Documente Academic

Documente Profesional

Documente Cultură

MI Barite Tank 2 Mpi Rep

Încărcat de

Christopher JonesDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MI Barite Tank 2 Mpi Rep

Încărcat de

Christopher JonesDrepturi de autor:

Formate disponibile

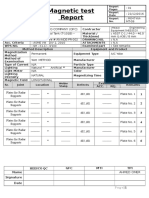

Serial # Magnetizing Process: Residual

13312 x

Magnetic Current: Alternating x

Half Wave Direct

Magnetic Particles Batch # Magnetizing Method: Yoke X

145566 Permanent Coil

145564 Magnetic Field Indicator:

Blacklight Intensity:

Qualification : ASNT Level 2

Signature :

Magnetic Particle Inspection Report

Report # : LTT/NDT/MPI/MI-SWC-19/14

Date : 03 - 07 - 2014

Customer PO #: Work Order # : 19 - 1001 - 14

Customer: M-I NIGERIA LTD.

Location : MI - BASE

Item Inspected : VERTICAL BARYTE TANK 2 ( DISCHARGE LINE)

Surface condition : Ground

Test Temperature : Ambient

Serial # : N/A

Material : CARBON STEEL

Welding Process : SMAW

Welder ID #

Inspection Equipment / Details

Mag. Equipment Cal. Due Date

AC YOKE 22/07/2014 Continuous

Drawing #:

lllumination : White Light

Inspection Date : 03- 07- 2014

CASTROL STRIP

Demagnetization:

Wet Fluorescent

Dry Powder

photographic view:-

Type

White Contrast ELY WCP 712

Black Ink ELY SUPRAMOR 4

Acceptance Code : ASME E709 /API

SCOPE OF WORK: Cleaning, Visual and Magnetic Particle Inspection Was Carried Out On

Critical Stress Welded Areas( 4" pipe Discharge line) of Barite Tank # 2.

S.W.L - 150 Tonnes

Technician : JOHN BASSEY

Date : 09 / 07 / 2014

Inspection Result : No Crack Indications Were Detected At The Time Of Inspection And Found

Satisfactory. The Item Proved To Be Acceptable And Fit For Use.

Serial # Magnetizing Process: Residual

13312 x

Magnetic Current: Alternating x

Half Wave Direct

Magnetic Particles Batch # Magnetizing Method: Yoke X

145566 Permanent Coil

145564 Magnetic Field Indicator:

Blacklight Intensity:

Qualification : ASNT Level 2

Signature :

Customer PO #: Work Order # : 19 - 1001 - 14

Item Inspected : VERTICAL BARYTE TANK 2 ( JET LINE)

Serial # : N/A

Magnetic Particle Inspection Report

Customer: M-I NIGERIA LTD. Report # : LTT/NDT/MPI/MI-SWC-19/14

Location : MI BASE Date : 03 - 07 - 2014

Drawing #: Inspection Date : 03- 07- 2014

Inspection Equipment / Details

Mag. Equipment Cal. Due Date

Material : CARBON STEEL Surface condition : Ground

Welding Process : SMAW Test Temperature : Ambient

Welder ID # lllumination : White Light

Type

White Contrast ELY WCP 712

AC YOKE 22/07/2014 Continuous

Dry Powder Demagnetization:

Acceptance Code : ASME E709 /API

Black Ink ELY SUPRAMOR 4 CASTROL STRIP

Wet Fluorescent

photographic view:-

Technician : JOHN BASSEY

Date : 09 / 07 / 2014

SCOPE OF WORK: Cleaning, Visual and Magnetic Particle Inspection Was Carried Out On

Critical Stress Welded Areas( 4" pipe Jet line) of Barite Tank # 2.

S.W.L - 150 Tonnes

Inspection Result : No Crack Indications Were Detected At The Time Of Inspection And Found

Satisfactory. The Item Proved To Be Acceptable and Fit For Use.

Serial # Magnetizing Process: Residual

13312 x

Magnetic Current: Alternating x

Half Wave Direct

Magnetic Particles Batch # Magnetizing Method: Yoke X

145566 Permanent Coil

145564 Magnetic Field Indicator:

Blacklight Intensity:

Qualification : ASNT Level 2

Signature :

Customer PO #: Work Order # : 19 - 1001 - 14

Item Inspected : VERTICAL BARYTE TANK 2 ( BOTTOM DRAIN OUTLET)

Serial # : N/A

Magnetic Particle Inspection Report

Customer: M-I NIGERIA LTD. Report # : LTT/NDT/MPI/MI-SWC-19/14

Location : MI BASE Date : 03 - 07 - 2014

Drawing #: Inspection Date : 03- 07- 2014

Inspection Equipment / Details

Mag. Equipment Cal. Due Date

Material : CARBON STEEL Surface condition : Ground

Welding Process : SMAW Test Temperature : Ambient

Welder ID # lllumination : White Light

Type

White Contrast ELY WCP 712

AC YOKE 22/07/2014 Continuous

Dry Powder Demagnetization:

Acceptance Code : ASME E709 /API

Black Ink ELY SUPRAMOR 4 CASTROL STRIP

Wet Fluorescent

photographic view:-

Technician : JOHN BASSEY

Date : 09 / 07 / 2014

SCOPE OF WORK: Cleaning, Visual and Magnetic Particle Inspection Was Carried Out On

Critical Stress Welded Areas( 4" pipe Bottom Drain outlet) of Barite Tank # 2.

S.W.L - 150 Tonnes

Inspection Result : No Crack Indications Were Detected At The Time Of Inspection And Found

Satisfactory. The Item Proved To Be Acceptable and Fit For Use.

Serial # Magnetizing Process: Residual

13312 x

Magnetic Current: Alternating x

Half Wave Direct

Magnetic Particles Batch # Magnetizing Method: Yoke X

145566 Permanent Coil

145564 Magnetic Field Indicator:

Blacklight Intensity:

Qualification : ASNT Level 2

Signature :

Customer PO #: Work Order # : 19 - 1001 - 14

Item Inspected : VERTICAL BARYTE TANK 2 ( VENT LINE)

Serial # : N/A

Magnetic Particle Inspection Report

Customer: M-I NIGERIA LTD. Report # : LTT/NDT/MPI/MI-SWC-19/14

Location : MI BASE Date : 03 - 07 - 2014

Drawing #: Inspection Date : 03- 07- 2014

Inspection Equipment / Details

Mag. Equipment Cal. Due Date

Material : CARBON STEEL Surface condition : Ground

Welding Process : SMAW Test Temperature : Ambient

Welder ID # lllumination : White Light

Type

White Contrast ELY WCP 712

AC YOKE 22/07/2014 Continuous

Dry Powder Demagnetization:

Acceptance Code : ASME E709 /API

Black Ink ELY SUPRAMOR 4 CASTROL STRIP

Wet Fluorescent

photographic view:-

Technician : JOHN BASSEY

Date : 09 / 07 / 2014

SCOPE OF WORK: Cleaning, Visual and Magnetic Particle Inspection Was Carried Out On

Critical Stress Welded Areas( 4" pipe Vent line ) of Barite Tank # 2 .

S.W.L - 150 Tonnes

Inspection Result : No Crack Indications Were Detected At The Time Of Inspection And Found

Satisfactory. The Item Proved To Be Acceptable and Fit For Use.

Serial # Magnetizing Process: Residual

13312 x

Magnetic Current: Alternating x

Half Wave Direct

Magnetic Particles Batch # Magnetizing Method: Yoke X

145566 Permanent Coil

145564 Magnetic Field Indicator:

Blacklight Intensity:

Qualification : ASNT Level 2

Signature :

Customer PO #: Work Order # : 19 - 1001 - 14

Item Inspected : VERTICAL BARYTE TANK 2 ( SUCTION INLET LINE)

Serial # : N/A

Magnetic Particle Inspection Report

Customer: M-I NIGERIA LTD. Report # : LTT/NDT/MPI/MI-SWC-19/14

Location : MI BASE Date : 03 - 07 - 2014

Drawing #: Inspection Date : 03- 07- 2014

Inspection Equipment / Details

Mag. Equipment Cal. Due Date

Material : CARBON STEEL Surface condition : Ground

Welding Process : SMAW Test Temperature : Ambient

Welder ID # lllumination : White Light

Type

White Contrast ELY WCP 712

AC YOKE 22/07/2014 Continuous

Dry Powder Demagnetization:

Acceptance Code : ASME E709 /API

Black Ink ELY SUPRAMOR 4 CASTROL STRIP

Wet Fluorescent

photographic view:-

Technician : JOHN BASSEY

Date : 09 / 07 / 2014

SCOPE OF WORK: Cleaning, Visual and Magnetic Particle Inspection Was Carried Out On

Critical Stress Welded Areas( 4" pipe Suction Inlet line) of Barite Tank # 2 .

S.W.L - 150 Tonnes

Inspection Result : No Crack Indication Were Detected At The Time Of Inspection And Found

Satisfactory. The Item Proved To Be Acceptable and Fit For Use.

Serial # Magnetizing Process: Residual

13312 x

Magnetic Current: Alternating x

Half Wave Direct

Magnetic Particles Batch # Magnetizing Method: Yoke X

145566 Permanent Coil

145564 Magnetic Field Indicator:

Blacklight Intensity:

Qualification : ASNT Level 2

Signature :

Customer PO #: Work Order # : 19 - 1001 - 14

Item Inspected : VERTICAL BARYTE TANK 2 ( MAN HOLE )

Serial # : N/A

Magnetic Particle Inspection Report

Customer: M-I NIGERIA LTD. Report # : LTT/NDT/MPI/MI-SWC-19/14

Location : MI BASE Date : 03 - 07 - 2014

Drawing #: Inspection Date : 03- 07- 2014

Inspection Equipment / Details

Mag. Equipment Cal. Due Date

Material : CARBON STEEL Surface condition : Ground

Welding Process : SMAW Test Temperature : Ambient

Welder ID # lllumination : White Light

Type

White Contrast ELY WCP 712

AC YOKE 22/07/2014 Continuous

Dry Powder Demagnetization:

Acceptance Code : ASME E709 /API

Black Ink ELY SUPRAMOR 4 CASTROL STRIP

Wet Fluorescent

photographic view:-

Technician : JOHN BASSEY

Date : 09 / 07 /2014

SCOPE OF WORK: Cleaning, Visual and Magnetic Particle Inspection Was Carried Out On

Critical Stress Welded Areas Man hole of Barite Tank # 2 .

S.W.L - 150 Tonnes

Inspection Result : No Crack Indications Were Detected At The Time Of Inspection And Found

Satisfactory. The Item Proved To Be Acceptable and Fit For Use.

S-ar putea să vă placă și

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Document2 paginiMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhÎncă nu există evaluări

- MPT Report FormatDocument1 paginăMPT Report FormatRoshan ThomasÎncă nu există evaluări

- Magnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiDocument1 paginăMagnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiMurugan RajaÎncă nu există evaluări

- Magnetic Particle Inspection Report DetailsDocument1 paginăMagnetic Particle Inspection Report DetailsJindarat Kasemsooksakul100% (1)

- Magnetic Particle Testing Report SummaryDocument4 paginiMagnetic Particle Testing Report Summarypankaj ranaÎncă nu există evaluări

- Magnetic Particle Test Quality Control and Inspection Report FormDocument1 paginăMagnetic Particle Test Quality Control and Inspection Report FormRicardo MachadoÎncă nu există evaluări

- Sample Magnetic Particle Inspection ReportDocument3 paginiSample Magnetic Particle Inspection ReportOby100% (2)

- Weld Visual Inspection ReportDocument1 paginăWeld Visual Inspection ReportfarjadulhaqÎncă nu există evaluări

- Radiographic Inspection Report SummaryDocument1 paginăRadiographic Inspection Report SummaryJindarat Kasemsooksakul0% (1)

- Fcaw 16 THKDocument5 paginiFcaw 16 THKparesh2387Încă nu există evaluări

- MT Tta NDT Mpi 01 AsmeDocument13 paginiMT Tta NDT Mpi 01 AsmeTuan DangÎncă nu există evaluări

- Magnetic Particle Test Procedure Magnetic Particle Test Procedure MTDocument14 paginiMagnetic Particle Test Procedure Magnetic Particle Test Procedure MTsamer8saif100% (3)

- GMAW welding parameters for SS400 pipeDocument2 paginiGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- Aws 001Document1 paginăAws 001akshay sarfareÎncă nu există evaluări

- RT Procedure 10.09.16Document9 paginiRT Procedure 10.09.16mukeshsingh6Încă nu există evaluări

- Ut FormDocument1 paginăUt FormTrung Tinh Ho100% (1)

- WPQR No. 2016 02Document14 paginiWPQR No. 2016 02GANESH AÎncă nu există evaluări

- Weld Visual Inspection NDT Sample Test Report FormatDocument1 paginăWeld Visual Inspection NDT Sample Test Report FormatAvneet MaanÎncă nu există evaluări

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 paginiHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnÎncă nu există evaluări

- Welder Qualification Test Certificate for Mohan ReddyDocument2 paginiWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 paginăAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityÎncă nu există evaluări

- Alumana Welder IDDocument7 paginiAlumana Welder IDZuberYousufÎncă nu există evaluări

- Wps FormatDocument12 paginiWps FormatGohilakrishnan ThiagarajanÎncă nu există evaluări

- UT Report FormDocument1 paginăUT Report FormElisha NguyenÎncă nu există evaluări

- Wps Aws d1.1 NEWDocument2 paginiWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- RT Report FormatDocument1 paginăRT Report FormatRonanki RaviÎncă nu există evaluări

- WPS ISO 15614-1 WeldNote MetricDocument1 paginăWPS ISO 15614-1 WeldNote MetricVirgil SorcaruÎncă nu există evaluări

- Welder Performace Qualification Report 2014..Document132 paginiWelder Performace Qualification Report 2014..Kayra Riri ChirulÎncă nu există evaluări

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Document2 paginiWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhÎncă nu există evaluări

- Vacuum Box Test PDFDocument3 paginiVacuum Box Test PDFWilson RodriguezÎncă nu există evaluări

- FIT UP ReportDocument2 paginiFIT UP Reportsiva8000Încă nu există evaluări

- Liquid Penetrant Examination ProcedureDocument13 paginiLiquid Penetrant Examination ProcedureSandiSandiiÎncă nu există evaluări

- WPQDocument10 paginiWPQayoki100% (3)

- Ultrasonic Test Report SummaryDocument6 paginiUltrasonic Test Report SummaryGibson FisherÎncă nu există evaluări

- Magnetic Particle Test Quality Control and Inspection Report Form PDFDocument1 paginăMagnetic Particle Test Quality Control and Inspection Report Form PDFKamal Bhandari100% (1)

- Toshiba Brazing Procedure SpecificationDocument3 paginiToshiba Brazing Procedure Specificationsheikmoin100% (1)

- Ultrasonic Testing Report For PipingDocument54 paginiUltrasonic Testing Report For Pipingeldobie3Încă nu există evaluări

- All NDE ProcedureDocument35 paginiAll NDE ProcedureArun Karthikeyan100% (2)

- QW-484A (WPQ) GTAW 4MM FilletDocument2 paginiQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Manual Ultrasonic Testing Procedure for 26Document12 paginiManual Ultrasonic Testing Procedure for 26Rohit Kumar Mishra100% (1)

- WPQR Welding Procedure Qualification RecordsDocument3 paginiWPQR Welding Procedure Qualification Recordsramesh rajaÎncă nu există evaluări

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 paginiWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniÎncă nu există evaluări

- WPS Format For ISO 9606-1 WelderDocument2 paginiWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 paginiAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- International Limited: Magnetic Particle Inspection ReportDocument43 paginiInternational Limited: Magnetic Particle Inspection ReportMichael OkwuwaÎncă nu există evaluări

- Ensco 5002. NDT Inspection Handling Tools and Wall Thickness Survey. Version - Original P.Document167 paginiEnsco 5002. NDT Inspection Handling Tools and Wall Thickness Survey. Version - Original P.mohamed fahsÎncă nu există evaluări

- Magnetic Particle Inspection Report:: Assemply-1&Assemply-2Document3 paginiMagnetic Particle Inspection Report:: Assemply-1&Assemply-2Murugan RajaÎncă nu există evaluări

- Pad Eye App 65 - 15 Feb 16Document1 paginăPad Eye App 65 - 15 Feb 16Irnaldi Yoza WijayaÎncă nu există evaluări

- Mpi D212Document1 paginăMpi D212K.s. Raghavendra KumarÎncă nu există evaluări

- Mpi Pipe Rack PR 03-1.Document1 paginăMpi Pipe Rack PR 03-1.Khalil ChabbouhÎncă nu există evaluări

- Mpi 44444286 ..Document1 paginăMpi 44444286 ..Khalil ChabbouhÎncă nu există evaluări

- Magnetic Test: Client: Gas Filling Company (GFC) ContractorDocument1 paginăMagnetic Test: Client: Gas Filling Company (GFC) ContractorHatem RagabÎncă nu există evaluări

- MPI Reports for ROMFOR Oilfield EquipmentDocument21 paginiMPI Reports for ROMFOR Oilfield EquipmentMehmet SoysalÎncă nu există evaluări

- Magnetic particle test report for FLSmidth hub type N itemsDocument1 paginăMagnetic particle test report for FLSmidth hub type N itemssomujazÎncă nu există evaluări

- Ir - L1904-32 17apr19-Mt (Sfjt-E)Document5 paginiIr - L1904-32 17apr19-Mt (Sfjt-E)Alleyson Akin100% (1)

- MT02Document1 paginăMT02اسران احمدÎncă nu există evaluări

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 pagină75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahÎncă nu există evaluări

- CB-043 Mpi Exp-02 Apr 2024Document1 paginăCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninÎncă nu există evaluări

- C6 Turbine LP Cylinder Casing (Bottom Half) - MPIDocument7 paginiC6 Turbine LP Cylinder Casing (Bottom Half) - MPIDave CheungÎncă nu există evaluări

- Reference and Calibration Standards - NDT TechnicianDocument1 paginăReference and Calibration Standards - NDT TechnicianrhinemineÎncă nu există evaluări

- Primary DutiesDocument1 paginăPrimary DutiesChristopher JonesÎncă nu există evaluări

- Reference and Calibration Standards - NDT TechnicianDocument1 paginăReference and Calibration Standards - NDT TechnicianrhinemineÎncă nu există evaluări

- Scrap CodesDocument1 paginăScrap CodesChristopher JonesÎncă nu există evaluări

- Reference and Calibration Standards - NDT TechnicianDocument1 paginăReference and Calibration Standards - NDT TechnicianrhinemineÎncă nu există evaluări

- Reference and Calibration Standards - NDT TechnicianDocument1 paginăReference and Calibration Standards - NDT TechnicianrhinemineÎncă nu există evaluări

- Reference and Calibration Standards - NDT TechnicianDocument1 paginăReference and Calibration Standards - NDT TechnicianrhinemineÎncă nu există evaluări

- Intro To NDTDocument34 paginiIntro To NDTkbldamÎncă nu există evaluări

- Hand Tools - To OrderDocument3 paginiHand Tools - To OrderChristopher JonesÎncă nu există evaluări

- Ultrasonic ProcedureDocument31 paginiUltrasonic ProcedureChristopher Jones100% (1)

- ACCOUNTANT Job DescriptionDocument2 paginiACCOUNTANT Job DescriptionChristopher JonesÎncă nu există evaluări

- Hand Tools - To OrderDocument3 paginiHand Tools - To OrderChristopher JonesÎncă nu există evaluări

- Ultrasonic ProcedureDocument31 paginiUltrasonic ProcedureChristopher Jones100% (1)

- VI-401466-PS-1 Example ISO 9001 Document Control ProcedureDocument7 paginiVI-401466-PS-1 Example ISO 9001 Document Control ProcedurevoyyÎncă nu există evaluări

- Types of Welding ElectrodesDocument6 paginiTypes of Welding ElectrodesChristopher JonesÎncă nu există evaluări

- Types of Welding ElectrodesDocument6 paginiTypes of Welding ElectrodesChristopher JonesÎncă nu există evaluări

- 5 5 DP-HT55-repDocument1 pagină5 5 DP-HT55-repChristopher Jones100% (1)

- 5 5 DP-HT55-repDocument1 pagină5 5 DP-HT55-repChristopher Jones100% (1)

- Cghrds ManualDocument280 paginiCghrds Manualmaster_anulunuÎncă nu există evaluări

- Cghrds ManualDocument280 paginiCghrds Manualmaster_anulunuÎncă nu există evaluări

- CV BobHulme LatestDocument2 paginiCV BobHulme LatestChristopher JonesÎncă nu există evaluări

- Line Graph Chart TemplatesDocument2 paginiLine Graph Chart TemplatesChristopher JonesÎncă nu există evaluări

- How to ping NodeB and RNC using RTN transmission IPDocument14 paginiHow to ping NodeB and RNC using RTN transmission IPPaulo DembiÎncă nu există evaluări

- Atmos GIGA N 32-160Document1 paginăAtmos GIGA N 32-160Efril dilen franciscoÎncă nu există evaluări

- True/False: List of Attempted Questions and AnswersDocument15 paginiTrue/False: List of Attempted Questions and AnswersDeepak Kumar VermaÎncă nu există evaluări

- MASTERSEAL 755 SPF v1 PDFDocument2 paginiMASTERSEAL 755 SPF v1 PDFJaga Nath100% (1)

- App 2015 Upb Spmo Format - 1Document56 paginiApp 2015 Upb Spmo Format - 1mkpqÎncă nu există evaluări

- Philips 26 PFL 3405 Chassis Tpn1.1e-La SM PDFDocument63 paginiPhilips 26 PFL 3405 Chassis Tpn1.1e-La SM PDFViorel GabrielÎncă nu există evaluări

- Sap Abap Programming SyllabusDocument5 paginiSap Abap Programming SyllabusSURAJ KUMAR SAHUÎncă nu există evaluări

- ISN SM 50 ManualDocument8 paginiISN SM 50 Manualsinggih bramantyoÎncă nu există evaluări

- CIRCULAR WATER TANK DESIGN-Layout1 AkhilDocument1 paginăCIRCULAR WATER TANK DESIGN-Layout1 AkhilVENKAT KALYANÎncă nu există evaluări

- Line Differential Protection and Control RED615: Product GuideDocument32 paginiLine Differential Protection and Control RED615: Product GuidebrahimÎncă nu există evaluări

- 12 585 Rov Latches Brochure v3 Web 1 PDFDocument8 pagini12 585 Rov Latches Brochure v3 Web 1 PDFIZayvenkoÎncă nu există evaluări

- Visit To Kadana Hydro Power Plant and Wanakbori Thermal Power Plant.Document5 paginiVisit To Kadana Hydro Power Plant and Wanakbori Thermal Power Plant.Kunal VaghasiyaÎncă nu există evaluări

- ALFA 4000 - Peru 2 PDFDocument2 paginiALFA 4000 - Peru 2 PDFErick MaderoÎncă nu există evaluări

- PACK PAR BoilersDocument31 paginiPACK PAR BoilersJosé MacedoÎncă nu există evaluări

- Digital Vision Installation PDFDocument2 paginiDigital Vision Installation PDFnikola5nikolicÎncă nu există evaluări

- Lecture 4-Unit 1 Lesson 4Document23 paginiLecture 4-Unit 1 Lesson 4Jameel MalikÎncă nu există evaluări

- InRoom Tech Data 31010 ApcDocument92 paginiInRoom Tech Data 31010 ApcRolandoÎncă nu există evaluări

- FUTURE SHOCK by ALVIN TOFFLERDocument5 paginiFUTURE SHOCK by ALVIN TOFFLERgeraldine100% (1)

- REEM Document SubmissionDocument8 paginiREEM Document Submissionkiller120Încă nu există evaluări

- Chap4 Student VersionDocument39 paginiChap4 Student VersionAzrif MoskamÎncă nu există evaluări

- Class PDF 516 QuestionDocument80 paginiClass PDF 516 QuestionRahul KashyapÎncă nu există evaluări

- 2019 Planning OverviewDocument7 pagini2019 Planning Overviewapi-323922022Încă nu există evaluări

- Online Ticket Reservation SystemDocument100 paginiOnline Ticket Reservation SystemPiya SharmaÎncă nu există evaluări

- Carrier LDU ManualDocument123 paginiCarrier LDU Manualdafrie rimbaÎncă nu există evaluări

- Byk - Garamite 1958 TDS (En) PDFDocument6 paginiByk - Garamite 1958 TDS (En) PDFsudhir5441Încă nu există evaluări

- Project Report - FormatsDocument7 paginiProject Report - Formatsfazela shaukatÎncă nu există evaluări

- Effect of CSR on Corporate Reputation and PerformanceDocument13 paginiEffect of CSR on Corporate Reputation and PerformanceAnthon AqÎncă nu există evaluări

- Spokane County Sheriff's Internal Communication PlanDocument11 paginiSpokane County Sheriff's Internal Communication Planjmcgrath208100% (1)

- Konica 7020 Error Codes: Code DescriptionDocument3 paginiKonica 7020 Error Codes: Code Descriptionsaito36Încă nu există evaluări

- NT Photocurre Ed Unmultipli Primary NT Photocurre MultipliedDocument50 paginiNT Photocurre Ed Unmultipli Primary NT Photocurre Multipliedmayuri sritharanÎncă nu există evaluări