Documente Academic

Documente Profesional

Documente Cultură

Question About Machinnes

Încărcat de

Joshua Hicks0 evaluări0% au considerat acest document util (0 voturi)

70 vizualizări3 paginiThis document contains questions and problems related to the design of various electrical machines. It covers topics like air gap design, magnetic circuit design, cooling system design, and determination of main dimensions for transformers, DC machines, induction machines, and synchronous machines. Various design considerations and parameters are discussed for optimizing machine performance and ratings.

Descriere originală:

weak students questions

Titlu original

question about machinnes

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document contains questions and problems related to the design of various electrical machines. It covers topics like air gap design, magnetic circuit design, cooling system design, and determination of main dimensions for transformers, DC machines, induction machines, and synchronous machines. Various design considerations and parameters are discussed for optimizing machine performance and ratings.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

70 vizualizări3 paginiQuestion About Machinnes

Încărcat de

Joshua HicksThis document contains questions and problems related to the design of various electrical machines. It covers topics like air gap design, magnetic circuit design, cooling system design, and determination of main dimensions for transformers, DC machines, induction machines, and synchronous machines. Various design considerations and parameters are discussed for optimizing machine performance and ratings.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

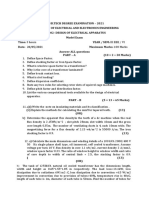

ROEVER ENGINEERING COLLEGE, PERAMBALUR

DEPARTMENT OF ELECTRICA & ELECTRONICS ENGINEERING

EE1352 ELECTRICAL MACHINE DESIGN

UNIT 1 : FUNDAMENTAL CONCEPTS

PART-A

1. Define air contraction factor for slots and ducts.

2. How is leakage magnetic flux different from useful magnetic flux?

3. List the advantages of direct cooling of rotating electrical

machines.

4. Distinguish between continuous rating and short time rating of an

electrical machines.

5. What is the difference between real and apparent magnetic flux

densities in rotating machines

6. State any two methods of cooling turbo alternators.

7. Calculate the mmf per meter for a flux density of 1.7 wb/m

2

. And a

permeability of 23.5 x10

-6

H/m

8. State any two methods of cooling turbo alternators.

9. List the methods of estimating the mmf for tapered tooth.

10. Define unbalanced magnetic pull.

PART-B

11) Define the terms specific electric loading and specific magnetic

loading as applied to electrical Machines. What are the

considerations in the choice of these for rotating machines?

12) i) Explain in detail about the MMF calculation for tapered teeth.

ii) Discuss in detail about the real and apparent flux densities.

13) i)Calculate the apparent flux density at a section of the teeth of an

armature of a D.C machine from the following data at that section. Slot

pitch=24mm, slot width=tooth width =12mm, length of armature core

including five ducts of 10mm each=0.38m,iron stacking factor=0.92.

True flux density in the teeth at that section is 2.2T for which the mmf

is 70000AT/m.

ii) Discuss in detail about the UMP.

UNIT - 2 : D.C.MACHINES

PART - A

1. List the advantages of lap winding in a DC

2. State the relationship between number of armature coils and

number of commutator segments in a dc machine.

3. State different losses in a dc generator.

4. List the factors that influences the separation of Dand L of a dc

machine .

5. In a dc machine what are the limiting values of armature peripheral

speed and voltage between adjacent commutator segments .

6. What are the factors that affect the size of the rotating machines?

7. What are the factors to be considered for the selection of number

of poles in a dc machine?

8. Why square poles preferred?

9. What is the effect of interpole on main pole?

10. Write the guiding factors for choice of number of armature slots of

D.C machine.

PART- B

11) A 250 kW, 500V, 600 r.p.m. d.c. generator is built with an

armature diameter of 0.75m and a core length of 0.3m. The lap

connected armature has 720 conductors. Using the data obtained

from this machine, determine the armature diameter, core length,

number of armature slots, armature conductors and commutator

segments for a 350kW, 440V, 720 r.p.m 6pole d.c. generator.

Assume a square pole face with ratio of pole arc to pole pitch equal

to 0.66. The full load efficiency is 0.91 and the internal voltage

drop is 4% of rated voltage.The diameter of commutator is 0.7 of

armature diameter. The pitch of commutator segments should not

be less than 4mm. The voltage between adjacent segments should

not exceed 15Vat no load.

12) i) Explain the design procedure for the shunt field winding of

D.C.machine

ii) Derive the output equation of a d.c.machine and point out its

salient features.

13) i) Discuss the factors that influence the choice of number of poles

of a dc machine

ii) A 5 kW, 250 volts, 4 pole and 1500 rpm dc shunt generator is

designed to have a square pole face. The average magnetic flux

density in the air gap is 0.42wb/m

2

and ampere conductors per

meter = 15,000. Compute the main dimensions of the machine.

Assume full load efficiency = 87%. The ratio of pole arc to pole

pitch = 0.66.

UNIT - 3: TRANSFORMERS

PART- A

1. What are the advantages of having circular in a transformer?

2. State the merits of three phase transformers over single phase

transformer.

3. Distinguish between shell type and core type transformer.

4. What you mean by stacking factor? What its usual value?

5. The voltage per turn of a 500KVA, 11KV, /Y three phase

transformer is 8.7V calculate the number of turns per phase of LV

and HV windings

6. What are conservator and breather?

7. State the various methods of cooling of power transformers.

8. Write the relation between core area and weight of iron and copper

for a single phase transformer.

9. Comment on the hysteresis and eddy current loss when voltage and

frequency of a transformer is doubled.

10. Explain the significance of the ratio r=m/AT in the design of

transformer.

PART- B

11. i) Estimate the main dimensions including winding conductor

area of a 3 phase delta-star core type transformer rated at

300KVA, 6600/400 V, 50 Hz. A suitable core with 3 steps

having a circumscribing circle of 0.25m diameter and leg

spacing of 0.4 m is available. EMF / turn = 8.5 V, _ = 2.5 A

/mm2,kw=0.28 and Sf = 0.9 (stacking factor)

ii) Derive the output equation of a single phase transformer.

12. i) Estimate the no-load current of a three phase transformer.

ii) For a transformer show that the emf per turn Et=K KVA.

Where KVA= rating of transformer. What are the factors on

which the value of K depends on?

13. A 250KVA 6600/400 volts. three phase core type transformer has

total loss of 4800 watts at full load. The transformer tank is 1.25

meter in height and 1m X 0.5m in plan. Design a suitable scheme

of tubes if the average temperature rise is to be limited to 35

degree Celsius . The diameter of each tube is 50 mm and the

tubes area spaced 75mm from each other. The average height of

each tube is 1.05m. Specific heat dissipation due to radiation and

convection is respectively 6 and 6.5w/m

2

/degree Celsius. Assume

that convection is improved by 35 percent due to provision of

tubes.

UNIT - 4 : INDUCTION MACHINES

PART- A

1. State the main constructional difference between cage and slip ring

induction motor.

2. Give the methods to reduce harmonic torques in an induction

motor.

3. What are the effects of change of air gap length in an Induction

motor?

4. What are the merits of slip ring induction motor over squirrel cage

induction motor?

5. What are the materials used for slip rings and brushes in induction

motor?

6. What are the factors to be considered for the choice of specific

magnetic loading in I.M?

7. What are the types of slots preferred in induction motor?

8. What are the advantages and disadvantages of large air gap length

in induction motor?

9. List out the methods to improve the power factor of induction

motor.

10. What is crawling and cogging?

PART - B

11) Estimate the stator core dimensions, number of stator slots and

number of stator conductors per slot for a 100kw, 3300V, 50Hz,

12 pole star connected slip ring induction motor. Assume

average gap density =0.4wb/m

2

; Conductors per metre

=25000A/m; Efficiency =0.9; Power factor =0.9 and winding

factor =0.96. Choose main dimensions to give best power factor.

The slot loading should not exceed 500-ampere conductors.

Explain the design of rotor bars and slots.

12) Write short notes on i) design of rotor bars and slots ii) design of

end rings

13) i) Derive the output equation of a three phase induction motor

ii) State and explain factors governing the choice of ampere

conductors per metre in the

UNIT - 5 SYNCHRONOUS MACHINES

PART - A

1. What are the merits of computer aided design?

2. What is run away speed?

3. What are the constructional differences between salient pole

alternator and cylindrical rotor type alternator?

4. How Cylindrical pole different from salient pole in asynchronous

machine?

5. Define short circuit ratio (SCR) of a synchronous generator.

6. What is critical speed of Alternator?

7. Mention the uses of damper winding in a synchronous machine.

8. List the factors to be considered for separation of D and L for

salient pole machines.

9. What are the factors to be considered for the choice of specific

magnetic loading in synchronous machine?

10. List the factors to be considered for the choice of number of slots

in synchronous machine

PART - B

11. Determine the main dimension for 1000 kVA, 50 Hz, three phase,

375 rpm alternator. The average air gap flux density = 0.55

wb/m2 and ampere conductors / m = 28000. Use rectangular

pole. Assume a suitable value for L / in order that bolted on pole

construction is used for which machine permissible peripheral

speed is 50 m/s. The runway speed is 1:8 times synchronous speed.

12. i) Explain the design of field winding if alternator

ii) Derive the output equation of a synchronous machine

13. i) Explain the role of digital computers in the design of electrical

machines

ii) Discuss the factors leading to the choice of length of air gap in

alternator design.

---- %%%% ----

S-ar putea să vă placă și

- 01B-ElectSchematics Feb2015Document19 pagini01B-ElectSchematics Feb2015Alive100% (2)

- Electrical Machines: Lecture Notes for Electrical Machines CourseDe la EverandElectrical Machines: Lecture Notes for Electrical Machines CourseÎncă nu există evaluări

- Murphy Asm 160 Manual PDFDocument4 paginiMurphy Asm 160 Manual PDFJorge Luis Cucunuba RoyeroÎncă nu există evaluări

- Doc.8973 - 05 - Security Manual - Seventh EditionDocument107 paginiDoc.8973 - 05 - Security Manual - Seventh EditionLatuihamallo Victory93% (80)

- QAP-09 Equipment CalibrationDocument20 paginiQAP-09 Equipment Calibrationnaseema1100% (5)

- GE T2100 Treadmill Service Manual Rev A.Document152 paginiGE T2100 Treadmill Service Manual Rev A.Marckus Brody0% (1)

- Ee 1403 - Design of Electrical ApparatusDocument3 paginiEe 1403 - Design of Electrical ApparatussubhazÎncă nu există evaluări

- Solution Manual for 100 Genesys Design Examples: Second EditionDe la EverandSolution Manual for 100 Genesys Design Examples: Second EditionÎncă nu există evaluări

- Pneumatic Tools and EquipmentsDocument15 paginiPneumatic Tools and EquipmentsJoshua HicksÎncă nu există evaluări

- Differential Forms on Electromagnetic NetworksDe la EverandDifferential Forms on Electromagnetic NetworksEvaluare: 4 din 5 stele4/5 (1)

- Marine Auxiliary Machinery: 4 Positive Displacement PumpsDocument36 paginiMarine Auxiliary Machinery: 4 Positive Displacement PumpsJoshua HicksÎncă nu există evaluări

- Catalogue SGF Eng PDFDocument8 paginiCatalogue SGF Eng PDFrimce77Încă nu există evaluări

- Power System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)De la EverandPower System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)Încă nu există evaluări

- Pengkhianatan G30S:PKIDocument11 paginiPengkhianatan G30S:PKIJoshua Hicks100% (1)

- Electrical Machine DesignDocument9 paginiElectrical Machine DesignSandeep KumarkjÎncă nu există evaluări

- Electrical Machine DesignDocument10 paginiElectrical Machine DesignSri GobzÎncă nu există evaluări

- Question Bank: Ee 1403 - Design of Electrical ApparatusDocument11 paginiQuestion Bank: Ee 1403 - Design of Electrical ApparatussuriyasureshÎncă nu există evaluări

- EE 1403 DESIGN OF ELECTRICAL APPARATUS Question BankDocument4 paginiEE 1403 DESIGN OF ELECTRICAL APPARATUS Question BankBavi ThraaÎncă nu există evaluări

- Electrical Machine DesignDocument5 paginiElectrical Machine DesignsharmiladevyÎncă nu există evaluări

- Emd-I AssignmentDocument6 paginiEmd-I Assignmentayan PatelÎncă nu există evaluări

- Ee 1403 Design of Electrical ApparatusDocument9 paginiEe 1403 Design of Electrical Apparatusdoo123oodÎncă nu există evaluări

- Dem Unit I-VDocument11 paginiDem Unit I-VHari SankarÎncă nu există evaluări

- Ee 1403 - Design of Electrical ApparatusDocument9 paginiEe 1403 - Design of Electrical ApparatusskrtamilÎncă nu există evaluări

- Electrical Machine Design - Department of Electrical and Electronics EngineeringDocument8 paginiElectrical Machine Design - Department of Electrical and Electronics Engineeringni60Încă nu există evaluări

- DEADocument4 paginiDEAKavitha BaluÎncă nu există evaluări

- Emd QPDocument6 paginiEmd QPrubyviswanathanÎncă nu există evaluări

- Emd QBDocument7 paginiEmd QBAditya ShrivastavÎncă nu există evaluări

- DEM ModelDocument2 paginiDEM ModelAnonymous IT2ouJqQÎncă nu există evaluări

- 11e501 Electrical Machine DesignDocument4 pagini11e501 Electrical Machine DesignnandhakumarmeÎncă nu există evaluări

- Electrical Machine Design QBDocument9 paginiElectrical Machine Design QBPrince Janesh UniqueÎncă nu există evaluări

- EE8002 DEA QB All UnitsDocument7 paginiEE8002 DEA QB All Units5062-SANJAY RÎncă nu există evaluări

- Electrical Machine Design Question BankDocument4 paginiElectrical Machine Design Question BankReshmaÎncă nu există evaluări

- Question Bank: Dayananda Sagar College of EngineeringDocument15 paginiQuestion Bank: Dayananda Sagar College of EngineeringshashikumarÎncă nu există evaluări

- Gujarat Technological University: InstructionsDocument2 paginiGujarat Technological University: InstructionsMitesh GandhiÎncă nu există evaluări

- Gujarat Technological UniversityDocument2 paginiGujarat Technological UniversityPalak AriwalaÎncă nu există evaluări

- Question Bank For Emd-1Document5 paginiQuestion Bank For Emd-1the_ray004Încă nu există evaluări

- Ee09 704 - Electrical Machine Design Model QPDocument2 paginiEe09 704 - Electrical Machine Design Model QPGīřïşh McÎncă nu există evaluări

- Model Questions Unit2Document2 paginiModel Questions Unit2RohitonlyforuÎncă nu există evaluări

- Ee 8002 - DeaDocument2 paginiEe 8002 - DeaJerome ColinÎncă nu există evaluări

- Ee2355 - Iv SemDocument10 paginiEe2355 - Iv SemBALAKRISHNANÎncă nu există evaluări

- Unit-1+2 +3+4+5Document5 paginiUnit-1+2 +3+4+5Jesper JacksonÎncă nu există evaluări

- Name: Reg - No. Sixth Semester B.Tech Degree Examination, JUNE 2009Document2 paginiName: Reg - No. Sixth Semester B.Tech Degree Examination, JUNE 2009maniÎncă nu există evaluări

- Electrical Machine DesignDocument2 paginiElectrical Machine DesignAnonymous 1abQZIÎncă nu există evaluări

- QPDocument4 paginiQPnandhakumarmeÎncă nu există evaluări

- Ee8002 - Dem - Question Bank - Unit5Document4 paginiEe8002 - Dem - Question Bank - Unit5DEVIÎncă nu există evaluări

- Design TheoryDocument12 paginiDesign Theoryr.anushyaÎncă nu există evaluări

- Dem 1Document3 paginiDem 1Kishore RavichandranÎncă nu există evaluări

- Gujarat Technological UniversityDocument2 paginiGujarat Technological UniversityPalak AriwalaÎncă nu există evaluări

- Unit 2 Two Marks1Document3 paginiUnit 2 Two Marks1SafjrocnÎncă nu există evaluări

- EE6604-Design of Electrical MachinesDocument12 paginiEE6604-Design of Electrical MachinesGokul ChandrasekaranÎncă nu există evaluări

- Ee 6604 Design of Electrical Machines Question BankDocument12 paginiEe 6604 Design of Electrical Machines Question BankAlex Neo XanderÎncă nu există evaluări

- April 08Document3 paginiApril 08vnatarajanÎncă nu există evaluări

- Question Bank EMDDocument23 paginiQuestion Bank EMDd_rajmtechÎncă nu există evaluări

- EEE Questions Anna University ChennaiDocument42 paginiEEE Questions Anna University ChennaielectricalconsultantÎncă nu există evaluări

- Ee8002 - Dem - Question Bank - Unit4Document4 paginiEe8002 - Dem - Question Bank - Unit4DEVIÎncă nu există evaluări

- Wa0010.Document6 paginiWa0010.Zaid Hasan KhanÎncă nu există evaluări

- Acharya Institute of Technology Department of Electrical and Electronics Engineering Bengaluru 560107Document3 paginiAcharya Institute of Technology Department of Electrical and Electronics Engineering Bengaluru 560107RAVIKIRAN CÎncă nu există evaluări

- 9A02303 Electrical & Mechanical TechnologyDocument4 pagini9A02303 Electrical & Mechanical TechnologysivabharathamurthyÎncă nu există evaluări

- 1.elec AppDocument12 pagini1.elec AppNishant KamalÎncă nu există evaluări

- EE8002 Design of Electrical ApparatusDocument2 paginiEE8002 Design of Electrical ApparatuskrishnandrkÎncă nu există evaluări

- 22 Electrical Machine Design May 2018 PDFDocument4 pagini22 Electrical Machine Design May 2018 PDFBalaji DhanabalÎncă nu există evaluări

- Ee6401 IqDocument6 paginiEe6401 IqK.Swetha PriyadharshiniÎncă nu există evaluări

- Gujarat Technological UniversityDocument2 paginiGujarat Technological UniversityPalak AriwalaÎncă nu există evaluări

- WWW - Universityquestions.in: Department of Electrical and Electronics EngineeringDocument12 paginiWWW - Universityquestions.in: Department of Electrical and Electronics EngineeringmaheshboobalanÎncă nu există evaluări

- Question Paper Code:: Reg. No.Document3 paginiQuestion Paper Code:: Reg. No.ABISHEK AJAYÎncă nu există evaluări

- Assignment by Electrical Mentor: Author: BNSS Shankar, M.Tech (IITK)Document11 paginiAssignment by Electrical Mentor: Author: BNSS Shankar, M.Tech (IITK)anjaneyuluÎncă nu există evaluări

- DSM 2Document2 paginiDSM 2fazalur6Încă nu există evaluări

- Electric Machine DesignDocument2 paginiElectric Machine DesignSabeeh HasnainÎncă nu există evaluări

- Ty EmdDocument2 paginiTy Emdafatab SheikhÎncă nu există evaluări

- Yale UniversityDocument19 paginiYale UniversityJoshua HicksÎncă nu există evaluări

- Electrical Study GuideDocument258 paginiElectrical Study GuideHM5100% (1)

- USS MaconDocument7 paginiUSS MaconJoshua HicksÎncă nu există evaluări

- Case Study Wal MartDocument3 paginiCase Study Wal MartJoshua HicksÎncă nu există evaluări

- European Political Development As An Historical and Analytical NarrativeDocument2 paginiEuropean Political Development As An Historical and Analytical NarrativeJoshua HicksÎncă nu există evaluări

- Air Conditioning SystemsDocument3 paginiAir Conditioning SystemsJoshua Hicks0% (1)

- This Is A Test Document For The Harvard Case of MechanismDocument1 paginăThis Is A Test Document For The Harvard Case of MechanismJoshua HicksÎncă nu există evaluări

- Bio ReactorsDocument24 paginiBio ReactorsJoshua HicksÎncă nu există evaluări

- HomeworkDocument1 paginăHomeworkJoshua HicksÎncă nu există evaluări

- LaMotte 5-0034 PH Meter pH5 Plus Handheld ManualDocument20 paginiLaMotte 5-0034 PH Meter pH5 Plus Handheld ManualPromagEnviro.comÎncă nu există evaluări

- DGT Quick Setup 07.03 13.03 ENDocument1 paginăDGT Quick Setup 07.03 13.03 ENseabellÎncă nu există evaluări

- The Sound Project EssayDocument2 paginiThe Sound Project EssaymrpicklesmediaÎncă nu există evaluări

- 15KW-18.5KW InverterDocument1 pagină15KW-18.5KW InverterMAROC INVESTISSEMENTÎncă nu există evaluări

- Data Sheet: para Light Electronics Co., LTDDocument14 paginiData Sheet: para Light Electronics Co., LTDmuaadhÎncă nu există evaluări

- ClimateMaster Troubleshooting Info Revised 10-04-11Document5 paginiClimateMaster Troubleshooting Info Revised 10-04-11Daniel VeraÎncă nu există evaluări

- QP THC-Q5713 Multi Skilled TechnicianDocument101 paginiQP THC-Q5713 Multi Skilled TechnicianABIR ADHIKARIÎncă nu există evaluări

- Health Index Monitoring Assessment of A TransformerDocument6 paginiHealth Index Monitoring Assessment of A TransformerOmkar WaghÎncă nu există evaluări

- Hisense Lcd3233eu 2633eu Chassis M-Star LCD TV SM Service Manual PDFDocument42 paginiHisense Lcd3233eu 2633eu Chassis M-Star LCD TV SM Service Manual PDFAnonymous CSnweOxÎncă nu există evaluări

- DP LAN Others 13115 DriversDocument2.284 paginiDP LAN Others 13115 DriversSyed AliÎncă nu există evaluări

- Sensor and TransducerDocument7 paginiSensor and TransducerjuniÎncă nu există evaluări

- Infocus 930 920 900 PDFDocument85 paginiInfocus 930 920 900 PDFspeedyeduÎncă nu există evaluări

- Ade Lab ManualDocument73 paginiAde Lab ManualAshutosh PatilÎncă nu există evaluări

- TCM1.0E TCM2.0E: May, 2008Document69 paginiTCM1.0E TCM2.0E: May, 2008JejeÎncă nu există evaluări

- 2CSG257153R4051 Anr96prf 230 Network AnalyserDocument2 pagini2CSG257153R4051 Anr96prf 230 Network AnalyserLuis EduardoÎncă nu există evaluări

- s71200 Easy Book en-US en-USDocument364 paginis71200 Easy Book en-US en-USReynanBorliniÎncă nu există evaluări

- Number SystemDocument6 paginiNumber SystemJoerel NicolasÎncă nu există evaluări

- Ccna4 Chapter 1 Intro WANsDocument71 paginiCcna4 Chapter 1 Intro WANsdjqriusgeorgeÎncă nu există evaluări

- ListOf PHD Students OngoingDocument5 paginiListOf PHD Students OngoingBiswajit DebnathÎncă nu există evaluări

- Blu-Ray Disc™/ DVD Home Theatre System: Operating InstructionsDocument68 paginiBlu-Ray Disc™/ DVD Home Theatre System: Operating InstructionsKamal FaridÎncă nu există evaluări

- Level3 - Application Note Earth Leakage RelayDocument4 paginiLevel3 - Application Note Earth Leakage RelayChhinPidenÎncă nu există evaluări

- 1SDA074678R1 xt1s 125 TMF 125 1250 3p F F Ul CsaDocument3 pagini1SDA074678R1 xt1s 125 TMF 125 1250 3p F F Ul CsaJose FloresÎncă nu există evaluări

- Energies: Design and Implementation of A Low-Power Low-Cost Digital Current-Sink Electronic LoadDocument14 paginiEnergies: Design and Implementation of A Low-Power Low-Cost Digital Current-Sink Electronic LoadciccioÎncă nu există evaluări

- User's Guide: Smartpack2 Basic ControllerDocument16 paginiUser's Guide: Smartpack2 Basic ControllerIsac ClaroÎncă nu există evaluări

- FIFODocument13 paginiFIFOrenju91Încă nu există evaluări