Documente Academic

Documente Profesional

Documente Cultură

Application Inert e

Încărcat de

tapaix0 evaluări0% au considerat acest document util (0 voturi)

93 vizualizări14 paginiBlanketing valve principle

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentBlanketing valve principle

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

93 vizualizări14 paginiApplication Inert e

Încărcat de

tapaixBlanketing valve principle

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 14

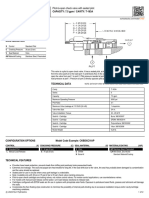

Principle of Inertization / Blanketing

Low pressure reducing valve

Type LPR or ZM-R

20 mbar g N

2

2 bar g

Back pressure relief valve

Type LPS or ZM-B

40 mbar g

to ambient

Standard Pressure Service

www.zimmerli-inert.com, J anuary 2009, page 1/14 Under reserve of modifications

Principle of Inertization / Blanketing

Modern inertization

The technology of ZIMMERLI Messtechnik AG can safe you a lot of money and energy. This is how it works:

From the supply network, nitrogen with a pressure of up to 10 bar g is fed directly into the Zimmerli low pressure

regulator (ZM-R or LPR) where its pressure is reduced down to e.g. +20 mbar g.

On the exit side of the process, a pressure relief valve (ZM-B or LPS) does not release protective gas until the

pressure has risen to e.g. 40 mbar g. As long as the process pressure ranges between 20 and 40 mbar g, absolutely

no nitrogen is consumed.

Process Filling:

When material is filled into the process, the protective gas is compressed accordingly. This raises the reactor

pressure. As soon as its limit (e.g. 40 mbar g) has been reached, the Zimmerli pressure relief valve opens thus

preventing any further pressure increase. Zimmerli pressure relief valves are also called back pressure relief valves.

Process Discharge:

When material is taken from process, the protective gas atmosphere expands accordingly. This decreases the

reactor pressure. As soon as the pressure falls below the limit (e.g. 20 mbar g) the Zimmerli reducing valve opens to

prevent any further loss of pressure. Hence the blanketing pressure always ranges between the limit of the reducer

(20 mbar g) and that of the pressure relief valve (40 mbar g).

Technology:

Zimmerli low pressure reducing valves and Zimmerli low pressure relief valves are sensitive differential pressure

regulators, which always maintain their set limits on the basis of the momentary atmospheric pressure. This

safeguards constant blanketing pressure under any atmospheric conditions.

Optionally, all low pressure regulators can be equipped ex works with active OFF or active ON safety features.

www.zimmerli-inert.com, J anuary 2009, page 2/14 Under reserve of modifications

Low pressure reducing valve

Type LPR/D or ZM-R/D

20 mbar g

2020 mbar g

N

2

5 bar g

Back pressure relief valve

Type LPS/D or ZM-B/D

Electro / Pneumatic

servo control

max. 2000 mbar g

to ambient

Principle of Dome-loaded Regulation

40 mbar g

2040 mbar g

Variable Pressure Service

www.zimmerli-inert.com, J anuary 2009, page 3/14 Under reserve of modifications

Principle of Dome-loaded Regulation

High pressure blanketing:

This application describes the operation of a plant using dome-loaded pressure regulation. From the supply network,

nitrogen with a pressure of up to 10 bar g is fed directly into the Zimmerli dome-loaded pressure regulator (ZM-R/D or

LPR/D) where its pressure is reduced to e.g. +20 mbar g.

On the exit side of the process, a dome-loaded pressure relief valve (ZM-B/D or LPS/D) does not release protective

gas until the pressure has risen to e.g. 40 mbar g. As long as process pressure ranges between 20 and 40 mbar g,

absolutely no nitrogen is consumed.

Process Filling:

When material is filled into the process, the protective gas is compressed accordingly. This raises the reactor pressure.

As soon as its limit (e.g. 40 mbar g) has been reached, the Zimmerli pressure relief valve opens thus preventing any

further pressure increase. Zimmerli pressure relief valves are also called back pressure relief valves.

Process Discharge:

When material is taken from reactor, the protective gas atmosphere expands accordingly. This decreases the reactor

pressure. As soon as the pressure falls below the limit (e.g. 20 mbar g) the Zimmerli reducing valve opens to prevent

any further loss of pressure. Hence the blanketing pressure always ranges between the limit of the reducer (20 mbar g)

and that of the pressure relief valve (40 mbar g).

Dome-loaded pressure regulation using a pilot controller:

A pilot controller actuates Zimmerli low pressure regulators and Zimmerli pressure relief valves simultaneously with a

dome-loaded pressure of up to 2000 mbar g for high pressure blanketing. This shifts the limit values proportionally up

to e.g. 2020 and 2040 mbar g. Various types of suitable pilot controllers are available on request. High pressure

blanketing allows, for example, faster inertization or product conveyance without a pump.

Optionally, all low pressure regulators can be equipped ex works with active OFF or active ON safety features.

www.zimmerli-inert.com, J anuary 2009, page 4/14 Under reserve of modifications

Vacuum pressure reducing valve

Type LPR/N or ZM-R/N

-40 mbar g

N

2

2 bar g

Permanent Vacuum Service

Vacuum pressure relief valve

Type LPS/N or ZM-B/N

-20 mbar g

Vacuum

Pump

Principle of Negative Pressure Regulation

www.zimmerli-inert.com, J anuary 2009, page 5/15 Under reserve of modifications

Principle of Negative Pressure Regulation

Negative pressure blanketing:

This application describes the operation of a plant using negative pressure regulation. From the supply network, nitrogen

with a pressure of up to 10 bar g is fed directly into the Zimmerli negative pressure regulator (ZM-R/N or LPR/N) where its

pressure is reduced to e.g. -40 mbar g.

On the exit side of the process, a Zimmerli negative pressure relief valve (ZM-B/N or LPS/N) does not release protective

gas until the pressure has risen to e.g. -20 mbar g. As long as the process pressure ranges between -40 and -20 mbar g,

absolutely no nitrogen is consumed.

Process Filling:

When material is filled into the process, the protective gas is compressed accordingly. This raises the reactor pressure. As

soon as its limit (e.g. -20 mbar g) has been reached, the Zimmerli pressure relief valve opens thus preventing any further

pressure increase. Zimmerli pressure relief valves are also called back pressure relief valves.

Process Discharge:

When material is taken from reactor, the protective gas atmosphere expands accordingly. This decreases the reactor

pressure. As soon as the pressure falls below the limit (e.g. -40 mbar g) the Zimmerli reducing valve opens to prevent any

further loss of pressure. Hence the blanketing pressure always ranges between the limit of the reducer (-40 mbar g) and

that of the pressure relief valve (-20 mbar g).

Important note:

Negative pressure blanketing only works if, for example, a vacuum pump provides the necessary negative pressure

behind the pressure relief valve. In the case outlined above, this negative pressure has to be below -20 mbar g in any

case, so that the pressure relief valve can discharge at all.

Zimmerli negative pressure regulators and Zimmerli negative pressure relief valves are vacuum tight.

Optionally, all low pressure regulators can be equipped ex works with active OFF or active ON safety features.

www.zimmerli-inert.com, J anuary 2009, page 6/14 Under reserve of modifications

Short distance*:

Install regulators as close to tank or process as ever possible. Dynamic pressure drop in

longer pipes may limit gas flow dramatically.

Flow direction:

Care on correct flow direction as per flow tag on each regulator. Wrong flow direction

causes malfunction (no flow or no pressure control).

Recommended:

vertical installation

Top/bottom flow

Recommended:

horizontal installation

*

*

Application Hints

www.zimmerli-inert.com, J anuary 2009, page 7/14 Under reserve of modifications

*In case of longer distance between

regulator and process a C-connection

with pulse line is required at all.

Flow direction:

Horizontal flow direction is ideal.

Top/bottom flow direction is acceptable

Do not:

Do never ever install device upside/down!

Prevent bottom/top flow direction (danger of condensate in diaphragm housing)

No/Go Questionable

Acceptable Ideal

Application Hints

www.zimmerli-inert.com, J anuary 2009, page 8/14 Under reserve of modifications

Example

V

1

= 118 m3

P

1

= 7 bar abs

V

2

= ?

P

2

= 1 bar abs

V

1

x P

1

p

2

V

2

=

118 x 7

1

= 826 m3

P

1

= 7 bar abs P

2

= 1 bar abs

V

1

= 118 m3

V

2

= ?*

Care on Boyle Mariott Gas Low p

1

x V

1

= p

2

x V

2

*Prevent dynamic pressure drop on secondary

V

2

=

Application Hints

www.zimmerli-inert.com, J anuary 2009, page 9/14 Under reserve of modifications

FI

PICV

PCV

N

2

entry

Product exit

N

2

exit

Product entry

No/Go

No/Go

This installation creates malfunction

due to pulsation and chatter effects!

Flowmeter pressure drop is too high!

Application Hints

www.zimmerli-inert.com, J anuary 2009, page 10/14 Under reserve of modifications

FI

Product entry

PICV

PCV

N

2

entry

Product exit

N

2

exit

Install any

Flowmeter

on primary only

Application Hints

www.zimmerli-inert.com, J anuary 2009, page 11/14 Under reserve of modifications

Application: out-door

Protect this area against

moisture penetration

with a type of cover

Also: as per model option

Application Hints

www.zimmerli-inert.com, J anuary 2009, page 12/14 Under reserve of modifications

Bench Calibration:

Calibrate set-point as per

real installation position

(vertical or horizontal)

Make calibration under

dynamic flow conditions

(device is not self venting)

Prevent pressure shock

during calibration

(open valve carefully)

Application Hints

www.zimmerli-inert.com, J anuary 2009, page 13/14 Under reserve of modifications

1. Select reducer valve seat at least as per max product discharge rate of tank

or vessel (worst case flow rate) x 2*

2. Select relief valves seat at least as per max product filling rate of tank or

vessel (worst case flow rate) x 2*

3. * Alternatively, use Flow Computation program (as per download)

4. Reducing- and Relief-valves need to be installed as close to process as ever

possible (prevent long pipe sections and any flow restrictions)

5. Prefer horizontal installation (vertical installation on request)

6. Care on flow direction as per flow mark

7. In case of collectors or longer pipe sections used between reducer and

process, use generally option C-connection(with pulse line to process)

8. Prevent pressure shock on primary side (open ball valve slowly)

9. In case of questions left, email questionnaire we help you!

If you care on this, you will be happy with Zimmerli valves, long term!

Application Hints

www.zimmerli-inert.com, J anuary 2009, page 14/14 Under reserve of modifications

S-ar putea să vă placă și

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- ComapDocument44 paginiComapfabianoal50% (2)

- Pneumatic, Vacuum and Auxiliary Components Introduction of Custom Order Products (0.2MB)Document4 paginiPneumatic, Vacuum and Auxiliary Components Introduction of Custom Order Products (0.2MB)Rick HunterÎncă nu există evaluări

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationDe la EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationÎncă nu există evaluări

- STF Kemim ValveDocument3 paginiSTF Kemim ValveTayebASherifÎncă nu există evaluări

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDe la EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationÎncă nu există evaluări

- STF Kemim ValveDocument3 paginiSTF Kemim ValveTayebASherifÎncă nu există evaluări

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SDe la EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SÎncă nu există evaluări

- STF Kemim ValveDocument3 paginiSTF Kemim ValveTayebASherifÎncă nu există evaluări

- Pipenet News Summer 2007Document10 paginiPipenet News Summer 2007Bánh Cuốn Tôm ThịtÎncă nu există evaluări

- Afe Main Acc EsdDocument2 paginiAfe Main Acc EsdEthan HuntÎncă nu există evaluări

- Pressure Powered PumpDocument8 paginiPressure Powered Pumptatoo1Încă nu există evaluări

- Regulador 1253 B - American M.Document8 paginiRegulador 1253 B - American M.Jheysson FloresÎncă nu există evaluări

- GC2020C SDocument50 paginiGC2020C Sfoto_geneÎncă nu există evaluări

- Mankenberg Vacuum ValveDocument10 paginiMankenberg Vacuum ValveAnibal QuezadaÎncă nu există evaluări

- Reciprocating CompressorDocument37 paginiReciprocating CompressorJithin DasÎncă nu există evaluări

- A5 - 01en - BELIMO Ball Valve in A Compressed Air Application - PrintDocument2 paginiA5 - 01en - BELIMO Ball Valve in A Compressed Air Application - PrintPhung HoÎncă nu există evaluări

- FDBA en Metric LetterDocument1 paginăFDBA en Metric LetterY.EbadiÎncă nu există evaluări

- CKBDXCV ApDocument2 paginiCKBDXCV ApŁukasz OlszewskiÎncă nu există evaluări

- ZM KV Idag eDocument6 paginiZM KV Idag elutfi awnÎncă nu există evaluări

- 05 01 0 FRG 2MB 2MC 2MCC 5bar DN 15-25Document19 pagini05 01 0 FRG 2MB 2MC 2MCC 5bar DN 15-25milivojÎncă nu există evaluări

- Jornadas Técnicas Medium Voltage SERVICE Retrofit & Revamping Santiago 26 April 2007 Roberto PilengaDocument54 paginiJornadas Técnicas Medium Voltage SERVICE Retrofit & Revamping Santiago 26 April 2007 Roberto PilengaMostafa MohmmedÎncă nu există evaluări

- VCTDS-01042 Models Y1 BV-1 RA-Blanketing Regulator-EnDocument6 paginiVCTDS-01042 Models Y1 BV-1 RA-Blanketing Regulator-EnvipinÎncă nu există evaluări

- DRESSER Regulators FlowgridDocument12 paginiDRESSER Regulators Flowgridzalziza100% (1)

- Pneumatic Air Booster Pump PDFDocument10 paginiPneumatic Air Booster Pump PDFMaxÎncă nu există evaluări

- Wabco 9753034730 REGULADOR DE PRECION GOBERNADOR PDFDocument5 paginiWabco 9753034730 REGULADOR DE PRECION GOBERNADOR PDFOmar GarciaÎncă nu există evaluări

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 paginiSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoÎncă nu există evaluări

- High Pressure Regulators R100 Series: Specialist Distribution GassesDocument6 paginiHigh Pressure Regulators R100 Series: Specialist Distribution GassesDendeÎncă nu există evaluări

- Relief Valves: V SeriesDocument8 paginiRelief Valves: V SeriesRafael OrtizperezÎncă nu există evaluări

- Manual Rooftop On-OffDocument73 paginiManual Rooftop On-OffGerman CiclonÎncă nu există evaluări

- Accessories - ESD DrainDocument2 paginiAccessories - ESD Drainmuhamad.badar9285Încă nu există evaluări

- Data Sheet S7 - 2020 - ENG - Light - CavagnaDocument12 paginiData Sheet S7 - 2020 - ENG - Light - CavagnaWND PRTMÎncă nu există evaluări

- Anesthesia Machine Modification BSCDocument109 paginiAnesthesia Machine Modification BSCbiruk wondemuÎncă nu există evaluări

- SB 8540.3 - 1800 and 2000 Industrial RegDocument12 paginiSB 8540.3 - 1800 and 2000 Industrial RegImam BuchairiÎncă nu există evaluări

- PRDDocument30 paginiPRDMostafa MohmmedÎncă nu există evaluări

- Regulator RMG 201Document12 paginiRegulator RMG 201Farraz Sarmento SalimÎncă nu există evaluări

- WMR NLDocument4 paginiWMR NLmarioLhrÎncă nu există evaluări

- Full Bore Emerg Unloading Valve O&m - 02-24-2011Document9 paginiFull Bore Emerg Unloading Valve O&m - 02-24-2011Enrique AssmannÎncă nu există evaluări

- MesuraDocument2 paginiMesuraNirav DesaiÎncă nu există evaluări

- Armstrong Solving StallDocument9 paginiArmstrong Solving StallsaverrÎncă nu există evaluări

- Fisher Y690aDocument12 paginiFisher Y690ayg89Încă nu există evaluări

- Advance Valves Pvt. LTD: Cryogenic Test RecordDocument3 paginiAdvance Valves Pvt. LTD: Cryogenic Test RecordPriya KaleÎncă nu există evaluări

- CL31Document8 paginiCL31Juan JuanÎncă nu există evaluări

- B&M Series 1000 SwitchesDocument12 paginiB&M Series 1000 SwitchesscribdkhatnÎncă nu există evaluări

- Regulator Iom EnglishDocument32 paginiRegulator Iom EnglishShaoranÎncă nu există evaluări

- Pressure Relief Devices For Power Transformers (With Electric Contacts)Document8 paginiPressure Relief Devices For Power Transformers (With Electric Contacts)nagpurwale2011Încă nu există evaluări

- Reguladores de Presion para LPGDocument4 paginiReguladores de Presion para LPGNelson VargasÎncă nu există evaluări

- Proportional Pressure Relief Valve Screw-In Cartridge - Direct Operated - Q 8 L/min - P 400 Bar - P 315 BarDocument2 paginiProportional Pressure Relief Valve Screw-In Cartridge - Direct Operated - Q 8 L/min - P 400 Bar - P 315 BarDavidson GattoniÎncă nu există evaluări

- Pressure Controls: Fitters NotesDocument12 paginiPressure Controls: Fitters NotesMohammad AmerÎncă nu există evaluări

- VCESDocument2 paginiVCES한기륜Încă nu există evaluări

- Damper Pressure LossDocument2 paginiDamper Pressure Lossfariboy123Încă nu există evaluări

- Reguladoras Primera EtapaDocument54 paginiReguladoras Primera EtapaEdwin QuicenoÎncă nu există evaluări

- Piston Pump PVDocument16 paginiPiston Pump PVtreinamentoÎncă nu există evaluări

- Daiphrgm Metre G10&G20Document4 paginiDaiphrgm Metre G10&G20malaÎncă nu există evaluări

- Series MC - Pressure RegulatorsDocument4 paginiSeries MC - Pressure RegulatorsAlexsandro TorezinÎncă nu există evaluări

- Calculation Acc. To Calame A. Hengst: Only For Gases Only For Low Pressure Regulator ZM-R, ZM-B and LPR, LPSDocument6 paginiCalculation Acc. To Calame A. Hengst: Only For Gases Only For Low Pressure Regulator ZM-R, ZM-B and LPR, LPSkarthipetro100% (2)

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 paginiModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaÎncă nu există evaluări

- Regulators Overall Offering Guide: Industrial Gas Cylinder RegulatorsDocument2 paginiRegulators Overall Offering Guide: Industrial Gas Cylinder RegulatorsDries VandezandeÎncă nu există evaluări

- Ipr RegDocument34 paginiIpr RegNicolae PopÎncă nu există evaluări

- AA16 - Advanced Process Control and Optimization of Alumina Calciners PDFDocument8 paginiAA16 - Advanced Process Control and Optimization of Alumina Calciners PDFerstendrainÎncă nu există evaluări

- Pip Eleha01 Electronic Entry Data Sheets For Determining Electrical Area ClassificationDocument2 paginiPip Eleha01 Electronic Entry Data Sheets For Determining Electrical Area ClassificationerstendrainÎncă nu există evaluări

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeederDocument8 paginiCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeedererstendrainÎncă nu există evaluări

- Gateway Concept Web 12pageDocument7 paginiGateway Concept Web 12pageerstendrainÎncă nu există evaluări

- 2.seguridad Intrinseca PDFDocument104 pagini2.seguridad Intrinseca PDFerstendrainÎncă nu există evaluări

- Pip Eleha01 Engineering Guide For Determining Electrical Area ClassificationDocument21 paginiPip Eleha01 Engineering Guide For Determining Electrical Area ClassificationerstendrainÎncă nu există evaluări

- Norsok MDS TableDocument2 paginiNorsok MDS TableerstendrainÎncă nu există evaluări

- Norsok T 003Document22 paginiNorsok T 003erstendrainÎncă nu există evaluări

- MTL - Flam Facts Poster PDFDocument1 paginăMTL - Flam Facts Poster PDFerstendrainÎncă nu există evaluări

- en Level and Pressure Instrumentation For The Offshore IndustryDocument18 paginien Level and Pressure Instrumentation For The Offshore IndustryerstendrainÎncă nu există evaluări

- Parker Moduflex ValvesDocument88 paginiParker Moduflex ValveserstendrainÎncă nu există evaluări

- Cable Glands CrossreferenceDocument8 paginiCable Glands CrossreferenceerstendrainÎncă nu există evaluări

- Timing Consideration On A Safety PLCDocument11 paginiTiming Consideration On A Safety PLCerstendrainÎncă nu există evaluări

- Fisher® Specification Manager Manual PDFDocument28 paginiFisher® Specification Manager Manual PDFerstendrainÎncă nu există evaluări

- Abb SPI User GuideDocument60 paginiAbb SPI User GuideerstendrainÎncă nu există evaluări

- Smartplant Import Assistant: Product SheetDocument2 paginiSmartplant Import Assistant: Product SheeterstendrainÎncă nu există evaluări

- Grundlagen enDocument36 paginiGrundlagen enmandrekÎncă nu există evaluări

- Automation Network Selection - IsADocument113 paginiAutomation Network Selection - IsAerstendrain100% (1)