări

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument56 paginiMaintenance Intervals: Operation and Maintenance Manual ExcerptAmr Abd ElrahmanÎncă nu există evaluări

- Chapter Three: Pumps and Their MaintenanceDocument6 paginiChapter Three: Pumps and Their MaintenanceAhmed RezkÎncă nu există evaluări

- X - Hydraulic Fluids Electronic HandoutDocument41 paginiX - Hydraulic Fluids Electronic HandoutRay Cepeda Mena100% (1)

- Ethanol Handling GuideDocument32 paginiEthanol Handling GuidePedro Manuel Rivera CalleÎncă nu există evaluări

- QSK60-M-2700hk - 1900rpmDocument97 paginiQSK60-M-2700hk - 1900rpmCalMoreira80% (5)

- Injera Baking MachineDocument12 paginiInjera Baking Machinebon voyage hasan100% (3)

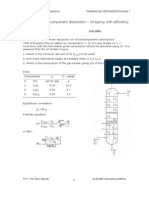

- Exercise 4: Multicomponent Absorption - Stripping With EfficiencyDocument3 paginiExercise 4: Multicomponent Absorption - Stripping With EfficiencyDanial KamranÎncă nu există evaluări

- Afpl CatalogDocument22 paginiAfpl CatalogYogeshÎncă nu există evaluări

- Ethylene BalanceDocument29 paginiEthylene BalanceCraigUnderwood100% (2)

- Diesel Engines Basic TheoryDocument3 paginiDiesel Engines Basic TheoryLaxman Singh SankhlaÎncă nu există evaluări

- JIG Bulletin 20 EI FAME Update Oct08.pdf Public PDFDocument4 paginiJIG Bulletin 20 EI FAME Update Oct08.pdf Public PDFpersadanusantaraÎncă nu există evaluări

- Refinery RR Model Documentation Final PDFDocument114 paginiRefinery RR Model Documentation Final PDFneiskerÎncă nu există evaluări

- Assignment 2 Q2Document2 paginiAssignment 2 Q2Johan Aliff0% (1)

- Ur Mom GayDocument2 paginiUr Mom Gaytom hillÎncă nu există evaluări

- Recommended Fluid VelocitiesDocument5 paginiRecommended Fluid Velocitiesger80100% (1)

- Student Practice Questions For Chemical Engineering Calculations For CombustionDocument6 paginiStudent Practice Questions For Chemical Engineering Calculations For CombustionDonPedrew60% (5)