Documente Academic

Documente Profesional

Documente Cultură

Diffuser Pipe Calculation

Încărcat de

mano_gce0 evaluări0% au considerat acest document util (0 voturi)

97 vizualizări15 paginidfsd

Titlu original

PRAE-J-1435-F_25.06.201

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLS, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentdfsd

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

97 vizualizări15 paginiDiffuser Pipe Calculation

Încărcat de

mano_gcedfsd

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 15

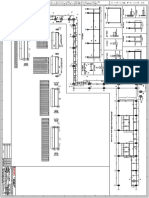

Description Value Unit

Component Name DIFFUSER PIPE -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 2.673 MPa

Design Temperature 540

o

C

550 NPS x 20 THK. -

559 x 20 OD x Nominal thickness

Material SA240 Gr.304 -

Ligament efficiency 51 %

Corrosion allowance 0 mm

Mill tolerance 0 %

Allowable stress 71.44 MPa

Available thickness 20.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 19.91 mm

Required thickness based on longitudinal stress 9.38 mm

Conclusion

DIFFUSER PIPE CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

SAFE

Description Value Unit

Component Name PIPE CAP -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 2.673 MPa

Design Temperature 540

o

C

550 NPS x 12 THK. Formed - 2:1 SEMI ELLIPSOIDAL

559 x 12 OD x Nominal thickness

Material SA240 Gr.304 -

Joint efficiency 100 %

Corrosion allowance 0 mm

Mill tolerance 0 %

Thinning allowance 15 %

Allowable stress 71.44 MPa

Crown radius 481.50 mm

Knuckle radius 90.95 mm

Available thickness 10.20 mm

Condition PASS -

Required thickness 10.05 mm

Conclusion

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 32

Size

SAFE

PIPE CAP CALCULATION

Description Value Unit

Component Name SILENCER SHELL -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 0.147 MPa

Design Temperature 540

o

C

Size 3600 x 6 THK OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 111 MPa

Available thickness 4.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 2.80 mm

Required thickness based on longitudinal stress 1.40 mm

Conclusion

According to ASME Section VIII Division I Edition 2010 Addenda 2011a - UG 27

SAFE

SILENCER SHELL CALCULATION

Description Value Unit

Component Name SILENCER DISHED HEAD -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 0.147 MPa

Design Temperature 540

o

C

Size 3600 x 10 THK OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 100 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Thinning allowance 15 %

Allowable stress 111 MPa

Crown radius 3222.00 mm

Knuckle radius 608.6 mm

Available thickness 6.50 mm

Condition PASS -

Required thickness 2.37 mm

Conclusion

Nozzle size 559 x 20 OD x Nominal thickness

Required thickness of nozzle 19.91 mm

Allowable stress of nozzle 71.44 MPa

Nozzle inside projection 500 mm

Pad plate provision YES -

Pad plate thickness 12 -

Pad plate width 200 -

Compensation area required 1264.27 mm

2

compensation area available 2669.45 mm

2

Conclusion

According to ASME Section VIII Division I Edition 2010 Addenda 2011a - UG 32 & UG 37

SAFE

SILENCER DISHED HEAD CALCULATION

SAFE

Description Value Unit

Component Name CONNECTING PIPE-I -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

450 NPS x 40 THK. -

457 x 40 OD x Nominal thickness

Material SA240 Gr.304 -

Joint efficiency 85 %

Corrosion allowance 0 mm

Mill tolerance 0 %

Allowable stress 71.44 MPa

Available thickness 40.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 37.10 mm

Required thickness based on longitudinal stress 16.03 mm

Conclusion

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

SAFE

CONNECTING PIPE-I CALCULATION

FLANGE SA182 F91 MATERIAL 1500# IS REQUIRED.

Description Value Unit

Component Name CONNECTING PIPE-II -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 5.345 MPa

Design Temperature 540

o

C

500 NPS x 24 THK. -

508 x 24 OD x Nominal thickness

Material SA240 Gr.304 -

Joint efficiency 85 %

Corrosion allowance 0 mm

Mill tolerance 0 %

Allowable stress 71.44 MPa

Available thickness 24.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 21.37 mm

Required thickness based on longitudinal stress 9.95 mm

Conclusion

CONNECTING PIPE-II CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

SAFE

Description Value Unit

Component Name DIFFUSER PIPE -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 2.673 MPa

Design Temperature 540

o

C

550 NPS x 16 THK. -

559 x 16 OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Ligament efficiency 51 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 111 MPa

Available thickness 14.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 12.80 mm

Required thickness based on longitudinal stress 6.16 mm

Conclusion

DIFFUSER PIPE CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

SAFE

Description Value Unit

Component Name PIPE CAP -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 2.673 MPa

Design Temperature 540

o

C

550 NPS x 12 THK. Formed - 2:1 SEMI ELLIPSOIDAL

559 x 12 OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 100 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Thinning allowance 15 %

Allowable stress 111 MPa

Crown radius 481.50 mm

Knuckle radius 90.95 mm

Available thickness 8.20 mm

Condition PASS -

Required thickness 6.46 mm

Conclusion

Size

SAFE

PIPE CAP CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 32

Description Value Unit

Component Name SILENCER SHELL -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 0.147 MPa

Design Temperature 540

o

C

Size 3600 x 6 THK OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 111 MPa

Available thickness 4.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 2.80 mm

Required thickness based on longitudinal stress 1.40 mm

Conclusion

SILENCER SHELL CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a - UG 27

SAFE

Description Value Unit

Component Name SILENCER DISHED HEAD -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 0.147 MPa

Design Temperature 540

o

C

Size 3600 x 10 THK OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 100 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Thinning allowance 15 %

Allowable stress 111 MPa

Crown radius 3222.00 mm

Knuckle radius 608.6 mm

Available thickness 6.50 mm

Condition PASS -

Required thickness 2.37 mm

Conclusion

Nozzle size 559 x 16 OD x Nominal thickness

Required thickness of nozzle 12.80 mm

Allowable stress of nozzle 111 MPa

Nozzle inside projection 500 mm

Pad plate provision YES -

Pad plate thickness 12 -

Pad plate width 200 -

Compensation area required 1249.44 mm

2

compensation area available 2932.04 mm

2

Conclusion

According to ASME Section VIII Division I Edition 2010 Addenda 2011a - UG 32 & UG 37

SAFE

SAFE

SILENCER DISHED HEAD CALCULATION

Description Value Unit

Component Name CONNECTING PIPE-I -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

450 NPS x 28 THK. -

457 x 28 OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 111 MPa

Available thickness 26.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 24.37 mm

Required thickness based on longitudinal stress 11.11 mm

Conclusion SAFE

CONNECTING PIPE-I CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

FLANGE SA182 F91 MATERIAL 1500# IS REQUIRED.

Description Value Unit

Component Name CONNECTING PIPE-II -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 5.345 MPa

Design Temperature 540

o

C

500 NPS x 16 THK. -

508 x 16 OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 111 MPa

Available thickness 14.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 13.96 mm

Required thickness based on longitudinal stress 6.67 mm

Conclusion

CONNECTING PIPE-II CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

SAFE

SA240 Gr.304 SA387 Gr.91 CL.2

SILENCER SHELL - 6

SILENCER DISHED HEAD - 10

DIFFUSER PIPE 20 16

DIFFUSER CAP 12 12

CONNECTING PIPE-I 40 28

CONNECTING PIPE-II 24 16

THICKNESS OF THE MATERAIAL IN "mm"

ITEMS

S-ar putea să vă placă și

- 2400 Tema DCDocument7 pagini2400 Tema DCMasoodMiyanÎncă nu există evaluări

- Compress EvaluateDocument23 paginiCompress EvaluateVishalDhiman100% (1)

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 paginiASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaÎncă nu există evaluări

- Ideametrics Company Profile V1.3Document3 paginiIdeametrics Company Profile V1.3Sangram P Powar100% (1)

- FEA Validation Release 2010Document7 paginiFEA Validation Release 2010DHAVAL PANCHALÎncă nu există evaluări

- Fan Noise EstimateDocument5 paginiFan Noise EstimateBen ClackÎncă nu există evaluări

- Design by AnalysisDocument22 paginiDesign by AnalysisJEELE77Încă nu există evaluări

- ASME SecVIII Div-2 Hydro TestDocument2 paginiASME SecVIII Div-2 Hydro Testsouren1975Încă nu există evaluări

- PDF2 L Hydraulic CylinderDocument56 paginiPDF2 L Hydraulic CylinderShyam Srinivasan100% (1)

- Pressure Vessel Inspection ReportDocument34 paginiPressure Vessel Inspection ReportJinlong SuÎncă nu există evaluări

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationDocument2 paginiWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarÎncă nu există evaluări

- Analysis of a rectangular pressure vesselDocument7 paginiAnalysis of a rectangular pressure vesselPressure VesselÎncă nu există evaluări

- SP-2069 Specification For Pressure VesselsDocument68 paginiSP-2069 Specification For Pressure Vesselsarjunprasannan7Încă nu există evaluări

- Caesar Wrc107and297Document3 paginiCaesar Wrc107and297spiritizÎncă nu există evaluări

- Nozzle Load - PumpDocument1 paginăNozzle Load - Pumpduf fu0% (1)

- Chibro Press Fit Piping Data SheetDocument5 paginiChibro Press Fit Piping Data SheetBoyd JohnstonÎncă nu există evaluări

- Pipe Thickness Calculation Data SheetDocument1 paginăPipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9Încă nu există evaluări

- Back Pressure Exhaust System Calculation Generating Set Perkins 2X650 Kva Project NovotelDocument4 paginiBack Pressure Exhaust System Calculation Generating Set Perkins 2X650 Kva Project NovotelWisnu Andra Isdianto100% (1)

- BS 5500 Appendix K and DDocument14 paginiBS 5500 Appendix K and DCRISTIAN SILVIU IANUCÎncă nu există evaluări

- Control Flownex SimulinkDocument8 paginiControl Flownex SimulinkSrashmiÎncă nu există evaluări

- Actuator Selection Guide For Flow-Tek Ball ValvesDocument16 paginiActuator Selection Guide For Flow-Tek Ball ValvesArt G. EnziÎncă nu există evaluări

- Asme Viii Calculation Xls PDF FreeDocument28 paginiAsme Viii Calculation Xls PDF FreeMisbachul ChoirÎncă nu există evaluări

- External Pressure Calculation Results SummaryDocument8 paginiExternal Pressure Calculation Results SummaryAndika DearsonÎncă nu există evaluări

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 paginiCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- ASCE 7-05 Table 15-4-2Document1 paginăASCE 7-05 Table 15-4-2barouniamineÎncă nu există evaluări

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 paginiCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareÎncă nu există evaluări

- Vent Silencer Specification SheetDocument2 paginiVent Silencer Specification SheetAqeel Bisma100% (1)

- Skid Frame Calculation Sheet: LPG MeteringDocument11 paginiSkid Frame Calculation Sheet: LPG MeteringidilfitriÎncă nu există evaluări

- Expansion LoopDocument54 paginiExpansion Loopsteepa22Încă nu există evaluări

- Pressure Vessel Fea Consulting Services - Asme Section Viii Division 2 Fatigue AnalysisDocument6 paginiPressure Vessel Fea Consulting Services - Asme Section Viii Division 2 Fatigue AnalysisAbhay UpadhyayÎncă nu există evaluări

- Codeware Interface 2018 Installation GuideDocument20 paginiCodeware Interface 2018 Installation GuideRaul GonzaloÎncă nu există evaluări

- 2013 SECTION IX GUIDANCE FOR USING CUSTOMARY AND SI UNITSDocument3 pagini2013 SECTION IX GUIDANCE FOR USING CUSTOMARY AND SI UNITSMohdBadruddinKarimÎncă nu există evaluări

- Pipe Cap Thickness Calculation for ASME Section VIIIDocument9 paginiPipe Cap Thickness Calculation for ASME Section VIIILcm TnlÎncă nu există evaluări

- Finglowv2Document16 paginiFinglowv2RobinReyndersÎncă nu există evaluări

- Calculation of RC PAD2Document1 paginăCalculation of RC PAD2m 418Încă nu există evaluări

- Oil Cooler - Pre Design Data SheetDocument3 paginiOil Cooler - Pre Design Data SheetSakthi VelÎncă nu există evaluări

- Deaera DesignDocument13 paginiDeaera DesignBhanu K PrakashÎncă nu există evaluări

- Elliptical Head Design ToolDocument1 paginăElliptical Head Design ToolSudjono BroÎncă nu există evaluări

- Stress RelievingDocument1 paginăStress RelievingCruz Gabriel Rosetti100% (1)

- AB 520 Finite Element Analysis FEA Requirements PDFDocument4 paginiAB 520 Finite Element Analysis FEA Requirements PDFbello imamÎncă nu există evaluări

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocument1 paginăK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjÎncă nu există evaluări

- Sa 420Document10 paginiSa 420Widya widyaÎncă nu există evaluări

- Ccsviiid1 2260Document2 paginiCcsviiid1 2260DieguitoOmarMoralesÎncă nu există evaluări

- Nozzle Load Check As Per TEMADocument2 paginiNozzle Load Check As Per TEMAvm153748763Încă nu există evaluări

- FVCDocument0 paginiFVCsmileya_vpÎncă nu există evaluări

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 paginiFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyÎncă nu există evaluări

- AES Type Heat ExchangerDocument8 paginiAES Type Heat ExchangerSudhanshu67100% (1)

- Joule Thomson EffectDocument2 paginiJoule Thomson EffectElliott100% (1)

- SEISMIC ANALYSIS KazzincDocument14 paginiSEISMIC ANALYSIS KazzincArees KhambattaÎncă nu există evaluări

- Ansi B16.9-16.28-MSS SP-43Document3 paginiAnsi B16.9-16.28-MSS SP-43vangie3339515Încă nu există evaluări

- Astm F436.04 PDFDocument6 paginiAstm F436.04 PDFWelington Volpatto MoraisÎncă nu există evaluări

- Internal Pipe Distributor Design ProcedureDocument5 paginiInternal Pipe Distributor Design Proceduresenthil kumarÎncă nu există evaluări

- Nioec SP 00 89 (R0) (Ed1)Document8 paginiNioec SP 00 89 (R0) (Ed1)aminÎncă nu există evaluări

- 5.7 Asmeviii A-2 & Tema Split Backing RingDocument1 pagină5.7 Asmeviii A-2 & Tema Split Backing RingpastylÎncă nu există evaluări

- Stress Analysis and Design Optimization of A Pressure Vessel Using Ansys PackageDocument12 paginiStress Analysis and Design Optimization of A Pressure Vessel Using Ansys Packageanthony zegarra ochoaÎncă nu există evaluări

- Tailing LugDocument3 paginiTailing LugSajad AbdulÎncă nu există evaluări

- Loadings and Sign Convention SummaryDocument9 paginiLoadings and Sign Convention SummaryGovindan KrishnamoorthybashyamÎncă nu există evaluări

- Solar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsDe la EverandSolar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsM. G. HutchinsÎncă nu există evaluări

- Prae J 1435 F Output Rev00Document12 paginiPrae J 1435 F Output Rev00mano_gceÎncă nu există evaluări

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 paginiDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Încă nu există evaluări

- FS0002 Document Number-R0Document5 paginiFS0002 Document Number-R0mano_gceÎncă nu există evaluări

- Cethar Vessels LTD.,: Wind Pressure Calculations (As Per Is - 875 1983)Document2 paginiCethar Vessels LTD.,: Wind Pressure Calculations (As Per Is - 875 1983)mano_gceÎncă nu există evaluări

- CR 15-17 Pump Performance CurveDocument3 paginiCR 15-17 Pump Performance Curvemano_gceÎncă nu există evaluări

- Chennai - KolkataDocument2 paginiChennai - Kolkatamano_gceÎncă nu există evaluări

- S Vinoth BankDocument1 paginăS Vinoth Bankmano_gceÎncă nu există evaluări

- CV GandhiDocument5 paginiCV Gandhimano_gceÎncă nu există evaluări

- Ga - Elevation & Side View PDFDocument1 paginăGa - Elevation & Side View PDFmano_gceÎncă nu există evaluări

- Ismc MB ModelDocument1 paginăIsmc MB Modelmano_gceÎncă nu există evaluări

- Ga - Elevation & Side View PDFDocument1 paginăGa - Elevation & Side View PDFmano_gceÎncă nu există evaluări

- Lifting Lug Design CalculationDocument8 paginiLifting Lug Design Calculationmano_gceÎncă nu există evaluări

- Car Loan ClosedDocument3 paginiCar Loan Closedmano_gceÎncă nu există evaluări

- IBR_SHELL_NOZZLE_CALCDocument3 paginiIBR_SHELL_NOZZLE_CALCmano_gceÎncă nu există evaluări

- SENTHIL TRANSFER-tank RoofDocument1 paginăSENTHIL TRANSFER-tank Roofmano_gceÎncă nu există evaluări

- System-5 D Vengadesan Projects 2018 RCL Structure Update Ad007!06!002-0-001 R0-ModelDocument1 paginăSystem-5 D Vengadesan Projects 2018 RCL Structure Update Ad007!06!002-0-001 R0-Modelmano_gceÎncă nu există evaluări

- 2M15250 2 ModelDocument1 pagină2M15250 2 Modelmano_gceÎncă nu există evaluări

- Hosts UmbrellaDocument1 paginăHosts UmbrellaFabsor SoralÎncă nu există evaluări

- Is 14684 - 1999 Determination of Nitrogen and Nitrogenous Compounds in SoilsDocument5 paginiIs 14684 - 1999 Determination of Nitrogen and Nitrogenous Compounds in SoilsPrapa KaranÎncă nu există evaluări

- Appendix ADocument14 paginiAppendix ACristiano Eduardo AntunesÎncă nu există evaluări

- Rectangular Tank Design PDFDocument71 paginiRectangular Tank Design PDFPrajwal Shetty87% (15)

- Prae J 1435 F Output Rev00Document12 paginiPrae J 1435 F Output Rev00mano_gceÎncă nu există evaluări

- ValveDocument2 paginiValvemano_gceÎncă nu există evaluări

- Droit Consulting Engineers: 1. Address SealDocument2 paginiDroit Consulting Engineers: 1. Address Sealmano_gceÎncă nu există evaluări

- Diffuser Pipe CalculationDocument15 paginiDiffuser Pipe Calculationmano_gceÎncă nu există evaluări

- Prae J 1435 F OutputDocument14 paginiPrae J 1435 F Outputmano_gceÎncă nu există evaluări

- Suresh V Palisetti scribdDocument1 paginăSuresh V Palisetti scribdmano_gceÎncă nu există evaluări

- Storage Tank With Steam Sparger PipeDocument1 paginăStorage Tank With Steam Sparger Pipemano_gceÎncă nu există evaluări

- Deaerator - Reference ProjectDocument1 paginăDeaerator - Reference Projectmano_gceÎncă nu există evaluări

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument8 paginiAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Storage Tank With Steam Sparger PipeDocument1 paginăStorage Tank With Steam Sparger Pipemano_gceÎncă nu există evaluări

- FIRST TERMINAL EVALUATION 2021-22 PHYSICS CLASS XDocument3 paginiFIRST TERMINAL EVALUATION 2021-22 PHYSICS CLASS XLahnÎncă nu există evaluări

- ADIABATIC FLOW IN A DUCT WITH FRICTION (FANNO FLOWDocument30 paginiADIABATIC FLOW IN A DUCT WITH FRICTION (FANNO FLOWHamza AshrafÎncă nu există evaluări

- Project SynopsisDocument8 paginiProject Synopsistaran jot100% (1)

- Niven, Larry - at The Bottom of A HoleDocument10 paginiNiven, Larry - at The Bottom of A Holehilly8Încă nu există evaluări

- NuFlo. MC-II. Plus EXP Flow AnalyzerDocument2 paginiNuFlo. MC-II. Plus EXP Flow AnalyzerFouad MenidjelÎncă nu există evaluări

- Ючай каталог 1Document78 paginiЮчай каталог 1Евгений100% (1)

- 2 - Acid and Base TitrationDocument90 pagini2 - Acid and Base TitrationEnin SofiyaÎncă nu există evaluări

- Cable Installation Manual For Power and Control Cables: Global ReachDocument100 paginiCable Installation Manual For Power and Control Cables: Global Reacharjmandquest100% (1)

- Liebert EXM 80-200 kVA PDFDocument123 paginiLiebert EXM 80-200 kVA PDFrogeriopaulaÎncă nu există evaluări

- International MaxxForce engine fault code troubleshooting guideDocument14 paginiInternational MaxxForce engine fault code troubleshooting guidePablo CervantesÎncă nu există evaluări

- Proforma 300 L Dye. Alibaba PDFDocument3 paginiProforma 300 L Dye. Alibaba PDFFer ChicoÎncă nu există evaluări

- 436 - 1 - 1 - Sampling of CoalDocument24 pagini436 - 1 - 1 - Sampling of CoalSudhanshu DashÎncă nu există evaluări

- Effinet Service Manual1Document63 paginiEffinet Service Manual1Willian Santiago CardenasÎncă nu există evaluări

- rr320801 Mass Transfer Operations IIDocument7 paginirr320801 Mass Transfer Operations IISRINIVASA RAO GANTAÎncă nu există evaluări

- Carrier Chiller CatalogDocument28 paginiCarrier Chiller CatalogYh Leong100% (1)

- Clivet Carel PcoDocument80 paginiClivet Carel PcoToni Dlabac100% (2)

- Information Sheets 6.1.4Document12 paginiInformation Sheets 6.1.4api-196541959Încă nu există evaluări

- GreenTech EC Technology enDocument44 paginiGreenTech EC Technology enspscribd1Încă nu există evaluări

- Ecovillage TesisDocument92 paginiEcovillage TesisLaura Mirella Morote LAricoÎncă nu există evaluări

- Green Building Rating Systems ExplainedDocument42 paginiGreen Building Rating Systems ExplainedJake CerezoÎncă nu există evaluări

- DigitalDocument4 paginiDigitalideal assignment helper 2629Încă nu există evaluări

- Green ConcreteDocument22 paginiGreen ConcreteQseem Khan100% (1)

- Fermentor TypesDocument33 paginiFermentor TypesFahad MukhtarÎncă nu există evaluări

- Mahle GrafalDocument273 paginiMahle GrafalErnesto CruzaltaÎncă nu există evaluări

- Reiki - More Concerning The SymbolsDocument25 paginiReiki - More Concerning The SymbolsJames Deacon100% (7)

- Partial Molar Heat Content and Chemical Potential, Significance and Factors Affecting, Gibb's-Duhem EquationDocument11 paginiPartial Molar Heat Content and Chemical Potential, Significance and Factors Affecting, Gibb's-Duhem EquationRhakhoÎncă nu există evaluări

- Group 2 Financial Brick Case StudyDocument9 paginiGroup 2 Financial Brick Case StudyMDÎncă nu există evaluări

- Problems PDFDocument246 paginiProblems PDFJasdeep singhÎncă nu există evaluări

- Learn Discrete ComponentsDocument2 paginiLearn Discrete ComponentsamitcrathodÎncă nu există evaluări

- Diagrama de Interconexion XL 200 PDFDocument9 paginiDiagrama de Interconexion XL 200 PDFjoseÎncă nu există evaluări